Vacuum Forming's Influence on Efficient Water Management Technologies

JUL 30, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Forming in Water Management: Background and Objectives

Vacuum forming has emerged as a transformative technology in the field of water management, offering innovative solutions to address the growing challenges of water scarcity and efficient resource utilization. This technology, rooted in the plastics industry, has found novel applications in developing advanced water management systems, particularly in irrigation, water storage, and distribution.

The evolution of vacuum forming in water management can be traced back to the mid-20th century when plastic materials began to replace traditional materials in various industries. As water management became a critical global concern, engineers and researchers started exploring the potential of vacuum-formed components to create more efficient and cost-effective water systems.

The primary objective of integrating vacuum forming into water management technologies is to enhance the efficiency, durability, and sustainability of water-related infrastructure. This includes developing lightweight yet robust components for irrigation systems, creating innovative water storage solutions, and designing precision-engineered parts for water treatment facilities.

One of the key drivers behind the adoption of vacuum forming in water management is its ability to produce complex shapes with high precision and consistency. This characteristic is particularly valuable in creating optimized flow channels, reducing water loss through evaporation, and improving the overall hydraulic efficiency of water systems.

The technology's versatility allows for the production of a wide range of components, from large-scale water tanks to intricate drip irrigation components. This flexibility has opened up new possibilities in designing integrated water management solutions that can be tailored to specific environmental conditions and water conservation needs.

As the global focus on sustainable development intensifies, vacuum forming is playing a crucial role in developing eco-friendly water management technologies. The ability to use recycled and recyclable plastics in the vacuum forming process aligns with the growing emphasis on circular economy principles in water resource management.

Looking ahead, the trajectory of vacuum forming in water management is expected to intersect with other emerging technologies such as IoT (Internet of Things) and AI (Artificial Intelligence). This convergence promises to create smart, responsive water management systems that can adapt to changing environmental conditions and water demands in real-time.

In conclusion, vacuum forming's influence on efficient water management technologies represents a significant technological leap forward. By enabling the creation of innovative, high-performance components, this technology is poised to play a pivotal role in addressing global water challenges and shaping the future of sustainable water resource management.

The evolution of vacuum forming in water management can be traced back to the mid-20th century when plastic materials began to replace traditional materials in various industries. As water management became a critical global concern, engineers and researchers started exploring the potential of vacuum-formed components to create more efficient and cost-effective water systems.

The primary objective of integrating vacuum forming into water management technologies is to enhance the efficiency, durability, and sustainability of water-related infrastructure. This includes developing lightweight yet robust components for irrigation systems, creating innovative water storage solutions, and designing precision-engineered parts for water treatment facilities.

One of the key drivers behind the adoption of vacuum forming in water management is its ability to produce complex shapes with high precision and consistency. This characteristic is particularly valuable in creating optimized flow channels, reducing water loss through evaporation, and improving the overall hydraulic efficiency of water systems.

The technology's versatility allows for the production of a wide range of components, from large-scale water tanks to intricate drip irrigation components. This flexibility has opened up new possibilities in designing integrated water management solutions that can be tailored to specific environmental conditions and water conservation needs.

As the global focus on sustainable development intensifies, vacuum forming is playing a crucial role in developing eco-friendly water management technologies. The ability to use recycled and recyclable plastics in the vacuum forming process aligns with the growing emphasis on circular economy principles in water resource management.

Looking ahead, the trajectory of vacuum forming in water management is expected to intersect with other emerging technologies such as IoT (Internet of Things) and AI (Artificial Intelligence). This convergence promises to create smart, responsive water management systems that can adapt to changing environmental conditions and water demands in real-time.

In conclusion, vacuum forming's influence on efficient water management technologies represents a significant technological leap forward. By enabling the creation of innovative, high-performance components, this technology is poised to play a pivotal role in addressing global water challenges and shaping the future of sustainable water resource management.

Market Analysis for Vacuum-Formed Water Management Solutions

The market for vacuum-formed water management solutions has shown significant growth in recent years, driven by increasing global water scarcity concerns and the need for more efficient water management technologies. This sector encompasses a wide range of products, including water storage tanks, drainage systems, irrigation components, and water treatment equipment, all of which can benefit from vacuum forming processes.

The global water management market is projected to reach substantial value in the coming years, with vacuum-formed solutions playing an increasingly important role. Factors contributing to this growth include urbanization, population growth, and climate change, all of which are putting pressure on existing water infrastructure and necessitating innovative solutions.

In the agricultural sector, vacuum-formed irrigation systems are gaining traction due to their ability to improve water distribution efficiency and reduce water waste. These systems are particularly valuable in regions facing water scarcity, where precision irrigation is crucial for crop yields and sustainability.

The construction industry is another key market for vacuum-formed water management products. Drainage systems, rainwater harvesting components, and erosion control solutions made through vacuum forming are in high demand for both residential and commercial projects. These products offer advantages in terms of durability, cost-effectiveness, and ease of installation.

Municipal water management represents a significant market opportunity for vacuum-formed solutions. Cities and towns are increasingly adopting these technologies for stormwater management, sewage systems, and water treatment facilities. The lightweight nature and corrosion resistance of vacuum-formed components make them attractive for infrastructure projects.

Geographically, North America and Europe currently lead the market for vacuum-formed water management solutions, owing to their advanced infrastructure and stringent environmental regulations. However, the Asia-Pacific region is expected to see the fastest growth in this sector, driven by rapid urbanization, industrial development, and increasing water stress in countries like China and India.

Consumer awareness of water conservation is also fueling demand for household water management products. Vacuum-formed rainwater collection systems, water-saving plumbing fixtures, and greywater recycling components are gaining popularity among environmentally conscious homeowners.

The market is characterized by a mix of large multinational corporations and specialized manufacturers. Key players are investing in research and development to improve the performance and sustainability of their vacuum-formed water management products, with a focus on using recycled materials and enhancing the recyclability of end products.

The global water management market is projected to reach substantial value in the coming years, with vacuum-formed solutions playing an increasingly important role. Factors contributing to this growth include urbanization, population growth, and climate change, all of which are putting pressure on existing water infrastructure and necessitating innovative solutions.

In the agricultural sector, vacuum-formed irrigation systems are gaining traction due to their ability to improve water distribution efficiency and reduce water waste. These systems are particularly valuable in regions facing water scarcity, where precision irrigation is crucial for crop yields and sustainability.

The construction industry is another key market for vacuum-formed water management products. Drainage systems, rainwater harvesting components, and erosion control solutions made through vacuum forming are in high demand for both residential and commercial projects. These products offer advantages in terms of durability, cost-effectiveness, and ease of installation.

Municipal water management represents a significant market opportunity for vacuum-formed solutions. Cities and towns are increasingly adopting these technologies for stormwater management, sewage systems, and water treatment facilities. The lightweight nature and corrosion resistance of vacuum-formed components make them attractive for infrastructure projects.

Geographically, North America and Europe currently lead the market for vacuum-formed water management solutions, owing to their advanced infrastructure and stringent environmental regulations. However, the Asia-Pacific region is expected to see the fastest growth in this sector, driven by rapid urbanization, industrial development, and increasing water stress in countries like China and India.

Consumer awareness of water conservation is also fueling demand for household water management products. Vacuum-formed rainwater collection systems, water-saving plumbing fixtures, and greywater recycling components are gaining popularity among environmentally conscious homeowners.

The market is characterized by a mix of large multinational corporations and specialized manufacturers. Key players are investing in research and development to improve the performance and sustainability of their vacuum-formed water management products, with a focus on using recycled materials and enhancing the recyclability of end products.

Current Challenges in Vacuum Forming for Water Technologies

Vacuum forming technology, while widely used in various industries, faces several challenges when applied to water management technologies. One of the primary issues is the limited complexity of shapes that can be achieved through this process. Water management systems often require intricate designs with complex internal structures, which are difficult to produce using traditional vacuum forming techniques. This limitation restricts the potential for creating highly efficient water flow channels and filtration systems.

Material selection poses another significant challenge. While vacuum forming is compatible with a range of thermoplastics, not all materials suitable for water management applications can be effectively processed using this method. Some high-performance polymers with excellent water resistance and durability may not be amenable to vacuum forming due to their high melting points or specific molecular structures. This constraint can lead to compromises in material properties, potentially affecting the longevity and performance of water management components.

The thickness uniformity of vacuum-formed parts is also a concern in water technology applications. Uneven material distribution during the forming process can result in weak points or areas of excessive thickness, which may impact the structural integrity and hydraulic efficiency of water management systems. Achieving consistent wall thickness across complex geometries remains a technical hurdle, particularly for large-scale components used in water infrastructure.

Precision and repeatability present additional challenges in vacuum forming for water technologies. Water management systems often require tight tolerances to ensure proper sealing and flow characteristics. However, the inherent variability in the vacuum forming process, influenced by factors such as temperature fluctuations and material behavior, can lead to inconsistencies between produced parts. This variability may necessitate additional quality control measures, increasing production costs and time.

The scalability of vacuum forming for large water management components is another area of concern. While the process is well-suited for medium-sized parts, producing very large components, such as those required for industrial-scale water treatment facilities, can be problematic. Limitations in machine size, heating capacity, and vacuum power can restrict the maximum dimensions of vacuum-formed parts, potentially necessitating alternative manufacturing methods for oversized components.

Lastly, the environmental impact of vacuum forming in water technology applications is an emerging challenge. As sustainability becomes increasingly important in water management, the use of single-use plastics and energy-intensive processes is under scrutiny. Developing more eco-friendly materials and improving the energy efficiency of vacuum forming processes are critical areas for innovation to ensure the long-term viability of this technology in the water management sector.

Material selection poses another significant challenge. While vacuum forming is compatible with a range of thermoplastics, not all materials suitable for water management applications can be effectively processed using this method. Some high-performance polymers with excellent water resistance and durability may not be amenable to vacuum forming due to their high melting points or specific molecular structures. This constraint can lead to compromises in material properties, potentially affecting the longevity and performance of water management components.

The thickness uniformity of vacuum-formed parts is also a concern in water technology applications. Uneven material distribution during the forming process can result in weak points or areas of excessive thickness, which may impact the structural integrity and hydraulic efficiency of water management systems. Achieving consistent wall thickness across complex geometries remains a technical hurdle, particularly for large-scale components used in water infrastructure.

Precision and repeatability present additional challenges in vacuum forming for water technologies. Water management systems often require tight tolerances to ensure proper sealing and flow characteristics. However, the inherent variability in the vacuum forming process, influenced by factors such as temperature fluctuations and material behavior, can lead to inconsistencies between produced parts. This variability may necessitate additional quality control measures, increasing production costs and time.

The scalability of vacuum forming for large water management components is another area of concern. While the process is well-suited for medium-sized parts, producing very large components, such as those required for industrial-scale water treatment facilities, can be problematic. Limitations in machine size, heating capacity, and vacuum power can restrict the maximum dimensions of vacuum-formed parts, potentially necessitating alternative manufacturing methods for oversized components.

Lastly, the environmental impact of vacuum forming in water technology applications is an emerging challenge. As sustainability becomes increasingly important in water management, the use of single-use plastics and energy-intensive processes is under scrutiny. Developing more eco-friendly materials and improving the energy efficiency of vacuum forming processes are critical areas for innovation to ensure the long-term viability of this technology in the water management sector.

Existing Vacuum Forming Solutions for Water Management

01 Improved vacuum forming apparatus design

Enhancements in vacuum forming apparatus design can significantly improve efficiency. This includes optimizing the vacuum chamber, heating elements, and mold design to ensure uniform heat distribution and consistent vacuum pressure. Advanced control systems can also be implemented to automate and fine-tune the forming process.- Improved vacuum forming apparatus design: Enhancements in vacuum forming apparatus design can significantly improve efficiency. This includes optimizing the vacuum chamber, platen design, and heating elements to ensure uniform heat distribution and effective material shaping. Advanced designs may incorporate automated features for faster processing and reduced manual intervention.

- Material selection and preparation: Selecting appropriate materials and preparing them correctly can enhance vacuum forming efficiency. This involves choosing materials with optimal thermal properties, ensuring proper thickness, and pre-treating surfaces for better forming results. Proper material handling and storage also contribute to improved efficiency and product quality.

- Temperature and pressure control: Precise control of temperature and pressure during the vacuum forming process is crucial for efficiency. Advanced systems may use sensors and feedback mechanisms to maintain optimal conditions throughout the forming cycle. This can lead to faster processing times, reduced material waste, and improved product consistency.

- Mold design and optimization: Efficient mold design plays a significant role in vacuum forming efficiency. This includes considerations for draft angles, undercuts, and air evacuation channels. Computer-aided design and simulation tools can be used to optimize mold geometry for faster forming cycles and easier part removal.

- Process automation and integration: Integrating vacuum forming processes with other manufacturing steps and implementing automation can greatly enhance overall efficiency. This may involve robotic material handling, in-line trimming and finishing operations, and advanced control systems for coordinating multiple process steps. Such integration can reduce cycle times and labor costs while improving product consistency.

02 Material selection and preparation

Choosing appropriate materials and properly preparing them before vacuum forming can enhance efficiency. This involves selecting thermoplastics with optimal forming characteristics, preheating materials to the correct temperature, and ensuring proper sheet thickness for the intended application.Expand Specific Solutions03 Mold design and fabrication techniques

Efficient mold design and fabrication techniques can significantly impact vacuum forming efficiency. This includes creating molds with proper draft angles, smooth surfaces, and strategically placed vacuum holes. Advanced mold materials and coatings can also improve release characteristics and extend mold life.Expand Specific Solutions04 Process parameter optimization

Optimizing process parameters such as heating time, vacuum pressure, and cooling rate can greatly enhance vacuum forming efficiency. This may involve using sensors and data analysis to determine ideal settings for different materials and product geometries, as well as implementing adaptive control systems to maintain optimal conditions throughout the forming process.Expand Specific Solutions05 Post-forming operations and quality control

Improving efficiency in post-forming operations and implementing robust quality control measures can enhance overall vacuum forming productivity. This includes optimizing trimming and finishing processes, implementing automated inspection systems, and developing strategies to minimize waste and rework.Expand Specific Solutions

Key Players in Vacuum Forming and Water Management Industries

The vacuum forming technology in water management is in a growth phase, with increasing market size due to rising demand for efficient water solutions. The market is characterized by a mix of established players and innovative startups, indicating moderate technological maturity. Companies like Valmet Technologies Oy and Fraunhofer-Gesellschaft are driving innovation in industrial applications, while firms such as Hangzhou Jinli Energy Saving Technology and Hydroforming Design Light AB focus on energy-efficient solutions. The involvement of research institutions like Chengdu University of Technology and King's College London suggests ongoing advancements in the field. Major corporations like Mitsubishi Gas Chemical and ExxonMobil Upstream Research Co. are also contributing to the sector's development, indicating its growing importance in various industries.

Valmet Technologies Oy

Technical Solution: Valmet Technologies Oy has developed advanced vacuum forming technologies for efficient water management in paper and pulp industries. Their solution incorporates a high-vacuum dewatering system that significantly reduces water consumption in the papermaking process. The technology utilizes specially designed vacuum boxes and foils to optimize water removal from the paper web[1]. This system is integrated with intelligent control systems that adjust vacuum levels based on real-time process data, ensuring optimal water removal efficiency across different paper grades and production speeds[3].

Strengths: Highly efficient water removal, adaptable to various paper grades, and integrated intelligent control. Weaknesses: High initial investment cost and potential energy consumption concerns.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft eV has pioneered a novel vacuum-assisted membrane distillation (VMD) technology for water purification and desalination. This innovative approach combines vacuum forming principles with membrane technology to enhance water treatment efficiency. The system utilizes a hydrophobic membrane and applies a vacuum on the permeate side, creating a vapor pressure difference that drives water vapor through the membrane[2]. This process effectively separates pure water from contaminants, including salts and pollutants. The technology incorporates advanced membrane materials and optimized vacuum chamber designs to maximize flux rates and minimize energy consumption[4].

Strengths: High separation efficiency, low energy consumption, and versatility in treating various water sources. Weaknesses: Potential for membrane fouling and scaling, requiring regular maintenance.

Innovative Vacuum Forming Techniques for Water Efficiency

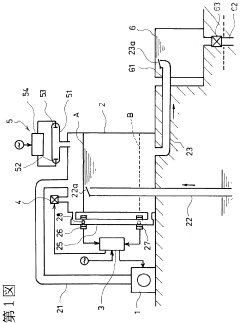

Vacuum pumping apparatus

PatentWO1998040629A1

Innovation

- A vacuum pumping device with a vacuum pump, vacuum pumping tank, and control mechanisms using photoelectric sensors and an electromagnetic vacuum valve to automatically regulate water pumping based on usage fluctuations, ensuring a constant water supply while reducing power consumption.

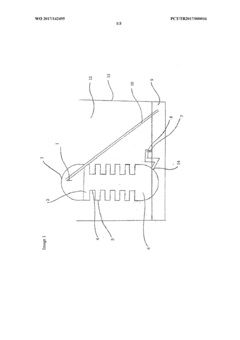

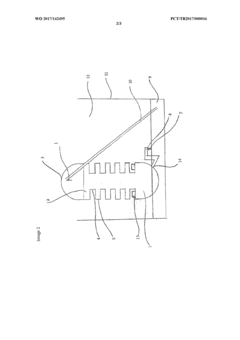

Vacuum created liquid flow

PatentWO2017142495A1

Innovation

- A system utilizing high-density mercury and atmospheric pressure, combined with a vacuum, to generate continuous liquid flow through a sealed tube with a vacuum side and a fluid-filled side, where atmospheric and liquid pressure are increased using indents and a metal cylinder weight to enhance flow, and a non-leaking faucet apparatus prevents leakage.

Environmental Impact and Sustainability Considerations

Vacuum forming technology, while offering significant advantages in efficient water management, also presents important environmental and sustainability considerations. The process of heating and molding plastic sheets inherently consumes energy and resources, potentially contributing to carbon emissions and plastic waste. However, the long-term benefits of improved water management systems may outweigh these initial environmental costs.

One of the primary environmental concerns is the use of plastics in vacuum forming. Many water management components produced through this method are made from petroleum-based plastics, which have a significant carbon footprint and can persist in the environment for hundreds of years. To address this issue, manufacturers are increasingly exploring biodegradable and recycled plastics as alternative materials. These eco-friendly options can significantly reduce the environmental impact of vacuum-formed water management products while maintaining their functionality.

Energy consumption during the vacuum forming process is another critical factor to consider. The heating and molding stages require substantial amounts of electricity, which, depending on the energy source, can contribute to greenhouse gas emissions. To mitigate this impact, companies are investing in more energy-efficient vacuum forming machines and exploring the use of renewable energy sources to power their manufacturing facilities. Additionally, optimizing the production process to reduce waste and improve energy efficiency can further enhance the sustainability of vacuum-formed water management technologies.

Water usage in the manufacturing process itself is an important consideration, given that these technologies are designed to improve water management. Implementing closed-loop water systems in vacuum forming facilities can significantly reduce water consumption and minimize wastewater discharge. This approach not only conserves water resources but also demonstrates a commitment to sustainable practices in the production of water management solutions.

The durability and longevity of vacuum-formed water management products contribute positively to their sustainability profile. These components are typically designed to withstand harsh environmental conditions and prolonged use, reducing the need for frequent replacements. This durability translates to less material consumption and waste generation over time, aligning with principles of sustainable resource management.

End-of-life considerations for vacuum-formed water management products are crucial for overall environmental impact assessment. Implementing effective recycling programs for these components can significantly reduce their environmental footprint. Some manufacturers are adopting design-for-disassembly principles, making it easier to separate different materials at the end of the product's life cycle, thus facilitating recycling and reducing landfill waste.

In conclusion, while vacuum forming in water management technologies presents certain environmental challenges, ongoing innovations in materials, energy efficiency, and recycling are continuously improving its sustainability profile. The long-term benefits of efficient water management, coupled with these sustainability efforts, position vacuum forming as a valuable tool in addressing global water challenges responsibly.

One of the primary environmental concerns is the use of plastics in vacuum forming. Many water management components produced through this method are made from petroleum-based plastics, which have a significant carbon footprint and can persist in the environment for hundreds of years. To address this issue, manufacturers are increasingly exploring biodegradable and recycled plastics as alternative materials. These eco-friendly options can significantly reduce the environmental impact of vacuum-formed water management products while maintaining their functionality.

Energy consumption during the vacuum forming process is another critical factor to consider. The heating and molding stages require substantial amounts of electricity, which, depending on the energy source, can contribute to greenhouse gas emissions. To mitigate this impact, companies are investing in more energy-efficient vacuum forming machines and exploring the use of renewable energy sources to power their manufacturing facilities. Additionally, optimizing the production process to reduce waste and improve energy efficiency can further enhance the sustainability of vacuum-formed water management technologies.

Water usage in the manufacturing process itself is an important consideration, given that these technologies are designed to improve water management. Implementing closed-loop water systems in vacuum forming facilities can significantly reduce water consumption and minimize wastewater discharge. This approach not only conserves water resources but also demonstrates a commitment to sustainable practices in the production of water management solutions.

The durability and longevity of vacuum-formed water management products contribute positively to their sustainability profile. These components are typically designed to withstand harsh environmental conditions and prolonged use, reducing the need for frequent replacements. This durability translates to less material consumption and waste generation over time, aligning with principles of sustainable resource management.

End-of-life considerations for vacuum-formed water management products are crucial for overall environmental impact assessment. Implementing effective recycling programs for these components can significantly reduce their environmental footprint. Some manufacturers are adopting design-for-disassembly principles, making it easier to separate different materials at the end of the product's life cycle, thus facilitating recycling and reducing landfill waste.

In conclusion, while vacuum forming in water management technologies presents certain environmental challenges, ongoing innovations in materials, energy efficiency, and recycling are continuously improving its sustainability profile. The long-term benefits of efficient water management, coupled with these sustainability efforts, position vacuum forming as a valuable tool in addressing global water challenges responsibly.

Cost-Benefit Analysis of Vacuum Forming in Water Management

The cost-benefit analysis of vacuum forming in water management reveals a complex interplay of economic, environmental, and operational factors. Initial investment in vacuum forming equipment and molds represents a significant upfront cost for water management facilities. However, this investment can be offset by the long-term benefits of improved efficiency and reduced operational expenses.

Vacuum forming allows for the production of lightweight, durable components used in water management systems, such as tanks, pipes, and filtration units. The reduced weight of these components leads to lower transportation and installation costs compared to traditional materials like metal or concrete. Additionally, the corrosion-resistant properties of vacuum-formed plastics extend the lifespan of water management infrastructure, reducing maintenance and replacement costs over time.

The process of vacuum forming itself is relatively energy-efficient, consuming less power than alternative manufacturing methods for similar components. This energy efficiency translates to lower production costs and a reduced carbon footprint, aligning with sustainability goals in the water management sector.

One of the most significant benefits of vacuum forming in water management is the ability to create complex shapes and designs that optimize water flow and treatment processes. Custom-designed components can improve the efficiency of water distribution systems, reduce water loss, and enhance the effectiveness of treatment processes. These improvements lead to substantial water and energy savings, which can result in significant cost reductions for water utilities and end-users.

However, the environmental impact of plastic production and disposal must be considered in the cost-benefit analysis. While vacuum-formed components are often recyclable, the overall lifecycle impact should be evaluated against alternative materials. Implementing proper recycling and disposal programs can mitigate these concerns and potentially create additional value streams.

From an operational perspective, vacuum forming offers flexibility in production, allowing for rapid prototyping and customization of components to meet specific water management needs. This adaptability can lead to faster problem-solving and innovation in water management technologies, potentially resulting in new revenue streams and market opportunities for companies in the sector.

In conclusion, while the initial costs of implementing vacuum forming in water management can be substantial, the long-term benefits in terms of operational efficiency, durability, and customization capabilities often outweigh these expenses. As water scarcity and management challenges continue to grow globally, the cost-effectiveness of vacuum forming technologies in addressing these issues becomes increasingly apparent, making it a valuable investment for the future of water management.

Vacuum forming allows for the production of lightweight, durable components used in water management systems, such as tanks, pipes, and filtration units. The reduced weight of these components leads to lower transportation and installation costs compared to traditional materials like metal or concrete. Additionally, the corrosion-resistant properties of vacuum-formed plastics extend the lifespan of water management infrastructure, reducing maintenance and replacement costs over time.

The process of vacuum forming itself is relatively energy-efficient, consuming less power than alternative manufacturing methods for similar components. This energy efficiency translates to lower production costs and a reduced carbon footprint, aligning with sustainability goals in the water management sector.

One of the most significant benefits of vacuum forming in water management is the ability to create complex shapes and designs that optimize water flow and treatment processes. Custom-designed components can improve the efficiency of water distribution systems, reduce water loss, and enhance the effectiveness of treatment processes. These improvements lead to substantial water and energy savings, which can result in significant cost reductions for water utilities and end-users.

However, the environmental impact of plastic production and disposal must be considered in the cost-benefit analysis. While vacuum-formed components are often recyclable, the overall lifecycle impact should be evaluated against alternative materials. Implementing proper recycling and disposal programs can mitigate these concerns and potentially create additional value streams.

From an operational perspective, vacuum forming offers flexibility in production, allowing for rapid prototyping and customization of components to meet specific water management needs. This adaptability can lead to faster problem-solving and innovation in water management technologies, potentially resulting in new revenue streams and market opportunities for companies in the sector.

In conclusion, while the initial costs of implementing vacuum forming in water management can be substantial, the long-term benefits in terms of operational efficiency, durability, and customization capabilities often outweigh these expenses. As water scarcity and management challenges continue to grow globally, the cost-effectiveness of vacuum forming technologies in addressing these issues becomes increasingly apparent, making it a valuable investment for the future of water management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!