Solid Polymer Electrolyte Application in Grid-Scale Energy Storage

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SPE Technology Background and Objectives

Solid Polymer Electrolytes (SPEs) represent a transformative technology in the energy storage landscape, evolving significantly since their initial development in the 1970s. Originally conceived as alternatives to liquid electrolytes in small-scale batteries, SPEs have undergone substantial advancement in ionic conductivity, mechanical stability, and electrochemical performance over the past five decades. The trajectory of SPE development has been characterized by progressive improvements in polymer matrices, from early polyethylene oxide (PEO) systems to contemporary composite and block copolymer architectures.

The evolution of SPEs has been driven by the increasing demand for safer, more efficient energy storage solutions across various applications. While initial research focused primarily on portable electronics and electric vehicles, recent technological advancements have expanded the potential application scope to include grid-scale energy storage systems, where traditional liquid electrolyte technologies present significant safety and durability challenges.

Current technological objectives for SPE implementation in grid-scale storage center on addressing several critical performance parameters. Primary among these is achieving room-temperature ionic conductivity exceeding 10^-3 S/cm, comparable to liquid electrolytes, while maintaining mechanical stability sufficient for large-format cell designs. Additionally, SPE systems must demonstrate electrochemical stability windows exceeding 4.5V to accommodate high-voltage cathode materials increasingly utilized in grid applications.

Long-term cycling stability represents another crucial objective, with targets exceeding 5,000 complete charge-discharge cycles at high depth of discharge to ensure economic viability in grid deployment scenarios. Interface stability between the polymer electrolyte and electrode materials remains a significant focus area, particularly in mitigating dendrite formation in lithium-metal systems being considered for next-generation grid storage.

Manufacturing scalability constitutes a parallel technological objective, as grid-scale implementation necessitates production processes compatible with existing battery manufacturing infrastructure while maintaining consistent performance across large-format cells. Cost reduction pathways are being actively explored, with targets of achieving SPE production costs below $10/kg to ensure competitive positioning against established liquid electrolyte technologies.

The technological trajectory for SPEs in grid storage applications is increasingly focused on hybrid and composite systems that combine the safety advantages of solid electrolytes with the performance characteristics required for large-scale implementation. Research efforts are converging on multifunctional polymer systems that simultaneously address ionic conductivity, mechanical properties, and interfacial stability through innovative material design and engineering approaches.

The evolution of SPEs has been driven by the increasing demand for safer, more efficient energy storage solutions across various applications. While initial research focused primarily on portable electronics and electric vehicles, recent technological advancements have expanded the potential application scope to include grid-scale energy storage systems, where traditional liquid electrolyte technologies present significant safety and durability challenges.

Current technological objectives for SPE implementation in grid-scale storage center on addressing several critical performance parameters. Primary among these is achieving room-temperature ionic conductivity exceeding 10^-3 S/cm, comparable to liquid electrolytes, while maintaining mechanical stability sufficient for large-format cell designs. Additionally, SPE systems must demonstrate electrochemical stability windows exceeding 4.5V to accommodate high-voltage cathode materials increasingly utilized in grid applications.

Long-term cycling stability represents another crucial objective, with targets exceeding 5,000 complete charge-discharge cycles at high depth of discharge to ensure economic viability in grid deployment scenarios. Interface stability between the polymer electrolyte and electrode materials remains a significant focus area, particularly in mitigating dendrite formation in lithium-metal systems being considered for next-generation grid storage.

Manufacturing scalability constitutes a parallel technological objective, as grid-scale implementation necessitates production processes compatible with existing battery manufacturing infrastructure while maintaining consistent performance across large-format cells. Cost reduction pathways are being actively explored, with targets of achieving SPE production costs below $10/kg to ensure competitive positioning against established liquid electrolyte technologies.

The technological trajectory for SPEs in grid storage applications is increasingly focused on hybrid and composite systems that combine the safety advantages of solid electrolytes with the performance characteristics required for large-scale implementation. Research efforts are converging on multifunctional polymer systems that simultaneously address ionic conductivity, mechanical properties, and interfacial stability through innovative material design and engineering approaches.

Grid-Scale Energy Storage Market Analysis

The global grid-scale energy storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources and the need for grid stability. As of 2023, the market size has reached approximately $8.1 billion and is projected to grow at a CAGR of 28% through 2030, potentially reaching $45 billion by the end of the decade. This remarkable expansion is primarily fueled by governmental policies promoting clean energy transition and substantial investments in grid modernization projects worldwide.

Lithium-ion batteries currently dominate the market with over 70% share of newly installed capacity, but alternative technologies including flow batteries, compressed air, and emerging solid-state solutions are gaining traction. Particularly, solid polymer electrolyte (SPE) based storage systems are attracting significant attention due to their enhanced safety profiles and potential for cost reduction in large-scale applications.

Regional analysis reveals that Asia-Pacific leads the market with China accounting for approximately 40% of global grid-scale energy storage deployments. North America follows closely, with the United States implementing numerous utility-scale projects across California, Texas, and New York. Europe is rapidly accelerating deployments, particularly in Germany, UK, and Spain, driven by aggressive decarbonization targets.

The market segmentation shows distinct application categories: frequency regulation represents about 35% of deployments, peak shaving accounts for 28%, renewable integration comprises 25%, and the remaining applications include backup power and other grid services. This distribution highlights the versatility required from modern energy storage solutions, creating opportunities for SPE technologies that can address multiple use cases.

Key market drivers include declining battery costs (approximately 85% reduction over the past decade), increasing renewable penetration exceeding 30% in many advanced economies, and regulatory frameworks that increasingly recognize and compensate storage services. However, challenges persist, including supply chain constraints for critical materials, regulatory uncertainties in emerging markets, and technical limitations related to energy density and cycle life.

Customer segments in this market include utilities (representing 65% of demand), independent power producers (20%), commercial and industrial users seeking behind-the-meter solutions (10%), and microgrids/remote applications (5%). Each segment presents unique requirements regarding performance specifications, cost structures, and operational parameters that SPE technologies must address to gain significant market share.

Lithium-ion batteries currently dominate the market with over 70% share of newly installed capacity, but alternative technologies including flow batteries, compressed air, and emerging solid-state solutions are gaining traction. Particularly, solid polymer electrolyte (SPE) based storage systems are attracting significant attention due to their enhanced safety profiles and potential for cost reduction in large-scale applications.

Regional analysis reveals that Asia-Pacific leads the market with China accounting for approximately 40% of global grid-scale energy storage deployments. North America follows closely, with the United States implementing numerous utility-scale projects across California, Texas, and New York. Europe is rapidly accelerating deployments, particularly in Germany, UK, and Spain, driven by aggressive decarbonization targets.

The market segmentation shows distinct application categories: frequency regulation represents about 35% of deployments, peak shaving accounts for 28%, renewable integration comprises 25%, and the remaining applications include backup power and other grid services. This distribution highlights the versatility required from modern energy storage solutions, creating opportunities for SPE technologies that can address multiple use cases.

Key market drivers include declining battery costs (approximately 85% reduction over the past decade), increasing renewable penetration exceeding 30% in many advanced economies, and regulatory frameworks that increasingly recognize and compensate storage services. However, challenges persist, including supply chain constraints for critical materials, regulatory uncertainties in emerging markets, and technical limitations related to energy density and cycle life.

Customer segments in this market include utilities (representing 65% of demand), independent power producers (20%), commercial and industrial users seeking behind-the-meter solutions (10%), and microgrids/remote applications (5%). Each segment presents unique requirements regarding performance specifications, cost structures, and operational parameters that SPE technologies must address to gain significant market share.

Current SPE Development Status and Challenges

Solid Polymer Electrolytes (SPEs) have emerged as promising alternatives to liquid electrolytes in energy storage systems, particularly for grid-scale applications. Currently, the global development of SPE technology demonstrates significant regional variations, with major research clusters in North America, Europe, and East Asia. The United States, Japan, South Korea, and China lead in patent filings and commercial development, while European research institutions contribute substantially to fundamental research advancements.

The current state of SPE technology faces several critical challenges that limit widespread adoption in grid-scale energy storage. Ionic conductivity remains a primary concern, with most polymer electrolytes exhibiting conductivity values between 10^-5 and 10^-4 S/cm at room temperature—significantly lower than the 10^-3 S/cm threshold considered necessary for practical applications. This conductivity limitation directly impacts power density and charge-discharge rates, making current SPEs suboptimal for high-power grid applications.

Mechanical stability presents another significant hurdle. While SPEs offer advantages over liquid systems in terms of leakage prevention and safety, they often suffer from poor mechanical properties that affect cycle life and durability. The trade-off between mechanical strength and ionic conductivity continues to challenge researchers, as modifications that enhance mechanical properties frequently result in reduced ionic mobility.

Interfacial resistance between the electrolyte and electrodes represents a third major technical barrier. High interfacial resistance leads to increased internal cell resistance, voltage drops, and decreased energy efficiency. Current SPE systems typically exhibit electrode-electrolyte interfacial resistances 5-10 times higher than conventional liquid electrolyte systems.

Temperature sensitivity further complicates SPE implementation in grid storage. Most polymer electrolytes demonstrate optimal performance only within narrow temperature ranges, with significant conductivity drops at lower temperatures. This characteristic limits deployment in regions with variable climate conditions, a critical consideration for grid infrastructure.

Scalability and manufacturing challenges also impede commercial adoption. Current production methods for high-quality SPEs involve complex processes that are difficult to scale economically. The cost of specialized polymers and additives remains high, with production costs estimated at 3-5 times those of conventional liquid electrolyte systems on a per-kWh basis.

Recent technological developments have shown promise in addressing these limitations through composite approaches, polymer blending, and novel synthesis methods. However, the gap between laboratory demonstrations and commercial viability remains substantial, particularly for the demanding requirements of grid-scale energy storage applications.

The current state of SPE technology faces several critical challenges that limit widespread adoption in grid-scale energy storage. Ionic conductivity remains a primary concern, with most polymer electrolytes exhibiting conductivity values between 10^-5 and 10^-4 S/cm at room temperature—significantly lower than the 10^-3 S/cm threshold considered necessary for practical applications. This conductivity limitation directly impacts power density and charge-discharge rates, making current SPEs suboptimal for high-power grid applications.

Mechanical stability presents another significant hurdle. While SPEs offer advantages over liquid systems in terms of leakage prevention and safety, they often suffer from poor mechanical properties that affect cycle life and durability. The trade-off between mechanical strength and ionic conductivity continues to challenge researchers, as modifications that enhance mechanical properties frequently result in reduced ionic mobility.

Interfacial resistance between the electrolyte and electrodes represents a third major technical barrier. High interfacial resistance leads to increased internal cell resistance, voltage drops, and decreased energy efficiency. Current SPE systems typically exhibit electrode-electrolyte interfacial resistances 5-10 times higher than conventional liquid electrolyte systems.

Temperature sensitivity further complicates SPE implementation in grid storage. Most polymer electrolytes demonstrate optimal performance only within narrow temperature ranges, with significant conductivity drops at lower temperatures. This characteristic limits deployment in regions with variable climate conditions, a critical consideration for grid infrastructure.

Scalability and manufacturing challenges also impede commercial adoption. Current production methods for high-quality SPEs involve complex processes that are difficult to scale economically. The cost of specialized polymers and additives remains high, with production costs estimated at 3-5 times those of conventional liquid electrolyte systems on a per-kWh basis.

Recent technological developments have shown promise in addressing these limitations through composite approaches, polymer blending, and novel synthesis methods. However, the gap between laboratory demonstrations and commercial viability remains substantial, particularly for the demanding requirements of grid-scale energy storage applications.

Current SPE Solutions for Grid-Scale Applications

01 Polymer-based solid electrolyte compositions

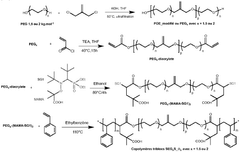

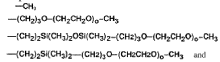

Solid polymer electrolytes are composed of polymeric materials that serve as both the matrix and ion conductor. These compositions typically include a polymer host (such as polyethylene oxide, polyvinylidene fluoride, or polyacrylonitrile) combined with lithium salts. The polymer matrix provides mechanical stability while facilitating ion transport through segmental motion of polymer chains. These electrolytes offer advantages including improved safety, flexibility, and compatibility with electrode materials in battery applications.- Polymer matrix composition for solid electrolytes: Various polymer matrices can be used as the base for solid polymer electrolytes, including polyethylene oxide (PEO), polyvinylidene fluoride (PVDF), and their copolymers. These polymers provide mechanical stability while allowing ion transport. The selection of polymer matrix significantly affects the ionic conductivity, mechanical properties, and electrochemical stability of the solid electrolyte. Modifications such as cross-linking or blending different polymers can enhance overall performance.

- Ionic conductivity enhancement additives: Various additives can be incorporated into solid polymer electrolytes to enhance ionic conductivity. These include ceramic fillers like Al2O3, SiO2, and TiO2, which create additional ion transport pathways. Plasticizers such as ethylene carbonate and propylene carbonate can increase chain mobility. Ionic liquids may also be added to improve conductivity at room temperature. These additives work by reducing crystallinity, increasing free volume, or providing alternative ion transport mechanisms.

- Lithium salt selection and concentration: The type and concentration of lithium salts significantly impact the performance of solid polymer electrolytes. Common salts include LiPF6, LiTFSI, LiBF4, and LiClO4. The salt concentration must be optimized to balance ionic conductivity and mechanical properties. Higher salt concentrations can increase conductivity up to a certain point, after which ion aggregation may occur, reducing performance. The anion size and coordination ability also affect lithium ion transport and the stability of the electrolyte.

- Interface engineering and stability enhancement: Interface engineering is crucial for solid polymer electrolytes to ensure good contact with electrodes and stable performance. Approaches include surface modifications of electrodes, addition of interfacial layers, and incorporation of functional groups in the polymer. These techniques help reduce interfacial resistance, prevent dendrite formation, and enhance electrochemical stability. Additives that scavenge impurities or form stable solid electrolyte interphase (SEI) layers can also improve long-term cycling performance.

- Composite and hybrid electrolyte systems: Composite and hybrid electrolyte systems combine different materials to overcome limitations of single-component solid polymer electrolytes. These include polymer-ceramic composites, gel polymer electrolytes, and polymer-ionic liquid hybrids. The composite approach can simultaneously enhance ionic conductivity, mechanical strength, and electrochemical stability. Hierarchical structures and 3D networks can be designed to create continuous ion transport pathways while maintaining structural integrity. These systems often show superior performance at room temperature compared to conventional solid polymer electrolytes.

02 Composite solid electrolytes with inorganic fillers

Composite solid polymer electrolytes incorporate inorganic fillers such as ceramic particles (Al2O3, SiO2, TiO2) into the polymer matrix to enhance ionic conductivity and mechanical properties. These fillers create additional ion transport pathways at the polymer-ceramic interfaces and help suppress crystallization of the polymer phase. The resulting composites exhibit improved electrochemical stability, higher lithium-ion transference numbers, and better dimensional stability compared to pure polymer electrolytes.Expand Specific Solutions03 Gel polymer electrolytes

Gel polymer electrolytes represent a hybrid between liquid and solid electrolytes, consisting of a polymer network that traps liquid electrolyte components. These systems combine the high ionic conductivity of liquid electrolytes with the mechanical stability of solid polymers. Common polymers used include PVDF-HFP copolymers, PEO, and PMMA. Gel polymer electrolytes are prepared through various methods including thermal crosslinking, UV curing, or phase inversion techniques, offering improved safety and flexibility for battery applications.Expand Specific Solutions04 Single-ion conducting polymer electrolytes

Single-ion conducting polymer electrolytes feature anionic groups covalently attached to the polymer backbone, allowing only cations (typically lithium ions) to move freely. This design achieves a lithium-ion transference number approaching unity, eliminating concentration polarization issues common in dual-ion conductors. These materials are synthesized through various approaches including grafting of sulfonate, carboxylate, or perfluorinated groups onto polymer chains, resulting in improved electrochemical performance and stability in battery applications.Expand Specific Solutions05 Solid polymer electrolytes with flame-retardant properties

Flame-retardant solid polymer electrolytes incorporate specialized additives or modified polymer structures to enhance safety by reducing flammability. These electrolytes utilize phosphorus-containing compounds, halogenated materials, or inherently flame-resistant polymers as the electrolyte matrix. The flame-retardant components can be either chemically bonded to the polymer backbone or physically blended into the electrolyte system. These materials maintain electrochemical performance while significantly improving the thermal stability and safety of battery systems.Expand Specific Solutions

Key Industry Players in SPE and Grid Storage

The solid polymer electrolyte market for grid-scale energy storage is in a growth phase, with increasing market size driven by the global push for renewable energy integration. The technology is approaching commercial maturity, with key players demonstrating varied levels of advancement. Companies like IBM, Toyota, and Hitachi are leading innovation through significant R&D investments, while specialized firms such as Soelect and JSR Corp are developing breakthrough materials. Academic institutions including Cornell University and Kyoto University are contributing fundamental research. BMW, Honda, and Siemens are focusing on industrial applications, leveraging their manufacturing expertise to scale solutions. The competitive landscape is characterized by strategic partnerships between technology developers and energy storage system integrators, with increasing patent activity signaling intensifying competition.

Battelle Energy Alliance LLC

Technical Solution: Battelle Energy Alliance has developed advanced solid polymer electrolyte (SPE) systems specifically designed for grid-scale energy storage applications. Their proprietary technology combines high-conductivity polymer matrices with ceramic fillers to create composite electrolytes that demonstrate superior ionic conductivity (>10^-3 S/cm at room temperature) while maintaining excellent mechanical stability. The company has pioneered a cross-linked polymer network architecture that significantly reduces dendrite formation in large-format batteries, addressing one of the key challenges in grid storage applications. Their SPE technology incorporates flame-retardant additives that enhance safety profiles critical for utility-scale deployments, while their manufacturing process allows for roll-to-roll production of large-area electrolyte membranes suitable for grid-scale battery systems. Battelle's approach also focuses on long-term stability, with demonstrated cycling performance exceeding 3000 cycles with minimal capacity degradation in grid simulation tests.

Strengths: Superior safety characteristics with non-flammable properties ideal for large-scale installations; excellent thermal stability across wide temperature ranges; scalable manufacturing process suitable for utility-scale production. Weaknesses: Higher production costs compared to liquid electrolyte systems; lower ionic conductivity at sub-zero temperatures; requires specialized integration with existing grid infrastructure.

Toyota Motor Corp.

Technical Solution: Toyota has developed an innovative solid polymer electrolyte technology for grid-scale energy storage that builds upon their extensive experience in automotive battery systems. Their approach utilizes a proprietary blend of polyethylene oxide (PEO) derivatives modified with functional groups that enhance lithium-ion transport while maintaining mechanical integrity. Toyota's SPE incorporates nano-scale ceramic fillers (5-10% by weight) that create preferential pathways for ion migration, achieving conductivity values of 1.2×10^-3 S/cm at operating temperatures. A key innovation is their multi-layer electrolyte design that incorporates gradient functionality - with different polymer compositions optimized for electrode interfaces and bulk transport. This architecture has demonstrated exceptional cycling stability in large-format cells (>5000 cycles with <15% capacity fade) and improved power density compared to conventional systems. Toyota has also developed specialized manufacturing techniques that enable production of uniform, defect-free electrolyte membranes at scales suitable for grid applications, with thicknesses precisely controlled between 15-30μm depending on application requirements.

Strengths: Exceptional cycling stability suitable for long-duration grid storage applications; proven scalability from automotive to utility-scale implementations; strong integration with existing battery management systems. Weaknesses: Requires elevated operating temperatures (40-60°C) for optimal performance; higher initial capital costs compared to conventional technologies; limited field demonstration data in actual grid environments.

Critical SPE Patents and Technical Innovations

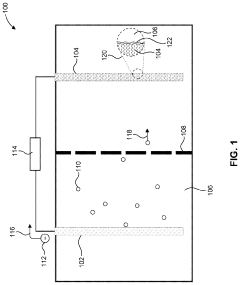

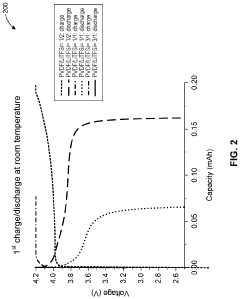

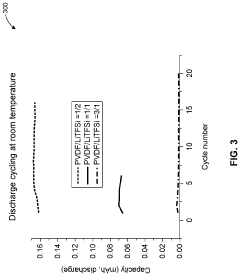

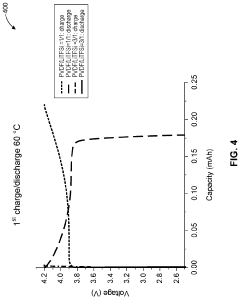

Solid-state polymer electrolyte for an energy storage device

PatentPendingUS20230378529A1

Innovation

- A solid polymer electrolyte composition based on polyvinylidene fluoride (PVDF) and lithium bis(trifluoromethanesulfonyl)imide (LiTFSI) with a higher mass content of LiTFSI, potentially combined with lithium lanthanum zirconate oxide (LLZO) and plasticizers like succinonitrile, is used to enhance ion conductivity and mechanical stability, forming a solid medium that can be processed from a solution with a solid content of approximately 0.19 or greater.

Solid polymer electrolyte, method for the production thereof, and electrochemical storage battery/cell comprising same

PatentWO2019243519A1

Innovation

- A new Solid Polymer Electrolyte (EPS) comprising linear A-B-A triblock or A-B diblock copolymers with vitreous or semi-crystalline blocks A and alkylene glycol-based blocks B, combined with an electrolyte salt and a plasticizer, which is crosslinked to enhance mechanical strength and ionic conductivity, allowing for efficient lithium ion conduction at low temperatures.

Environmental Impact Assessment

The environmental impact of solid polymer electrolyte (SPE) technology in grid-scale energy storage represents a critical consideration for sustainable energy transition. When compared to conventional liquid electrolyte systems, SPEs demonstrate significant environmental advantages throughout their lifecycle. The absence of volatile organic compounds and toxic liquid electrolytes substantially reduces the risk of environmental contamination during manufacturing, operation, and disposal phases.

Manufacturing processes for SPEs typically require less energy and generate fewer emissions than traditional battery technologies. The production of polymer-based electrolytes generally involves lower temperature processes and reduced use of environmentally harmful solvents. This translates to a smaller carbon footprint during the manufacturing stage, contributing to overall sustainability goals in energy storage deployment.

During operational lifetime, SPE-based storage systems exhibit minimal environmental leakage risk, a stark contrast to liquid electrolyte alternatives that pose significant contamination hazards in case of containment failure. This inherent safety feature becomes particularly valuable in grid-scale applications where storage systems may be deployed in environmentally sensitive areas or near water resources.

End-of-life considerations further highlight SPE environmental benefits. The solid-state nature of these electrolytes facilitates more straightforward recycling processes compared to liquid systems. Polymer components can potentially be recovered and repurposed, reducing waste generation and resource consumption. Additionally, the absence of toxic liquid components simplifies disposal procedures and minimizes hazardous waste management requirements.

Carbon footprint analysis of grid-scale SPE storage systems reveals potential for significant greenhouse gas emission reductions throughout the technology lifecycle. When paired with renewable energy sources, these systems enable greater integration of intermittent renewables into the grid, displacing fossil fuel generation and associated emissions. The improved efficiency and longer cycle life of advanced SPE systems further enhance this environmental benefit through reduced material consumption per unit of energy stored over system lifetime.

Land use impacts of SPE grid storage installations generally compare favorably to alternative large-scale storage technologies such as pumped hydro. The compact nature of battery installations, combined with flexible siting options, minimizes habitat disruption and allows for deployment in previously developed areas, reducing pressure on natural landscapes.

Water resource impacts also demonstrate advantages, as SPE systems require minimal water for operation compared to thermal generation or certain other storage technologies. This characteristic becomes increasingly valuable in water-stressed regions where resource competition is intensifying due to climate change impacts.

Manufacturing processes for SPEs typically require less energy and generate fewer emissions than traditional battery technologies. The production of polymer-based electrolytes generally involves lower temperature processes and reduced use of environmentally harmful solvents. This translates to a smaller carbon footprint during the manufacturing stage, contributing to overall sustainability goals in energy storage deployment.

During operational lifetime, SPE-based storage systems exhibit minimal environmental leakage risk, a stark contrast to liquid electrolyte alternatives that pose significant contamination hazards in case of containment failure. This inherent safety feature becomes particularly valuable in grid-scale applications where storage systems may be deployed in environmentally sensitive areas or near water resources.

End-of-life considerations further highlight SPE environmental benefits. The solid-state nature of these electrolytes facilitates more straightforward recycling processes compared to liquid systems. Polymer components can potentially be recovered and repurposed, reducing waste generation and resource consumption. Additionally, the absence of toxic liquid components simplifies disposal procedures and minimizes hazardous waste management requirements.

Carbon footprint analysis of grid-scale SPE storage systems reveals potential for significant greenhouse gas emission reductions throughout the technology lifecycle. When paired with renewable energy sources, these systems enable greater integration of intermittent renewables into the grid, displacing fossil fuel generation and associated emissions. The improved efficiency and longer cycle life of advanced SPE systems further enhance this environmental benefit through reduced material consumption per unit of energy stored over system lifetime.

Land use impacts of SPE grid storage installations generally compare favorably to alternative large-scale storage technologies such as pumped hydro. The compact nature of battery installations, combined with flexible siting options, minimizes habitat disruption and allows for deployment in previously developed areas, reducing pressure on natural landscapes.

Water resource impacts also demonstrate advantages, as SPE systems require minimal water for operation compared to thermal generation or certain other storage technologies. This characteristic becomes increasingly valuable in water-stressed regions where resource competition is intensifying due to climate change impacts.

Regulatory Framework for Grid Storage Technologies

The regulatory landscape for grid-scale energy storage technologies incorporating Solid Polymer Electrolyte (SPE) systems is evolving rapidly across global markets. In the United States, the Federal Energy Regulatory Commission (FERC) has established Order 841, which requires regional transmission organizations to develop market rules enabling energy storage participation in wholesale electricity markets. This regulatory framework has created significant opportunities for SPE technologies to compete alongside traditional storage solutions.

European regulations have taken a more integrated approach through the Clean Energy Package, which explicitly recognizes energy storage as a distinct asset class within electricity markets. The European Union's Taxonomy for Sustainable Activities further provides clear guidelines for classifying energy storage technologies based on their environmental impact, with SPE systems potentially qualifying for sustainable investment designations due to their reduced environmental footprint compared to conventional battery technologies.

Safety standards represent a critical regulatory consideration for SPE grid storage deployment. Organizations such as UL (Underwriters Laboratories) and IEC (International Electrotechnical Commission) have developed specific testing protocols for solid-state battery technologies, addressing thermal runaway risks, cycling stability, and long-term performance degradation. These standards are continuously evolving as SPE technologies mature, with recent updates focusing on large-scale implementation scenarios.

Grid interconnection requirements present another regulatory dimension affecting SPE adoption. IEEE 1547 standards in the United States and similar frameworks internationally establish technical specifications for connecting distributed energy resources to the grid. SPE storage systems must demonstrate compliance with these standards, including response to grid anomalies, power quality maintenance, and communication protocols.

Permitting processes for large-scale SPE storage installations vary significantly by jurisdiction. While some regions have streamlined approval pathways for battery energy storage systems, others maintain complex multi-agency review processes that can extend project timelines. Recent regulatory reforms in California, New York, and Australia have created expedited permitting tracks specifically for energy storage technologies that meet certain safety and performance criteria.

End-of-life regulations are increasingly important as grid storage deployments scale. The EU Battery Directive and similar frameworks in Asia establish requirements for recycling and proper disposal of battery components. SPE technologies may offer advantages in this regulatory domain due to their potentially simpler material separation processes compared to liquid electrolyte systems, though specific recycling protocols for polymer-based electrolytes are still developing.

European regulations have taken a more integrated approach through the Clean Energy Package, which explicitly recognizes energy storage as a distinct asset class within electricity markets. The European Union's Taxonomy for Sustainable Activities further provides clear guidelines for classifying energy storage technologies based on their environmental impact, with SPE systems potentially qualifying for sustainable investment designations due to their reduced environmental footprint compared to conventional battery technologies.

Safety standards represent a critical regulatory consideration for SPE grid storage deployment. Organizations such as UL (Underwriters Laboratories) and IEC (International Electrotechnical Commission) have developed specific testing protocols for solid-state battery technologies, addressing thermal runaway risks, cycling stability, and long-term performance degradation. These standards are continuously evolving as SPE technologies mature, with recent updates focusing on large-scale implementation scenarios.

Grid interconnection requirements present another regulatory dimension affecting SPE adoption. IEEE 1547 standards in the United States and similar frameworks internationally establish technical specifications for connecting distributed energy resources to the grid. SPE storage systems must demonstrate compliance with these standards, including response to grid anomalies, power quality maintenance, and communication protocols.

Permitting processes for large-scale SPE storage installations vary significantly by jurisdiction. While some regions have streamlined approval pathways for battery energy storage systems, others maintain complex multi-agency review processes that can extend project timelines. Recent regulatory reforms in California, New York, and Australia have created expedited permitting tracks specifically for energy storage technologies that meet certain safety and performance criteria.

End-of-life regulations are increasingly important as grid storage deployments scale. The EU Battery Directive and similar frameworks in Asia establish requirements for recycling and proper disposal of battery components. SPE technologies may offer advantages in this regulatory domain due to their potentially simpler material separation processes compared to liquid electrolyte systems, though specific recycling protocols for polymer-based electrolytes are still developing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!