Solid Polymer Electrolyte Coating Techniques for High-Voltage Cells

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SPE Coating Evolution and Objectives

Solid Polymer Electrolyte (SPE) coating technology has evolved significantly over the past two decades, transforming from experimental laboratory concepts to commercially viable solutions for high-voltage lithium-ion batteries. The evolution began in the early 2000s with rudimentary polymer gel electrolytes that suffered from poor mechanical stability and limited ionic conductivity. By 2010, researchers had developed the first generation of true solid polymer electrolytes based on polyethylene oxide (PEO) matrices, marking a crucial milestone in the field.

The mid-2010s witnessed a paradigm shift with the introduction of composite SPE systems incorporating ceramic fillers such as Al2O3, SiO2, and LLZO, which dramatically improved ionic conductivity while maintaining mechanical integrity. This period also saw the development of novel coating methodologies, transitioning from basic solution casting to more sophisticated techniques including electrospinning, atomic layer deposition, and plasma-enhanced chemical vapor deposition specifically optimized for polymer electrolyte materials.

Recent advancements have focused on addressing the critical interface challenges between the SPE coating and electrode materials. The introduction of gradient-structured SPEs and chemically modified interfaces has significantly reduced interfacial resistance, a longstanding barrier to commercial implementation. Concurrently, manufacturing processes have evolved from laboratory-scale batch production to roll-to-roll continuous coating technologies capable of uniform deposition at industrial scales.

The primary technical objectives for SPE coating development center on achieving room-temperature ionic conductivity exceeding 10^-4 S/cm while maintaining excellent electrochemical stability windows beyond 5V. This conductivity threshold represents the minimum requirement for practical application in high-voltage cells, while the expanded voltage window is essential for next-generation cathode materials.

Additional objectives include enhancing mechanical properties to prevent dendrite penetration, a critical safety concern in high-energy-density batteries. Researchers aim to develop SPE coatings with Young's modulus values above 1 GPa while maintaining sufficient flexibility to accommodate volume changes during cycling. Thermal stability targets have also been established, with SPE systems required to maintain structural integrity and performance at temperatures ranging from -20°C to 80°C.

Looking forward, the field is moving toward multifunctional SPE coatings that simultaneously serve as electrolytes, separators, and protective layers. The ultimate goal is to enable safe operation of high-voltage (>4.5V) cells with energy densities exceeding 400 Wh/kg, representing a 30% improvement over current commercial lithium-ion technologies. This advancement would significantly impact electric vehicle range, grid storage economics, and portable electronics capabilities.

The mid-2010s witnessed a paradigm shift with the introduction of composite SPE systems incorporating ceramic fillers such as Al2O3, SiO2, and LLZO, which dramatically improved ionic conductivity while maintaining mechanical integrity. This period also saw the development of novel coating methodologies, transitioning from basic solution casting to more sophisticated techniques including electrospinning, atomic layer deposition, and plasma-enhanced chemical vapor deposition specifically optimized for polymer electrolyte materials.

Recent advancements have focused on addressing the critical interface challenges between the SPE coating and electrode materials. The introduction of gradient-structured SPEs and chemically modified interfaces has significantly reduced interfacial resistance, a longstanding barrier to commercial implementation. Concurrently, manufacturing processes have evolved from laboratory-scale batch production to roll-to-roll continuous coating technologies capable of uniform deposition at industrial scales.

The primary technical objectives for SPE coating development center on achieving room-temperature ionic conductivity exceeding 10^-4 S/cm while maintaining excellent electrochemical stability windows beyond 5V. This conductivity threshold represents the minimum requirement for practical application in high-voltage cells, while the expanded voltage window is essential for next-generation cathode materials.

Additional objectives include enhancing mechanical properties to prevent dendrite penetration, a critical safety concern in high-energy-density batteries. Researchers aim to develop SPE coatings with Young's modulus values above 1 GPa while maintaining sufficient flexibility to accommodate volume changes during cycling. Thermal stability targets have also been established, with SPE systems required to maintain structural integrity and performance at temperatures ranging from -20°C to 80°C.

Looking forward, the field is moving toward multifunctional SPE coatings that simultaneously serve as electrolytes, separators, and protective layers. The ultimate goal is to enable safe operation of high-voltage (>4.5V) cells with energy densities exceeding 400 Wh/kg, representing a 30% improvement over current commercial lithium-ion technologies. This advancement would significantly impact electric vehicle range, grid storage economics, and portable electronics capabilities.

Market Analysis for High-Voltage Battery Applications

The high-voltage battery market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs) and renewable energy storage systems. Current market projections indicate that the global high-voltage battery market will reach approximately $240 billion by 2030, with a compound annual growth rate of 18.7% from 2023 to 2030. This growth trajectory is significantly steeper than previous forecasts, reflecting accelerated EV adoption rates worldwide.

Solid polymer electrolyte (SPE) coatings represent a critical technological advancement for high-voltage cells, addressing key market demands for improved safety, energy density, and cycle life. Market research indicates that batteries incorporating advanced electrolyte technologies command premium pricing, with margins 15-20% higher than conventional lithium-ion batteries, creating substantial revenue opportunities for early adopters of SPE coating technologies.

The automotive sector currently dominates demand for high-voltage batteries with SPE coatings, accounting for approximately 67% of market share. Electric vehicle manufacturers are increasingly specifying batteries capable of operating at voltages above 4.5V to achieve greater range and faster charging capabilities. Tesla, Volkswagen Group, and BYD have all announced plans to incorporate high-voltage cells in their next-generation EV platforms, signaling strong market pull for this technology.

Beyond automotive applications, grid-scale energy storage represents the second-largest and fastest-growing market segment for high-voltage batteries, expanding at 24.3% annually. This growth is driven by increasing renewable energy integration and grid modernization initiatives across North America, Europe, and Asia-Pacific regions.

Consumer electronics manufacturers are also showing heightened interest in high-voltage cells with SPE coatings for premium devices, particularly in applications requiring extended battery life and rapid charging capabilities. This segment is projected to grow at 16.2% annually through 2030.

Regionally, Asia-Pacific dominates high-voltage battery production and consumption, accounting for 58% of global market share, followed by Europe (24%) and North America (15%). China leads manufacturing capacity, while South Korea and Japan maintain technological leadership in advanced electrolyte systems. European demand is accelerating rapidly due to stringent emissions regulations and substantial government incentives for EV adoption.

Market analysis reveals that customers prioritize three key performance attributes in high-voltage batteries: safety performance (cited by 87% of OEMs as "critical"), cycle life stability (82%), and fast-charging capability (76%). SPE coating technologies directly address these priorities, positioning them as a high-value innovation within the battery technology landscape.

Solid polymer electrolyte (SPE) coatings represent a critical technological advancement for high-voltage cells, addressing key market demands for improved safety, energy density, and cycle life. Market research indicates that batteries incorporating advanced electrolyte technologies command premium pricing, with margins 15-20% higher than conventional lithium-ion batteries, creating substantial revenue opportunities for early adopters of SPE coating technologies.

The automotive sector currently dominates demand for high-voltage batteries with SPE coatings, accounting for approximately 67% of market share. Electric vehicle manufacturers are increasingly specifying batteries capable of operating at voltages above 4.5V to achieve greater range and faster charging capabilities. Tesla, Volkswagen Group, and BYD have all announced plans to incorporate high-voltage cells in their next-generation EV platforms, signaling strong market pull for this technology.

Beyond automotive applications, grid-scale energy storage represents the second-largest and fastest-growing market segment for high-voltage batteries, expanding at 24.3% annually. This growth is driven by increasing renewable energy integration and grid modernization initiatives across North America, Europe, and Asia-Pacific regions.

Consumer electronics manufacturers are also showing heightened interest in high-voltage cells with SPE coatings for premium devices, particularly in applications requiring extended battery life and rapid charging capabilities. This segment is projected to grow at 16.2% annually through 2030.

Regionally, Asia-Pacific dominates high-voltage battery production and consumption, accounting for 58% of global market share, followed by Europe (24%) and North America (15%). China leads manufacturing capacity, while South Korea and Japan maintain technological leadership in advanced electrolyte systems. European demand is accelerating rapidly due to stringent emissions regulations and substantial government incentives for EV adoption.

Market analysis reveals that customers prioritize three key performance attributes in high-voltage batteries: safety performance (cited by 87% of OEMs as "critical"), cycle life stability (82%), and fast-charging capability (76%). SPE coating technologies directly address these priorities, positioning them as a high-value innovation within the battery technology landscape.

Current SPE Coating Challenges and Limitations

Despite the promising potential of Solid Polymer Electrolytes (SPEs) in high-voltage cells, their implementation faces significant coating challenges that impede widespread commercial adoption. Current coating techniques struggle with achieving uniform thickness distribution across large-area substrates, resulting in performance inconsistencies and potential safety risks. The non-uniform coating creates localized thin spots that become vulnerable to dendrite penetration during cycling, compromising the cell's safety advantages.

Material compatibility issues present another major hurdle, as many SPE formulations exhibit poor adhesion to electrode surfaces. This adhesion problem creates interfacial resistance that diminishes energy density and power capabilities. The coating processes must accommodate diverse electrode materials while maintaining consistent interfacial properties, a balance difficult to achieve with current technologies.

Processing temperature constraints significantly limit manufacturing options for SPEs. Many polymer electrolyte systems require high-temperature processing (>100°C) for optimal performance, yet these temperatures can degrade active electrode materials or trigger unwanted side reactions. Conversely, low-temperature coating methods often result in suboptimal polymer chain alignment and reduced ionic conductivity.

Scalability remains a critical limitation for SPE coating technologies. Laboratory-scale techniques like spin coating and doctor blade methods produce excellent results in research settings but face substantial challenges in industrial-scale implementation. The transition from small-scale production to high-throughput manufacturing introduces variables that affect coating quality, including solvent evaporation rates, environmental controls, and mechanical precision at scale.

Solvent-related issues further complicate SPE coating processes. Many coating techniques rely on solvent-based approaches that introduce environmental and safety concerns. The complete removal of residual solvents is essential yet difficult to achieve consistently in production environments. Trace solvent contamination can significantly impact electrochemical performance and long-term stability of high-voltage cells.

Thickness control precision presents ongoing challenges, with current technologies struggling to maintain the optimal 10-30μm thickness range consistently across large-format cells. Thicker coatings increase internal resistance while thinner sections compromise mechanical integrity and dendrite resistance. The industry lacks robust in-line quality control methods to detect thickness variations during high-speed manufacturing processes.

Porosity management during coating represents another significant limitation. Controlling the microstructure of SPE coatings to balance mechanical properties with ionic transport pathways remains difficult with existing technologies. Uncontrolled porosity can create pathways for dendrite growth or reduce mechanical strength, undermining the fundamental advantages of solid electrolytes in high-voltage applications.

Material compatibility issues present another major hurdle, as many SPE formulations exhibit poor adhesion to electrode surfaces. This adhesion problem creates interfacial resistance that diminishes energy density and power capabilities. The coating processes must accommodate diverse electrode materials while maintaining consistent interfacial properties, a balance difficult to achieve with current technologies.

Processing temperature constraints significantly limit manufacturing options for SPEs. Many polymer electrolyte systems require high-temperature processing (>100°C) for optimal performance, yet these temperatures can degrade active electrode materials or trigger unwanted side reactions. Conversely, low-temperature coating methods often result in suboptimal polymer chain alignment and reduced ionic conductivity.

Scalability remains a critical limitation for SPE coating technologies. Laboratory-scale techniques like spin coating and doctor blade methods produce excellent results in research settings but face substantial challenges in industrial-scale implementation. The transition from small-scale production to high-throughput manufacturing introduces variables that affect coating quality, including solvent evaporation rates, environmental controls, and mechanical precision at scale.

Solvent-related issues further complicate SPE coating processes. Many coating techniques rely on solvent-based approaches that introduce environmental and safety concerns. The complete removal of residual solvents is essential yet difficult to achieve consistently in production environments. Trace solvent contamination can significantly impact electrochemical performance and long-term stability of high-voltage cells.

Thickness control precision presents ongoing challenges, with current technologies struggling to maintain the optimal 10-30μm thickness range consistently across large-format cells. Thicker coatings increase internal resistance while thinner sections compromise mechanical integrity and dendrite resistance. The industry lacks robust in-line quality control methods to detect thickness variations during high-speed manufacturing processes.

Porosity management during coating represents another significant limitation. Controlling the microstructure of SPE coatings to balance mechanical properties with ionic transport pathways remains difficult with existing technologies. Uncontrolled porosity can create pathways for dendrite growth or reduce mechanical strength, undermining the fundamental advantages of solid electrolytes in high-voltage applications.

Existing SPE Coating Methodologies

01 Solution-based coating methods for solid polymer electrolytes

Various solution-based methods can be used to apply solid polymer electrolyte coatings, including dip coating, spray coating, and spin coating. These techniques involve dissolving polymer electrolyte materials in appropriate solvents, applying the solution to a substrate, and then removing the solvent through evaporation or drying processes. These methods allow for uniform coating thickness control and are suitable for both laboratory and industrial scale applications.- Solution-based coating methods for solid polymer electrolytes: Solution-based methods involve dissolving polymer electrolyte materials in suitable solvents and applying them to substrates through techniques such as dip coating, spin coating, or spray coating. These methods allow for uniform thin film formation with controlled thickness. The solvent evaporates after application, leaving behind a solid polymer electrolyte layer. This approach is particularly useful for coating complex geometries and achieving good interfacial contact with electrode materials.

- Thermal processing techniques for solid polymer electrolyte coatings: Thermal processing techniques involve the application of heat during or after the coating process to enhance the properties of solid polymer electrolytes. Methods include hot pressing, melt extrusion, and thermal curing. These techniques improve polymer chain mobility, enhance crystallinity, and strengthen interfacial bonding between the electrolyte and electrodes. Thermal processing can significantly impact ionic conductivity and mechanical stability of the resulting electrolyte layer.

- In-situ polymerization and crosslinking methods: In-situ polymerization involves applying monomers or oligomers directly to the substrate and initiating polymerization on the surface. This approach creates solid polymer electrolyte coatings with excellent adhesion and uniform coverage. Crosslinking agents can be incorporated to enhance mechanical strength and thermal stability. These methods allow for the formation of interpenetrating polymer networks that combine high ionic conductivity with good mechanical properties, making them suitable for flexible battery applications.

- Composite and hybrid coating techniques: Composite coating techniques involve incorporating inorganic fillers, such as ceramic particles or nanostructures, into polymer electrolyte matrices. These hybrid approaches combine solution processing with particle dispersion methods to create coatings with enhanced mechanical and electrochemical properties. The resulting composite electrolytes often exhibit improved ionic conductivity, reduced interfacial resistance, and better dimensional stability compared to pure polymer systems.

- Advanced deposition and surface modification techniques: Advanced deposition techniques include layer-by-layer assembly, electrospinning, and vapor deposition methods for creating highly engineered solid polymer electrolyte coatings. Surface modification approaches such as plasma treatment, UV grafting, and chemical functionalization can be used to improve wettability and adhesion. These sophisticated methods enable precise control over coating thickness, morphology, and interfacial properties, resulting in enhanced battery performance and safety.

02 Electrochemical deposition techniques

Electrochemical deposition is an effective method for applying solid polymer electrolyte coatings, particularly for battery and capacitor applications. This technique involves the use of electric current to deposit polymer electrolyte materials onto conductive substrates. The process allows for precise control of coating thickness and composition, resulting in improved ionic conductivity and mechanical properties of the electrolyte layer.Expand Specific Solutions03 Vapor deposition methods for thin-film solid polymer electrolytes

Vapor deposition techniques, including chemical vapor deposition (CVD) and physical vapor deposition (PVD), are advanced methods for creating thin-film solid polymer electrolyte coatings. These techniques involve converting polymer precursors into vapor phase and then condensing them onto a substrate surface. Vapor deposition methods enable the formation of extremely thin, uniform, and pinhole-free electrolyte layers with excellent adhesion properties and can be performed at lower temperatures than traditional coating methods.Expand Specific Solutions04 Layer-by-layer assembly for composite electrolyte coatings

Layer-by-layer assembly is a versatile technique for creating composite solid polymer electrolyte coatings with enhanced properties. This method involves sequential deposition of alternating layers of different polymer electrolyte materials or additives. The technique allows for precise control over the composition and structure of the electrolyte coating, enabling the incorporation of functional additives such as ceramic particles or flame retardants to improve ionic conductivity, mechanical strength, and thermal stability.Expand Specific Solutions05 In-situ polymerization and crosslinking methods

In-situ polymerization and crosslinking methods involve applying monomers or pre-polymers to a substrate and then initiating polymerization or crosslinking directly on the surface. These techniques can be triggered by heat, UV light, or chemical initiators. The approach results in solid polymer electrolyte coatings with excellent adhesion to substrates, reduced interfacial resistance, and improved mechanical properties. Additionally, this method allows for the formation of interpenetrating polymer networks that can enhance ionic conductivity while maintaining dimensional stability.Expand Specific Solutions

Leading Companies in SPE Coating Technology

The solid polymer electrolyte coating techniques for high-voltage cells market is currently in a growth phase, with increasing demand driven by the electric vehicle and energy storage sectors. The global market size is expanding rapidly, expected to reach significant valuation as battery technologies advance. Technologically, this field is in mid-maturity, with established players like Panasonic, BASF, and Hitachi developing commercial solutions alongside innovative approaches from specialized companies like Ionic Materials and Prieto Battery. Academic-industry partnerships are accelerating development, with institutions like MIT and Fraunhofer-Gesellschaft collaborating with automotive manufacturers including BMW, Hyundai, and Volkswagen. Chinese companies such as Chongqing Tailan and Tianjin B&M are rapidly advancing their capabilities, while Japanese firms maintain strong positions through established expertise in battery materials and manufacturing processes.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has pioneered an innovative solid polymer electrolyte coating technique utilizing radiation-induced polymerization for high-voltage cell applications. Their approach involves applying a precursor solution containing monomers, lithium salts, and specialized additives directly onto electrode surfaces, followed by controlled exposure to electron beam or UV radiation to trigger in-situ polymerization. This process creates a highly conformal coating that penetrates the electrode's porous structure, establishing intimate contact between active materials and the polymer electrolyte. The technique employs specially designed radiation-resistant lithium salts that maintain stability during the curing process while providing excellent ionic conductivity. Fraunhofer's method allows precise control over the crosslinking density of the polymer network, enabling optimization of mechanical properties and ion transport characteristics. Their coating system incorporates gradient functionality, with different polymer compositions at the electrode interfaces compared to the bulk electrolyte, specifically engineered to enhance compatibility with high-voltage cathode materials (>4.6V vs Li/Li+).

Strengths: Excellent conformality and penetration into complex electrode geometries; tunable mechanical properties through controlled crosslinking; solvent-free processing option reducing environmental impact. Weaknesses: Specialized equipment requirements for radiation processing may increase manufacturing complexity; potential challenges in scaling to very high production volumes.

Ionic Materials Inc.

Technical Solution: Ionic Materials has developed a revolutionary solid polymer electrolyte platform specifically designed for high-voltage cells. Their proprietary technology utilizes a polymer matrix that conducts ions at room temperature without the need for liquid components. The polymer electrolyte forms a uniform coating on electrode surfaces through a solution-based processing method, enabling seamless integration with existing battery manufacturing infrastructure. Their coating technique involves dissolving the polymer in a suitable solvent, applying it to electrode surfaces via methods such as slot-die coating or spray coating, followed by a controlled drying process that ensures optimal interface formation between the electrode and electrolyte. The resulting solid-state architecture demonstrates superior electrochemical stability at high voltages (>4.5V), effectively suppressing dendrite formation while maintaining excellent ionic conductivity (>1 mS/cm at room temperature).

Strengths: Superior safety profile with non-flammable materials; excellent high-voltage stability enabling higher energy density cells; compatibility with existing manufacturing processes reducing implementation costs. Weaknesses: Potential challenges in achieving consistent coating thickness across large-format cells; polymer aging effects under extended cycling may impact long-term performance.

Key Patents in High-Voltage SPE Coating

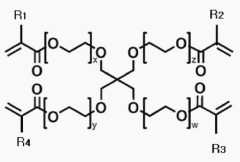

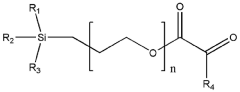

Solid polymer electrolyte, electrode structure and lithium secondary battery including the same, and manufacturing method of solid polymer electrolyte film

PatentActiveKR1020200030975A

Innovation

- A copolymer of ethoxylated pentaerythritol acrylate and silyl group-containing acrylate monomers, combined with a lithium salt, is used to create a crosslinked polymer electrolyte that maintains amorphous structure for high ionic conductivity and mechanical strength.

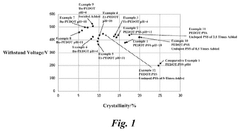

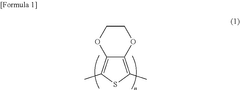

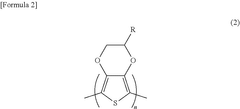

Solid electrolyte, solid electrolytic capacitor, electroconductive polymer dispersion, method for producing solid electrolyte, and method for producing electroconductive polymer dispersion

PatentPendingUS20250140484A1

Innovation

- A solid electrolyte is developed using a conductive polymer dispersion with doped poly(3,4-ethylenedioxythiophene) or its derivatives, where the crystallinity of the conductive polymer is maintained at 20% or less. This solid electrolyte is formed with a pH of 10 or more, and includes additives such as sorbitol to enhance withstand voltage and capacitance.

Safety Standards for High-Voltage Cell Materials

The safety standards for high-voltage cell materials have evolved significantly in response to the growing adoption of solid polymer electrolyte coating techniques. International organizations such as UL (Underwriters Laboratories), IEC (International Electrotechnical Commission), and ISO (International Organization for Standardization) have established comprehensive frameworks specifically addressing the unique safety considerations of high-voltage cells utilizing polymer electrolyte coatings.

UL 1642 and IEC 62133 have been updated to include specific provisions for cells incorporating solid polymer electrolytes, with particular emphasis on thermal stability requirements. These standards mandate that polymer electrolyte coatings must maintain structural integrity at temperatures ranging from -40°C to 85°C, significantly higher than previous requirements for traditional liquid electrolyte systems.

The UN Transportation Testing standards (UN 38.3) have also been revised to address the specific characteristics of solid polymer electrolyte coated cells, requiring enhanced mechanical abuse testing protocols. These include more rigorous crush tests and penetration resistance evaluations to ensure safety during transportation and handling of high-voltage cells.

Safety certification now requires extensive cycling stability tests under various environmental conditions, with polymer-coated high-voltage cells needing to demonstrate less than 5% capacity degradation after 1000 cycles at elevated temperatures. This represents a substantial increase in performance requirements compared to previous standards for conventional lithium-ion batteries.

Fire safety standards have been particularly strengthened, with UL 9540A introducing specialized test methods for evaluating thermal runaway propagation in systems utilizing solid polymer electrolyte coatings. These standards require that high-voltage cells with polymer coatings demonstrate self-extinguishing properties and minimal heat generation during failure modes.

The European Union's Battery Directive (2006/66/EC) and its recent amendments have incorporated specific provisions for high-voltage cells with advanced electrolyte systems, focusing on end-of-life management and recycling considerations for polymer-based components. These regulations mandate recoverable design approaches and detailed material declaration requirements.

Industry consortia such as the Battery Safety Council have developed supplementary guidelines specifically addressing the interface between solid polymer electrolytes and high-voltage cathode materials, recommending additional safety features such as pressure-activated shutdown mechanisms and advanced battery management system protocols tailored to the unique characteristics of these advanced cell designs.

UL 1642 and IEC 62133 have been updated to include specific provisions for cells incorporating solid polymer electrolytes, with particular emphasis on thermal stability requirements. These standards mandate that polymer electrolyte coatings must maintain structural integrity at temperatures ranging from -40°C to 85°C, significantly higher than previous requirements for traditional liquid electrolyte systems.

The UN Transportation Testing standards (UN 38.3) have also been revised to address the specific characteristics of solid polymer electrolyte coated cells, requiring enhanced mechanical abuse testing protocols. These include more rigorous crush tests and penetration resistance evaluations to ensure safety during transportation and handling of high-voltage cells.

Safety certification now requires extensive cycling stability tests under various environmental conditions, with polymer-coated high-voltage cells needing to demonstrate less than 5% capacity degradation after 1000 cycles at elevated temperatures. This represents a substantial increase in performance requirements compared to previous standards for conventional lithium-ion batteries.

Fire safety standards have been particularly strengthened, with UL 9540A introducing specialized test methods for evaluating thermal runaway propagation in systems utilizing solid polymer electrolyte coatings. These standards require that high-voltage cells with polymer coatings demonstrate self-extinguishing properties and minimal heat generation during failure modes.

The European Union's Battery Directive (2006/66/EC) and its recent amendments have incorporated specific provisions for high-voltage cells with advanced electrolyte systems, focusing on end-of-life management and recycling considerations for polymer-based components. These regulations mandate recoverable design approaches and detailed material declaration requirements.

Industry consortia such as the Battery Safety Council have developed supplementary guidelines specifically addressing the interface between solid polymer electrolytes and high-voltage cathode materials, recommending additional safety features such as pressure-activated shutdown mechanisms and advanced battery management system protocols tailored to the unique characteristics of these advanced cell designs.

Environmental Impact of SPE Manufacturing

The manufacturing processes for Solid Polymer Electrolyte (SPE) coatings in high-voltage cells present significant environmental considerations that must be evaluated within a comprehensive sustainability framework. Current production methods for SPE materials involve multiple chemical processes that generate varying degrees of environmental impact throughout their lifecycle.

Primary environmental concerns stem from solvent usage in conventional coating techniques. Traditional SPE manufacturing often relies on toxic organic solvents such as N-methyl-2-pyrrolidone (NMP), dimethylformamide (DMF), and acetonitrile, which pose substantial environmental hazards through volatile organic compound (VOC) emissions. These emissions contribute to air pollution, photochemical smog formation, and potential health risks for manufacturing workers and surrounding communities.

Water consumption represents another critical environmental factor in SPE production. Wet coating processes typically require significant quantities of water for both the coating application and subsequent cleaning operations. In regions facing water scarcity, this intensive usage pattern raises sustainability concerns and may contribute to local resource depletion.

Energy requirements for SPE manufacturing also merit careful consideration. The drying and curing stages of polymer electrolyte coatings demand substantial thermal energy, traditionally supplied through fossil fuel consumption. This energy-intensive process contributes significantly to the carbon footprint of high-voltage cell production, with estimates suggesting that coating and drying operations may account for 15-25% of the total energy consumption in battery manufacturing.

Waste generation throughout the SPE production chain presents additional environmental challenges. Chemical byproducts, unused raw materials, and rejected batches create waste streams requiring specialized disposal protocols. Current industry practices show that for every kilogram of SPE material produced, approximately 0.3-0.5 kg of solid waste is generated, necessitating proper treatment to prevent environmental contamination.

Recent advancements in green chemistry approaches offer promising pathways to mitigate these environmental impacts. Water-based SPE formulations, solvent-free coating techniques, and energy-efficient curing methods are emerging as sustainable alternatives. Life cycle assessment (LCA) studies indicate that transitioning to these environmentally conscious manufacturing methods could reduce the carbon footprint of SPE production by 30-40% while simultaneously decreasing hazardous waste generation.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of battery component manufacturing, including SPE production. The European Union's REACH regulations, California's Proposition 65, and similar initiatives in Asia are establishing stricter guidelines for chemical usage, emissions control, and waste management in battery manufacturing processes, driving industry innovation toward more sustainable practices.

Primary environmental concerns stem from solvent usage in conventional coating techniques. Traditional SPE manufacturing often relies on toxic organic solvents such as N-methyl-2-pyrrolidone (NMP), dimethylformamide (DMF), and acetonitrile, which pose substantial environmental hazards through volatile organic compound (VOC) emissions. These emissions contribute to air pollution, photochemical smog formation, and potential health risks for manufacturing workers and surrounding communities.

Water consumption represents another critical environmental factor in SPE production. Wet coating processes typically require significant quantities of water for both the coating application and subsequent cleaning operations. In regions facing water scarcity, this intensive usage pattern raises sustainability concerns and may contribute to local resource depletion.

Energy requirements for SPE manufacturing also merit careful consideration. The drying and curing stages of polymer electrolyte coatings demand substantial thermal energy, traditionally supplied through fossil fuel consumption. This energy-intensive process contributes significantly to the carbon footprint of high-voltage cell production, with estimates suggesting that coating and drying operations may account for 15-25% of the total energy consumption in battery manufacturing.

Waste generation throughout the SPE production chain presents additional environmental challenges. Chemical byproducts, unused raw materials, and rejected batches create waste streams requiring specialized disposal protocols. Current industry practices show that for every kilogram of SPE material produced, approximately 0.3-0.5 kg of solid waste is generated, necessitating proper treatment to prevent environmental contamination.

Recent advancements in green chemistry approaches offer promising pathways to mitigate these environmental impacts. Water-based SPE formulations, solvent-free coating techniques, and energy-efficient curing methods are emerging as sustainable alternatives. Life cycle assessment (LCA) studies indicate that transitioning to these environmentally conscious manufacturing methods could reduce the carbon footprint of SPE production by 30-40% while simultaneously decreasing hazardous waste generation.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of battery component manufacturing, including SPE production. The European Union's REACH regulations, California's Proposition 65, and similar initiatives in Asia are establishing stricter guidelines for chemical usage, emissions control, and waste management in battery manufacturing processes, driving industry innovation toward more sustainable practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!