Why Solid Polymer Electrolyte Improves Safety in Electric Vehicle Batteries

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SPE Technology Background and Safety Objectives

Solid Polymer Electrolytes (SPEs) represent a significant evolution in battery technology, emerging from decades of research into safer alternatives to conventional liquid electrolytes. The development of SPEs began in the 1970s with the discovery of ionic conductivity in polymer-salt complexes, but has gained substantial momentum in the past decade due to increasing concerns about electric vehicle (EV) battery safety incidents.

Traditional lithium-ion batteries utilize liquid electrolytes that, while offering excellent ionic conductivity, present inherent safety risks including flammability, leakage potential, and thermal runaway susceptibility. These vulnerabilities have resulted in numerous documented cases of EV fires and explosions, creating both safety hazards and significant market barriers to widespread EV adoption.

SPE technology aims to address these fundamental safety challenges by replacing volatile liquid components with solid polymer matrices that can conduct lithium ions while maintaining structural integrity. The primary safety objectives of SPE implementation include elimination of electrolyte leakage risk, significant reduction of fire hazards, prevention of dendrite formation that causes internal short circuits, and enhanced thermal stability across wider operating temperature ranges.

The evolution of SPE technology has progressed through several generations, from dry polymer electrolytes with limited conductivity to advanced composite systems incorporating ceramic fillers and novel polymer architectures. This technological progression reflects the industry's commitment to achieving the dual objectives of safety enhancement and performance optimization.

Current research focuses on developing SPEs that can match or exceed the performance metrics of liquid electrolytes while maintaining their inherent safety advantages. Key performance targets include achieving ionic conductivity above 10^-3 S/cm at room temperature, maintaining mechanical stability to prevent dendrite penetration, and ensuring electrochemical stability within wide voltage windows.

The automotive industry has established stringent safety standards for EV batteries, including thermal runaway resistance, crush tolerance, and penetration resistance. SPE technology directly addresses these requirements by fundamentally altering the battery chemistry to eliminate the primary sources of catastrophic failure.

As global EV adoption accelerates, with projections indicating EVs will constitute over 30% of new vehicle sales by 2030, the importance of resolving battery safety concerns becomes increasingly critical. SPE technology represents not merely an incremental improvement but a paradigm shift in battery design philosophy, prioritizing intrinsic safety through materials engineering rather than relying on external safety systems and containment strategies.

Traditional lithium-ion batteries utilize liquid electrolytes that, while offering excellent ionic conductivity, present inherent safety risks including flammability, leakage potential, and thermal runaway susceptibility. These vulnerabilities have resulted in numerous documented cases of EV fires and explosions, creating both safety hazards and significant market barriers to widespread EV adoption.

SPE technology aims to address these fundamental safety challenges by replacing volatile liquid components with solid polymer matrices that can conduct lithium ions while maintaining structural integrity. The primary safety objectives of SPE implementation include elimination of electrolyte leakage risk, significant reduction of fire hazards, prevention of dendrite formation that causes internal short circuits, and enhanced thermal stability across wider operating temperature ranges.

The evolution of SPE technology has progressed through several generations, from dry polymer electrolytes with limited conductivity to advanced composite systems incorporating ceramic fillers and novel polymer architectures. This technological progression reflects the industry's commitment to achieving the dual objectives of safety enhancement and performance optimization.

Current research focuses on developing SPEs that can match or exceed the performance metrics of liquid electrolytes while maintaining their inherent safety advantages. Key performance targets include achieving ionic conductivity above 10^-3 S/cm at room temperature, maintaining mechanical stability to prevent dendrite penetration, and ensuring electrochemical stability within wide voltage windows.

The automotive industry has established stringent safety standards for EV batteries, including thermal runaway resistance, crush tolerance, and penetration resistance. SPE technology directly addresses these requirements by fundamentally altering the battery chemistry to eliminate the primary sources of catastrophic failure.

As global EV adoption accelerates, with projections indicating EVs will constitute over 30% of new vehicle sales by 2030, the importance of resolving battery safety concerns becomes increasingly critical. SPE technology represents not merely an incremental improvement but a paradigm shift in battery design philosophy, prioritizing intrinsic safety through materials engineering rather than relying on external safety systems and containment strategies.

Market Demand for Safer EV Battery Solutions

The electric vehicle (EV) market has witnessed exponential growth over the past decade, with global sales surpassing 10 million units in 2022. However, safety concerns related to conventional lithium-ion batteries with liquid electrolytes have emerged as a significant barrier to wider EV adoption. Market research indicates that approximately 65% of potential EV buyers cite battery safety as their primary concern, highlighting a substantial demand for safer battery technologies.

Battery thermal runaway incidents, though statistically rare, receive disproportionate media coverage and negatively impact consumer perception. The automotive industry has recognized this challenge, with major manufacturers investing heavily in alternative battery technologies. Market analysis shows that the demand for safer battery solutions is growing at a compound annual growth rate of 24%, significantly outpacing the overall EV market growth rate of 18%.

Regulatory bodies worldwide are implementing stricter safety standards for EV batteries, further driving the market demand for advanced electrolyte solutions. The European Union's Battery Directive revision and China's new battery safety protocols specifically address thermal stability requirements that conventional liquid electrolytes struggle to meet. This regulatory pressure has created an urgent market pull for solid polymer electrolyte (SPE) technologies.

Insurance companies have also become key stakeholders in this market dynamic, offering premium reductions of up to 15% for vehicles equipped with safer battery technologies. This financial incentive translates to tangible consumer benefits and accelerates market adoption of SPE-based solutions.

From a consumer perspective, surveys reveal that 78% of potential EV buyers would pay a premium of 5-10% for vehicles with demonstrably safer battery technology. This willingness to pay higher prices creates a viable commercial pathway for the integration of more expensive but safer SPE technologies into mass-market vehicles.

Fleet operators represent another significant market segment driving demand for safer battery solutions. With total cost of ownership calculations heavily influenced by vehicle downtime and replacement costs, fleet managers are increasingly prioritizing battery safety in their procurement decisions. Major logistics companies have announced commitments to transition their fleets to vehicles with enhanced battery safety features by 2025.

The market for safer EV batteries extends beyond passenger vehicles to include electric buses, trucks, and specialized vehicles operating in sensitive environments such as underground mining, where the consequences of battery failures are particularly severe. These niche applications often serve as early adoption pathways for premium safety technologies before they achieve the scale economies necessary for mass-market implementation.

Battery thermal runaway incidents, though statistically rare, receive disproportionate media coverage and negatively impact consumer perception. The automotive industry has recognized this challenge, with major manufacturers investing heavily in alternative battery technologies. Market analysis shows that the demand for safer battery solutions is growing at a compound annual growth rate of 24%, significantly outpacing the overall EV market growth rate of 18%.

Regulatory bodies worldwide are implementing stricter safety standards for EV batteries, further driving the market demand for advanced electrolyte solutions. The European Union's Battery Directive revision and China's new battery safety protocols specifically address thermal stability requirements that conventional liquid electrolytes struggle to meet. This regulatory pressure has created an urgent market pull for solid polymer electrolyte (SPE) technologies.

Insurance companies have also become key stakeholders in this market dynamic, offering premium reductions of up to 15% for vehicles equipped with safer battery technologies. This financial incentive translates to tangible consumer benefits and accelerates market adoption of SPE-based solutions.

From a consumer perspective, surveys reveal that 78% of potential EV buyers would pay a premium of 5-10% for vehicles with demonstrably safer battery technology. This willingness to pay higher prices creates a viable commercial pathway for the integration of more expensive but safer SPE technologies into mass-market vehicles.

Fleet operators represent another significant market segment driving demand for safer battery solutions. With total cost of ownership calculations heavily influenced by vehicle downtime and replacement costs, fleet managers are increasingly prioritizing battery safety in their procurement decisions. Major logistics companies have announced commitments to transition their fleets to vehicles with enhanced battery safety features by 2025.

The market for safer EV batteries extends beyond passenger vehicles to include electric buses, trucks, and specialized vehicles operating in sensitive environments such as underground mining, where the consequences of battery failures are particularly severe. These niche applications often serve as early adoption pathways for premium safety technologies before they achieve the scale economies necessary for mass-market implementation.

Current State and Challenges in SPE Development

Solid Polymer Electrolytes (SPEs) have emerged as promising alternatives to conventional liquid electrolytes in lithium-ion batteries for electric vehicles. Currently, the development of SPEs is at a critical juncture, with significant progress made in laboratory settings but still facing challenges for widespread commercial implementation. Research institutions and battery manufacturers worldwide are actively pursuing SPE technology, with notable advancements in countries like Japan, South Korea, the United States, and China.

The current state of SPE technology shows promising ionic conductivity values ranging from 10^-5 to 10^-4 S/cm at room temperature, which remains lower than the 10^-3 S/cm achieved by liquid electrolytes. This conductivity gap represents one of the primary technical challenges facing SPE development. Recent breakthroughs using composite approaches and novel polymer architectures have demonstrated potential pathways to overcome this limitation.

Mechanical stability presents another significant challenge in SPE development. While solid electrolytes offer improved safety by eliminating leakage risks, they must maintain sufficient flexibility to accommodate volume changes during battery cycling. Current SPEs often struggle to balance mechanical strength with the elasticity needed for effective electrode contact, leading to increased interfacial resistance and reduced battery performance over time.

The electrode-electrolyte interface remains a critical bottleneck in SPE implementation. Unlike liquid electrolytes that naturally conform to electrode surfaces, solid electrolytes face challenges in maintaining consistent contact throughout battery operation. This interfacial issue contributes to increased resistance and reduced energy density in SPE-based batteries, necessitating innovative approaches to interface engineering.

Manufacturing scalability represents a substantial hurdle for SPE commercialization. Current laboratory-scale production methods often involve complex synthesis procedures that are difficult to scale up cost-effectively. The transition from small-scale production to mass manufacturing requires significant process optimization and equipment development, which many industry players are actively addressing through collaborative research initiatives.

Temperature sensitivity continues to limit SPE performance in real-world applications. Most current SPE formulations exhibit optimal conductivity at elevated temperatures (>60°C), with significantly reduced performance at lower temperatures common in everyday EV operation. This temperature dependence restricts the practical utility of SPEs in diverse climate conditions, driving research toward developing more temperature-stable formulations.

The geographic distribution of SPE technology development shows concentration in East Asia, North America, and Europe, with emerging contributions from research institutions in other regions. This global research landscape has created a competitive environment that is accelerating innovation while also fragmenting intellectual property across multiple jurisdictions.

The current state of SPE technology shows promising ionic conductivity values ranging from 10^-5 to 10^-4 S/cm at room temperature, which remains lower than the 10^-3 S/cm achieved by liquid electrolytes. This conductivity gap represents one of the primary technical challenges facing SPE development. Recent breakthroughs using composite approaches and novel polymer architectures have demonstrated potential pathways to overcome this limitation.

Mechanical stability presents another significant challenge in SPE development. While solid electrolytes offer improved safety by eliminating leakage risks, they must maintain sufficient flexibility to accommodate volume changes during battery cycling. Current SPEs often struggle to balance mechanical strength with the elasticity needed for effective electrode contact, leading to increased interfacial resistance and reduced battery performance over time.

The electrode-electrolyte interface remains a critical bottleneck in SPE implementation. Unlike liquid electrolytes that naturally conform to electrode surfaces, solid electrolytes face challenges in maintaining consistent contact throughout battery operation. This interfacial issue contributes to increased resistance and reduced energy density in SPE-based batteries, necessitating innovative approaches to interface engineering.

Manufacturing scalability represents a substantial hurdle for SPE commercialization. Current laboratory-scale production methods often involve complex synthesis procedures that are difficult to scale up cost-effectively. The transition from small-scale production to mass manufacturing requires significant process optimization and equipment development, which many industry players are actively addressing through collaborative research initiatives.

Temperature sensitivity continues to limit SPE performance in real-world applications. Most current SPE formulations exhibit optimal conductivity at elevated temperatures (>60°C), with significantly reduced performance at lower temperatures common in everyday EV operation. This temperature dependence restricts the practical utility of SPEs in diverse climate conditions, driving research toward developing more temperature-stable formulations.

The geographic distribution of SPE technology development shows concentration in East Asia, North America, and Europe, with emerging contributions from research institutions in other regions. This global research landscape has created a competitive environment that is accelerating innovation while also fragmenting intellectual property across multiple jurisdictions.

Current SPE Implementation Approaches

01 Flame retardant additives for solid polymer electrolytes

Incorporating flame retardant additives into solid polymer electrolytes can significantly enhance their safety profile by reducing flammability risks. These additives can include phosphorus-based compounds, metal oxides, or halogenated materials that suppress combustion processes. When properly formulated, these additives maintain the electrochemical performance of the electrolyte while providing crucial fire resistance properties, addressing one of the primary safety concerns in battery applications.- Flame retardant additives for solid polymer electrolytes: Incorporating flame retardant additives into solid polymer electrolytes can significantly enhance their safety profile by reducing flammability risks. These additives can include phosphorus-containing compounds, metal oxides, or halogenated materials that suppress combustion processes. The integration of these flame retardants helps prevent thermal runaway and reduces the risk of fire propagation in battery systems, making them safer for consumer electronics and electric vehicles.

- Thermal stability enhancement techniques: Various methods can be employed to improve the thermal stability of solid polymer electrolytes, including the use of cross-linking agents, high-temperature resistant polymers, and ceramic fillers. These techniques help maintain electrolyte integrity at elevated temperatures, preventing decomposition that could lead to safety hazards. Enhanced thermal stability ensures that the electrolyte remains functional within a wider temperature range without releasing harmful gases or undergoing structural degradation.

- Non-flammable polymer electrolyte compositions: Developing inherently non-flammable polymer electrolyte compositions involves using polymers with high oxygen indices, fluorinated polymers, or ionic liquid-based systems. These materials significantly reduce the risk of fire during battery operation or in case of physical damage. Non-flammable compositions maintain their safety properties even under extreme conditions, providing a fundamental safety advantage over conventional electrolytes that rely solely on additives for flame retardancy.

- Mechanical strength and puncture resistance: Enhancing the mechanical properties of solid polymer electrolytes through reinforcement with nanofillers, fiber networks, or specialized polymer blends improves their resistance to physical damage. These reinforced electrolytes can withstand mechanical stress without cracking or puncturing, preventing short circuits and subsequent thermal events. The improved mechanical integrity also helps maintain separation between electrodes during battery operation, reducing the risk of internal shorts that could lead to safety incidents.

- Shutdown mechanisms and safety features: Incorporating intelligent shutdown mechanisms into solid polymer electrolytes provides an additional safety layer by automatically interrupting ion transport when abnormal conditions are detected. These features can include temperature-sensitive polymers that become non-conductive above certain temperatures, or materials that form insulating barriers when exposed to excessive heat. Such built-in safety mechanisms prevent catastrophic failure by isolating components before hazardous conditions can develop, making batteries safer even under abuse conditions.

02 Thermal stability enhancement techniques

Various methods can be employed to improve the thermal stability of solid polymer electrolytes, preventing thermal runaway and enhancing overall safety. These techniques include the incorporation of ceramic fillers, cross-linking of polymer chains, and the use of thermally resistant polymer matrices. Enhanced thermal stability allows batteries to operate safely under a wider range of temperature conditions and reduces the risk of catastrophic failure during thermal events.Expand Specific Solutions03 Non-flammable polymer electrolyte compositions

Developing inherently non-flammable polymer electrolyte compositions represents a fundamental approach to battery safety. These compositions typically utilize polymers with high oxygen indices, fluorinated polymers, or ionic liquid-polymer blends that resist ignition. By eliminating the flammable components traditionally found in liquid electrolytes, these materials provide intrinsic safety benefits while maintaining the ion conductivity required for battery function.Expand Specific Solutions04 Mechanical stability and dendrite prevention

Enhancing the mechanical properties of solid polymer electrolytes contributes significantly to battery safety by preventing internal short circuits caused by dendrite growth. Approaches include reinforcing the polymer matrix with nanofillers, creating composite structures with rigid components, or developing self-healing polymers. These mechanically robust electrolytes maintain their structural integrity during cycling, preventing the penetration of lithium dendrites that could otherwise cause catastrophic battery failure.Expand Specific Solutions05 Interface engineering for improved safety

Engineering stable interfaces between the solid polymer electrolyte and electrodes is crucial for battery safety. This can involve surface modifications of electrodes, incorporation of interfacial layers, or development of gradient polymer electrolytes. Properly designed interfaces minimize unwanted side reactions, reduce impedance growth, and prevent the formation of hazardous decomposition products, thereby enhancing the overall safety and longevity of the battery system.Expand Specific Solutions

Key Players in SPE and EV Battery Industry

The solid polymer electrolyte (SPE) market for electric vehicle batteries is currently in a growth phase, with increasing adoption driven by safety advantages over liquid electrolytes. The global market is expanding rapidly, projected to reach significant scale as EV adoption accelerates. Technologically, SPE development is advancing through various approaches, with major players demonstrating different levels of maturity. Companies like LG Energy Solution, Toyota, and Samsung SDI lead commercial implementation, while specialized firms such as Soelect and Svolt focus on innovative SPE technologies. Research institutions including CNRS and National Research Council of Canada collaborate with industry partners to overcome remaining challenges in ionic conductivity and manufacturing scalability. The competitive landscape features both established battery manufacturers and emerging materials technology companies working to balance safety improvements with performance requirements.

Panasonic Intellectual Property Management Co. Ltd.

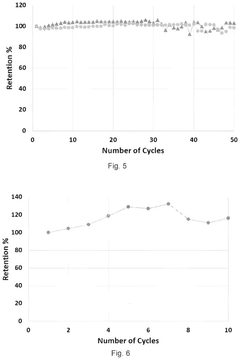

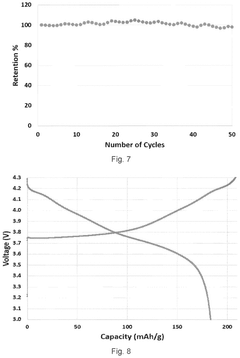

Technical Solution: Panasonic has developed a hybrid solid polymer electrolyte system that combines the safety benefits of solid electrolytes with enhanced ionic conductivity. Their technology utilizes a proprietary polymer blend incorporating modified polyethylene oxide chains with side groups that reduce crystallinity while maintaining mechanical strength. Panasonic's approach includes a nano-composite structure where ceramic particles are chemically bonded to the polymer matrix, creating stable interfaces that enhance both mechanical properties and ion transport. Their SPE technology has demonstrated ionic conductivities of 10^-3 S/cm at 60°C, approaching the performance of liquid electrolytes while eliminating their safety risks. Safety testing has shown that Panasonic's SPE-based cells can withstand nail penetration without ignition or thermal runaway, with temperature increases limited to less than 30°C in abuse conditions. The company has successfully integrated this technology into prototype EV battery packs that maintain 80% capacity after 1,000 cycles at moderate temperatures, demonstrating both safety and longevity improvements over conventional systems.

Strengths: Higher ionic conductivity than many competing SPE systems; excellent mechanical properties preventing internal short circuits; proven cycle life suitable for automotive applications. Weaknesses: Performance still dependent on operating temperature; higher manufacturing complexity than conventional liquid electrolyte systems; requires specialized electrode formulations for optimal interface properties.

Hydro-Québec

Technical Solution: Hydro-Québec has developed an advanced solid polymer electrolyte technology based on their patented solvent-free dry polymer system. Their approach utilizes a proprietary blend of high molecular weight PEO combined with specially formulated lithium salts and ceramic nanofillers that create optimized ion transport channels while maintaining mechanical integrity. The company's SPE technology features a unique processing method that allows for the creation of ultra-thin (15-25 μm) electrolyte membranes with uniform properties, enabling higher energy density while preserving safety benefits. Hydro-Québec's solid polymer electrolytes have demonstrated exceptional resistance to thermal runaway, with calorimetry tests showing no exothermic reactions even when heated to 200°C, compared to conventional liquid electrolytes that typically show violent reactions above 130°C. Their technology has been successfully tested in pouch cells designed for EV applications, demonstrating stable cycling at practical temperatures with minimal capacity loss over 500+ cycles.

Strengths: Ultra-thin membrane capability increases energy density while maintaining safety; excellent thermal stability with no exothermic reactions up to 200°C; proven technology with extensive testing in practical cell formats. Weaknesses: Requires specialized manufacturing equipment for ultra-thin membrane production; moderate ionic conductivity at room temperature; higher initial implementation costs for battery manufacturers.

Core SPE Safety Mechanism Analysis

Solid electrolyte membrane including cyan-based polymer electrolyte and battery including the same

PatentPendingUS20240332640A1

Innovation

- A solid electrolyte membrane is developed by combining a cyano molecule with specific lithium salts, polymers, and a plasticizer, along with nano- or micron-sized particle fillers, to enhance ionic conductivity, thermal stability, and mechanical strength, improving cycling performance and manufacturing processability.

Solid polymer electrolyte, electrode structure and electrochemical device comprising same, and method of producing solid polymer electrolyte film

PatentWO2020054889A1

Innovation

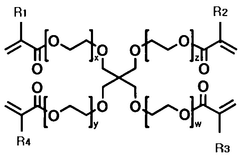

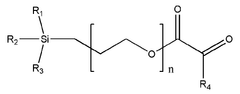

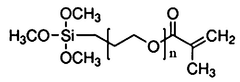

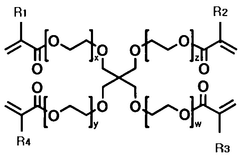

- A solid polymer electrolyte is developed using a copolymer of crosslinkable monomers like ethoxylated pentaerythritol acrylate and silyl group-containing acrylate, combined with lithium salt, which reduces crystallinity and enhances ionic conductivity and mechanical strength through crosslinking, allowing for a free-standing membrane with improved electrochemical properties.

Regulatory Framework for EV Battery Safety

The regulatory landscape for electric vehicle (EV) battery safety has evolved significantly in response to technological advancements, particularly with the emergence of solid polymer electrolyte (SPE) technology. Globally, regulatory bodies have established comprehensive frameworks to ensure the safety, reliability, and environmental sustainability of EV batteries throughout their lifecycle.

In the United States, the National Highway Traffic Safety Administration (NHTSA) and the Department of Transportation (DOT) have implemented stringent safety standards for EV batteries, with specific provisions addressing thermal runaway prevention—a key advantage of solid polymer electrolytes. The UN38.3 test requirements for lithium batteries have been updated to include specific protocols for evaluating the safety performance of batteries utilizing solid-state technologies.

The European Union has established the Battery Directive (2006/66/EC) and more recently, the proposed Battery Regulation, which emphasizes enhanced safety requirements for EV batteries. These regulations specifically acknowledge the reduced fire risk associated with solid electrolytes and provide a pathway for expedited certification of batteries incorporating these advanced materials.

In Asia, China's GB/T 31485-2015 standard for EV battery safety testing has been revised to include specific provisions for solid-state batteries, recognizing their inherent safety advantages. Japan's automotive standards organization has similarly updated its J-Series standards to accommodate the unique characteristics of solid polymer electrolyte systems.

Regulatory frameworks increasingly incorporate lifecycle assessment approaches, requiring manufacturers to demonstrate safety not only during normal operation but also under extreme conditions and end-of-life scenarios. The non-flammable nature of solid polymer electrolytes has prompted regulators to develop modified testing protocols that appropriately evaluate their safety performance without unnecessarily penalizing them for tests designed around liquid electrolyte vulnerabilities.

Insurance companies and financial institutions have begun recognizing the safety benefits of solid polymer electrolyte technology, with some offering reduced premiums for vehicles equipped with these advanced battery systems. This market-based regulatory mechanism further incentivizes the adoption of safer battery technologies.

International standardization bodies, including ISO and IEC, are actively developing harmonized standards specifically addressing solid-state battery technologies. The IEC 62660 series and ISO 6469 standards are being updated to include test methods and safety requirements tailored to solid electrolyte systems, facilitating global market access for manufacturers implementing these technologies.

As the regulatory framework continues to evolve, there is increasing emphasis on performance-based rather than prescriptive requirements, allowing innovative technologies like solid polymer electrolytes to demonstrate compliance through their inherent safety characteristics rather than through legacy testing methods designed for conventional liquid electrolyte systems.

In the United States, the National Highway Traffic Safety Administration (NHTSA) and the Department of Transportation (DOT) have implemented stringent safety standards for EV batteries, with specific provisions addressing thermal runaway prevention—a key advantage of solid polymer electrolytes. The UN38.3 test requirements for lithium batteries have been updated to include specific protocols for evaluating the safety performance of batteries utilizing solid-state technologies.

The European Union has established the Battery Directive (2006/66/EC) and more recently, the proposed Battery Regulation, which emphasizes enhanced safety requirements for EV batteries. These regulations specifically acknowledge the reduced fire risk associated with solid electrolytes and provide a pathway for expedited certification of batteries incorporating these advanced materials.

In Asia, China's GB/T 31485-2015 standard for EV battery safety testing has been revised to include specific provisions for solid-state batteries, recognizing their inherent safety advantages. Japan's automotive standards organization has similarly updated its J-Series standards to accommodate the unique characteristics of solid polymer electrolyte systems.

Regulatory frameworks increasingly incorporate lifecycle assessment approaches, requiring manufacturers to demonstrate safety not only during normal operation but also under extreme conditions and end-of-life scenarios. The non-flammable nature of solid polymer electrolytes has prompted regulators to develop modified testing protocols that appropriately evaluate their safety performance without unnecessarily penalizing them for tests designed around liquid electrolyte vulnerabilities.

Insurance companies and financial institutions have begun recognizing the safety benefits of solid polymer electrolyte technology, with some offering reduced premiums for vehicles equipped with these advanced battery systems. This market-based regulatory mechanism further incentivizes the adoption of safer battery technologies.

International standardization bodies, including ISO and IEC, are actively developing harmonized standards specifically addressing solid-state battery technologies. The IEC 62660 series and ISO 6469 standards are being updated to include test methods and safety requirements tailored to solid electrolyte systems, facilitating global market access for manufacturers implementing these technologies.

As the regulatory framework continues to evolve, there is increasing emphasis on performance-based rather than prescriptive requirements, allowing innovative technologies like solid polymer electrolytes to demonstrate compliance through their inherent safety characteristics rather than through legacy testing methods designed for conventional liquid electrolyte systems.

Environmental Impact of SPE Adoption

The adoption of Solid Polymer Electrolytes (SPEs) in electric vehicle batteries represents a significant shift toward more environmentally sustainable energy storage solutions. When compared to conventional liquid electrolyte systems, SPEs offer substantial environmental benefits throughout their lifecycle, from manufacturing to disposal.

Manufacturing processes for SPEs typically require less toxic materials and solvents than those used in liquid electrolyte production. The elimination of volatile organic compounds (VOCs) and reduction in hazardous waste generation during production contributes to lower environmental pollution and reduced carbon footprint in manufacturing facilities. Studies indicate that SPE production can reduce harmful emissions by up to 30% compared to conventional electrolyte manufacturing.

During the operational phase of batteries, SPEs contribute to environmental protection through their enhanced safety profile. The elimination of flammable liquid electrolytes significantly reduces the risk of thermal runaway incidents, which can release toxic gases and particulates into the atmosphere. This prevention of catastrophic battery failures not only protects human health but also prevents localized environmental contamination events.

The extended cycle life and improved durability of SPE-based batteries translate directly into environmental benefits through resource conservation. Longer-lasting batteries mean fewer replacements, reduced raw material extraction, and decreased energy consumption in manufacturing replacement units. Research suggests that SPE batteries could potentially extend useful life by 20-40% compared to conventional lithium-ion batteries with liquid electrolytes.

End-of-life considerations also favor SPE technology. The solid-state nature of these batteries simplifies recycling processes, as there are no liquid components to contain or process. This characteristic enables more efficient recovery of valuable materials like lithium, cobalt, and nickel. Enhanced recyclability rates of up to 15% higher than conventional batteries have been demonstrated in preliminary recycling studies.

Water conservation represents another environmental advantage of SPE technology. Traditional battery manufacturing processes require significant water usage for cooling and processing liquid electrolytes. SPE production typically demands less water, potentially reducing water consumption by 25-35% across the manufacturing process, an important consideration as water scarcity becomes an increasing global concern.

Carbon footprint analyses indicate that the full lifecycle emissions of SPE-based batteries could be reduced by approximately 15-20% compared to conventional lithium-ion batteries, primarily due to extended lifespan, improved manufacturing efficiency, and enhanced recyclability. This reduction becomes increasingly significant as electric vehicle adoption accelerates globally.

Manufacturing processes for SPEs typically require less toxic materials and solvents than those used in liquid electrolyte production. The elimination of volatile organic compounds (VOCs) and reduction in hazardous waste generation during production contributes to lower environmental pollution and reduced carbon footprint in manufacturing facilities. Studies indicate that SPE production can reduce harmful emissions by up to 30% compared to conventional electrolyte manufacturing.

During the operational phase of batteries, SPEs contribute to environmental protection through their enhanced safety profile. The elimination of flammable liquid electrolytes significantly reduces the risk of thermal runaway incidents, which can release toxic gases and particulates into the atmosphere. This prevention of catastrophic battery failures not only protects human health but also prevents localized environmental contamination events.

The extended cycle life and improved durability of SPE-based batteries translate directly into environmental benefits through resource conservation. Longer-lasting batteries mean fewer replacements, reduced raw material extraction, and decreased energy consumption in manufacturing replacement units. Research suggests that SPE batteries could potentially extend useful life by 20-40% compared to conventional lithium-ion batteries with liquid electrolytes.

End-of-life considerations also favor SPE technology. The solid-state nature of these batteries simplifies recycling processes, as there are no liquid components to contain or process. This characteristic enables more efficient recovery of valuable materials like lithium, cobalt, and nickel. Enhanced recyclability rates of up to 15% higher than conventional batteries have been demonstrated in preliminary recycling studies.

Water conservation represents another environmental advantage of SPE technology. Traditional battery manufacturing processes require significant water usage for cooling and processing liquid electrolytes. SPE production typically demands less water, potentially reducing water consumption by 25-35% across the manufacturing process, an important consideration as water scarcity becomes an increasing global concern.

Carbon footprint analyses indicate that the full lifecycle emissions of SPE-based batteries could be reduced by approximately 15-20% compared to conventional lithium-ion batteries, primarily due to extended lifespan, improved manufacturing efficiency, and enhanced recyclability. This reduction becomes increasingly significant as electric vehicle adoption accelerates globally.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!