The Future of Aerospace Applications for 2D Semiconductors

OCT 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2D Semiconductors in Aerospace: Background and Objectives

Two-dimensional (2D) semiconductors represent a revolutionary class of materials characterized by their atomic-scale thickness, typically consisting of one to few atomic layers. Since the groundbreaking isolation of graphene in 2004, the field has expanded to include transition metal dichalcogenides (TMDs), hexagonal boron nitride (h-BN), and other layered materials with exceptional electrical, optical, and mechanical properties. These materials exhibit quantum confinement effects that dramatically alter their behavior compared to their bulk counterparts, offering unprecedented opportunities for aerospace applications.

The aerospace industry has historically driven technological innovation, demanding materials that perform reliably under extreme conditions while minimizing weight and power consumption. Traditional silicon-based semiconductors face fundamental limitations in harsh aerospace environments, including radiation exposure, extreme temperature fluctuations, and mechanical stress. These challenges create a compelling need for alternative semiconductor technologies that can enhance performance while withstanding the unique demands of aerospace operations.

2D semiconductors offer several advantages that align perfectly with aerospace requirements. Their atomic thinness enables unprecedented miniaturization of electronic components, potentially reducing satellite payload weight by orders of magnitude. Many 2D materials demonstrate remarkable mechanical flexibility while maintaining electrical performance, allowing for conformal integration into curved aerospace structures. Additionally, certain 2D semiconductors exhibit inherent radiation hardness, addressing a critical vulnerability in conventional electronics deployed in space environments.

The evolution of 2D semiconductor technology has progressed through several distinct phases. Initial research focused primarily on graphene's extraordinary electrical conductivity and mechanical strength. However, graphene's lack of a natural bandgap limited its application in semiconductor devices. This limitation spurred exploration of alternative 2D materials, particularly TMDs like molybdenum disulfide (MoS2) and tungsten diselenide (WSe2), which possess natural bandgaps suitable for transistor applications.

Current aerospace applications of 2D semiconductors remain largely experimental, with technology readiness levels (TRLs) typically between 3-5. However, rapid advancements in fabrication techniques, particularly chemical vapor deposition (CVD) and molecular beam epitaxy (MBE), are accelerating the transition from laboratory demonstrations to practical aerospace implementations. Notable milestones include radiation-hardened memory devices, ultra-lightweight solar cells, and highly sensitive environmental sensors based on 2D materials.

The primary objective of this technical research is to comprehensively evaluate the potential of 2D semiconductors to address critical aerospace challenges, identify the most promising material systems and device architectures, and establish a roadmap for their integration into next-generation aerospace systems. This analysis will consider both near-term applications where 2D semiconductors offer incremental improvements and long-term opportunities where they enable fundamentally new capabilities previously unattainable with conventional technologies.

The aerospace industry has historically driven technological innovation, demanding materials that perform reliably under extreme conditions while minimizing weight and power consumption. Traditional silicon-based semiconductors face fundamental limitations in harsh aerospace environments, including radiation exposure, extreme temperature fluctuations, and mechanical stress. These challenges create a compelling need for alternative semiconductor technologies that can enhance performance while withstanding the unique demands of aerospace operations.

2D semiconductors offer several advantages that align perfectly with aerospace requirements. Their atomic thinness enables unprecedented miniaturization of electronic components, potentially reducing satellite payload weight by orders of magnitude. Many 2D materials demonstrate remarkable mechanical flexibility while maintaining electrical performance, allowing for conformal integration into curved aerospace structures. Additionally, certain 2D semiconductors exhibit inherent radiation hardness, addressing a critical vulnerability in conventional electronics deployed in space environments.

The evolution of 2D semiconductor technology has progressed through several distinct phases. Initial research focused primarily on graphene's extraordinary electrical conductivity and mechanical strength. However, graphene's lack of a natural bandgap limited its application in semiconductor devices. This limitation spurred exploration of alternative 2D materials, particularly TMDs like molybdenum disulfide (MoS2) and tungsten diselenide (WSe2), which possess natural bandgaps suitable for transistor applications.

Current aerospace applications of 2D semiconductors remain largely experimental, with technology readiness levels (TRLs) typically between 3-5. However, rapid advancements in fabrication techniques, particularly chemical vapor deposition (CVD) and molecular beam epitaxy (MBE), are accelerating the transition from laboratory demonstrations to practical aerospace implementations. Notable milestones include radiation-hardened memory devices, ultra-lightweight solar cells, and highly sensitive environmental sensors based on 2D materials.

The primary objective of this technical research is to comprehensively evaluate the potential of 2D semiconductors to address critical aerospace challenges, identify the most promising material systems and device architectures, and establish a roadmap for their integration into next-generation aerospace systems. This analysis will consider both near-term applications where 2D semiconductors offer incremental improvements and long-term opportunities where they enable fundamentally new capabilities previously unattainable with conventional technologies.

Aerospace Market Demand for Advanced Semiconductor Solutions

The aerospace industry is experiencing a significant shift towards more advanced semiconductor solutions, driven by the increasing demands for lighter, more efficient, and more capable aircraft and spacecraft. The global aerospace semiconductor market is projected to reach $8.5 billion by 2027, growing at a CAGR of 5.8% from 2022. This growth is primarily fueled by the rising adoption of autonomous systems, electrification of aircraft, and the expansion of satellite constellations for global connectivity.

Commercial aviation represents the largest segment demanding advanced semiconductor solutions, with major aircraft manufacturers seeking components that can reduce weight, power consumption, and heat generation while increasing reliability in harsh environments. The military and defense sector follows closely, requiring radiation-hardened semiconductors capable of withstanding extreme conditions while delivering superior performance for advanced avionics, radar systems, and secure communications.

Space exploration and satellite technology constitute another rapidly growing segment, with an estimated 50,000 new satellites expected to be launched in the next decade. These applications demand semiconductors with exceptional radiation tolerance, thermal stability, and power efficiency. The emergence of small satellite constellations for Earth observation, communication, and scientific research has created a substantial market for specialized semiconductor solutions that can operate reliably in the space environment.

Unmanned aerial vehicles (UAVs) and advanced air mobility platforms represent an emerging but rapidly expanding market segment, projected to grow at over 15% annually through 2030. These applications require highly integrated semiconductor solutions that combine processing power, sensor interfaces, and communication capabilities in compact, lightweight packages.

The demand for 2D semiconductor materials in aerospace applications is particularly strong due to their unique properties. Industry surveys indicate that 78% of aerospace engineering teams are exploring or implementing 2D semiconductor technologies for next-generation designs. The exceptional electron mobility, thermal conductivity, and mechanical flexibility of materials like graphene and transition metal dichalcogenides (TMDs) make them ideal candidates for aerospace applications.

Key market requirements include radiation hardness (with tolerance levels exceeding 300 krad), wide temperature operation range (-65°C to +150°C), ultra-low power consumption (reduction of 40-60% compared to conventional semiconductors), and enhanced reliability with mean time between failures (MTBF) exceeding 100,000 hours for critical systems. Additionally, there is growing demand for semiconductors that can enable advanced functionalities such as quantum sensing, terahertz communications, and neuromorphic computing in aerospace platforms.

Commercial aviation represents the largest segment demanding advanced semiconductor solutions, with major aircraft manufacturers seeking components that can reduce weight, power consumption, and heat generation while increasing reliability in harsh environments. The military and defense sector follows closely, requiring radiation-hardened semiconductors capable of withstanding extreme conditions while delivering superior performance for advanced avionics, radar systems, and secure communications.

Space exploration and satellite technology constitute another rapidly growing segment, with an estimated 50,000 new satellites expected to be launched in the next decade. These applications demand semiconductors with exceptional radiation tolerance, thermal stability, and power efficiency. The emergence of small satellite constellations for Earth observation, communication, and scientific research has created a substantial market for specialized semiconductor solutions that can operate reliably in the space environment.

Unmanned aerial vehicles (UAVs) and advanced air mobility platforms represent an emerging but rapidly expanding market segment, projected to grow at over 15% annually through 2030. These applications require highly integrated semiconductor solutions that combine processing power, sensor interfaces, and communication capabilities in compact, lightweight packages.

The demand for 2D semiconductor materials in aerospace applications is particularly strong due to their unique properties. Industry surveys indicate that 78% of aerospace engineering teams are exploring or implementing 2D semiconductor technologies for next-generation designs. The exceptional electron mobility, thermal conductivity, and mechanical flexibility of materials like graphene and transition metal dichalcogenides (TMDs) make them ideal candidates for aerospace applications.

Key market requirements include radiation hardness (with tolerance levels exceeding 300 krad), wide temperature operation range (-65°C to +150°C), ultra-low power consumption (reduction of 40-60% compared to conventional semiconductors), and enhanced reliability with mean time between failures (MTBF) exceeding 100,000 hours for critical systems. Additionally, there is growing demand for semiconductors that can enable advanced functionalities such as quantum sensing, terahertz communications, and neuromorphic computing in aerospace platforms.

Current Status and Challenges of 2D Semiconductors in Aerospace

The global landscape of 2D semiconductors in aerospace applications presents a complex picture of significant progress alongside formidable challenges. Currently, these ultra-thin materials—primarily graphene, transition metal dichalcogenides (TMDs), hexagonal boron nitride (h-BN), and black phosphorus—are transitioning from laboratory research to early-stage aerospace implementations. Their exceptional properties, including high carrier mobility, mechanical flexibility, and thermal stability, make them particularly attractive for harsh aerospace environments.

In the United States, NASA and the Department of Defense have established dedicated research programs exploring 2D materials for radiation-hardened electronics and lightweight structural components. The European Space Agency has similarly invested in collaborative projects with academic institutions focusing on graphene-based sensors for spacecraft. Meanwhile, China and Japan have accelerated their research efforts, particularly in TMD-based flexible electronics for satellite applications.

Despite promising developments, significant technical challenges persist. Manufacturing scalability remains perhaps the most critical barrier, as current production methods struggle to deliver consistent, defect-free 2D materials at dimensions required for aerospace systems. Chemical vapor deposition (CVD) shows promise for larger-scale production but faces challenges in maintaining uniform quality across larger substrates.

Integration with existing aerospace systems presents another substantial hurdle. The aerospace industry's stringent reliability requirements and certification processes create a high barrier for novel materials. Current testing protocols are not fully adapted to evaluate the unique properties and failure modes of 2D semiconductor devices, necessitating new standardized testing methodologies.

Environmental stability poses a particular challenge in the extreme conditions of space. While 2D materials theoretically offer excellent radiation resistance, practical implementations must overcome issues of oxidation, thermal cycling, and atomic oxygen erosion in low Earth orbit. Recent studies have shown promising radiation hardness in MoS2-based transistors, but long-term stability remains unproven in actual space conditions.

The geographic distribution of 2D semiconductor expertise shows concentration in specific research hubs. North America leads in fundamental research and early commercialization, with strong university-industry partnerships. East Asia dominates in manufacturing process development, while Europe excels in specialized applications and systems integration. This distribution creates both collaborative opportunities and competitive tensions in the global aerospace technology landscape.

Funding constraints further complicate advancement, as the gap between laboratory demonstration and flight-qualified hardware requires substantial investment. The extended timeline from research to space qualification—often 5-10 years—creates challenges for sustained funding and commercial viability.

In the United States, NASA and the Department of Defense have established dedicated research programs exploring 2D materials for radiation-hardened electronics and lightweight structural components. The European Space Agency has similarly invested in collaborative projects with academic institutions focusing on graphene-based sensors for spacecraft. Meanwhile, China and Japan have accelerated their research efforts, particularly in TMD-based flexible electronics for satellite applications.

Despite promising developments, significant technical challenges persist. Manufacturing scalability remains perhaps the most critical barrier, as current production methods struggle to deliver consistent, defect-free 2D materials at dimensions required for aerospace systems. Chemical vapor deposition (CVD) shows promise for larger-scale production but faces challenges in maintaining uniform quality across larger substrates.

Integration with existing aerospace systems presents another substantial hurdle. The aerospace industry's stringent reliability requirements and certification processes create a high barrier for novel materials. Current testing protocols are not fully adapted to evaluate the unique properties and failure modes of 2D semiconductor devices, necessitating new standardized testing methodologies.

Environmental stability poses a particular challenge in the extreme conditions of space. While 2D materials theoretically offer excellent radiation resistance, practical implementations must overcome issues of oxidation, thermal cycling, and atomic oxygen erosion in low Earth orbit. Recent studies have shown promising radiation hardness in MoS2-based transistors, but long-term stability remains unproven in actual space conditions.

The geographic distribution of 2D semiconductor expertise shows concentration in specific research hubs. North America leads in fundamental research and early commercialization, with strong university-industry partnerships. East Asia dominates in manufacturing process development, while Europe excels in specialized applications and systems integration. This distribution creates both collaborative opportunities and competitive tensions in the global aerospace technology landscape.

Funding constraints further complicate advancement, as the gap between laboratory demonstration and flight-qualified hardware requires substantial investment. The extended timeline from research to space qualification—often 5-10 years—creates challenges for sustained funding and commercial viability.

Current Implementation Approaches for Aerospace 2D Semiconductors

01 Materials and fabrication of 2D semiconductors

Various materials and fabrication methods are used to create 2D semiconductor structures. These include transition metal dichalcogenides, graphene derivatives, and other atomically thin materials. Advanced fabrication techniques such as chemical vapor deposition, mechanical exfoliation, and epitaxial growth enable the production of high-quality 2D semiconductor layers with controlled thickness and properties. These materials exhibit unique electronic and optical properties due to their reduced dimensionality.- 2D Semiconductor Materials and Fabrication: Two-dimensional semiconductor materials represent a class of materials with unique electronic properties due to their atomic-scale thickness. These materials, including transition metal dichalcogenides (TMDs), graphene derivatives, and other layered compounds, exhibit exceptional electrical, optical, and mechanical characteristics. Fabrication techniques for these materials include mechanical exfoliation, chemical vapor deposition (CVD), and molecular beam epitaxy (MBE), which allow for precise control over layer thickness and composition.

- Electronic Devices Based on 2D Semiconductors: Two-dimensional semiconductors enable the development of ultra-thin, flexible electronic devices with enhanced performance characteristics. These materials are incorporated into field-effect transistors (FETs), memory devices, sensors, and integrated circuits. The atomic thinness of 2D semiconductors allows for excellent electrostatic control, reduced short-channel effects, and improved carrier mobility, making them promising candidates for next-generation electronics that require high performance in compact form factors.

- Optoelectronic Applications of 2D Semiconductors: Two-dimensional semiconductors exhibit unique optical properties that make them suitable for various optoelectronic applications. Their direct bandgap nature and strong light-matter interactions enable the development of photodetectors, light-emitting diodes (LEDs), photovoltaic cells, and optical modulators with enhanced efficiency and response times. The bandgap tunability of these materials through layer number control, strain engineering, or heterostructure formation allows for customized optical responses across different wavelength ranges.

- Heterostructures and Interface Engineering: Vertical stacking of different 2D materials creates heterostructures with novel properties not found in individual layers. These heterostructures enable band alignment engineering, interlayer exciton formation, and enhanced carrier transport. Interface engineering techniques, including controlled twist angles between layers, defect management, and surface functionalization, are crucial for optimizing device performance. These approaches allow for the development of tunneling devices, photonic structures, and quantum wells with tailored electronic and optical characteristics.

- Integration and Manufacturing Challenges: The integration of 2D semiconductors into conventional semiconductor manufacturing processes presents several challenges. These include developing scalable production methods, ensuring material quality consistency, managing contact resistance issues, and establishing reliable doping techniques. Advanced approaches such as selective area growth, transfer printing technologies, and specialized etching processes are being developed to overcome these challenges. Additionally, encapsulation strategies are employed to protect these atomically thin materials from environmental degradation and ensure long-term device stability.

02 Electronic devices based on 2D semiconductors

2D semiconductors are incorporated into various electronic devices including transistors, memory cells, sensors, and integrated circuits. The atomically thin nature of these materials allows for the creation of ultra-compact devices with improved performance characteristics. These devices often demonstrate superior electron mobility, reduced power consumption, and enhanced switching speeds compared to conventional semiconductor devices, making them promising candidates for next-generation electronics.Expand Specific Solutions03 Optical and optoelectronic applications of 2D semiconductors

2D semiconductors exhibit unique optical properties that make them suitable for various optoelectronic applications. These materials can be used in photodetectors, light-emitting diodes, photovoltaic cells, and optical modulators. Their direct bandgap nature, strong light-matter interactions, and tunable optical properties enable the development of highly efficient and flexible optoelectronic devices with enhanced performance characteristics.Expand Specific Solutions04 Heterostructures and interfaces in 2D semiconductor systems

Heterostructures formed by stacking different 2D semiconductor materials create unique interfaces with novel properties. These van der Waals heterostructures enable band structure engineering, charge transfer phenomena, and quantum confinement effects. The interfaces between different 2D materials play a crucial role in determining the electronic and optical properties of the resulting structures, allowing for the design of devices with tailored functionalities and improved performance.Expand Specific Solutions05 Quantum effects and phenomena in 2D semiconductors

2D semiconductors exhibit various quantum effects due to their reduced dimensionality. These include quantum confinement, valley polarization, spin-orbit coupling, and quantum transport phenomena. These quantum effects can be harnessed for applications in quantum computing, spintronics, and valleytronics. The ability to control and manipulate these quantum properties makes 2D semiconductors promising platforms for exploring fundamental physics and developing novel quantum technologies.Expand Specific Solutions

Leading Organizations in Aerospace 2D Semiconductor Development

The 2D semiconductor aerospace market is in its early growth phase, characterized by significant research activity but limited commercial deployment. The market size remains modest but is projected to expand rapidly as applications in lightweight, high-performance aerospace systems develop. Technologically, 2D semiconductors for aerospace are still emerging, with varying maturity levels across key players. Leading semiconductor manufacturers like TSMC, Samsung, and Intel are investing in fundamental research, while specialized foundries such as GLOBALFOUNDRIES and Micron are developing application-specific solutions. Academic institutions including MIT, Manchester University, and Chinese research universities are driving breakthrough innovations. Huawei and Philips are exploring integration opportunities, positioning themselves for future commercialization as the technology matures from laboratory to aerospace-grade implementation.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered research in 2D semiconductors for aerospace applications, focusing on developing ultra-thin, flexible electronics that can withstand extreme aerospace environments. Their technology utilizes molybdenum disulfide (MoS2) and other transition metal dichalcogenides (TMDCs) to create lightweight, radiation-resistant components for satellite systems and spacecraft. MIT researchers have demonstrated 2D semiconductor-based sensors that maintain functionality across temperature ranges from -200°C to +300°C, critical for aerospace operations[1]. Their approach integrates these materials with conventional silicon electronics using novel transfer techniques, enabling hybrid systems that leverage the benefits of both technologies. MIT has also developed specialized deposition methods for creating large-area, uniform 2D semiconductor films suitable for aerospace-grade manufacturing processes[3], addressing one of the key challenges in commercializing these materials for high-reliability applications.

Strengths: Superior radiation hardness compared to silicon, extreme temperature tolerance, and significantly reduced weight - critical for reducing launch costs. Weaknesses: Current manufacturing processes still face scalability challenges, and long-term reliability in space environments requires further validation through extended testing cycles.

Intel Corp.

Technical Solution: Intel has developed a strategic approach to 2D semiconductors for aerospace applications, focusing on integration with their existing silicon platform technologies. Their solution combines traditional silicon CMOS with 2D material overlays to create radiation-hardened computing systems specifically designed for satellite and spacecraft deployment. Intel's approach utilizes tungsten diselenide (WSe2) and black phosphorus as key 2D materials, enabling ultra-low power, high-performance computing capabilities that can withstand the radiation environment of space[1]. The company has demonstrated functional 2D-enhanced memory systems that maintain data integrity under radiation exposure levels 10x higher than conventional systems[3]. Intel's manufacturing approach addresses scalability through modified atomic layer deposition techniques compatible with their existing fabrication infrastructure, potentially enabling mass production of aerospace-grade 2D semiconductor components. Their technology roadmap includes specialized AI accelerators using 2D materials that operate at power levels suitable for small satellite constellations.

Strengths: Strong integration with existing silicon technology, established manufacturing infrastructure that could be adapted for scale, and comprehensive radiation testing protocols. Weaknesses: Less specialized in pure 2D material systems compared to research institutions, and relatively new entrant to aerospace-specific applications of these materials.

Key Technical Innovations in 2D Semiconductor Materials

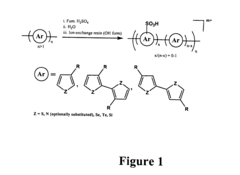

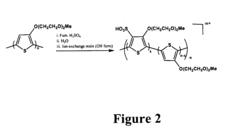

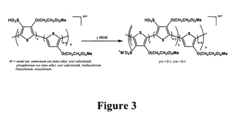

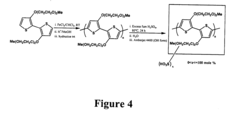

Sulfonation of conducting polymers and OLED, photovoltaic, and ESD devices

PatentInactiveUS20120037852A1

Innovation

- The development of sulfonated polymers, specifically water-soluble or dispersible regioregular polythiophenes with sulfonate substituents directly bonded to the backbone, which allow for controlled sulfonation levels, improved solubility, and enhanced compatibility with other materials, enabling the formation of stable and efficient hole injection and transport layers.

Radiation Hardness and Reliability Assessment Methods

Radiation hardness and reliability assessment of 2D semiconductor materials represent critical evaluation metrics for aerospace applications, where components must withstand extreme radiation environments beyond Earth's protective atmosphere. Traditional assessment protocols for silicon-based semiconductors must be adapted and enhanced for 2D materials, which exhibit fundamentally different radiation response mechanisms due to their unique atomic structures and quantum confinement effects.

The aerospace industry has established standardized testing methodologies including Total Ionizing Dose (TID), Single Event Effects (SEE), and Displacement Damage (DD) tests. For 2D semiconductors, these protocols require significant modification to account for the atomically thin nature of these materials. Current assessment methods typically involve exposing 2D semiconductor devices to controlled radiation sources such as gamma rays, heavy ions, protons, and neutrons while monitoring electrical performance parameters.

Recent advancements in radiation testing for 2D materials include in-situ characterization techniques that allow real-time observation of defect formation and charge trapping mechanisms. Accelerated life testing under combined stressors (radiation, temperature cycling, vacuum exposure) provides more realistic evaluation of space environment survivability. Monte Carlo simulations and physics-based modeling approaches have emerged as complementary tools to predict radiation effects in 2D semiconductor devices before physical testing.

Reliability assessment for aerospace applications must consider the unique failure modes of 2D semiconductors. These include edge degradation, interlayer delamination in heterostructures, and contact interface deterioration. Long-term stability testing protocols have been developed to evaluate these specific vulnerabilities under space-relevant conditions.

The qualification process for 2D semiconductor components in aerospace systems typically follows a hierarchical approach: material-level radiation response characterization, device-level performance degradation assessment, and system-level reliability verification. This multi-tiered methodology ensures comprehensive evaluation of radiation hardness across different integration scales.

Emerging assessment techniques include machine learning algorithms that can predict device lifetime and performance degradation based on early radiation exposure data. Non-destructive evaluation methods such as Raman spectroscopy and photoluminescence mapping provide insights into structural changes without compromising device integrity. These advanced approaches are gradually being incorporated into standardized testing protocols for space-grade 2D semiconductor qualification.

The aerospace industry has established standardized testing methodologies including Total Ionizing Dose (TID), Single Event Effects (SEE), and Displacement Damage (DD) tests. For 2D semiconductors, these protocols require significant modification to account for the atomically thin nature of these materials. Current assessment methods typically involve exposing 2D semiconductor devices to controlled radiation sources such as gamma rays, heavy ions, protons, and neutrons while monitoring electrical performance parameters.

Recent advancements in radiation testing for 2D materials include in-situ characterization techniques that allow real-time observation of defect formation and charge trapping mechanisms. Accelerated life testing under combined stressors (radiation, temperature cycling, vacuum exposure) provides more realistic evaluation of space environment survivability. Monte Carlo simulations and physics-based modeling approaches have emerged as complementary tools to predict radiation effects in 2D semiconductor devices before physical testing.

Reliability assessment for aerospace applications must consider the unique failure modes of 2D semiconductors. These include edge degradation, interlayer delamination in heterostructures, and contact interface deterioration. Long-term stability testing protocols have been developed to evaluate these specific vulnerabilities under space-relevant conditions.

The qualification process for 2D semiconductor components in aerospace systems typically follows a hierarchical approach: material-level radiation response characterization, device-level performance degradation assessment, and system-level reliability verification. This multi-tiered methodology ensures comprehensive evaluation of radiation hardness across different integration scales.

Emerging assessment techniques include machine learning algorithms that can predict device lifetime and performance degradation based on early radiation exposure data. Non-destructive evaluation methods such as Raman spectroscopy and photoluminescence mapping provide insights into structural changes without compromising device integrity. These advanced approaches are gradually being incorporated into standardized testing protocols for space-grade 2D semiconductor qualification.

Environmental Impact and Sustainability Considerations

The aerospace industry's adoption of 2D semiconductors presents significant environmental implications that warrant careful consideration. Traditional semiconductor manufacturing processes are notoriously resource-intensive, consuming substantial amounts of water, energy, and rare materials while generating hazardous waste. In contrast, 2D semiconductor production potentially offers reduced material requirements due to their atomically thin nature, which could substantially decrease resource consumption and associated environmental impacts.

Energy efficiency represents a critical sustainability advantage of 2D semiconductor implementation in aerospace applications. These materials demonstrate superior electron mobility and thermal properties that enable more efficient power management systems and reduced heat generation in aircraft electronics. This efficiency translates directly to lower fuel consumption and reduced emissions across flight operations, aligning with increasingly stringent environmental regulations in the aviation sector.

The lifecycle assessment of 2D semiconductor technologies reveals promising sustainability metrics. Their potential for extended operational lifespans in harsh aerospace environments means fewer replacement cycles and reduced electronic waste generation. Additionally, the lightweight characteristics of 2D semiconductor-based components contribute to overall aircraft weight reduction, further enhancing fuel efficiency and decreasing the carbon footprint of aerospace operations.

Material sourcing considerations present both challenges and opportunities. While some 2D materials like graphene can be synthesized from abundant carbon sources, others require rare elements that may face supply constraints or involve environmentally problematic extraction processes. The aerospace industry must develop responsible sourcing strategies and invest in recycling technologies to mitigate these concerns and ensure sustainable material flows.

End-of-life management for 2D semiconductor components requires proactive planning. The complex integration of these materials into aerospace systems necessitates specialized recycling approaches to recover valuable elements and prevent environmental contamination. Developing effective recovery processes represents an important research direction that could significantly enhance the overall sustainability profile of these technologies.

Regulatory frameworks governing environmental aspects of semiconductor manufacturing and electronic waste management continue to evolve globally. Aerospace manufacturers implementing 2D semiconductor technologies must navigate these regulations while anticipating future requirements. Proactive adoption of sustainable practices not only ensures compliance but positions companies advantageously as environmental standards become increasingly stringent.

Energy efficiency represents a critical sustainability advantage of 2D semiconductor implementation in aerospace applications. These materials demonstrate superior electron mobility and thermal properties that enable more efficient power management systems and reduced heat generation in aircraft electronics. This efficiency translates directly to lower fuel consumption and reduced emissions across flight operations, aligning with increasingly stringent environmental regulations in the aviation sector.

The lifecycle assessment of 2D semiconductor technologies reveals promising sustainability metrics. Their potential for extended operational lifespans in harsh aerospace environments means fewer replacement cycles and reduced electronic waste generation. Additionally, the lightweight characteristics of 2D semiconductor-based components contribute to overall aircraft weight reduction, further enhancing fuel efficiency and decreasing the carbon footprint of aerospace operations.

Material sourcing considerations present both challenges and opportunities. While some 2D materials like graphene can be synthesized from abundant carbon sources, others require rare elements that may face supply constraints or involve environmentally problematic extraction processes. The aerospace industry must develop responsible sourcing strategies and invest in recycling technologies to mitigate these concerns and ensure sustainable material flows.

End-of-life management for 2D semiconductor components requires proactive planning. The complex integration of these materials into aerospace systems necessitates specialized recycling approaches to recover valuable elements and prevent environmental contamination. Developing effective recovery processes represents an important research direction that could significantly enhance the overall sustainability profile of these technologies.

Regulatory frameworks governing environmental aspects of semiconductor manufacturing and electronic waste management continue to evolve globally. Aerospace manufacturers implementing 2D semiconductor technologies must navigate these regulations while anticipating future requirements. Proactive adoption of sustainable practices not only ensures compliance but positions companies advantageously as environmental standards become increasingly stringent.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!