Streamlining Electronic Substrate Production Using Vacuum Forming

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Forming in Electronics: Background and Objectives

Vacuum forming has emerged as a transformative technology in the electronics industry, revolutionizing the production of electronic substrates. This technique, which involves heating a plastic sheet and shaping it over a mold using vacuum suction, has its roots in the mid-20th century. Initially developed for packaging applications, vacuum forming has evolved significantly over the past decades to meet the demanding requirements of electronic component manufacturing.

The evolution of vacuum forming in electronics is closely tied to the miniaturization trend in the industry. As electronic devices became smaller and more complex, traditional manufacturing methods struggled to produce substrates with the required precision and consistency. Vacuum forming offered a solution by enabling the creation of intricate, three-dimensional structures with high accuracy and repeatability.

The primary objective of implementing vacuum forming in electronic substrate production is to streamline the manufacturing process while enhancing product quality. This technology aims to address several key challenges faced by the electronics industry, including reducing production costs, improving yield rates, and increasing design flexibility. By leveraging vacuum forming, manufacturers seek to achieve faster production cycles, minimize material waste, and create more complex substrate geometries that were previously difficult or impossible to produce using conventional methods.

Another crucial goal is to improve the thermal management capabilities of electronic substrates. As electronic devices become more powerful and compact, heat dissipation has become a critical concern. Vacuum forming allows for the integration of advanced cooling features directly into the substrate design, such as channels for liquid cooling or optimized heat sink structures.

Furthermore, the adoption of vacuum forming in electronics aligns with the industry's push towards more sustainable manufacturing practices. This technology enables the use of recyclable and eco-friendly materials, reducing the environmental impact of electronic component production. It also offers the potential for significant energy savings compared to traditional substrate manufacturing methods.

As the electronics industry continues to evolve, vacuum forming is expected to play an increasingly important role in meeting future challenges. The technology is poised to support the development of next-generation electronic devices, including flexible and wearable electronics, which require substrates with unique properties and form factors. By continually refining vacuum forming techniques and materials, researchers and manufacturers aim to push the boundaries of what is possible in electronic substrate design and production.

The evolution of vacuum forming in electronics is closely tied to the miniaturization trend in the industry. As electronic devices became smaller and more complex, traditional manufacturing methods struggled to produce substrates with the required precision and consistency. Vacuum forming offered a solution by enabling the creation of intricate, three-dimensional structures with high accuracy and repeatability.

The primary objective of implementing vacuum forming in electronic substrate production is to streamline the manufacturing process while enhancing product quality. This technology aims to address several key challenges faced by the electronics industry, including reducing production costs, improving yield rates, and increasing design flexibility. By leveraging vacuum forming, manufacturers seek to achieve faster production cycles, minimize material waste, and create more complex substrate geometries that were previously difficult or impossible to produce using conventional methods.

Another crucial goal is to improve the thermal management capabilities of electronic substrates. As electronic devices become more powerful and compact, heat dissipation has become a critical concern. Vacuum forming allows for the integration of advanced cooling features directly into the substrate design, such as channels for liquid cooling or optimized heat sink structures.

Furthermore, the adoption of vacuum forming in electronics aligns with the industry's push towards more sustainable manufacturing practices. This technology enables the use of recyclable and eco-friendly materials, reducing the environmental impact of electronic component production. It also offers the potential for significant energy savings compared to traditional substrate manufacturing methods.

As the electronics industry continues to evolve, vacuum forming is expected to play an increasingly important role in meeting future challenges. The technology is poised to support the development of next-generation electronic devices, including flexible and wearable electronics, which require substrates with unique properties and form factors. By continually refining vacuum forming techniques and materials, researchers and manufacturers aim to push the boundaries of what is possible in electronic substrate design and production.

Market Analysis for Vacuum-Formed Electronic Substrates

The market for vacuum-formed electronic substrates is experiencing significant growth, driven by the increasing demand for lightweight, cost-effective, and customizable electronic components across various industries. This manufacturing technique offers several advantages over traditional methods, including reduced production time, lower material costs, and improved design flexibility.

The electronics industry, particularly in consumer electronics and automotive sectors, is the primary driver of demand for vacuum-formed substrates. As devices become smaller, thinner, and more complex, manufacturers are seeking innovative solutions to meet these requirements while maintaining cost-effectiveness. Vacuum forming allows for the production of intricate shapes and designs that are difficult to achieve with other methods, making it an attractive option for many applications.

In the consumer electronics market, vacuum-formed substrates are increasingly used in smartphones, tablets, and wearable devices. These components provide the necessary structural support and protection for delicate electronic components while contributing to the overall sleek design of modern gadgets. The automotive industry is another significant market, with vacuum-formed substrates finding applications in dashboard components, interior panels, and even in emerging electric vehicle battery casings.

The global market for vacuum-formed electronic substrates is expected to grow steadily over the next five years. This growth is attributed to the expanding electronics industry, particularly in emerging economies, and the increasing adoption of advanced manufacturing techniques in developed markets. Additionally, the push for more sustainable and recyclable materials in electronics manufacturing is likely to boost the demand for vacuum-formed substrates, as they can be produced using eco-friendly thermoplastics.

However, the market faces some challenges. The initial investment in vacuum forming equipment can be substantial, which may deter smaller manufacturers from adopting this technology. There is also a learning curve associated with optimizing the vacuum forming process for electronic substrates, which requires skilled operators and engineers.

Despite these challenges, the future outlook for the vacuum-formed electronic substrates market remains positive. Technological advancements in materials science and manufacturing processes are expected to further enhance the capabilities of vacuum forming, potentially opening up new applications and markets. As industries continue to prioritize lightweight, durable, and cost-effective components, the demand for vacuum-formed electronic substrates is likely to expand, presenting significant opportunities for manufacturers and suppliers in this space.

The electronics industry, particularly in consumer electronics and automotive sectors, is the primary driver of demand for vacuum-formed substrates. As devices become smaller, thinner, and more complex, manufacturers are seeking innovative solutions to meet these requirements while maintaining cost-effectiveness. Vacuum forming allows for the production of intricate shapes and designs that are difficult to achieve with other methods, making it an attractive option for many applications.

In the consumer electronics market, vacuum-formed substrates are increasingly used in smartphones, tablets, and wearable devices. These components provide the necessary structural support and protection for delicate electronic components while contributing to the overall sleek design of modern gadgets. The automotive industry is another significant market, with vacuum-formed substrates finding applications in dashboard components, interior panels, and even in emerging electric vehicle battery casings.

The global market for vacuum-formed electronic substrates is expected to grow steadily over the next five years. This growth is attributed to the expanding electronics industry, particularly in emerging economies, and the increasing adoption of advanced manufacturing techniques in developed markets. Additionally, the push for more sustainable and recyclable materials in electronics manufacturing is likely to boost the demand for vacuum-formed substrates, as they can be produced using eco-friendly thermoplastics.

However, the market faces some challenges. The initial investment in vacuum forming equipment can be substantial, which may deter smaller manufacturers from adopting this technology. There is also a learning curve associated with optimizing the vacuum forming process for electronic substrates, which requires skilled operators and engineers.

Despite these challenges, the future outlook for the vacuum-formed electronic substrates market remains positive. Technological advancements in materials science and manufacturing processes are expected to further enhance the capabilities of vacuum forming, potentially opening up new applications and markets. As industries continue to prioritize lightweight, durable, and cost-effective components, the demand for vacuum-formed electronic substrates is likely to expand, presenting significant opportunities for manufacturers and suppliers in this space.

Current Challenges in Electronic Substrate Manufacturing

The electronic substrate manufacturing industry faces several significant challenges that hinder efficiency and productivity. One of the primary issues is the complexity of the manufacturing process, which involves multiple steps and requires precise control over various parameters. This complexity often leads to increased production time and costs, as well as a higher likelihood of defects and quality inconsistencies.

Material waste is another major concern in electronic substrate production. Traditional manufacturing methods often result in substantial material loss during the cutting and shaping processes. This not only increases production costs but also raises environmental concerns due to the disposal of excess materials, some of which may contain hazardous substances.

The demand for miniaturization and higher performance in electronic devices has put pressure on manufacturers to produce substrates with increasingly fine features and tighter tolerances. This trend has pushed the limits of conventional manufacturing techniques, making it challenging to achieve the required precision and consistency at scale.

Energy consumption is a significant issue in electronic substrate manufacturing. Many traditional processes, such as etching and photolithography, are energy-intensive and contribute to high operational costs and environmental impact. The industry is under pressure to find more energy-efficient manufacturing methods to reduce both costs and carbon footprint.

Flexibility in production is another challenge faced by manufacturers. The rapidly evolving electronics market demands quick adaptation to new designs and specifications. However, current manufacturing setups often lack the agility to switch between different product types or sizes without significant retooling or downtime.

The use of hazardous chemicals in conventional substrate manufacturing processes poses health and safety risks to workers and requires strict handling and disposal protocols. This not only increases operational complexity but also raises concerns about long-term environmental impact and regulatory compliance.

Yield rates remain a persistent challenge in the industry. Despite advancements in manufacturing technology, achieving consistently high yields, especially for complex, multi-layer substrates, continues to be difficult. Low yields result in increased costs and reduced production efficiency.

Lastly, the industry faces challenges in scaling up production to meet growing demand while maintaining quality and cost-effectiveness. As the global electronics market expands, manufacturers struggle to increase output without compromising on precision or incurring prohibitive capital expenses for new equipment and facilities.

Material waste is another major concern in electronic substrate production. Traditional manufacturing methods often result in substantial material loss during the cutting and shaping processes. This not only increases production costs but also raises environmental concerns due to the disposal of excess materials, some of which may contain hazardous substances.

The demand for miniaturization and higher performance in electronic devices has put pressure on manufacturers to produce substrates with increasingly fine features and tighter tolerances. This trend has pushed the limits of conventional manufacturing techniques, making it challenging to achieve the required precision and consistency at scale.

Energy consumption is a significant issue in electronic substrate manufacturing. Many traditional processes, such as etching and photolithography, are energy-intensive and contribute to high operational costs and environmental impact. The industry is under pressure to find more energy-efficient manufacturing methods to reduce both costs and carbon footprint.

Flexibility in production is another challenge faced by manufacturers. The rapidly evolving electronics market demands quick adaptation to new designs and specifications. However, current manufacturing setups often lack the agility to switch between different product types or sizes without significant retooling or downtime.

The use of hazardous chemicals in conventional substrate manufacturing processes poses health and safety risks to workers and requires strict handling and disposal protocols. This not only increases operational complexity but also raises concerns about long-term environmental impact and regulatory compliance.

Yield rates remain a persistent challenge in the industry. Despite advancements in manufacturing technology, achieving consistently high yields, especially for complex, multi-layer substrates, continues to be difficult. Low yields result in increased costs and reduced production efficiency.

Lastly, the industry faces challenges in scaling up production to meet growing demand while maintaining quality and cost-effectiveness. As the global electronics market expands, manufacturers struggle to increase output without compromising on precision or incurring prohibitive capital expenses for new equipment and facilities.

Existing Vacuum Forming Solutions for Electronics

01 Automated manufacturing processes

Implementing automated manufacturing processes can significantly streamline electronic substrate production. This includes the use of robotics, computer-controlled equipment, and advanced sensors to improve efficiency, reduce human error, and increase production speed. Automation can be applied to various stages of substrate production, from material handling to quality control.- Automated manufacturing processes: Implementing automated manufacturing processes can significantly streamline electronic substrate production. This includes the use of robotic systems, automated assembly lines, and computer-controlled equipment to increase efficiency, reduce human error, and improve overall production speed.

- Advanced materials and design optimization: Utilizing advanced materials and optimizing substrate designs can enhance production efficiency. This involves selecting high-performance materials, implementing novel substrate architectures, and employing computer-aided design tools to improve substrate performance and manufacturability.

- Integration of IoT and data analytics: Incorporating Internet of Things (IoT) devices and data analytics into the production process can lead to better monitoring, predictive maintenance, and real-time optimization of manufacturing parameters. This approach enables more efficient resource allocation and reduces downtime.

- Supply chain optimization: Streamlining the supply chain for electronic substrate production involves improving inventory management, logistics, and supplier relationships. This can be achieved through the implementation of just-in-time manufacturing principles and the use of advanced forecasting and planning tools.

- Quality control and testing automation: Automating quality control and testing procedures can significantly improve production efficiency and reduce defects. This includes the use of machine vision systems, automated inspection equipment, and in-line testing methods to ensure consistent product quality throughout the manufacturing process.

02 Advanced materials and design optimization

Utilizing advanced materials and optimizing substrate designs can enhance production efficiency. This involves selecting high-performance materials, implementing novel substrate architectures, and employing computer-aided design tools to optimize substrate layouts. These improvements can lead to reduced material waste, improved electrical performance, and easier manufacturing processes.Expand Specific Solutions03 Integration of IoT and data analytics

Incorporating Internet of Things (IoT) devices and data analytics into the production process can streamline electronic substrate manufacturing. This approach enables real-time monitoring of equipment performance, predictive maintenance, and data-driven decision-making. By analyzing production data, manufacturers can identify bottlenecks, optimize processes, and improve overall efficiency.Expand Specific Solutions04 Supply chain optimization

Streamlining the supply chain for electronic substrate production can significantly improve overall efficiency. This includes implementing just-in-time inventory systems, optimizing logistics, and fostering closer collaboration with suppliers. By reducing lead times and minimizing inventory holding costs, manufacturers can achieve more flexible and responsive production processes.Expand Specific Solutions05 Sustainable and energy-efficient production

Implementing sustainable and energy-efficient production methods can streamline electronic substrate manufacturing while reducing environmental impact. This includes adopting energy-saving equipment, optimizing resource utilization, and implementing waste reduction strategies. These approaches can lead to cost savings, improved production efficiency, and enhanced corporate social responsibility.Expand Specific Solutions

Key Players in Vacuum Forming for Electronics

The electronic substrate production using vacuum forming technology is in a growth phase, with increasing market size driven by demand for advanced electronics. The market is characterized by moderate technological maturity, with ongoing innovations to improve efficiency and quality. Key players like Seiko Epson, Canon, and Fujitsu are investing in R&D to enhance their vacuum forming capabilities for electronic substrates. Companies such as ULVAC and Sumitomo Bakelite are developing specialized equipment and materials, while Innolux and Shengyi Technology focus on integrating vacuum forming into their production processes. The competitive landscape is diverse, with both established electronics manufacturers and specialized materials suppliers vying for market share.

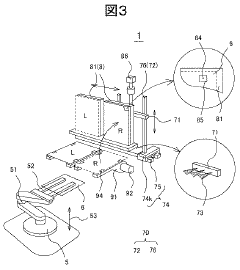

ULVAC, Inc.

Technical Solution: ULVAC has developed advanced vacuum forming technologies for electronic substrate production. Their approach involves high-precision vacuum deposition systems that can create ultra-thin, uniform layers on various substrate materials. ULVAC's technology utilizes a combination of physical vapor deposition (PVD) and chemical vapor deposition (CVD) processes, allowing for precise control over film thickness and composition[1]. The company has also introduced innovative in-line sputtering systems that can handle large-area substrates, significantly improving throughput in electronic component manufacturing[3]. ULVAC's vacuum forming solutions incorporate real-time monitoring and control systems, ensuring consistent quality across large production batches[5].

Strengths: High precision deposition, versatility in substrate materials, and scalability for large-area production. Weaknesses: High initial equipment costs and complexity in process optimization for different materials.

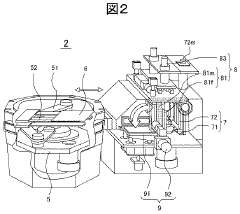

Panasonic Holdings Corp.

Technical Solution: Panasonic has developed an innovative vacuum forming technology for electronic substrate production, focusing on flexible and printed electronics. Their system utilizes a roll-to-roll vacuum deposition process that enables continuous production of large-area flexible substrates[8]. Panasonic's technology incorporates a unique plasma treatment stage that enhances adhesion between the substrate and deposited layers, improving overall product reliability[10]. The company has also integrated advanced thermal management systems into their vacuum forming equipment, allowing for precise temperature control during deposition, which is crucial for maintaining substrate integrity and film quality in flexible electronics production[12].

Strengths: Continuous roll-to-roll processing capability, enhanced adhesion through plasma treatment, and precise thermal management. Weaknesses: Potential limitations in processing thicker or rigid substrates, and challenges in scaling down for small-batch production.

Innovations in Vacuum Forming for Substrates

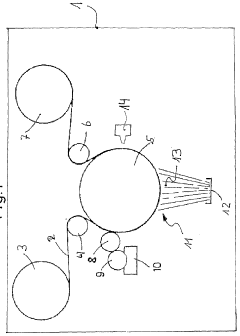

Method for production of a transponder

PatentWO2005043965A2

Innovation

- A method that simplifies the production by forming antenna and integrated circuit structures directly on the substrate using vapor deposition or sputtering in a vacuum system, utilizing a pre-treated substrate and evaporating oil to prevent material deposition on unwanted areas, allowing for continuous and rapid processing.

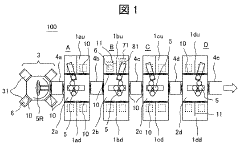

Apparatus and method for manufacturing organic el device, and apparatus and method for forming film

PatentInactiveJP2010086956A

Innovation

- The method involves processing multiple substrates simultaneously in a vacuum chamber, aligning and vapor-depositing one substrate while unloading another, using a divided vacuum chamber design with separate deposition and alignment units, and employing a movable evaporation source to optimize material usage and reduce unnecessary deposition time.

Environmental Impact of Vacuum Forming Processes

Vacuum forming processes, while efficient for electronic substrate production, have notable environmental implications that warrant careful consideration. The primary environmental concerns stem from energy consumption, material waste, and emissions associated with the manufacturing process.

Energy usage is a significant factor in the environmental impact of vacuum forming. The process requires substantial electrical power to operate heating elements, vacuum pumps, and cooling systems. This energy demand contributes to greenhouse gas emissions if sourced from non-renewable energy sources. However, advancements in energy-efficient equipment and the integration of renewable energy sources in manufacturing facilities can mitigate this impact.

Material waste is another critical environmental aspect of vacuum forming. The process often generates excess material in the form of trim waste and rejected parts. While some thermoplastics used in vacuum forming are recyclable, the recycling process itself requires energy and may result in material degradation. Implementing closed-loop recycling systems and optimizing material usage through precise mold design can significantly reduce waste generation.

Emissions from vacuum forming processes primarily consist of volatile organic compounds (VOCs) released during the heating of thermoplastic materials. These emissions can contribute to air pollution and pose potential health risks to workers and surrounding communities. The implementation of proper ventilation systems and the use of low-VOC materials can help minimize these emissions.

Water usage in vacuum forming is relatively low compared to other manufacturing processes. However, cooling systems may require water, and proper management of wastewater is essential to prevent contamination of local water sources.

The choice of materials used in vacuum forming also impacts its environmental footprint. Traditional petroleum-based plastics contribute to resource depletion and have long-term environmental persistence. The industry is increasingly exploring bio-based and biodegradable alternatives to reduce the ecological impact of electronic substrates.

End-of-life considerations for vacuum-formed electronic substrates are crucial. Many electronic components contain hazardous materials that require special handling and disposal. Designing for disassembly and implementing take-back programs can facilitate proper recycling and reduce the environmental burden of electronic waste.

Advancements in vacuum forming technology are addressing these environmental concerns. Innovations such as more precise temperature control, improved mold designs, and the use of recycled materials are enhancing the sustainability of the process. Additionally, life cycle assessments are becoming more common in the industry, allowing manufacturers to identify and address the most significant environmental impacts throughout the product's life cycle.

Energy usage is a significant factor in the environmental impact of vacuum forming. The process requires substantial electrical power to operate heating elements, vacuum pumps, and cooling systems. This energy demand contributes to greenhouse gas emissions if sourced from non-renewable energy sources. However, advancements in energy-efficient equipment and the integration of renewable energy sources in manufacturing facilities can mitigate this impact.

Material waste is another critical environmental aspect of vacuum forming. The process often generates excess material in the form of trim waste and rejected parts. While some thermoplastics used in vacuum forming are recyclable, the recycling process itself requires energy and may result in material degradation. Implementing closed-loop recycling systems and optimizing material usage through precise mold design can significantly reduce waste generation.

Emissions from vacuum forming processes primarily consist of volatile organic compounds (VOCs) released during the heating of thermoplastic materials. These emissions can contribute to air pollution and pose potential health risks to workers and surrounding communities. The implementation of proper ventilation systems and the use of low-VOC materials can help minimize these emissions.

Water usage in vacuum forming is relatively low compared to other manufacturing processes. However, cooling systems may require water, and proper management of wastewater is essential to prevent contamination of local water sources.

The choice of materials used in vacuum forming also impacts its environmental footprint. Traditional petroleum-based plastics contribute to resource depletion and have long-term environmental persistence. The industry is increasingly exploring bio-based and biodegradable alternatives to reduce the ecological impact of electronic substrates.

End-of-life considerations for vacuum-formed electronic substrates are crucial. Many electronic components contain hazardous materials that require special handling and disposal. Designing for disassembly and implementing take-back programs can facilitate proper recycling and reduce the environmental burden of electronic waste.

Advancements in vacuum forming technology are addressing these environmental concerns. Innovations such as more precise temperature control, improved mold designs, and the use of recycled materials are enhancing the sustainability of the process. Additionally, life cycle assessments are becoming more common in the industry, allowing manufacturers to identify and address the most significant environmental impacts throughout the product's life cycle.

Cost-Benefit Analysis of Vacuum Forming Implementation

Implementing vacuum forming technology in electronic substrate production requires a comprehensive cost-benefit analysis to determine its economic viability and potential return on investment. This analysis should consider both the immediate financial implications and the long-term strategic advantages of adopting this manufacturing process.

The initial capital expenditure for vacuum forming equipment represents a significant upfront cost. This includes the purchase of vacuum forming machines, molds, and associated tooling. Additionally, facility modifications may be necessary to accommodate the new production line, potentially involving changes to layout, power supply, and ventilation systems. These costs can vary widely depending on the scale of implementation and the specific requirements of the electronic substrate production process.

However, the potential benefits of vacuum forming can offset these initial investments over time. One of the primary advantages is the reduction in material waste. Vacuum forming allows for more precise shaping of substrates, minimizing excess material and reducing scrap rates. This not only lowers raw material costs but also decreases waste disposal expenses, contributing to both economic and environmental sustainability.

Labor costs may also see a significant reduction with the implementation of vacuum forming. The process is largely automated, requiring fewer manual interventions compared to traditional substrate production methods. This can lead to increased productivity per worker and potentially reduce the overall workforce required for substrate manufacturing. However, it's important to factor in the need for skilled operators and maintenance personnel who can manage the more advanced equipment.

Energy efficiency is another area where vacuum forming can provide cost benefits. Modern vacuum forming machines are designed to be more energy-efficient than older manufacturing processes, potentially leading to lower utility costs over time. This efficiency can be particularly impactful in large-scale production environments where energy consumption is a significant operational expense.

The improved quality and consistency of substrates produced through vacuum forming can lead to indirect cost savings. Higher quality substrates may result in fewer defects in final electronic products, reducing warranty claims and improving customer satisfaction. This can enhance the company's reputation and potentially lead to increased market share and revenue.

Time-to-market considerations should also be factored into the cost-benefit analysis. Vacuum forming typically allows for faster production cycles and greater flexibility in design changes. This agility can be particularly valuable in the fast-paced electronics industry, where rapid product iterations and customization are often required to meet market demands.

In conclusion, while the initial investment in vacuum forming technology for electronic substrate production can be substantial, the potential for long-term cost savings and operational improvements makes it a compelling option for many manufacturers. A thorough analysis of specific production requirements, market conditions, and financial projections is essential to determine the true value proposition of this technology implementation.

The initial capital expenditure for vacuum forming equipment represents a significant upfront cost. This includes the purchase of vacuum forming machines, molds, and associated tooling. Additionally, facility modifications may be necessary to accommodate the new production line, potentially involving changes to layout, power supply, and ventilation systems. These costs can vary widely depending on the scale of implementation and the specific requirements of the electronic substrate production process.

However, the potential benefits of vacuum forming can offset these initial investments over time. One of the primary advantages is the reduction in material waste. Vacuum forming allows for more precise shaping of substrates, minimizing excess material and reducing scrap rates. This not only lowers raw material costs but also decreases waste disposal expenses, contributing to both economic and environmental sustainability.

Labor costs may also see a significant reduction with the implementation of vacuum forming. The process is largely automated, requiring fewer manual interventions compared to traditional substrate production methods. This can lead to increased productivity per worker and potentially reduce the overall workforce required for substrate manufacturing. However, it's important to factor in the need for skilled operators and maintenance personnel who can manage the more advanced equipment.

Energy efficiency is another area where vacuum forming can provide cost benefits. Modern vacuum forming machines are designed to be more energy-efficient than older manufacturing processes, potentially leading to lower utility costs over time. This efficiency can be particularly impactful in large-scale production environments where energy consumption is a significant operational expense.

The improved quality and consistency of substrates produced through vacuum forming can lead to indirect cost savings. Higher quality substrates may result in fewer defects in final electronic products, reducing warranty claims and improving customer satisfaction. This can enhance the company's reputation and potentially lead to increased market share and revenue.

Time-to-market considerations should also be factored into the cost-benefit analysis. Vacuum forming typically allows for faster production cycles and greater flexibility in design changes. This agility can be particularly valuable in the fast-paced electronics industry, where rapid product iterations and customization are often required to meet market demands.

In conclusion, while the initial investment in vacuum forming technology for electronic substrate production can be substantial, the potential for long-term cost savings and operational improvements makes it a compelling option for many manufacturers. A thorough analysis of specific production requirements, market conditions, and financial projections is essential to determine the true value proposition of this technology implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!