The Chemistry Behind UHMWPE's Exceptional Chemical Resistance

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Evolution and Objectives

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a remarkable material with exceptional chemical resistance, revolutionizing various industries. The evolution of UHMWPE can be traced back to the 1950s when it was first synthesized by Karl Ziegler and his team. Since then, continuous research and development efforts have propelled UHMWPE to its current status as a high-performance polymer with unparalleled properties.

The primary objective in the development of UHMWPE has been to create a material that combines superior mechanical strength with exceptional chemical resistance. This dual focus has driven researchers to explore innovative synthesis methods and processing techniques to enhance the material's performance across diverse applications.

Over the years, the chemistry behind UHMWPE's exceptional chemical resistance has been a subject of intense study. The unique molecular structure of UHMWPE, characterized by extremely long chains of polyethylene molecules, contributes significantly to its resistance against a wide range of chemicals. This structure results in a highly crystalline material with minimal chain ends exposed to potential chemical attack.

The evolution of UHMWPE has been marked by several key milestones. In the 1960s and 1970s, researchers focused on improving the polymerization process to achieve higher molecular weights, resulting in enhanced mechanical properties. The 1980s saw the development of cross-linking techniques, which further improved the wear resistance of UHMWPE, particularly in orthopedic implants.

Recent advancements in UHMWPE technology have centered on enhancing its chemical resistance even further. This includes the development of specialized additives and surface treatments that can impart additional protection against specific chemical agents. Researchers are also exploring the potential of nanocomposites to create UHMWPE materials with tailored chemical resistance profiles for specific industrial applications.

Looking ahead, the objectives for UHMWPE research and development are multifaceted. There is a growing emphasis on developing sustainable production methods and exploring bio-based alternatives to traditional petroleum-derived UHMWPE. Additionally, researchers are working on improving the material's resistance to extreme temperatures and harsh environmental conditions, expanding its potential applications in aerospace and deep-sea exploration.

Another key objective is to gain a deeper understanding of the molecular-level interactions between UHMWPE and various chemicals. This knowledge will be crucial in designing next-generation UHMWPE materials with even greater chemical resistance and specificity. Advanced characterization techniques and computational modeling are expected to play a significant role in this endeavor.

The primary objective in the development of UHMWPE has been to create a material that combines superior mechanical strength with exceptional chemical resistance. This dual focus has driven researchers to explore innovative synthesis methods and processing techniques to enhance the material's performance across diverse applications.

Over the years, the chemistry behind UHMWPE's exceptional chemical resistance has been a subject of intense study. The unique molecular structure of UHMWPE, characterized by extremely long chains of polyethylene molecules, contributes significantly to its resistance against a wide range of chemicals. This structure results in a highly crystalline material with minimal chain ends exposed to potential chemical attack.

The evolution of UHMWPE has been marked by several key milestones. In the 1960s and 1970s, researchers focused on improving the polymerization process to achieve higher molecular weights, resulting in enhanced mechanical properties. The 1980s saw the development of cross-linking techniques, which further improved the wear resistance of UHMWPE, particularly in orthopedic implants.

Recent advancements in UHMWPE technology have centered on enhancing its chemical resistance even further. This includes the development of specialized additives and surface treatments that can impart additional protection against specific chemical agents. Researchers are also exploring the potential of nanocomposites to create UHMWPE materials with tailored chemical resistance profiles for specific industrial applications.

Looking ahead, the objectives for UHMWPE research and development are multifaceted. There is a growing emphasis on developing sustainable production methods and exploring bio-based alternatives to traditional petroleum-derived UHMWPE. Additionally, researchers are working on improving the material's resistance to extreme temperatures and harsh environmental conditions, expanding its potential applications in aerospace and deep-sea exploration.

Another key objective is to gain a deeper understanding of the molecular-level interactions between UHMWPE and various chemicals. This knowledge will be crucial in designing next-generation UHMWPE materials with even greater chemical resistance and specificity. Advanced characterization techniques and computational modeling are expected to play a significant role in this endeavor.

Market Demand Analysis

The market demand for Ultra-High Molecular Weight Polyethylene (UHMWPE) has been steadily increasing due to its exceptional chemical resistance and unique properties. This material's ability to withstand harsh chemical environments has made it indispensable in various industries, driving its market growth.

In the chemical processing industry, UHMWPE's resistance to acids, bases, and organic solvents has led to its widespread adoption in tank linings, piping systems, and valve components. The material's longevity in these applications reduces maintenance costs and downtime, making it a preferred choice for many chemical manufacturers.

The oil and gas sector has also embraced UHMWPE for its resistance to hydrocarbons and corrosive substances. Its use in offshore platforms, pipelines, and storage tanks has grown significantly, as it outperforms traditional materials in these challenging environments. The increasing exploration and production activities in deep-sea and unconventional oil fields are expected to further boost the demand for UHMWPE in this sector.

In the medical field, UHMWPE's chemical resistance, combined with its biocompatibility, has made it a crucial material for implants and prosthetics. The aging population and rising incidence of joint replacement surgeries are driving the demand for UHMWPE in orthopedic applications. Additionally, its use in medical packaging and pharmaceutical processing equipment is expanding due to its resistance to sterilization chemicals and cleaning agents.

The water treatment industry has found UHMWPE to be an excellent material for filtration systems and membranes. Its resistance to chlorine and other water treatment chemicals, coupled with its durability, has led to increased adoption in desalination plants and wastewater treatment facilities. The growing global focus on clean water access is expected to further propel the demand for UHMWPE in this sector.

The automotive and aerospace industries are also contributing to the market growth of UHMWPE. Its resistance to fuels, lubricants, and other automotive fluids makes it suitable for various components, including fuel tanks and seals. In aerospace, UHMWPE's chemical resistance and lightweight properties make it valuable for interior components and fuel system parts.

As environmental regulations become more stringent, industries are seeking materials that can withstand aggressive cleaning agents and reduce chemical leaching. UHMWPE's ability to meet these requirements is driving its adoption in food processing equipment, laboratory apparatus, and consumer goods packaging.

The market for UHMWPE is expected to continue its growth trajectory, with emerging applications in battery separators for electric vehicles and advanced filtration technologies further expanding its potential. The material's unique combination of chemical resistance and other desirable properties positions it as a key player in addressing the evolving needs of various industries facing chemical challenges.

In the chemical processing industry, UHMWPE's resistance to acids, bases, and organic solvents has led to its widespread adoption in tank linings, piping systems, and valve components. The material's longevity in these applications reduces maintenance costs and downtime, making it a preferred choice for many chemical manufacturers.

The oil and gas sector has also embraced UHMWPE for its resistance to hydrocarbons and corrosive substances. Its use in offshore platforms, pipelines, and storage tanks has grown significantly, as it outperforms traditional materials in these challenging environments. The increasing exploration and production activities in deep-sea and unconventional oil fields are expected to further boost the demand for UHMWPE in this sector.

In the medical field, UHMWPE's chemical resistance, combined with its biocompatibility, has made it a crucial material for implants and prosthetics. The aging population and rising incidence of joint replacement surgeries are driving the demand for UHMWPE in orthopedic applications. Additionally, its use in medical packaging and pharmaceutical processing equipment is expanding due to its resistance to sterilization chemicals and cleaning agents.

The water treatment industry has found UHMWPE to be an excellent material for filtration systems and membranes. Its resistance to chlorine and other water treatment chemicals, coupled with its durability, has led to increased adoption in desalination plants and wastewater treatment facilities. The growing global focus on clean water access is expected to further propel the demand for UHMWPE in this sector.

The automotive and aerospace industries are also contributing to the market growth of UHMWPE. Its resistance to fuels, lubricants, and other automotive fluids makes it suitable for various components, including fuel tanks and seals. In aerospace, UHMWPE's chemical resistance and lightweight properties make it valuable for interior components and fuel system parts.

As environmental regulations become more stringent, industries are seeking materials that can withstand aggressive cleaning agents and reduce chemical leaching. UHMWPE's ability to meet these requirements is driving its adoption in food processing equipment, laboratory apparatus, and consumer goods packaging.

The market for UHMWPE is expected to continue its growth trajectory, with emerging applications in battery separators for electric vehicles and advanced filtration technologies further expanding its potential. The material's unique combination of chemical resistance and other desirable properties positions it as a key player in addressing the evolving needs of various industries facing chemical challenges.

Current State and Challenges

Ultra-high-molecular-weight polyethylene (UHMWPE) has gained significant attention in various industries due to its exceptional chemical resistance. The current state of UHMWPE technology showcases remarkable advancements, yet it also faces several challenges that researchers and manufacturers are actively addressing.

UHMWPE's chemical resistance stems from its unique molecular structure, characterized by extremely long chains of ethylene monomers. This structure results in a high degree of crystallinity and entanglement, which significantly impedes the penetration of chemical agents. The material's resistance to a wide range of chemicals, including acids, bases, and organic solvents, has made it invaluable in applications such as chemical processing equipment, laboratory apparatus, and protective gear.

Recent developments in UHMWPE technology have focused on enhancing its already impressive chemical resistance. Researchers have explored various methods, including cross-linking techniques and the incorporation of nanoparticles, to further improve the material's barrier properties. These advancements have led to UHMWPE variants with even greater resistance to aggressive chemicals and improved performance in extreme environments.

Despite these achievements, several challenges persist in the field of UHMWPE chemical resistance. One significant issue is the material's susceptibility to oxidative degradation, particularly in the presence of certain chemicals and elevated temperatures. This degradation can compromise the long-term performance and reliability of UHMWPE in critical applications.

Another challenge lies in balancing chemical resistance with other desirable properties. Efforts to enhance chemical resistance through methods like cross-linking can sometimes lead to reduced mechanical properties, such as decreased toughness or impact resistance. Finding the optimal balance between chemical resistance and other performance characteristics remains an ongoing area of research and development.

The processing of UHMWPE also presents challenges, particularly in achieving uniform properties throughout the material. The high molecular weight that contributes to its exceptional chemical resistance also makes it difficult to process using conventional methods. This can lead to variations in chemical resistance across different parts of a manufactured component, potentially compromising its overall performance.

Geographically, the development and production of chemically resistant UHMWPE are concentrated in regions with advanced polymer research facilities and manufacturing capabilities. North America, Western Europe, and parts of Asia, particularly Japan and South Korea, are at the forefront of UHMWPE innovation. However, emerging economies are increasingly investing in this technology, recognizing its potential in various industrial applications.

In conclusion, while UHMWPE has achieved remarkable success in chemical resistance, ongoing research and development efforts are crucial to addressing current limitations and unlocking new possibilities for this versatile material.

UHMWPE's chemical resistance stems from its unique molecular structure, characterized by extremely long chains of ethylene monomers. This structure results in a high degree of crystallinity and entanglement, which significantly impedes the penetration of chemical agents. The material's resistance to a wide range of chemicals, including acids, bases, and organic solvents, has made it invaluable in applications such as chemical processing equipment, laboratory apparatus, and protective gear.

Recent developments in UHMWPE technology have focused on enhancing its already impressive chemical resistance. Researchers have explored various methods, including cross-linking techniques and the incorporation of nanoparticles, to further improve the material's barrier properties. These advancements have led to UHMWPE variants with even greater resistance to aggressive chemicals and improved performance in extreme environments.

Despite these achievements, several challenges persist in the field of UHMWPE chemical resistance. One significant issue is the material's susceptibility to oxidative degradation, particularly in the presence of certain chemicals and elevated temperatures. This degradation can compromise the long-term performance and reliability of UHMWPE in critical applications.

Another challenge lies in balancing chemical resistance with other desirable properties. Efforts to enhance chemical resistance through methods like cross-linking can sometimes lead to reduced mechanical properties, such as decreased toughness or impact resistance. Finding the optimal balance between chemical resistance and other performance characteristics remains an ongoing area of research and development.

The processing of UHMWPE also presents challenges, particularly in achieving uniform properties throughout the material. The high molecular weight that contributes to its exceptional chemical resistance also makes it difficult to process using conventional methods. This can lead to variations in chemical resistance across different parts of a manufactured component, potentially compromising its overall performance.

Geographically, the development and production of chemically resistant UHMWPE are concentrated in regions with advanced polymer research facilities and manufacturing capabilities. North America, Western Europe, and parts of Asia, particularly Japan and South Korea, are at the forefront of UHMWPE innovation. However, emerging economies are increasingly investing in this technology, recognizing its potential in various industrial applications.

In conclusion, while UHMWPE has achieved remarkable success in chemical resistance, ongoing research and development efforts are crucial to addressing current limitations and unlocking new possibilities for this versatile material.

Chemical Resistance Mechanisms

01 Chemical resistance properties of UHMWPE

UHMWPE exhibits excellent chemical resistance to a wide range of substances, including acids, bases, and organic solvents. This property makes it suitable for applications in harsh chemical environments, such as chemical processing equipment, storage tanks, and laboratory equipment.- Chemical resistance properties of UHMWPE: UHMWPE exhibits excellent chemical resistance to a wide range of substances, including acids, bases, and organic solvents. This property makes it suitable for applications in harsh chemical environments, such as chemical processing equipment, storage tanks, and laboratory equipment.

- Modification techniques to enhance chemical resistance: Various modification techniques can be employed to further improve the chemical resistance of UHMWPE. These may include crosslinking, surface treatments, or the incorporation of additives. Such modifications can extend the material's resistance to specific chemicals or extreme conditions.

- Applications in corrosive environments: The superior chemical resistance of UHMWPE makes it an ideal material for use in corrosive environments. It is commonly used in the manufacturing of pipes, fittings, and linings for chemical processing plants, as well as in the production of protective gear and equipment for handling hazardous materials.

- Testing and characterization of chemical resistance: Various methods and standards are used to test and characterize the chemical resistance of UHMWPE. These may include immersion tests, stress cracking resistance tests, and long-term exposure studies. Such testing is crucial for determining the material's suitability for specific applications and ensuring its performance in different chemical environments.

- Comparison with other polymers: UHMWPE's chemical resistance is often compared to that of other polymers to highlight its advantages in certain applications. Its resistance to a broad spectrum of chemicals, combined with its mechanical properties, often makes it a preferred choice over other materials in challenging chemical environments.

02 Enhancing chemical resistance through additives

The chemical resistance of UHMWPE can be further improved by incorporating specific additives or fillers. These additives can include antioxidants, stabilizers, or nanoparticles that enhance the material's resistance to chemical degradation and extend its service life in aggressive environments.Expand Specific Solutions03 Surface modification techniques for improved chemical resistance

Various surface modification techniques can be applied to UHMWPE to enhance its chemical resistance. These methods may include plasma treatment, chemical grafting, or the application of protective coatings, which can create a barrier against chemical attack while maintaining the bulk properties of the material.Expand Specific Solutions04 Chemical resistance in specific applications

UHMWPE's chemical resistance is particularly valuable in specific applications such as medical implants, food processing equipment, and industrial piping systems. In these contexts, the material's ability to withstand exposure to various chemicals, bodily fluids, and cleaning agents is crucial for long-term performance and safety.Expand Specific Solutions05 Testing and characterization of chemical resistance

Standardized testing methods and characterization techniques are employed to evaluate the chemical resistance of UHMWPE. These tests may involve exposing the material to various chemicals under controlled conditions and measuring changes in physical properties, weight, or appearance to determine its resistance to specific substances.Expand Specific Solutions

Key Industry Players

The market for Ultra-High Molecular Weight Polyethylene (UHMWPE) is in a mature growth stage, with a global market size expected to reach several billion dollars by 2025. The technology's exceptional chemical resistance has driven its adoption across various industries, including medical, aerospace, and industrial applications. Major players like Shanghai Lianle Chemical, Braskem, and Reliance Industries have established strong positions in the market. Universities such as Sichuan University and Swiss Federal Institute of Technology are contributing to ongoing research and development efforts. The technology's maturity is evident in the diverse product offerings from companies like Kingfa Sci. & Tech. and Wanhua Chemical Group, ranging from fibers to specialized resins. However, there is still room for innovation in enhancing UHMWPE's properties and expanding its applications.

Reliance Industries Ltd.

Technical Solution: Reliance Industries has focused on developing UHMWPE with enhanced chemical resistance through a combination of molecular engineering and blending techniques. Their approach involves the synthesis of UHMWPE with carefully controlled molecular weight and distribution, followed by blending with specially designed additives that enhance chemical resistance[8]. The company has also explored the use of co-polymerization techniques to incorporate chemical-resistant monomers directly into the UHMWPE structure. Reliance's UHMWPE products have demonstrated exceptional resistance to a variety of industrial chemicals, including hydrocarbons and chlorinated solvents[9]. The company has also developed grades of UHMWPE specifically tailored for use in chemical processing equipment, where resistance to multiple types of chemicals is crucial.

Strengths: Versatile chemical resistance through blending and co-polymerization; Tailored solutions for specific industrial applications. Weaknesses: Potential trade-offs between chemical resistance and other properties; Complexity in manufacturing process.

Braskem SA

Technical Solution: Braskem has pioneered a novel catalytic system for UHMWPE production that results in a unique molecular structure with enhanced chemical resistance. Their process involves the use of specialized metallocene catalysts that allow for precise control over the polymer chain length and branching[4]. This results in UHMWPE with a more uniform molecular weight distribution and higher crystallinity, contributing to its exceptional chemical resistance. Braskem's UHMWPE demonstrates particular resistance to oxidative degradation and maintains its properties even in the presence of strong oxidizing agents[5]. The company has also developed additives that can be incorporated during polymerization to further enhance chemical resistance for specific applications.

Strengths: Excellent resistance to oxidative degradation; Customizable chemical resistance properties. Weaknesses: Potentially higher raw material costs; May require specialized processing equipment.

Core UHMWPE Innovations

Ultra-high molecular weight polyethylene and preparation method therefor

PatentPendingEP4286420A1

Innovation

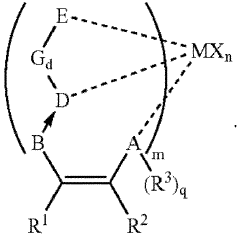

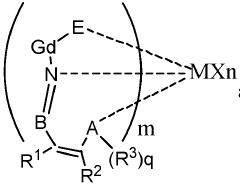

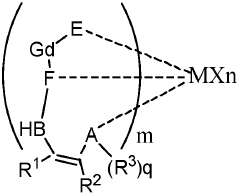

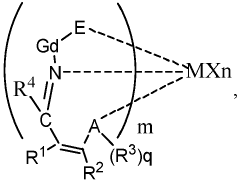

- The use of a supported non-metallocene catalyst system with an alkane or mixed alkane solvent in the ethylene slurry polymerization process, in the absence of hydrogen gas, to produce UHMWPE with low metal element content and high mechanical properties, allowing for stable polymerization and simplified post-treatment.

Ultra-high molecular weight polyethylene

PatentWO2011089017A1

Innovation

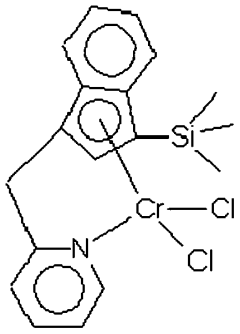

- The use of a blend of two metallocene-type catalysts, with Hafnium (Hf) and Chromium (Cr) as catalyst residues, to produce UHMW-PE with medium density and enhanced Charpy impact resistance, achieving a synergistic effect that improves both abrasion and impact resistance, and maintaining a suitable average grain size.

Environmental Impact Assessment

The environmental impact of Ultra-High Molecular Weight Polyethylene (UHMWPE) is a critical consideration in its production, use, and disposal. UHMWPE's exceptional chemical resistance, while beneficial for many applications, presents challenges in terms of environmental sustainability.

During the production process of UHMWPE, the primary environmental concerns are related to energy consumption and emissions. The high-pressure polymerization process requires significant energy input, contributing to greenhouse gas emissions if not sourced from renewable energy. Additionally, the use of catalysts and solvents in the production process may lead to potential chemical waste that requires proper management and disposal.

In its use phase, UHMWPE's durability and chemical resistance contribute positively to environmental sustainability. The material's longevity reduces the need for frequent replacements, thereby decreasing overall resource consumption and waste generation. Its resistance to chemicals also prevents leaching of harmful substances into the environment during use, particularly in applications such as chemical storage tanks or marine equipment.

However, the end-of-life stage of UHMWPE products presents significant environmental challenges. The same properties that make UHMWPE resistant to chemicals also make it highly resistant to biodegradation. As a result, UHMWPE products can persist in the environment for extended periods if not properly managed. This persistence raises concerns about potential accumulation in ecosystems, particularly in marine environments where plastic pollution is a growing issue.

Recycling UHMWPE is technically feasible but often economically challenging due to its high melting point and the specialized equipment required. The material's resistance to solvents also complicates chemical recycling processes. Consequently, a significant portion of UHMWPE waste may end up in landfills or incineration facilities, contributing to environmental pollution and greenhouse gas emissions.

Efforts to mitigate the environmental impact of UHMWPE are ongoing. Research into more sustainable production methods, including the use of bio-based feedstocks and green chemistry principles, aims to reduce the carbon footprint of UHMWPE manufacturing. Additionally, advancements in recycling technologies, such as improved mechanical recycling processes and novel chemical recycling approaches, are being explored to enhance the circularity of UHMWPE products.

The development of biodegradable additives or alternative materials with similar performance characteristics to UHMWPE is another area of active research. These innovations aim to address the end-of-life environmental challenges while maintaining the beneficial properties that make UHMWPE valuable in various applications.

During the production process of UHMWPE, the primary environmental concerns are related to energy consumption and emissions. The high-pressure polymerization process requires significant energy input, contributing to greenhouse gas emissions if not sourced from renewable energy. Additionally, the use of catalysts and solvents in the production process may lead to potential chemical waste that requires proper management and disposal.

In its use phase, UHMWPE's durability and chemical resistance contribute positively to environmental sustainability. The material's longevity reduces the need for frequent replacements, thereby decreasing overall resource consumption and waste generation. Its resistance to chemicals also prevents leaching of harmful substances into the environment during use, particularly in applications such as chemical storage tanks or marine equipment.

However, the end-of-life stage of UHMWPE products presents significant environmental challenges. The same properties that make UHMWPE resistant to chemicals also make it highly resistant to biodegradation. As a result, UHMWPE products can persist in the environment for extended periods if not properly managed. This persistence raises concerns about potential accumulation in ecosystems, particularly in marine environments where plastic pollution is a growing issue.

Recycling UHMWPE is technically feasible but often economically challenging due to its high melting point and the specialized equipment required. The material's resistance to solvents also complicates chemical recycling processes. Consequently, a significant portion of UHMWPE waste may end up in landfills or incineration facilities, contributing to environmental pollution and greenhouse gas emissions.

Efforts to mitigate the environmental impact of UHMWPE are ongoing. Research into more sustainable production methods, including the use of bio-based feedstocks and green chemistry principles, aims to reduce the carbon footprint of UHMWPE manufacturing. Additionally, advancements in recycling technologies, such as improved mechanical recycling processes and novel chemical recycling approaches, are being explored to enhance the circularity of UHMWPE products.

The development of biodegradable additives or alternative materials with similar performance characteristics to UHMWPE is another area of active research. These innovations aim to address the end-of-life environmental challenges while maintaining the beneficial properties that make UHMWPE valuable in various applications.

Regulatory Compliance Overview

The regulatory landscape surrounding Ultra-High Molecular Weight Polyethylene (UHMWPE) is complex and multifaceted, reflecting the material's widespread use across various industries. In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating UHMWPE, particularly in medical applications. The FDA has established specific guidelines for the use of UHMWPE in implantable medical devices, focusing on its biocompatibility, mechanical properties, and long-term stability.

The Environmental Protection Agency (EPA) also oversees aspects of UHMWPE production and disposal, ensuring compliance with environmental regulations. This includes monitoring emissions during manufacturing processes and addressing end-of-life considerations for UHMWPE products. The material's exceptional chemical resistance contributes to its environmental durability, which can be both an advantage and a challenge from a regulatory perspective.

In the European Union, UHMWPE falls under the purview of the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. This comprehensive framework assesses the potential impacts of chemical substances on human health and the environment. UHMWPE manufacturers must comply with REACH requirements, including registration of substances and adherence to specific use restrictions where applicable.

The chemical resistance of UHMWPE also necessitates compliance with transportation regulations. The material's inertness to most chemicals makes it an ideal choice for containing hazardous substances during transport. However, this use is subject to strict guidelines set by organizations such as the International Maritime Organization (IMO) and the International Air Transport Association (IATA).

In the food industry, UHMWPE's chemical resistance has led to its widespread use in food processing equipment. Consequently, it must meet the stringent standards set by food safety authorities, including the FDA in the US and the European Food Safety Authority (EFSA) in the EU. These regulations focus on ensuring that UHMWPE does not leach harmful substances into food products, even when exposed to various chemical environments.

The chemical industry also heavily utilizes UHMWPE, necessitating compliance with occupational safety and health regulations. Organizations such as the Occupational Safety and Health Administration (OSHA) in the US and the European Agency for Safety and Health at Work (EU-OSHA) provide guidelines for the safe handling and use of UHMWPE in industrial settings, particularly in environments where it may be exposed to harsh chemicals.

As research continues to uncover new applications for UHMWPE, regulatory bodies are likely to adapt and evolve their guidelines. This ongoing process ensures that the material's exceptional chemical resistance is leveraged safely and effectively across various industries, balancing innovation with public health and environmental protection.

The Environmental Protection Agency (EPA) also oversees aspects of UHMWPE production and disposal, ensuring compliance with environmental regulations. This includes monitoring emissions during manufacturing processes and addressing end-of-life considerations for UHMWPE products. The material's exceptional chemical resistance contributes to its environmental durability, which can be both an advantage and a challenge from a regulatory perspective.

In the European Union, UHMWPE falls under the purview of the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. This comprehensive framework assesses the potential impacts of chemical substances on human health and the environment. UHMWPE manufacturers must comply with REACH requirements, including registration of substances and adherence to specific use restrictions where applicable.

The chemical resistance of UHMWPE also necessitates compliance with transportation regulations. The material's inertness to most chemicals makes it an ideal choice for containing hazardous substances during transport. However, this use is subject to strict guidelines set by organizations such as the International Maritime Organization (IMO) and the International Air Transport Association (IATA).

In the food industry, UHMWPE's chemical resistance has led to its widespread use in food processing equipment. Consequently, it must meet the stringent standards set by food safety authorities, including the FDA in the US and the European Food Safety Authority (EFSA) in the EU. These regulations focus on ensuring that UHMWPE does not leach harmful substances into food products, even when exposed to various chemical environments.

The chemical industry also heavily utilizes UHMWPE, necessitating compliance with occupational safety and health regulations. Organizations such as the Occupational Safety and Health Administration (OSHA) in the US and the European Agency for Safety and Health at Work (EU-OSHA) provide guidelines for the safe handling and use of UHMWPE in industrial settings, particularly in environments where it may be exposed to harsh chemicals.

As research continues to uncover new applications for UHMWPE, regulatory bodies are likely to adapt and evolve their guidelines. This ongoing process ensures that the material's exceptional chemical resistance is leveraged safely and effectively across various industries, balancing innovation with public health and environmental protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!