Solid Polymer Electrolyte Safety Testing and Certification Standards

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SPE Safety Testing Background and Objectives

Solid Polymer Electrolytes (SPEs) have emerged as a promising alternative to conventional liquid electrolytes in lithium-ion batteries, offering enhanced safety characteristics by eliminating flammable organic solvents. The development of SPEs dates back to the 1970s when P.V. Wright discovered ionic conductivity in PEO-salt complexes. Since then, the field has evolved significantly, with major technological breakthroughs occurring in the past decade as the demand for safer energy storage solutions has intensified.

The primary objective of SPE safety testing and certification standards is to establish comprehensive protocols that can reliably evaluate the safety performance of these materials under various operational and extreme conditions. This includes assessing thermal stability, mechanical integrity, electrochemical stability, and resistance to dendrite formation—all critical factors that determine the overall safety profile of SPE-based battery systems.

Current technological trends in SPE development focus on achieving a balance between safety enhancement and maintaining competitive electrochemical performance. This includes the development of composite and hybrid systems that incorporate inorganic fillers, flame-retardant additives, and novel polymer architectures designed to optimize both safety and functionality. The integration of computational modeling with experimental validation has accelerated this development process, enabling more targeted approaches to SPE design.

The establishment of standardized safety testing protocols for SPEs represents a significant challenge due to the diverse chemical compositions and physical properties of these materials. Unlike liquid electrolytes, which have well-established safety standards, SPEs require new testing methodologies that account for their solid-state nature and unique failure modes. This necessitates a collaborative approach involving academic institutions, industry stakeholders, and regulatory bodies to develop consensus-based standards.

Global regulatory frameworks are increasingly recognizing the need for specific safety standards for solid-state battery technologies. Organizations such as the International Electrotechnical Commission (IEC), Underwriters Laboratories (UL), and various national standards bodies are working to develop testing protocols specifically tailored to SPE-based systems. These efforts aim to address the full lifecycle safety considerations, from manufacturing and transportation to operation and disposal.

The technical goals for SPE safety standards development include establishing quantifiable safety metrics, developing accelerated testing methodologies that can predict long-term safety performance, and creating harmonized global standards that facilitate international market access for SPE-based products. Additionally, there is a growing emphasis on developing standards that can accommodate the rapid pace of innovation in this field without compromising on safety assurance.

The primary objective of SPE safety testing and certification standards is to establish comprehensive protocols that can reliably evaluate the safety performance of these materials under various operational and extreme conditions. This includes assessing thermal stability, mechanical integrity, electrochemical stability, and resistance to dendrite formation—all critical factors that determine the overall safety profile of SPE-based battery systems.

Current technological trends in SPE development focus on achieving a balance between safety enhancement and maintaining competitive electrochemical performance. This includes the development of composite and hybrid systems that incorporate inorganic fillers, flame-retardant additives, and novel polymer architectures designed to optimize both safety and functionality. The integration of computational modeling with experimental validation has accelerated this development process, enabling more targeted approaches to SPE design.

The establishment of standardized safety testing protocols for SPEs represents a significant challenge due to the diverse chemical compositions and physical properties of these materials. Unlike liquid electrolytes, which have well-established safety standards, SPEs require new testing methodologies that account for their solid-state nature and unique failure modes. This necessitates a collaborative approach involving academic institutions, industry stakeholders, and regulatory bodies to develop consensus-based standards.

Global regulatory frameworks are increasingly recognizing the need for specific safety standards for solid-state battery technologies. Organizations such as the International Electrotechnical Commission (IEC), Underwriters Laboratories (UL), and various national standards bodies are working to develop testing protocols specifically tailored to SPE-based systems. These efforts aim to address the full lifecycle safety considerations, from manufacturing and transportation to operation and disposal.

The technical goals for SPE safety standards development include establishing quantifiable safety metrics, developing accelerated testing methodologies that can predict long-term safety performance, and creating harmonized global standards that facilitate international market access for SPE-based products. Additionally, there is a growing emphasis on developing standards that can accommodate the rapid pace of innovation in this field without compromising on safety assurance.

Market Demand Analysis for Safe SPE Technologies

The global market for solid polymer electrolytes (SPEs) is experiencing unprecedented growth, driven primarily by the expanding electric vehicle (EV) sector and increasing concerns about battery safety. Current market projections indicate that the SPE market will reach approximately $2.5 billion by 2027, with a compound annual growth rate of 18.7% from 2022. This growth trajectory is significantly influenced by heightened safety requirements across multiple industries.

Safety concerns regarding traditional liquid electrolytes have created a substantial market pull for SPE technologies. Liquid electrolyte-based batteries are prone to thermal runaway, leakage, and flammability issues, which have resulted in high-profile incidents across consumer electronics and automotive sectors. These incidents have accelerated regulatory scrutiny and consumer awareness, creating immediate market demand for safer alternatives.

The automotive industry represents the largest market segment for SPE technologies, accounting for nearly 45% of the total demand. Major automotive manufacturers have publicly committed to transitioning toward solid-state battery technologies, with safety being cited as the primary motivation. Tesla, Volkswagen, Toyota, and BMW have all announced significant investments in solid-state battery research and development programs, with safety testing protocols being a central focus.

Consumer electronics manufacturers constitute the second-largest market segment, representing approximately 30% of the demand. Following several widely publicized incidents involving smartphone and laptop battery fires, manufacturers are under increasing pressure to adopt safer battery technologies. This pressure comes not only from consumers but also from transportation authorities that have implemented stricter regulations for shipping lithium-based batteries.

Market research indicates that 78% of consumers would pay a premium of up to 15% for devices with demonstrably safer battery technology. This consumer willingness to pay for safety creates a significant market opportunity for SPE technologies that can meet rigorous safety standards and obtain recognized certifications.

The energy storage sector is emerging as another significant market for SPE technologies, particularly for grid-scale applications where safety concerns are paramount. Utility companies and energy storage system integrators are increasingly specifying enhanced safety requirements in their procurement processes, with specific references to solid-state technologies.

Geographically, North America and East Asia dominate the market demand for SPE safety technologies, accounting for 37% and 42% of the global market respectively. This regional concentration aligns with the locations of major battery manufacturers and automotive production facilities, creating localized ecosystems for safety testing and certification.

Safety concerns regarding traditional liquid electrolytes have created a substantial market pull for SPE technologies. Liquid electrolyte-based batteries are prone to thermal runaway, leakage, and flammability issues, which have resulted in high-profile incidents across consumer electronics and automotive sectors. These incidents have accelerated regulatory scrutiny and consumer awareness, creating immediate market demand for safer alternatives.

The automotive industry represents the largest market segment for SPE technologies, accounting for nearly 45% of the total demand. Major automotive manufacturers have publicly committed to transitioning toward solid-state battery technologies, with safety being cited as the primary motivation. Tesla, Volkswagen, Toyota, and BMW have all announced significant investments in solid-state battery research and development programs, with safety testing protocols being a central focus.

Consumer electronics manufacturers constitute the second-largest market segment, representing approximately 30% of the demand. Following several widely publicized incidents involving smartphone and laptop battery fires, manufacturers are under increasing pressure to adopt safer battery technologies. This pressure comes not only from consumers but also from transportation authorities that have implemented stricter regulations for shipping lithium-based batteries.

Market research indicates that 78% of consumers would pay a premium of up to 15% for devices with demonstrably safer battery technology. This consumer willingness to pay for safety creates a significant market opportunity for SPE technologies that can meet rigorous safety standards and obtain recognized certifications.

The energy storage sector is emerging as another significant market for SPE technologies, particularly for grid-scale applications where safety concerns are paramount. Utility companies and energy storage system integrators are increasingly specifying enhanced safety requirements in their procurement processes, with specific references to solid-state technologies.

Geographically, North America and East Asia dominate the market demand for SPE safety technologies, accounting for 37% and 42% of the global market respectively. This regional concentration aligns with the locations of major battery manufacturers and automotive production facilities, creating localized ecosystems for safety testing and certification.

Current SPE Safety Testing Landscape and Challenges

The current landscape of Solid Polymer Electrolyte (SPE) safety testing is characterized by fragmentation and inconsistency across different regions and regulatory frameworks. Unlike liquid electrolytes, which have well-established safety protocols, SPEs present unique challenges due to their distinct physical and chemical properties. The primary testing methodologies currently employed focus on thermal stability, mechanical integrity, electrochemical performance, and aging characteristics, but these are often adapted from liquid electrolyte standards rather than being specifically designed for solid-state materials.

In North America, organizations such as UL (Underwriters Laboratories) and ANSI (American National Standards Institute) have begun developing preliminary guidelines, but comprehensive certification standards specifically for SPEs remain underdeveloped. The European Union, through its Battery Directive and REACH regulations, has established broader frameworks that tangentially address SPE safety, though specific technical standards are still evolving through bodies like IEC (International Electrotechnical Commission).

Asia, particularly Japan and South Korea, leads in practical implementation of SPE testing protocols, with organizations like JARI (Japan Automobile Research Institute) and KBIA (Korea Battery Industry Association) actively developing specialized methodologies for solid-state battery components. China's GB standards have recently incorporated sections on solid-state electrolytes, though these remain in early stages of implementation.

A significant challenge in the current landscape is the lack of standardized testing conditions that accurately reflect real-world operating environments for SPEs. Temperature ranges, pressure conditions, and cycling protocols vary widely across testing facilities, making cross-comparison of results problematic. Additionally, accelerated aging tests—critical for predicting long-term safety performance—lack consensus methodologies for solid polymer systems.

Interface stability testing represents another major gap, as the unique interactions between SPEs and electrode materials create potential failure modes not present in liquid systems. Current testing rarely addresses these interface phenomena comprehensively, focusing instead on bulk material properties.

The certification process itself presents challenges, with lengthy timelines (typically 12-18 months) and high costs creating barriers to market entry, particularly for startups and smaller manufacturers. This situation is exacerbated by the rapid pace of innovation in SPE technology, which often outstrips the development of corresponding safety standards.

Regulatory harmonization remains elusive, with different requirements across major markets creating compliance complexities for global manufacturers. This fragmentation not only increases development costs but potentially compromises safety through regulatory arbitrage opportunities.

In North America, organizations such as UL (Underwriters Laboratories) and ANSI (American National Standards Institute) have begun developing preliminary guidelines, but comprehensive certification standards specifically for SPEs remain underdeveloped. The European Union, through its Battery Directive and REACH regulations, has established broader frameworks that tangentially address SPE safety, though specific technical standards are still evolving through bodies like IEC (International Electrotechnical Commission).

Asia, particularly Japan and South Korea, leads in practical implementation of SPE testing protocols, with organizations like JARI (Japan Automobile Research Institute) and KBIA (Korea Battery Industry Association) actively developing specialized methodologies for solid-state battery components. China's GB standards have recently incorporated sections on solid-state electrolytes, though these remain in early stages of implementation.

A significant challenge in the current landscape is the lack of standardized testing conditions that accurately reflect real-world operating environments for SPEs. Temperature ranges, pressure conditions, and cycling protocols vary widely across testing facilities, making cross-comparison of results problematic. Additionally, accelerated aging tests—critical for predicting long-term safety performance—lack consensus methodologies for solid polymer systems.

Interface stability testing represents another major gap, as the unique interactions between SPEs and electrode materials create potential failure modes not present in liquid systems. Current testing rarely addresses these interface phenomena comprehensively, focusing instead on bulk material properties.

The certification process itself presents challenges, with lengthy timelines (typically 12-18 months) and high costs creating barriers to market entry, particularly for startups and smaller manufacturers. This situation is exacerbated by the rapid pace of innovation in SPE technology, which often outstrips the development of corresponding safety standards.

Regulatory harmonization remains elusive, with different requirements across major markets creating compliance complexities for global manufacturers. This fragmentation not only increases development costs but potentially compromises safety through regulatory arbitrage opportunities.

Current SPE Safety Testing Methodologies

01 Flame retardant additives for solid polymer electrolytes

Incorporating flame retardant additives into solid polymer electrolytes can significantly enhance their safety profile. These additives can reduce the flammability of the polymer matrix, minimize thermal runaway risks, and improve the overall safety of batteries using these electrolytes. Common flame retardant additives include phosphorus-based compounds, halogenated materials, and inorganic fillers that can effectively suppress combustion while maintaining electrochemical performance.- Flame retardant additives for solid polymer electrolytes: Incorporating flame retardant additives into solid polymer electrolytes can significantly enhance their safety profile by reducing flammability risks. These additives can include phosphorus-containing compounds, metal oxides, or halogenated materials that suppress combustion processes. When properly formulated, these additives maintain the electrochemical performance of the electrolyte while providing crucial fire resistance properties, addressing one of the primary safety concerns in battery applications.

- Thermal stability enhancement techniques: Various methods can be employed to improve the thermal stability of solid polymer electrolytes, including the use of cross-linking agents, high-temperature resistant polymers, and ceramic fillers. These approaches help prevent electrolyte degradation at elevated temperatures, reducing the risk of thermal runaway events. Enhanced thermal stability is critical for battery safety, particularly in applications where exposure to high temperatures is possible, such as in electric vehicles or portable electronics.

- Non-flammable polymer matrix compositions: Developing inherently non-flammable polymer matrices for solid electrolytes represents a fundamental approach to safety enhancement. These specialized polymers may incorporate flame-resistant chemical structures or be synthesized from naturally fire-resistant materials. By replacing conventional flammable polymer hosts with these safer alternatives, the overall safety profile of batteries can be significantly improved without sacrificing electrochemical performance or mechanical properties.

- Mechanical stability and dendrite prevention: Enhancing the mechanical properties of solid polymer electrolytes helps prevent physical failures that could lead to safety incidents. High mechanical strength electrolytes can suppress lithium dendrite growth, which is a common cause of internal short circuits in batteries. Approaches include polymer reinforcement with nanofillers, cross-linking strategies, and composite structures that maintain flexibility while providing sufficient mechanical resistance to penetration and deformation under stress.

- Safety-enhancing electrolyte additives: Specialized additives can be incorporated into solid polymer electrolytes to provide multiple safety functions beyond flame retardancy. These include shutdown additives that increase resistance at dangerous temperatures, redox shuttle compounds that prevent overcharging, and gas-release suppressants that minimize pressure buildup. Such additives create multiple layers of protection against various failure modes, helping to prevent catastrophic battery failures even under extreme conditions or abuse.

02 Thermal stability enhancements for solid polymer electrolytes

Improving the thermal stability of solid polymer electrolytes is crucial for safety in high-temperature applications. This can be achieved through the incorporation of thermally stable polymers, cross-linking agents, or ceramic fillers that maintain structural integrity at elevated temperatures. Enhanced thermal stability prevents electrolyte degradation, reduces gas generation, and minimizes the risk of thermal runaway events in battery systems, thereby significantly improving operational safety.Expand Specific Solutions03 Non-flammable polymer electrolyte compositions

Developing inherently non-flammable solid polymer electrolyte compositions represents a fundamental approach to battery safety. These compositions typically utilize polymers with high oxygen indices, ionic liquids as plasticizers instead of volatile organic compounds, and specialized salt systems that resist decomposition at high temperatures. Such non-flammable formulations eliminate the primary safety hazard of conventional liquid electrolytes while maintaining or improving electrochemical performance.Expand Specific Solutions04 Mechanical strength and puncture resistance

Enhancing the mechanical properties of solid polymer electrolytes improves safety by preventing internal short circuits caused by dendrite growth or physical damage. Approaches include reinforcement with nanofibers, incorporation of mechanically robust fillers, and development of self-healing polymer networks. These improvements allow the electrolyte to maintain its barrier function even under mechanical stress, preventing catastrophic failure modes in battery systems.Expand Specific Solutions05 Interface stabilization and dendrite suppression

Stabilizing the electrode-electrolyte interfaces and suppressing lithium dendrite growth are critical safety aspects of solid polymer electrolytes. This can be achieved through surface modification of the polymer electrolyte, incorporation of ceramic particles at interfaces, or development of gradient structures that distribute mechanical stress. These approaches prevent the formation of dangerous dendrites that could penetrate the electrolyte and cause short circuits, significantly enhancing the long-term safety of battery systems.Expand Specific Solutions

Key Organizations in SPE Testing and Certification

The solid polymer electrolyte (SPE) safety testing and certification landscape is currently in a growth phase, with the market expanding as electric vehicle and energy storage applications drive demand. The global SPE market is projected to reach significant scale as manufacturers seek safer alternatives to liquid electrolytes. Technologically, the field remains in development with varying levels of maturity across applications. Leading players include established automotive manufacturers like Toyota Motor Corp. focusing on integration into EVs, specialized battery developers like Nuvvon and Cymbet pioneering novel SPE formulations, chemical companies including Arkema France and RESONAC HOLDINGS providing advanced materials, and major battery producers such as Dongguan Amperex Technology commercializing solutions. Academic institutions like Central South University and Cornell University are contributing fundamental research to address remaining technical challenges in safety standardization.

Toyota Motor Corp.

Technical Solution: Toyota has developed comprehensive safety testing protocols for solid polymer electrolytes (SPEs) that exceed standard industry requirements. Their approach includes multi-level thermal stability testing with differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) to evaluate decomposition temperatures and thermal runaway thresholds. Toyota implements accelerated aging tests that simulate 10+ years of operational conditions to verify long-term stability and performance degradation patterns. Their certification process incorporates mechanical integrity testing through puncture, compression, and vibration tests specifically designed for solid-state battery architectures. Toyota has also pioneered interface stability testing methodologies that examine the critical electrode-electrolyte interfaces under various operational conditions. Their safety standards include specialized testing for polymer-specific failure modes such as creep, stress relaxation, and environmental degradation that aren't adequately addressed in conventional liquid electrolyte standards.

Strengths: Toyota's approach benefits from extensive real-world automotive implementation experience and comprehensive testing infrastructure. Their standards effectively address the unique mechanical properties of polymers while maintaining focus on practical safety requirements for vehicle integration. Weaknesses: Their testing protocols may be overly conservative and time-consuming, potentially slowing time-to-market for new technologies. Some tests are specifically optimized for automotive applications and may not translate well to other use cases.

Heraeus Epurio GmbH

Technical Solution: Heraeus Epurio has developed specialized safety testing protocols for solid polymer electrolytes that leverage their expertise in high-performance polymers and electronic materials. Their approach centers on comprehensive electrochemical stability testing using advanced techniques such as electrochemical impedance spectroscopy (EIS) to characterize interfacial stability under various operational conditions. Heraeus employs accelerated environmental testing that subjects polymer electrolytes to extreme humidity, temperature cycling, and atmospheric contaminants to verify long-term stability. Their certification standards include detailed analysis of polymer degradation mechanisms through techniques like FTIR spectroscopy and gel permeation chromatography to identify potential safety risks from decomposition products. Heraeus has pioneered specialized testing for polymer electrolyte manufacturing consistency, including rheological property verification and molecular weight distribution analysis to ensure batch-to-batch safety performance. Their testing framework incorporates specialized protocols for evaluating polymer electrolyte behavior under abuse conditions such as overcharging, external short circuits, and mechanical deformation.

Strengths: Heraeus brings exceptional materials science expertise to their testing protocols, with particular strength in polymer chemistry and degradation mechanism analysis. Their standards effectively address manufacturing consistency issues that are critical for commercial-scale safety assurance. Weaknesses: Their approach may overemphasize materials characterization aspects while giving less attention to system-level safety considerations. Some of their specialized analytical techniques require sophisticated equipment that may not be widely available for routine testing.

Critical Safety Parameters and Testing Innovations

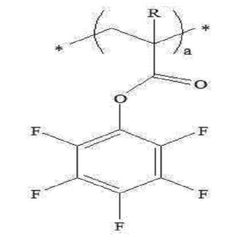

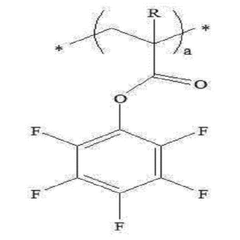

Solid polymer electrolyte and lithium secondary battery comprising same

PatentWO2018164407A1

Innovation

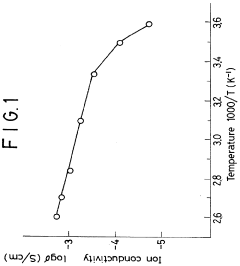

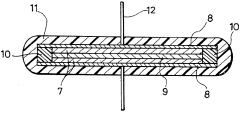

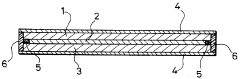

- A solid polymer electrolyte is developed containing a polymer with a phenyl group in the side chain and a polyethylene oxide group, along with additional repeating units, which enhances ionic conductivity and mechanical strength, and includes lithium salt to achieve improved electrochemical safety and stability.

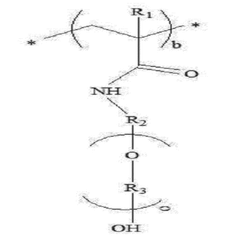

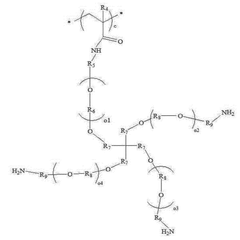

Solid polymer electrolyte, battery and solid-state electric double layer capacitor using the same as well as processes for the manufacture thereof

PatentInactiveUS5597661A

Innovation

- A solid polymer electrolyte with oxyalkyl side chains containing urethane bonding is developed, enhancing ionic conductivity and film strength, and allowing for high electrochemical activity and flexibility, enabling the creation of high-capacity, high-voltage batteries and electric double layer capacitors with improved reliability and processability.

Regulatory Framework for SPE Implementation

The regulatory landscape for Solid Polymer Electrolyte (SPE) implementation remains fragmented globally, with significant variations across regions. In the United States, the Department of Energy (DOE) has established preliminary guidelines for SPE-based battery systems, while the National Fire Protection Association (NFPA) has begun incorporating SPE-specific provisions into its standards for energy storage systems. The Consumer Product Safety Commission (CPSC) is currently developing consumer safety protocols specifically addressing SPE technologies in portable electronics.

The European Union has taken a more comprehensive approach through its Battery Directive (2006/66/EC) and subsequent amendments, which now include specific clauses for solid-state battery technologies. The European Committee for Electrotechnical Standardization (CENELEC) has established working groups dedicated to developing harmonized standards for SPE implementation across member states, with particular emphasis on thermal stability requirements and mechanical integrity assessments.

In Asia, Japan's Ministry of Economy, Trade and Industry (METI) has pioneered SPE-specific regulations through its Battery Safety Certification Program, requiring manufacturers to demonstrate compliance with stringent safety protocols before market entry. China has integrated SPE requirements into its GB/T standards framework, with particular focus on manufacturing process validation and quality control measures.

International standardization bodies play a crucial role in harmonizing these diverse regulatory approaches. The International Electrotechnical Commission (IEC) has established Technical Committee 21 to develop global standards for SPE technologies, with working groups focusing on testing methodologies, performance metrics, and safety requirements. Similarly, ISO/TC 197 is developing standards for hydrogen compatibility with polymer electrolytes for fuel cell applications.

Regulatory gaps remain significant, particularly regarding long-term aging effects, extreme environmental conditions, and integration with emerging energy storage architectures. The lack of standardized accelerated testing protocols for SPE systems presents challenges for certification bodies attempting to validate 10+ year lifespans within reasonable testing timeframes.

Industry consortia are increasingly filling these regulatory gaps through voluntary standards and best practices. The Solid-State Battery Consortium and Global Battery Alliance have established working groups to develop pre-competitive safety frameworks and testing methodologies, which often serve as precursors to formal regulatory requirements.

The European Union has taken a more comprehensive approach through its Battery Directive (2006/66/EC) and subsequent amendments, which now include specific clauses for solid-state battery technologies. The European Committee for Electrotechnical Standardization (CENELEC) has established working groups dedicated to developing harmonized standards for SPE implementation across member states, with particular emphasis on thermal stability requirements and mechanical integrity assessments.

In Asia, Japan's Ministry of Economy, Trade and Industry (METI) has pioneered SPE-specific regulations through its Battery Safety Certification Program, requiring manufacturers to demonstrate compliance with stringent safety protocols before market entry. China has integrated SPE requirements into its GB/T standards framework, with particular focus on manufacturing process validation and quality control measures.

International standardization bodies play a crucial role in harmonizing these diverse regulatory approaches. The International Electrotechnical Commission (IEC) has established Technical Committee 21 to develop global standards for SPE technologies, with working groups focusing on testing methodologies, performance metrics, and safety requirements. Similarly, ISO/TC 197 is developing standards for hydrogen compatibility with polymer electrolytes for fuel cell applications.

Regulatory gaps remain significant, particularly regarding long-term aging effects, extreme environmental conditions, and integration with emerging energy storage architectures. The lack of standardized accelerated testing protocols for SPE systems presents challenges for certification bodies attempting to validate 10+ year lifespans within reasonable testing timeframes.

Industry consortia are increasingly filling these regulatory gaps through voluntary standards and best practices. The Solid-State Battery Consortium and Global Battery Alliance have established working groups to develop pre-competitive safety frameworks and testing methodologies, which often serve as precursors to formal regulatory requirements.

Environmental Impact Assessment of SPE Technologies

The environmental impact of Solid Polymer Electrolyte (SPE) technologies extends throughout their entire lifecycle, from raw material extraction to end-of-life disposal. Manufacturing processes for SPEs typically consume less energy compared to traditional liquid electrolyte production, resulting in reduced carbon emissions. The solvent-free nature of many SPE manufacturing methods eliminates volatile organic compound (VOC) emissions that are common in conventional battery production, contributing to improved air quality in manufacturing environments and surrounding communities.

SPE-based batteries demonstrate significant environmental advantages during their operational phase. The elimination of flammable liquid electrolytes reduces the risk of thermal runaway and subsequent fires, which can release toxic compounds into the atmosphere. Additionally, the enhanced stability of SPEs contributes to longer battery lifespans, reducing the frequency of replacement and associated resource consumption. Studies indicate that SPE-based batteries can achieve up to 30% longer operational lifetimes under optimal conditions, directly translating to reduced electronic waste generation.

End-of-life considerations for SPE technologies present both challenges and opportunities. The polymer matrices used in SPEs can be designed for improved recyclability compared to conventional electrolytes. Research indicates that certain polymer systems can be chemically or mechanically separated from electrode materials with greater efficiency, facilitating the recovery of valuable metals like lithium, cobalt, and nickel. However, the diversity of polymer chemistries being developed necessitates tailored recycling approaches, as no single method is universally applicable.

Water consumption represents another critical environmental parameter for SPE technologies. Traditional liquid electrolyte production requires significant water usage for solvent processing and purification. In contrast, many SPE manufacturing processes utilize dry processing techniques that substantially reduce water requirements. This advantage is particularly relevant in regions facing water scarcity challenges, where battery manufacturing facilities can place significant strain on local water resources.

Biodegradability remains an emerging area of research for SPE technologies. While conventional liquid electrolytes pose persistent environmental hazards, certain bio-derived polymer electrolytes show promising degradation profiles under controlled conditions. Research teams have demonstrated SPE formulations incorporating naturally-derived polymers that can biodegrade into non-toxic components, though these solutions currently face performance limitations compared to synthetic alternatives. The development of environmentally benign SPE materials represents a frontier for sustainable battery technology advancement.

SPE-based batteries demonstrate significant environmental advantages during their operational phase. The elimination of flammable liquid electrolytes reduces the risk of thermal runaway and subsequent fires, which can release toxic compounds into the atmosphere. Additionally, the enhanced stability of SPEs contributes to longer battery lifespans, reducing the frequency of replacement and associated resource consumption. Studies indicate that SPE-based batteries can achieve up to 30% longer operational lifetimes under optimal conditions, directly translating to reduced electronic waste generation.

End-of-life considerations for SPE technologies present both challenges and opportunities. The polymer matrices used in SPEs can be designed for improved recyclability compared to conventional electrolytes. Research indicates that certain polymer systems can be chemically or mechanically separated from electrode materials with greater efficiency, facilitating the recovery of valuable metals like lithium, cobalt, and nickel. However, the diversity of polymer chemistries being developed necessitates tailored recycling approaches, as no single method is universally applicable.

Water consumption represents another critical environmental parameter for SPE technologies. Traditional liquid electrolyte production requires significant water usage for solvent processing and purification. In contrast, many SPE manufacturing processes utilize dry processing techniques that substantially reduce water requirements. This advantage is particularly relevant in regions facing water scarcity challenges, where battery manufacturing facilities can place significant strain on local water resources.

Biodegradability remains an emerging area of research for SPE technologies. While conventional liquid electrolytes pose persistent environmental hazards, certain bio-derived polymer electrolytes show promising degradation profiles under controlled conditions. Research teams have demonstrated SPE formulations incorporating naturally-derived polymers that can biodegrade into non-toxic components, though these solutions currently face performance limitations compared to synthetic alternatives. The development of environmentally benign SPE materials represents a frontier for sustainable battery technology advancement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!