Technological Evolution of Ethylene Vinyl Acetate Solutions

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA Technology Background and Objectives

Ethylene Vinyl Acetate (EVA) has emerged as a versatile and essential material in various industries over the past few decades. The technological evolution of EVA solutions has been driven by the increasing demand for flexible, durable, and cost-effective materials across multiple sectors. This report aims to provide a comprehensive overview of the EVA technology landscape, its historical development, and the objectives guiding its future advancements.

EVA, a copolymer of ethylene and vinyl acetate, was first developed in the 1950s. Its unique properties, combining the flexibility of rubber with the processability of thermoplastics, quickly garnered attention from manufacturers and researchers alike. The initial applications of EVA were primarily in the packaging industry, where its excellent sealing properties and low-temperature toughness proved invaluable.

As the technology progressed, the focus shifted towards optimizing the vinyl acetate content and molecular structure of EVA to enhance its performance characteristics. This led to the development of various grades of EVA with tailored properties suitable for specific applications. The 1970s and 1980s saw significant advancements in EVA technology, with improvements in production processes and the introduction of new additives to enhance its properties.

The evolution of EVA technology has been closely tied to advancements in polymer science and materials engineering. Researchers have continually explored ways to modify EVA's structure and composition to improve its mechanical properties, thermal stability, and chemical resistance. This ongoing research has expanded EVA's application scope beyond packaging to include industries such as solar energy, footwear, and medical devices.

One of the key objectives driving the technological evolution of EVA solutions is sustainability. As environmental concerns have gained prominence, there has been a growing emphasis on developing eco-friendly EVA formulations. This includes efforts to increase the use of bio-based feedstocks, improve recyclability, and reduce the carbon footprint of EVA production processes.

Another significant goal in EVA technology development is enhancing its performance in extreme conditions. This is particularly relevant for applications in the solar industry, where EVA is used as an encapsulant material for photovoltaic modules. Researchers are working on improving EVA's UV resistance, moisture barrier properties, and long-term stability to extend the lifespan of solar panels and increase their efficiency.

The future objectives of EVA technology are focused on addressing the evolving needs of various industries. This includes developing EVA grades with improved flame retardancy for construction applications, enhancing its compatibility with other materials for advanced composites, and exploring its potential in emerging fields such as 3D printing and smart materials.

In conclusion, the technological evolution of EVA solutions has been marked by continuous innovation and adaptation to meet diverse industrial requirements. As we look to the future, the objectives for EVA technology development are centered on sustainability, performance enhancement, and expanding its application potential in cutting-edge technologies.

EVA, a copolymer of ethylene and vinyl acetate, was first developed in the 1950s. Its unique properties, combining the flexibility of rubber with the processability of thermoplastics, quickly garnered attention from manufacturers and researchers alike. The initial applications of EVA were primarily in the packaging industry, where its excellent sealing properties and low-temperature toughness proved invaluable.

As the technology progressed, the focus shifted towards optimizing the vinyl acetate content and molecular structure of EVA to enhance its performance characteristics. This led to the development of various grades of EVA with tailored properties suitable for specific applications. The 1970s and 1980s saw significant advancements in EVA technology, with improvements in production processes and the introduction of new additives to enhance its properties.

The evolution of EVA technology has been closely tied to advancements in polymer science and materials engineering. Researchers have continually explored ways to modify EVA's structure and composition to improve its mechanical properties, thermal stability, and chemical resistance. This ongoing research has expanded EVA's application scope beyond packaging to include industries such as solar energy, footwear, and medical devices.

One of the key objectives driving the technological evolution of EVA solutions is sustainability. As environmental concerns have gained prominence, there has been a growing emphasis on developing eco-friendly EVA formulations. This includes efforts to increase the use of bio-based feedstocks, improve recyclability, and reduce the carbon footprint of EVA production processes.

Another significant goal in EVA technology development is enhancing its performance in extreme conditions. This is particularly relevant for applications in the solar industry, where EVA is used as an encapsulant material for photovoltaic modules. Researchers are working on improving EVA's UV resistance, moisture barrier properties, and long-term stability to extend the lifespan of solar panels and increase their efficiency.

The future objectives of EVA technology are focused on addressing the evolving needs of various industries. This includes developing EVA grades with improved flame retardancy for construction applications, enhancing its compatibility with other materials for advanced composites, and exploring its potential in emerging fields such as 3D printing and smart materials.

In conclusion, the technological evolution of EVA solutions has been marked by continuous innovation and adaptation to meet diverse industrial requirements. As we look to the future, the objectives for EVA technology development are centered on sustainability, performance enhancement, and expanding its application potential in cutting-edge technologies.

Market Demand Analysis for EVA Solutions

The market demand for Ethylene Vinyl Acetate (EVA) solutions has been experiencing significant growth across various industries due to its versatile properties and wide range of applications. The global EVA market has shown a steady increase in recent years, driven by the rising demand in sectors such as packaging, footwear, solar panels, and automotive industries.

In the packaging industry, EVA copolymers are increasingly used for flexible packaging solutions, offering excellent clarity, flexibility, and barrier properties. The growing e-commerce sector and the shift towards sustainable packaging materials have further boosted the demand for EVA-based packaging solutions. The footwear industry has also been a major consumer of EVA, particularly in the production of midsoles for athletic shoes, due to its lightweight and shock-absorbing characteristics.

The solar energy sector has emerged as a significant driver for EVA demand, with the material being widely used as an encapsulant in photovoltaic modules. As the global push for renewable energy sources continues, the demand for EVA in solar panel manufacturing is expected to grow substantially in the coming years.

In the automotive industry, EVA is gaining traction in the production of interior components, gaskets, and seals. The material's resistance to heat, UV radiation, and chemicals makes it an attractive option for automotive manufacturers seeking to improve vehicle performance and durability.

The construction sector has also shown increased interest in EVA-based products, particularly in applications such as waterproofing membranes, adhesives, and sealants. The material's weather resistance and flexibility contribute to its growing adoption in building and infrastructure projects.

Geographically, Asia-Pacific has emerged as the largest market for EVA solutions, driven by rapid industrialization, urbanization, and the presence of major manufacturing hubs in countries like China and India. North America and Europe follow closely, with strong demand from established industries and a focus on sustainable materials.

The market demand for EVA solutions is expected to continue its upward trajectory, supported by ongoing technological advancements and the development of new applications. Manufacturers are increasingly focusing on developing high-performance EVA grades to meet the evolving requirements of various end-use industries, further expanding the market potential.

In the packaging industry, EVA copolymers are increasingly used for flexible packaging solutions, offering excellent clarity, flexibility, and barrier properties. The growing e-commerce sector and the shift towards sustainable packaging materials have further boosted the demand for EVA-based packaging solutions. The footwear industry has also been a major consumer of EVA, particularly in the production of midsoles for athletic shoes, due to its lightweight and shock-absorbing characteristics.

The solar energy sector has emerged as a significant driver for EVA demand, with the material being widely used as an encapsulant in photovoltaic modules. As the global push for renewable energy sources continues, the demand for EVA in solar panel manufacturing is expected to grow substantially in the coming years.

In the automotive industry, EVA is gaining traction in the production of interior components, gaskets, and seals. The material's resistance to heat, UV radiation, and chemicals makes it an attractive option for automotive manufacturers seeking to improve vehicle performance and durability.

The construction sector has also shown increased interest in EVA-based products, particularly in applications such as waterproofing membranes, adhesives, and sealants. The material's weather resistance and flexibility contribute to its growing adoption in building and infrastructure projects.

Geographically, Asia-Pacific has emerged as the largest market for EVA solutions, driven by rapid industrialization, urbanization, and the presence of major manufacturing hubs in countries like China and India. North America and Europe follow closely, with strong demand from established industries and a focus on sustainable materials.

The market demand for EVA solutions is expected to continue its upward trajectory, supported by ongoing technological advancements and the development of new applications. Manufacturers are increasingly focusing on developing high-performance EVA grades to meet the evolving requirements of various end-use industries, further expanding the market potential.

Current EVA Technology Challenges

Ethylene Vinyl Acetate (EVA) technology has made significant strides in recent years, yet it still faces several challenges that hinder its widespread adoption and optimal performance across various applications. One of the primary obstacles is the limited thermal stability of EVA copolymers at high temperatures. This constraint restricts their use in certain high-temperature applications, particularly in the automotive and aerospace industries where materials must withstand extreme conditions.

Another significant challenge lies in achieving a balance between flexibility and strength. While EVA is known for its excellent flexibility, improving its mechanical strength without compromising elasticity remains a complex task. This trade-off becomes particularly crucial in applications such as footwear and packaging, where both properties are equally important.

The crosslinking process of EVA, essential for enhancing its properties, presents its own set of challenges. Current crosslinking methods often require high temperatures or prolonged curing times, which can be energy-intensive and time-consuming. Developing more efficient crosslinking techniques that maintain or improve the final product properties is an ongoing area of research.

Environmental concerns also pose challenges to EVA technology. The growing demand for sustainable materials has put pressure on manufacturers to develop bio-based or recyclable EVA alternatives. However, achieving comparable performance and cost-effectiveness with these eco-friendly options remains a significant hurdle.

In the field of photovoltaics, where EVA is widely used as an encapsulant material, there are ongoing challenges related to long-term durability and resistance to environmental factors. Improving UV stability and moisture resistance of EVA encapsulants is crucial for extending the lifespan of solar panels and maintaining their efficiency over time.

The processing of EVA, particularly in foam production, faces challenges in controlling cell size and distribution uniformly. Achieving consistent foam quality across large-scale production runs is essential for applications in industries such as automotive and construction, where product uniformity is critical.

Lastly, the development of EVA grades with enhanced specific properties, such as improved adhesion, flame retardancy, or barrier properties, continues to be a focus area. Meeting these specialized requirements while maintaining the core benefits of EVA is a complex balancing act that researchers and manufacturers are constantly working to optimize.

Another significant challenge lies in achieving a balance between flexibility and strength. While EVA is known for its excellent flexibility, improving its mechanical strength without compromising elasticity remains a complex task. This trade-off becomes particularly crucial in applications such as footwear and packaging, where both properties are equally important.

The crosslinking process of EVA, essential for enhancing its properties, presents its own set of challenges. Current crosslinking methods often require high temperatures or prolonged curing times, which can be energy-intensive and time-consuming. Developing more efficient crosslinking techniques that maintain or improve the final product properties is an ongoing area of research.

Environmental concerns also pose challenges to EVA technology. The growing demand for sustainable materials has put pressure on manufacturers to develop bio-based or recyclable EVA alternatives. However, achieving comparable performance and cost-effectiveness with these eco-friendly options remains a significant hurdle.

In the field of photovoltaics, where EVA is widely used as an encapsulant material, there are ongoing challenges related to long-term durability and resistance to environmental factors. Improving UV stability and moisture resistance of EVA encapsulants is crucial for extending the lifespan of solar panels and maintaining their efficiency over time.

The processing of EVA, particularly in foam production, faces challenges in controlling cell size and distribution uniformly. Achieving consistent foam quality across large-scale production runs is essential for applications in industries such as automotive and construction, where product uniformity is critical.

Lastly, the development of EVA grades with enhanced specific properties, such as improved adhesion, flame retardancy, or barrier properties, continues to be a focus area. Meeting these specialized requirements while maintaining the core benefits of EVA is a complex balancing act that researchers and manufacturers are constantly working to optimize.

Current EVA Production Methods

01 Composition and properties of EVA

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to UV radiation and stress-cracking. The ratio of ethylene to vinyl acetate in the copolymer can be varied to achieve different characteristics, making it suitable for various applications.- Composition and properties of EVA: Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to achieve specific material characteristics for various applications.

- EVA in adhesive applications: EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It can be used in hot melt adhesives, pressure-sensitive adhesives, and as a base polymer in adhesive blends. The vinyl acetate content influences the adhesive strength and flexibility of the final product.

- EVA in foam and insulation materials: EVA is utilized in the production of foam and insulation materials due to its low density, good thermal insulation properties, and ability to be crosslinked. It can be processed into closed-cell foams for applications such as footwear, sports equipment, and building insulation.

- EVA in solar panel encapsulation: EVA is a popular material for solar panel encapsulation due to its transparency, weather resistance, and ability to protect solar cells from environmental factors. It helps to improve the durability and efficiency of photovoltaic modules by providing a protective barrier against moisture and UV radiation.

- Modification and blending of EVA: EVA can be modified or blended with other polymers and additives to enhance its properties for specific applications. This includes crosslinking, grafting, and the addition of fillers or compatibilizers. These modifications can improve characteristics such as heat resistance, mechanical strength, and processability.

02 EVA in adhesive applications

EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is commonly employed in hot melt adhesives, pressure-sensitive adhesives, and sealants. The adhesive strength and flexibility of EVA-based adhesives can be tailored by adjusting the vinyl acetate content and molecular weight.Expand Specific Solutions03 EVA in foam and insulation materials

EVA is utilized in the production of foam and insulation materials due to its low density, good thermal insulation properties, and shock-absorbing capabilities. It is commonly used in the manufacture of shoe soles, sports equipment padding, and building insulation. The foam can be crosslinked to enhance its properties further.Expand Specific Solutions04 EVA in solar panel encapsulation

EVA is a popular material for encapsulating solar cells in photovoltaic modules. It provides excellent transparency, weatherability, and electrical insulation properties. The material helps protect the solar cells from environmental factors and ensures long-term performance of the solar panels.Expand Specific Solutions05 Modifications and blends of EVA

EVA can be modified or blended with other polymers and additives to enhance its properties for specific applications. This includes the addition of flame retardants, UV stabilizers, or blending with other polymers like polyethylene or polypropylene. These modifications can improve the material's performance in areas such as flame resistance, weatherability, or mechanical strength.Expand Specific Solutions

Key Players in EVA Industry

The technological evolution of Ethylene Vinyl Acetate (EVA) solutions is currently in a mature growth stage, with a global market size expected to reach significant levels in the coming years. The industry is characterized by established players and ongoing innovation. Key companies like China Petroleum & Chemical Corp., Kuraray Co., Ltd., and Celanese International Corp. are driving advancements in EVA technology. These firms are focusing on improving product performance, expanding applications, and developing sustainable solutions. The market is seeing increased demand across various sectors, including packaging, solar panels, and footwear. As the technology matures, companies are investing in research and development to differentiate their offerings and capture market share in this competitive landscape.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has made significant advancements in Ethylene Vinyl Acetate (EVA) solutions. They have developed a proprietary process for producing high-quality EVA copolymers with varying vinyl acetate (VA) content, ranging from 10% to 40%[1]. This allows for tailored properties suitable for diverse applications. Sinopec has also implemented a continuous polymerization technology that enhances production efficiency and product consistency[2]. Their EVA solutions incorporate advanced catalyst systems that enable precise control over molecular weight distribution and branching, resulting in improved melt flow properties and thermal stability[3]. Additionally, Sinopec has invested in research to develop EVA grades with enhanced adhesion properties and UV resistance, catering to the growing demand in the solar panel encapsulation market[4].

Strengths: Diverse product range, advanced polymerization technology, and strong market presence in Asia. Weaknesses: Potential environmental concerns associated with petrochemical production and reliance on fossil fuel-based feedstocks.

Kuraray Co., Ltd.

Technical Solution: Kuraray has been at the forefront of EVA technology evolution, particularly in the development of specialized grades for high-performance applications. Their EVAL™ brand of ethylene vinyl alcohol (EVOH) copolymers, derived from EVA, offers exceptional barrier properties against gases, odors, and flavors[5]. Kuraray has pioneered a unique copolymerization process that allows for the production of EVA with ultra-high vinyl acetate content (up to 80%), resulting in materials with exceptional flexibility and transparency[6]. They have also developed crosslinkable EVA grades using silane-grafting technology, which enhances heat resistance and mechanical properties for wire and cable applications[7]. Furthermore, Kuraray's research has led to the creation of bio-based EVA variants, incorporating renewable resources to reduce environmental impact[8].

Strengths: Innovative product development, strong presence in specialty EVA markets, and focus on sustainable solutions. Weaknesses: Higher production costs for specialty grades and potential limitations in large-scale commodity EVA production.

Key Patents in EVA Technology

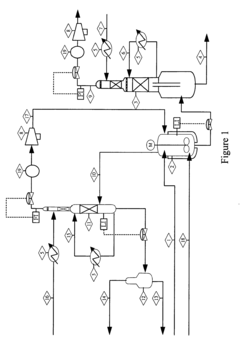

The process for continuously producing ethylene-vinyl acetate copolymer and reaction system

PatentInactiveEP1645574B1

Innovation

- A continuous process involving an impurity scrubbing column to remove low-boiling impurities like methyl acetate and acetaldehyde from the gaseous phase, using methanol as a scrubbing fluid, which are then recycled back into the polymerization system, ensuring minimal impurity concentration and improved copolymer quality.

The process for continuously producing ethylene-vinyl acetate copolymer and reaction system

PatentInactiveEP1645574B9

Innovation

- A continuous process involving an impurity scrubbing column to remove low-boiling impurities like methyl acetate and acetaldehyde from the gaseous phase, using methanol as a scrubbing fluid, which are then recycled back into the polymerization system, ensuring minimal impurity concentration and improved copolymer quality.

Environmental Impact of EVA Production

The production of Ethylene Vinyl Acetate (EVA) has significant environmental implications that warrant careful consideration. The manufacturing process involves the use of petrochemical feedstocks, which are derived from non-renewable resources and contribute to greenhouse gas emissions. The polymerization reaction itself requires substantial energy input, often sourced from fossil fuels, further exacerbating the carbon footprint of EVA production.

One of the primary environmental concerns associated with EVA manufacturing is the release of volatile organic compounds (VOCs) during the production process. These emissions can contribute to air pollution and the formation of ground-level ozone, potentially impacting both human health and ecosystems. Additionally, the use of solvents and other chemicals in the production process may lead to water pollution if not properly managed and treated.

The disposal of EVA products at the end of their lifecycle presents another environmental challenge. While EVA is technically recyclable, the process is often complex and energy-intensive due to the material's cross-linked structure. As a result, a significant portion of EVA waste ends up in landfills or is incinerated, contributing to soil and air pollution.

However, the industry has been making strides towards improving the environmental profile of EVA production. Many manufacturers are implementing cleaner production technologies, such as closed-loop systems that minimize waste and emissions. There is also a growing focus on developing bio-based alternatives to traditional EVA, using renewable feedstocks to reduce reliance on fossil fuels.

Energy efficiency improvements in the production process have been another area of focus. Advanced process control systems and heat recovery technologies are being employed to reduce energy consumption and associated emissions. Some facilities are also transitioning to renewable energy sources for their power needs, further reducing the carbon intensity of EVA production.

In response to concerns about end-of-life disposal, research is ongoing into more effective recycling methods for EVA products. Chemical recycling techniques show promise in breaking down the polymer into its constituent monomers, which can then be reused in new EVA production. Additionally, efforts are being made to design EVA products with improved recyclability, considering the entire lifecycle of the material from production to disposal.

As environmental regulations become more stringent globally, EVA manufacturers are increasingly adopting life cycle assessment (LCA) approaches to quantify and mitigate the environmental impacts of their products. This holistic view is driving innovation in production processes, material formulations, and waste management strategies, aiming to create a more sustainable future for EVA production and use.

One of the primary environmental concerns associated with EVA manufacturing is the release of volatile organic compounds (VOCs) during the production process. These emissions can contribute to air pollution and the formation of ground-level ozone, potentially impacting both human health and ecosystems. Additionally, the use of solvents and other chemicals in the production process may lead to water pollution if not properly managed and treated.

The disposal of EVA products at the end of their lifecycle presents another environmental challenge. While EVA is technically recyclable, the process is often complex and energy-intensive due to the material's cross-linked structure. As a result, a significant portion of EVA waste ends up in landfills or is incinerated, contributing to soil and air pollution.

However, the industry has been making strides towards improving the environmental profile of EVA production. Many manufacturers are implementing cleaner production technologies, such as closed-loop systems that minimize waste and emissions. There is also a growing focus on developing bio-based alternatives to traditional EVA, using renewable feedstocks to reduce reliance on fossil fuels.

Energy efficiency improvements in the production process have been another area of focus. Advanced process control systems and heat recovery technologies are being employed to reduce energy consumption and associated emissions. Some facilities are also transitioning to renewable energy sources for their power needs, further reducing the carbon intensity of EVA production.

In response to concerns about end-of-life disposal, research is ongoing into more effective recycling methods for EVA products. Chemical recycling techniques show promise in breaking down the polymer into its constituent monomers, which can then be reused in new EVA production. Additionally, efforts are being made to design EVA products with improved recyclability, considering the entire lifecycle of the material from production to disposal.

As environmental regulations become more stringent globally, EVA manufacturers are increasingly adopting life cycle assessment (LCA) approaches to quantify and mitigate the environmental impacts of their products. This holistic view is driving innovation in production processes, material formulations, and waste management strategies, aiming to create a more sustainable future for EVA production and use.

EVA Applications Across Industries

Ethylene Vinyl Acetate (EVA) has found widespread applications across various industries due to its versatile properties and adaptability. In the packaging industry, EVA copolymers are extensively used for flexible packaging materials, offering excellent clarity, toughness, and heat-sealing characteristics. These properties make EVA an ideal choice for food packaging, shrink wrap, and protective films.

In the footwear industry, EVA has revolutionized the production of comfortable and durable shoe soles. Its lightweight nature, combined with excellent shock absorption and cushioning properties, has made it a preferred material for athletic and casual footwear. EVA foam is particularly popular in the production of midsoles for running shoes, providing enhanced comfort and performance.

The automotive sector has also embraced EVA solutions for various applications. EVA is used in the production of gaskets, seals, and weather stripping, offering excellent resistance to weathering and UV radiation. Additionally, EVA copolymers are utilized in the manufacturing of car interiors, including dashboard components and door panels, due to their durability and ability to withstand extreme temperatures.

In the renewable energy sector, EVA has played a crucial role in the development of photovoltaic modules. EVA encapsulants are used to protect solar cells from environmental factors, ensuring long-term performance and reliability of solar panels. The material's transparency, UV resistance, and adhesive properties make it an ideal choice for this application.

The medical industry has also benefited from EVA's unique properties. EVA copolymers are used in the production of medical tubing, drug delivery systems, and prosthetic devices. The material's biocompatibility, flexibility, and resistance to chemicals make it suitable for various medical applications, including intravenous bags and catheters.

In the construction industry, EVA-based adhesives and sealants have gained popularity due to their excellent bonding properties and resistance to moisture. These materials are used in flooring installations, wall coverings, and roofing applications, providing durable and weather-resistant solutions.

The sports and leisure industry has also embraced EVA for its shock-absorbing and cushioning properties. EVA foam is widely used in the production of sports mats, protective gear, and flotation devices. Its lightweight nature and ability to be molded into various shapes make it an ideal material for these applications.

As EVA continues to evolve, new applications are emerging in fields such as 3D printing, where EVA filaments are being developed for flexible and durable printed objects. The ongoing research and development in EVA technology promise to expand its applications further, addressing the evolving needs of various industries.

In the footwear industry, EVA has revolutionized the production of comfortable and durable shoe soles. Its lightweight nature, combined with excellent shock absorption and cushioning properties, has made it a preferred material for athletic and casual footwear. EVA foam is particularly popular in the production of midsoles for running shoes, providing enhanced comfort and performance.

The automotive sector has also embraced EVA solutions for various applications. EVA is used in the production of gaskets, seals, and weather stripping, offering excellent resistance to weathering and UV radiation. Additionally, EVA copolymers are utilized in the manufacturing of car interiors, including dashboard components and door panels, due to their durability and ability to withstand extreme temperatures.

In the renewable energy sector, EVA has played a crucial role in the development of photovoltaic modules. EVA encapsulants are used to protect solar cells from environmental factors, ensuring long-term performance and reliability of solar panels. The material's transparency, UV resistance, and adhesive properties make it an ideal choice for this application.

The medical industry has also benefited from EVA's unique properties. EVA copolymers are used in the production of medical tubing, drug delivery systems, and prosthetic devices. The material's biocompatibility, flexibility, and resistance to chemicals make it suitable for various medical applications, including intravenous bags and catheters.

In the construction industry, EVA-based adhesives and sealants have gained popularity due to their excellent bonding properties and resistance to moisture. These materials are used in flooring installations, wall coverings, and roofing applications, providing durable and weather-resistant solutions.

The sports and leisure industry has also embraced EVA for its shock-absorbing and cushioning properties. EVA foam is widely used in the production of sports mats, protective gear, and flotation devices. Its lightweight nature and ability to be molded into various shapes make it an ideal material for these applications.

As EVA continues to evolve, new applications are emerging in fields such as 3D printing, where EVA filaments are being developed for flexible and durable printed objects. The ongoing research and development in EVA technology promise to expand its applications further, addressing the evolving needs of various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!