Solid Polymer Electrolyte for Flexible and Wearable Energy Storage Devices

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SPE Technology Background and Objectives

Solid Polymer Electrolytes (SPEs) have emerged as a transformative technology in the energy storage landscape over the past three decades. Initially developed as alternatives to liquid electrolytes in conventional batteries, SPEs have evolved significantly to address the growing demand for flexible, lightweight, and wearable energy storage solutions. The fundamental concept behind SPEs involves the incorporation of ionic conducting materials within polymer matrices to facilitate ion transport while maintaining mechanical stability and flexibility.

The evolution of SPE technology has been marked by several significant milestones. Early research in the 1970s focused primarily on polyethylene oxide (PEO)-based systems, which demonstrated the feasibility of ion conduction in solid polymers but suffered from low conductivity at ambient temperatures. The 1990s witnessed the introduction of composite and gel polymer electrolytes, which significantly enhanced ionic conductivity while preserving mechanical integrity.

Recent technological advancements have shifted toward multi-functional SPEs that not only conduct ions efficiently but also contribute to device flexibility, safety, and longevity. This progression has been driven by the convergence of polymer science, electrochemistry, and materials engineering, resulting in increasingly sophisticated electrolyte systems tailored for specific applications.

The primary technical objectives for SPE development in flexible and wearable energy storage devices center around five critical parameters: ionic conductivity, mechanical flexibility, electrochemical stability, interfacial compatibility, and long-term reliability. Achieving room-temperature ionic conductivity exceeding 10^-3 S/cm while maintaining excellent mechanical properties remains a central challenge. Additionally, SPEs must demonstrate wide electrochemical stability windows (>4V) to accommodate high-energy electrode materials.

For wearable applications specifically, SPEs must withstand repeated mechanical deformation without performance degradation. This necessitates the development of self-healing capabilities and strain-resistant ionic pathways within the polymer matrix. Furthermore, these materials must maintain performance stability under various environmental conditions, including temperature fluctuations and humidity exposure.

The technological trajectory points toward multifunctional SPEs that integrate energy storage capabilities with additional functionalities such as self-healing, self-regulation, and even energy harvesting. The ultimate goal is to develop SPE systems that enable truly conformal, lightweight, and high-performance energy storage solutions that can be seamlessly integrated into next-generation wearable electronics, medical devices, and smart textiles.

The evolution of SPE technology has been marked by several significant milestones. Early research in the 1970s focused primarily on polyethylene oxide (PEO)-based systems, which demonstrated the feasibility of ion conduction in solid polymers but suffered from low conductivity at ambient temperatures. The 1990s witnessed the introduction of composite and gel polymer electrolytes, which significantly enhanced ionic conductivity while preserving mechanical integrity.

Recent technological advancements have shifted toward multi-functional SPEs that not only conduct ions efficiently but also contribute to device flexibility, safety, and longevity. This progression has been driven by the convergence of polymer science, electrochemistry, and materials engineering, resulting in increasingly sophisticated electrolyte systems tailored for specific applications.

The primary technical objectives for SPE development in flexible and wearable energy storage devices center around five critical parameters: ionic conductivity, mechanical flexibility, electrochemical stability, interfacial compatibility, and long-term reliability. Achieving room-temperature ionic conductivity exceeding 10^-3 S/cm while maintaining excellent mechanical properties remains a central challenge. Additionally, SPEs must demonstrate wide electrochemical stability windows (>4V) to accommodate high-energy electrode materials.

For wearable applications specifically, SPEs must withstand repeated mechanical deformation without performance degradation. This necessitates the development of self-healing capabilities and strain-resistant ionic pathways within the polymer matrix. Furthermore, these materials must maintain performance stability under various environmental conditions, including temperature fluctuations and humidity exposure.

The technological trajectory points toward multifunctional SPEs that integrate energy storage capabilities with additional functionalities such as self-healing, self-regulation, and even energy harvesting. The ultimate goal is to develop SPE systems that enable truly conformal, lightweight, and high-performance energy storage solutions that can be seamlessly integrated into next-generation wearable electronics, medical devices, and smart textiles.

Market Analysis for Flexible Energy Storage Solutions

The global market for flexible and wearable energy storage devices is experiencing unprecedented growth, driven by the expanding wearable technology sector and increasing demand for portable electronics. Current market valuations indicate that the flexible battery market reached approximately 220 million USD in 2022 and is projected to grow at a compound annual growth rate of 30% through 2028, potentially reaching 1.1 billion USD by the end of the forecast period.

Consumer electronics remains the dominant application segment, accounting for nearly 45% of the market share. This is primarily due to the rising adoption of smartwatches, fitness trackers, and healthcare monitoring devices that require lightweight, flexible power sources. The healthcare sector represents the fastest-growing segment with a growth rate exceeding 35% annually, fueled by innovations in remote patient monitoring and implantable medical devices.

Geographically, North America and Asia-Pacific lead the market, collectively holding over 70% of the global share. China, South Korea, and Japan have emerged as manufacturing hubs for flexible energy storage technologies, while North American companies focus predominantly on research and development of advanced materials, including solid polymer electrolytes.

The demand drivers for flexible energy storage solutions are multifaceted. Consumer preference for sleek, lightweight devices with extended battery life has pushed manufacturers to explore alternatives to traditional rigid batteries. Additionally, the Internet of Things (IoT) expansion has created new application scenarios requiring decentralized power sources that can conform to various form factors.

Market challenges include high production costs, with flexible batteries currently costing 2-3 times more than their rigid counterparts. Technical limitations in energy density also persist, with flexible batteries typically delivering 30-40% less power per unit volume compared to conventional lithium-ion batteries. These factors have restricted mass-market adoption despite strong interest from device manufacturers.

Solid polymer electrolytes represent a particularly promising segment within this market. They address critical safety concerns associated with liquid electrolytes while enabling the flexibility required for wearable applications. Market analysis indicates that polymer-based electrolytes could capture up to 25% of the flexible battery market by 2026, representing a significant opportunity for materials innovation and commercialization.

Investment in this sector has been robust, with venture capital funding exceeding 500 million USD in 2022 alone. Major electronics manufacturers have established dedicated R&D divisions for flexible energy storage, signaling strong industry confidence in the technology's commercial potential.

Consumer electronics remains the dominant application segment, accounting for nearly 45% of the market share. This is primarily due to the rising adoption of smartwatches, fitness trackers, and healthcare monitoring devices that require lightweight, flexible power sources. The healthcare sector represents the fastest-growing segment with a growth rate exceeding 35% annually, fueled by innovations in remote patient monitoring and implantable medical devices.

Geographically, North America and Asia-Pacific lead the market, collectively holding over 70% of the global share. China, South Korea, and Japan have emerged as manufacturing hubs for flexible energy storage technologies, while North American companies focus predominantly on research and development of advanced materials, including solid polymer electrolytes.

The demand drivers for flexible energy storage solutions are multifaceted. Consumer preference for sleek, lightweight devices with extended battery life has pushed manufacturers to explore alternatives to traditional rigid batteries. Additionally, the Internet of Things (IoT) expansion has created new application scenarios requiring decentralized power sources that can conform to various form factors.

Market challenges include high production costs, with flexible batteries currently costing 2-3 times more than their rigid counterparts. Technical limitations in energy density also persist, with flexible batteries typically delivering 30-40% less power per unit volume compared to conventional lithium-ion batteries. These factors have restricted mass-market adoption despite strong interest from device manufacturers.

Solid polymer electrolytes represent a particularly promising segment within this market. They address critical safety concerns associated with liquid electrolytes while enabling the flexibility required for wearable applications. Market analysis indicates that polymer-based electrolytes could capture up to 25% of the flexible battery market by 2026, representing a significant opportunity for materials innovation and commercialization.

Investment in this sector has been robust, with venture capital funding exceeding 500 million USD in 2022 alone. Major electronics manufacturers have established dedicated R&D divisions for flexible energy storage, signaling strong industry confidence in the technology's commercial potential.

Current SPE Development Status and Challenges

Solid Polymer Electrolytes (SPEs) have emerged as promising components for next-generation flexible and wearable energy storage devices, offering advantages over traditional liquid electrolytes. Currently, the global research landscape shows significant advancements in SPE development, with major research hubs established in North America, Europe, and East Asia, particularly in China, Japan, and South Korea.

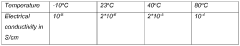

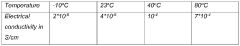

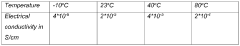

The current state of SPE technology faces several critical challenges. Ionic conductivity remains a primary limitation, with most polymer electrolytes exhibiting conductivity values between 10^-6 and 10^-4 S/cm at room temperature, significantly lower than the 10^-3 S/cm threshold required for practical applications. This conductivity gap represents the most substantial technical barrier to widespread commercial adoption.

Mechanical properties present another significant challenge. While flexibility is inherent to polymer-based systems, achieving the optimal balance between mechanical strength and elasticity remains difficult. Many high-conductivity SPEs suffer from poor mechanical stability, limiting their application in devices requiring repeated bending or stretching.

Electrochemical stability windows of current SPEs typically range from 3.5V to 4.2V, which is insufficient for high-voltage applications. This limitation restricts their use in advanced energy storage systems that require operating voltages above 4.5V. Additionally, interfacial resistance between SPEs and electrodes often leads to capacity fading and reduced cycling performance.

Manufacturing scalability presents substantial industrial challenges. Laboratory-scale synthesis methods for high-performance SPEs often involve complex processes that are difficult to scale up cost-effectively. The lack of standardized production protocols further complicates industrial implementation.

From a geographical perspective, research efforts are unevenly distributed. Asian institutions lead in patent filings related to SPE technology, while North American and European research centers contribute significantly to fundamental research publications. This distribution creates both collaborative opportunities and competitive challenges in the global technology landscape.

Environmental stability remains problematic, with many current SPEs showing degradation when exposed to moisture, oxygen, or temperature fluctuations. This vulnerability limits their application in wearable devices that must function reliably in diverse environmental conditions.

Recent technological breakthroughs include the development of composite polymer electrolytes incorporating ceramic fillers, which have shown promising improvements in both ionic conductivity and mechanical properties. However, these advances still fall short of meeting all requirements for commercial wearable energy storage applications, indicating substantial room for further innovation and development in this rapidly evolving field.

The current state of SPE technology faces several critical challenges. Ionic conductivity remains a primary limitation, with most polymer electrolytes exhibiting conductivity values between 10^-6 and 10^-4 S/cm at room temperature, significantly lower than the 10^-3 S/cm threshold required for practical applications. This conductivity gap represents the most substantial technical barrier to widespread commercial adoption.

Mechanical properties present another significant challenge. While flexibility is inherent to polymer-based systems, achieving the optimal balance between mechanical strength and elasticity remains difficult. Many high-conductivity SPEs suffer from poor mechanical stability, limiting their application in devices requiring repeated bending or stretching.

Electrochemical stability windows of current SPEs typically range from 3.5V to 4.2V, which is insufficient for high-voltage applications. This limitation restricts their use in advanced energy storage systems that require operating voltages above 4.5V. Additionally, interfacial resistance between SPEs and electrodes often leads to capacity fading and reduced cycling performance.

Manufacturing scalability presents substantial industrial challenges. Laboratory-scale synthesis methods for high-performance SPEs often involve complex processes that are difficult to scale up cost-effectively. The lack of standardized production protocols further complicates industrial implementation.

From a geographical perspective, research efforts are unevenly distributed. Asian institutions lead in patent filings related to SPE technology, while North American and European research centers contribute significantly to fundamental research publications. This distribution creates both collaborative opportunities and competitive challenges in the global technology landscape.

Environmental stability remains problematic, with many current SPEs showing degradation when exposed to moisture, oxygen, or temperature fluctuations. This vulnerability limits their application in wearable devices that must function reliably in diverse environmental conditions.

Recent technological breakthroughs include the development of composite polymer electrolytes incorporating ceramic fillers, which have shown promising improvements in both ionic conductivity and mechanical properties. However, these advances still fall short of meeting all requirements for commercial wearable energy storage applications, indicating substantial room for further innovation and development in this rapidly evolving field.

Current SPE Material Solutions and Implementations

01 Flexible polymer electrolyte compositions for wearable devices

Solid polymer electrolytes can be formulated with specific compositions to enhance flexibility for wearable applications. These compositions typically include a polymer matrix with added plasticizers or flexible polymer chains that maintain ionic conductivity while allowing the electrolyte to bend and conform to body movements. The flexibility enables integration into clothing or accessories without cracking or performance degradation during regular wear.- Flexible polymer electrolyte compositions for wearable devices: Solid polymer electrolytes can be formulated with specific compositions to enhance flexibility for wearable applications. These compositions typically include polymer matrices combined with plasticizers and conductive salts that maintain ionic conductivity while allowing the material to bend and conform to body movements. The flexibility enables integration into clothing and accessories without compromising electrochemical performance or user comfort.

- Cross-linked polymer networks for improved mechanical properties: Cross-linking techniques can be employed to develop solid polymer electrolytes with enhanced mechanical strength while maintaining flexibility. These networks create a balance between rigidity and elasticity, allowing the electrolyte to withstand repeated bending and stretching without structural failure. The cross-linked structure also helps prevent electrolyte leakage while maintaining good contact with electrodes in flexible battery configurations.

- Gel polymer electrolytes for enhanced flexibility: Gel polymer electrolytes represent a hybrid between solid and liquid systems, offering superior flexibility for wearable applications. These materials contain a polymer matrix that traps liquid electrolyte components, providing both mechanical stability and excellent ionic conductivity. The gel-like consistency allows for significant deformation without cracking, making them ideal for applications requiring conformability to curved surfaces or body contours.

- Nanocomposite polymer electrolytes for wearable electronics: Incorporating nanomaterials such as ceramic nanoparticles, carbon nanotubes, or graphene into polymer electrolytes can significantly enhance both mechanical flexibility and electrochemical performance. These nanocomposites create unique pathways for ion transport while reinforcing the polymer matrix. The resulting materials can withstand repeated bending and folding cycles, making them suitable for integration into textiles and flexible electronic devices.

- Thin-film polymer electrolytes for flexible batteries: Ultra-thin polymer electrolyte films offer exceptional flexibility and can be manufactured using techniques like solution casting or electrospinning. These films can be as thin as a few micrometers while maintaining sufficient mechanical integrity and ionic conductivity. Their reduced thickness allows for greater flexibility and conformability, enabling integration into slim wearable devices and smart textiles without adding bulk or restricting movement.

02 Gel polymer electrolytes with enhanced mechanical properties

Gel polymer electrolytes represent a hybrid between solid and liquid systems, offering improved flexibility and wearability while maintaining good ionic conductivity. These electrolytes incorporate a liquid component within a polymer network, resulting in a gel-like consistency that can withstand bending and stretching. The addition of specific cross-linking agents can further enhance mechanical stability while preserving the flexibility needed for wearable applications.Expand Specific Solutions03 Nanocomposite polymer electrolytes for flexible electronics

Incorporating nanomaterials such as nanoparticles, nanofibers, or nanosheets into polymer electrolytes can significantly improve both mechanical flexibility and electrochemical performance. These nanocomposites create unique polymer-filler interactions that enhance ionic conductivity while maintaining or improving flexibility. The resulting materials can be fabricated into thin, bendable sheets suitable for integration into wearable electronic devices without compromising safety or performance.Expand Specific Solutions04 Stretchable polymer electrolytes for conformable wearables

Advanced polymer electrolyte formulations can achieve not only flexibility but also stretchability, allowing them to conform to complex body contours and accommodate movement. These materials typically incorporate elastomeric polymers or specially designed polymer networks with reversible cross-links. The stretchable nature enables applications in skin-mounted sensors, electronic textiles, and other wearable devices that must maintain performance during body movement and deformation.Expand Specific Solutions05 Temperature-stable flexible polymer electrolytes

Polymer electrolytes designed for wearable applications must maintain flexibility and performance across a range of temperatures encountered during normal use. Specialized formulations incorporate temperature-resistant polymers and additives that prevent crystallization at low temperatures and maintain structural integrity at elevated temperatures. These temperature-stable electrolytes ensure consistent performance in varying environmental conditions while maintaining the flexibility required for wearable applications.Expand Specific Solutions

Leading Companies in SPE Research and Development

The solid polymer electrolyte market for flexible and wearable energy storage devices is in a growth phase, with increasing demand driven by the expanding wearable technology sector. Market size is projected to grow significantly as consumer electronics and IoT applications proliferate. Technologically, the field shows moderate maturity with ongoing innovation. Leading academic institutions (Peking University, Nanyang Technological University, Johns Hopkins University) are advancing fundamental research, while established corporations (Hitachi, BMW, Sharp) are developing commercial applications. Specialized companies like GS Yuasa and Seeo are focusing on polymer electrolyte innovations, while research organizations like CNRS and Toyota Central R&D Labs bridge the gap between academic discoveries and industrial implementation, creating a competitive landscape balanced between established players and emerging specialists.

Nanyang Technological University

Technical Solution: Nanyang Technological University has developed an innovative solid polymer electrolyte system based on interpenetrating polymer networks (IPNs) combined with ionic liquid additives. Their approach creates a semi-crystalline structure that balances mechanical strength with ionic mobility through precisely controlled phase separation. The technology incorporates bio-derived polymers modified with functional groups that enhance lithium-ion coordination and transport, achieving conductivities of 5×10^-4 S/cm at room temperature. A distinguishing feature is their proprietary self-healing capability, where the electrolyte can recover from mechanical damage through dynamic supramolecular interactions. This property is particularly valuable for wearable devices subject to repeated mechanical stress. NTU researchers have demonstrated these materials in flexible supercapacitors and thin-film batteries with excellent cycling stability (>5000 cycles) and consistent performance under various bending conditions (up to 180° with 1mm radius).

Strengths: Self-healing properties provide enhanced durability in wearable applications; excellent electrochemical stability with minimal interfacial resistance; environmentally friendly composition using partially bio-derived materials. Weaknesses: Complex synthesis procedures may challenge large-scale manufacturing; ionic liquid components increase production costs; temperature-dependent performance variations require further optimization.

Peking University

Technical Solution: Peking University has developed a groundbreaking solid polymer electrolyte technology based on hierarchically structured nanocomposites. Their approach combines modified polyethylene oxide (PEO) matrices with precisely engineered metal-organic framework (MOF) nanoparticles to create ordered ion transport channels. This structure achieves remarkable room-temperature ionic conductivity exceeding 1.2×10^-3 S/cm while maintaining excellent mechanical flexibility. The research team has implemented a proprietary surface modification technique that enhances the compatibility between organic and inorganic components, minimizing interfacial resistance. Their SPEs demonstrate exceptional electrochemical stability up to 5V vs. Li/Li+, enabling compatibility with high-voltage cathode materials. The manufacturing process employs environmentally benign solvent systems and can be adapted to various deposition techniques including spray coating and 3D printing. Peking University researchers have successfully demonstrated these materials in flexible lithium-sulfur batteries with energy densities approaching 400 Wh/kg and stable performance under repeated mechanical deformation.

Strengths: Exceptionally high ionic conductivity at ambient temperatures; superior electrochemical stability window enabling high-voltage applications; excellent mechanical properties with controlled elasticity for wearable devices. Weaknesses: Complex synthesis of MOF components may limit large-scale production; potential long-term stability issues in humid environments; higher material costs compared to conventional polymer electrolytes.

Key Patents and Innovations in SPE Technology

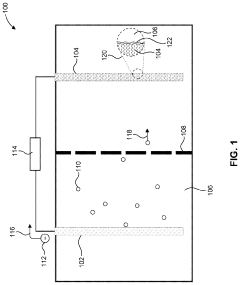

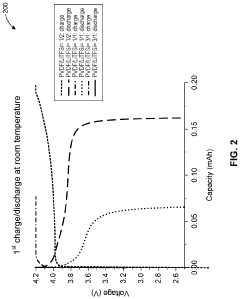

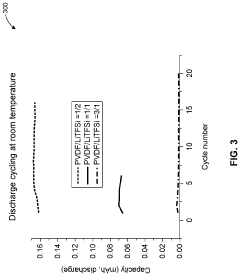

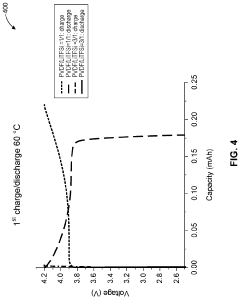

Solid-state polymer electrolyte for an energy storage device

PatentPendingUS20230378529A1

Innovation

- A solid polymer electrolyte composition based on polyvinylidene fluoride (PVDF) and lithium bis(trifluoromethanesulfonyl)imide (LiTFSI) with a higher mass content of LiTFSI, potentially combined with lithium lanthanum zirconate oxide (LLZO) and plasticizers like succinonitrile, is used to enhance ion conductivity and mechanical stability, forming a solid medium that can be processed from a solution with a solid content of approximately 0.19 or greater.

Solid polymer electrolyte

PatentWO2017005903A1

Innovation

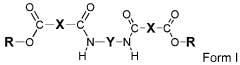

- A thermoplastic elastomer-based solid polymer electrolyte with polyester or polyamide hard blocks and ionically conductive soft blocks, having a total plasticizer content of less than 15 wt.%, which allows for easy processing and reduced sensitivity to dendrite formation, is used, featuring a composition that includes polyethylene oxide segments and a chain extender to enhance conductivity and mechanical robustness.

Safety and Reliability Assessment of SPE-based Devices

Safety assessment of Solid Polymer Electrolyte (SPE) based wearable energy storage devices requires comprehensive evaluation across multiple dimensions. The primary concern remains thermal stability, as SPEs must maintain structural integrity across wide temperature ranges encountered in wearable applications (-20°C to 60°C). Recent advancements in cross-linked polymer networks have significantly improved thermal resistance, with polyethylene oxide (PEO)-based electrolytes demonstrating stability up to 150°C in controlled testing environments.

Mechanical reliability presents another critical challenge, particularly for flexible and wearable applications. SPEs must withstand repeated bending, twisting, and stretching without performance degradation. Current generation SPEs incorporating elastomeric components show promising results, maintaining over 90% capacity after 1000 bending cycles at 180° angles, though long-term reliability beyond 5000 cycles remains problematic.

Electrochemical stability window (ESW) assessment reveals most contemporary SPEs operate safely between 0-4.5V, sufficient for many wearable applications but limiting for high-voltage systems. Advanced formulations incorporating fluorinated polymers have extended this range to 5.5V, though often at the expense of ionic conductivity. This trade-off requires careful consideration based on specific application requirements.

Leakage prevention represents a significant advantage of SPEs over liquid electrolytes, virtually eliminating toxic exposure risks. However, interface stability between SPE and electrodes remains challenging, with delamination occurring after prolonged usage or extreme deformation. Recent developments in covalently bonded interfaces show promise in addressing this limitation.

Accelerated aging tests indicate most current-generation SPEs maintain 80% of initial performance after simulated two-year usage periods. However, environmental factors significantly impact longevity, with humidity exposure particularly detrimental to PEO-based systems. Encapsulation technologies have improved, with multilayer barrier films reducing moisture penetration by 95% compared to earlier generations.

Standardized testing protocols for SPE-based wearable devices remain underdeveloped, creating challenges for consistent safety certification. Industry leaders have proposed harmonized testing frameworks incorporating wearable-specific metrics such as biocompatibility, skin-contact safety, and performance under perspiration exposure. Implementation of these standards would significantly enhance consumer confidence and regulatory compliance.

Mechanical reliability presents another critical challenge, particularly for flexible and wearable applications. SPEs must withstand repeated bending, twisting, and stretching without performance degradation. Current generation SPEs incorporating elastomeric components show promising results, maintaining over 90% capacity after 1000 bending cycles at 180° angles, though long-term reliability beyond 5000 cycles remains problematic.

Electrochemical stability window (ESW) assessment reveals most contemporary SPEs operate safely between 0-4.5V, sufficient for many wearable applications but limiting for high-voltage systems. Advanced formulations incorporating fluorinated polymers have extended this range to 5.5V, though often at the expense of ionic conductivity. This trade-off requires careful consideration based on specific application requirements.

Leakage prevention represents a significant advantage of SPEs over liquid electrolytes, virtually eliminating toxic exposure risks. However, interface stability between SPE and electrodes remains challenging, with delamination occurring after prolonged usage or extreme deformation. Recent developments in covalently bonded interfaces show promise in addressing this limitation.

Accelerated aging tests indicate most current-generation SPEs maintain 80% of initial performance after simulated two-year usage periods. However, environmental factors significantly impact longevity, with humidity exposure particularly detrimental to PEO-based systems. Encapsulation technologies have improved, with multilayer barrier films reducing moisture penetration by 95% compared to earlier generations.

Standardized testing protocols for SPE-based wearable devices remain underdeveloped, creating challenges for consistent safety certification. Industry leaders have proposed harmonized testing frameworks incorporating wearable-specific metrics such as biocompatibility, skin-contact safety, and performance under perspiration exposure. Implementation of these standards would significantly enhance consumer confidence and regulatory compliance.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for solid polymer electrolytes (SPEs) represents a critical factor in the commercial viability of flexible and wearable energy storage devices. Current production methods for SPEs include solution casting, electrospinning, and hot-pressing techniques, each with varying degrees of scalability. Solution casting offers relatively straightforward scale-up potential but faces challenges in maintaining uniform thickness and properties across large-area films. Electrospinning, while excellent for creating high-surface-area membranes, presents throughput limitations when scaled to industrial levels.

Cost analysis reveals that material inputs constitute approximately 40-60% of total production expenses for SPEs, with processing costs accounting for most of the remainder. High-performance polymers like PEO, PVDF-HFP, and their derivatives command premium prices, particularly when functionalized with specialized additives. The incorporation of ceramic fillers, ionic liquids, and lithium salts further increases material costs, though economies of scale could potentially reduce these expenses by 15-25% in high-volume production scenarios.

Equipment investment represents another significant cost factor, with specialized coating and drying equipment for solution-based processes requiring capital expenditures of $500,000-2,000,000 depending on production capacity. Roll-to-roll processing technologies show promise for continuous SPE production but require substantial initial investment and process optimization to achieve consistent quality.

Energy consumption during manufacturing varies significantly across production methods, with solvent-based processes requiring extensive drying steps that increase both production time and energy costs. Solvent-free methods like hot-pressing and melt extrusion offer potential energy savings but may compromise certain performance characteristics of the resulting electrolytes.

Labor costs vary by region but typically represent 10-20% of total production expenses. Automation potential exists particularly in mixing, coating, and quality control steps, potentially reducing labor costs while improving consistency. However, specialized expertise remains necessary for formulation development and process optimization.

Quality control represents a critical cost component often underestimated in preliminary analyses. Ensuring consistent ionic conductivity, mechanical properties, and electrochemical stability across production batches requires sophisticated testing equipment and protocols. Defect rates currently range from 5-15% in pilot-scale production, significantly impacting overall economics.

For commercial viability, production costs must decrease to approximately $10-15 per square meter of SPE material to compete with conventional liquid electrolyte systems when considering the performance advantages of solid-state systems. Current estimates place production costs at $25-40 per square meter, indicating the need for further process optimization and material innovations to achieve cost parity.

Cost analysis reveals that material inputs constitute approximately 40-60% of total production expenses for SPEs, with processing costs accounting for most of the remainder. High-performance polymers like PEO, PVDF-HFP, and their derivatives command premium prices, particularly when functionalized with specialized additives. The incorporation of ceramic fillers, ionic liquids, and lithium salts further increases material costs, though economies of scale could potentially reduce these expenses by 15-25% in high-volume production scenarios.

Equipment investment represents another significant cost factor, with specialized coating and drying equipment for solution-based processes requiring capital expenditures of $500,000-2,000,000 depending on production capacity. Roll-to-roll processing technologies show promise for continuous SPE production but require substantial initial investment and process optimization to achieve consistent quality.

Energy consumption during manufacturing varies significantly across production methods, with solvent-based processes requiring extensive drying steps that increase both production time and energy costs. Solvent-free methods like hot-pressing and melt extrusion offer potential energy savings but may compromise certain performance characteristics of the resulting electrolytes.

Labor costs vary by region but typically represent 10-20% of total production expenses. Automation potential exists particularly in mixing, coating, and quality control steps, potentially reducing labor costs while improving consistency. However, specialized expertise remains necessary for formulation development and process optimization.

Quality control represents a critical cost component often underestimated in preliminary analyses. Ensuring consistent ionic conductivity, mechanical properties, and electrochemical stability across production batches requires sophisticated testing equipment and protocols. Defect rates currently range from 5-15% in pilot-scale production, significantly impacting overall economics.

For commercial viability, production costs must decrease to approximately $10-15 per square meter of SPE material to compete with conventional liquid electrolyte systems when considering the performance advantages of solid-state systems. Current estimates place production costs at $25-40 per square meter, indicating the need for further process optimization and material innovations to achieve cost parity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!