The Role of Lithium Iron Phosphate Batteries in Hydrogen Economy

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Batteries in H2 Economy: Background and Objectives

Lithium Iron Phosphate (LFP) batteries have emerged as a pivotal technology in the evolving landscape of the hydrogen economy. As the world transitions towards cleaner energy sources, the integration of LFP batteries with hydrogen-based systems presents a promising avenue for sustainable energy storage and distribution. This convergence of technologies aims to address the intermittency issues associated with renewable energy sources and provide a more reliable and efficient energy infrastructure.

The development of LFP batteries can be traced back to the late 1990s, with significant advancements occurring in the past two decades. These batteries have gained prominence due to their superior safety profile, long cycle life, and cost-effectiveness compared to other lithium-ion battery chemistries. As the hydrogen economy gains momentum, LFP batteries are positioned to play a crucial role in various applications, from grid-scale energy storage to electric vehicles and portable power systems.

The hydrogen economy represents a vision of a future where hydrogen serves as a primary energy carrier, offering a clean and versatile alternative to fossil fuels. However, the successful implementation of this vision requires efficient energy storage solutions to manage the production, distribution, and utilization of hydrogen. LFP batteries, with their unique characteristics, are well-suited to address these challenges and complement hydrogen-based systems.

The primary objective of integrating LFP batteries into the hydrogen economy is to create a synergistic relationship between these two technologies. LFP batteries can serve as a buffer for hydrogen production systems, storing excess energy during periods of high renewable energy generation and releasing it when demand exceeds supply. This integration aims to enhance the overall efficiency of hydrogen production, particularly in electrolysis processes powered by intermittent renewable sources such as solar and wind.

Furthermore, LFP batteries can play a critical role in hydrogen distribution and end-use applications. In hydrogen refueling stations, these batteries can help manage peak loads and optimize the operation of compressors and cooling systems. In fuel cell electric vehicles, LFP batteries can complement fuel cells by providing additional power during acceleration and recovering energy through regenerative braking.

As we explore the potential of LFP batteries in the hydrogen economy, it is essential to consider the technological advancements, market dynamics, and regulatory landscape that will shape their adoption. The ongoing research and development efforts are focused on improving the energy density, charging speed, and overall performance of LFP batteries to better meet the demands of various hydrogen-related applications.

The development of LFP batteries can be traced back to the late 1990s, with significant advancements occurring in the past two decades. These batteries have gained prominence due to their superior safety profile, long cycle life, and cost-effectiveness compared to other lithium-ion battery chemistries. As the hydrogen economy gains momentum, LFP batteries are positioned to play a crucial role in various applications, from grid-scale energy storage to electric vehicles and portable power systems.

The hydrogen economy represents a vision of a future where hydrogen serves as a primary energy carrier, offering a clean and versatile alternative to fossil fuels. However, the successful implementation of this vision requires efficient energy storage solutions to manage the production, distribution, and utilization of hydrogen. LFP batteries, with their unique characteristics, are well-suited to address these challenges and complement hydrogen-based systems.

The primary objective of integrating LFP batteries into the hydrogen economy is to create a synergistic relationship between these two technologies. LFP batteries can serve as a buffer for hydrogen production systems, storing excess energy during periods of high renewable energy generation and releasing it when demand exceeds supply. This integration aims to enhance the overall efficiency of hydrogen production, particularly in electrolysis processes powered by intermittent renewable sources such as solar and wind.

Furthermore, LFP batteries can play a critical role in hydrogen distribution and end-use applications. In hydrogen refueling stations, these batteries can help manage peak loads and optimize the operation of compressors and cooling systems. In fuel cell electric vehicles, LFP batteries can complement fuel cells by providing additional power during acceleration and recovering energy through regenerative braking.

As we explore the potential of LFP batteries in the hydrogen economy, it is essential to consider the technological advancements, market dynamics, and regulatory landscape that will shape their adoption. The ongoing research and development efforts are focused on improving the energy density, charging speed, and overall performance of LFP batteries to better meet the demands of various hydrogen-related applications.

Market Analysis for LFP Batteries in Hydrogen Applications

The market for Lithium Iron Phosphate (LFP) batteries in hydrogen applications is experiencing significant growth, driven by the increasing focus on clean energy solutions and the transition towards a hydrogen economy. As the world seeks to reduce carbon emissions and enhance energy efficiency, LFP batteries are emerging as a crucial component in various hydrogen-related systems and applications.

In the context of hydrogen production, LFP batteries play a vital role in stabilizing the power supply for electrolyzers. These batteries can store excess renewable energy during periods of high production and low demand, which can then be used to power electrolyzers during times of low renewable energy generation. This integration helps to optimize the efficiency of green hydrogen production and reduce overall costs.

The transportation sector represents another significant market for LFP batteries in hydrogen applications. Fuel cell electric vehicles (FCEVs) often utilize LFP batteries as auxiliary power sources, providing additional energy for vehicle systems and improving overall performance. The combination of hydrogen fuel cells and LFP batteries offers extended range and faster refueling times compared to traditional battery electric vehicles.

Stationary power applications also present a growing market opportunity for LFP batteries in the hydrogen economy. These batteries can be used in conjunction with fuel cells to provide reliable backup power for critical infrastructure, such as data centers, hospitals, and telecommunications facilities. The long cycle life and improved safety characteristics of LFP batteries make them particularly suitable for these applications.

The market for LFP batteries in hydrogen storage systems is also expanding. These batteries can be integrated into hydrogen storage facilities to manage power fluctuations and optimize the compression and liquefaction processes. This integration enhances the overall efficiency of hydrogen storage and distribution systems.

As the hydrogen economy continues to develop, the demand for LFP batteries is expected to grow across various industries. The marine and aviation sectors are exploring hydrogen-powered propulsion systems that incorporate LFP batteries, while industrial applications such as steel production and chemical manufacturing are investigating the use of hydrogen as a clean energy source, creating additional opportunities for LFP battery integration.

The market potential for LFP batteries in hydrogen applications is further bolstered by ongoing technological advancements and cost reductions in both battery and hydrogen technologies. As production scales up and efficiencies improve, the synergies between LFP batteries and hydrogen systems are likely to become increasingly attractive to a wide range of industries and applications.

In the context of hydrogen production, LFP batteries play a vital role in stabilizing the power supply for electrolyzers. These batteries can store excess renewable energy during periods of high production and low demand, which can then be used to power electrolyzers during times of low renewable energy generation. This integration helps to optimize the efficiency of green hydrogen production and reduce overall costs.

The transportation sector represents another significant market for LFP batteries in hydrogen applications. Fuel cell electric vehicles (FCEVs) often utilize LFP batteries as auxiliary power sources, providing additional energy for vehicle systems and improving overall performance. The combination of hydrogen fuel cells and LFP batteries offers extended range and faster refueling times compared to traditional battery electric vehicles.

Stationary power applications also present a growing market opportunity for LFP batteries in the hydrogen economy. These batteries can be used in conjunction with fuel cells to provide reliable backup power for critical infrastructure, such as data centers, hospitals, and telecommunications facilities. The long cycle life and improved safety characteristics of LFP batteries make them particularly suitable for these applications.

The market for LFP batteries in hydrogen storage systems is also expanding. These batteries can be integrated into hydrogen storage facilities to manage power fluctuations and optimize the compression and liquefaction processes. This integration enhances the overall efficiency of hydrogen storage and distribution systems.

As the hydrogen economy continues to develop, the demand for LFP batteries is expected to grow across various industries. The marine and aviation sectors are exploring hydrogen-powered propulsion systems that incorporate LFP batteries, while industrial applications such as steel production and chemical manufacturing are investigating the use of hydrogen as a clean energy source, creating additional opportunities for LFP battery integration.

The market potential for LFP batteries in hydrogen applications is further bolstered by ongoing technological advancements and cost reductions in both battery and hydrogen technologies. As production scales up and efficiencies improve, the synergies between LFP batteries and hydrogen systems are likely to become increasingly attractive to a wide range of industries and applications.

Current State and Challenges of LFP Batteries in H2 Systems

Lithium Iron Phosphate (LFP) batteries have emerged as a promising energy storage solution in the evolving hydrogen economy. Currently, these batteries are being integrated into various hydrogen systems, particularly in fuel cell electric vehicles (FCEVs) and stationary power applications. The primary role of LFP batteries in these systems is to provide auxiliary power, manage energy flow, and enhance overall system efficiency.

In FCEVs, LFP batteries are used as a complementary power source to fuel cells. They assist in managing power demands during acceleration, recuperating energy through regenerative braking, and powering auxiliary systems. This integration allows for optimized fuel cell operation and improved vehicle performance. However, challenges remain in terms of weight optimization and system integration to maximize the synergy between fuel cells and LFP batteries.

For stationary hydrogen systems, such as electrolyzers and fuel cell power plants, LFP batteries serve as buffer storage. They help smooth out power fluctuations, enhance grid stability, and improve the overall efficiency of hydrogen production and utilization. The ability of LFP batteries to provide rapid response to power demands makes them particularly suitable for these applications.

Despite the progress, several technical challenges persist. One major hurdle is the limited energy density of LFP batteries compared to other lithium-ion chemistries. This constraint impacts the range and performance of FCEVs and the storage capacity of stationary systems. Researchers are actively working on improving the energy density through advanced electrode materials and cell designs.

Another significant challenge is the integration and control of LFP batteries within complex hydrogen systems. Developing sophisticated battery management systems (BMS) that can effectively coordinate between the battery, fuel cell, and other components is crucial. These systems must optimize power distribution, manage thermal issues, and ensure safe operation under various conditions.

The durability and longevity of LFP batteries in hydrogen applications also present ongoing challenges. While LFP chemistry is known for its stability, the specific demands of hydrogen systems, such as frequent charge-discharge cycles and exposure to varying environmental conditions, require further improvements in battery life and performance consistency.

Lastly, cost remains a significant factor. Although LFP batteries are generally more cost-effective than some other lithium-ion variants, further reductions in production costs are necessary to make hydrogen systems more economically viable. This includes not only the cost of the batteries themselves but also the associated integration and management systems.

In FCEVs, LFP batteries are used as a complementary power source to fuel cells. They assist in managing power demands during acceleration, recuperating energy through regenerative braking, and powering auxiliary systems. This integration allows for optimized fuel cell operation and improved vehicle performance. However, challenges remain in terms of weight optimization and system integration to maximize the synergy between fuel cells and LFP batteries.

For stationary hydrogen systems, such as electrolyzers and fuel cell power plants, LFP batteries serve as buffer storage. They help smooth out power fluctuations, enhance grid stability, and improve the overall efficiency of hydrogen production and utilization. The ability of LFP batteries to provide rapid response to power demands makes them particularly suitable for these applications.

Despite the progress, several technical challenges persist. One major hurdle is the limited energy density of LFP batteries compared to other lithium-ion chemistries. This constraint impacts the range and performance of FCEVs and the storage capacity of stationary systems. Researchers are actively working on improving the energy density through advanced electrode materials and cell designs.

Another significant challenge is the integration and control of LFP batteries within complex hydrogen systems. Developing sophisticated battery management systems (BMS) that can effectively coordinate between the battery, fuel cell, and other components is crucial. These systems must optimize power distribution, manage thermal issues, and ensure safe operation under various conditions.

The durability and longevity of LFP batteries in hydrogen applications also present ongoing challenges. While LFP chemistry is known for its stability, the specific demands of hydrogen systems, such as frequent charge-discharge cycles and exposure to varying environmental conditions, require further improvements in battery life and performance consistency.

Lastly, cost remains a significant factor. Although LFP batteries are generally more cost-effective than some other lithium-ion variants, further reductions in production costs are necessary to make hydrogen systems more economically viable. This includes not only the cost of the batteries themselves but also the associated integration and management systems.

Existing LFP Battery Solutions for Hydrogen Applications

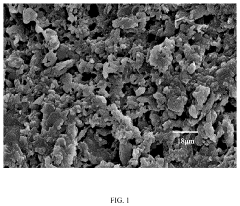

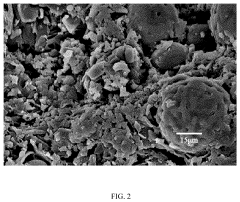

01 Electrode material composition and preparation

Innovations in the composition and preparation of electrode materials for lithium iron phosphate batteries. This includes methods for synthesizing high-performance cathode materials, optimizing particle size and morphology, and incorporating dopants or coatings to enhance electrochemical properties.- Electrode material composition and preparation: Innovations in the composition and preparation of electrode materials for lithium iron phosphate batteries. This includes methods for synthesizing high-performance cathode materials, optimizing particle size and morphology, and incorporating dopants or coatings to enhance electrochemical properties.

- Battery cell design and assembly: Advancements in the design and assembly of lithium iron phosphate battery cells. This encompasses innovations in electrode stacking, electrolyte formulation, separator technology, and overall cell architecture to improve energy density, safety, and cycle life.

- Battery management and control systems: Development of sophisticated battery management and control systems for lithium iron phosphate batteries. This includes algorithms for state-of-charge estimation, thermal management, balancing techniques, and safety monitoring to optimize battery performance and longevity.

- Manufacturing processes and scalability: Innovations in manufacturing processes and scalability of lithium iron phosphate batteries. This covers advancements in production techniques, quality control measures, and automation to enhance efficiency, reduce costs, and maintain consistency in large-scale manufacturing.

- Application-specific battery designs: Development of lithium iron phosphate batteries tailored for specific applications. This includes customized designs for electric vehicles, renewable energy storage, and portable electronics, focusing on optimizing performance characteristics such as power density, fast charging capabilities, and cycle life for each use case.

02 Battery cell design and assembly

Advancements in the design and assembly of lithium iron phosphate battery cells. This encompasses innovations in electrode stacking, electrolyte formulation, separator technology, and overall cell architecture to improve energy density, safety, and cycle life.Expand Specific Solutions03 Battery management systems

Development of sophisticated battery management systems for lithium iron phosphate batteries. These systems focus on optimizing charging and discharging processes, thermal management, state-of-charge estimation, and overall battery performance monitoring to enhance efficiency and longevity.Expand Specific Solutions04 Manufacturing processes and scalability

Innovations in manufacturing processes and scalability of lithium iron phosphate batteries. This includes advancements in mass production techniques, quality control measures, and cost-effective manufacturing methods to enable widespread adoption of these batteries in various applications.Expand Specific Solutions05 Application-specific battery designs

Development of lithium iron phosphate batteries tailored for specific applications. This involves customizing battery characteristics such as power output, energy density, and form factor to meet the requirements of various industries, including electric vehicles, renewable energy storage, and portable electronics.Expand Specific Solutions

Key Players in LFP Battery and Hydrogen Industry

The lithium iron phosphate (LFP) battery market in the hydrogen economy is in a growth phase, with increasing adoption in energy storage and electric vehicle applications. The market size is expanding rapidly, driven by the demand for sustainable energy solutions. Technologically, LFP batteries are relatively mature, with ongoing improvements in performance and cost-effectiveness. Key players like Contemporary Amperex Technology (CATL), A123 Systems, and BYD are leading innovation in this space. Research institutions such as Rutgers University and Indian Institute of Technology Bombay are also contributing to advancements. The competitive landscape is characterized by a mix of established manufacturers and emerging startups, with a focus on enhancing energy density, charging speeds, and production efficiency to meet the evolving needs of the hydrogen economy.

A123 Systems LLC

Technical Solution: A123 Systems has developed proprietary Nanophosphate® LFP technology, which offers enhanced power capability and extended cycle life compared to conventional LFP batteries. Their LFP batteries are being utilized in hybrid energy systems that combine battery storage with hydrogen fuel cells. A123's LFP batteries provide rapid response times and high power output, making them suitable for grid frequency regulation and load balancing in hydrogen-based microgrids[4]. The company has also focused on improving the low-temperature performance of their LFP batteries, addressing a common limitation of this chemistry[5].

Strengths: High power capability, extended cycle life, improved low-temperature performance. Weaknesses: Lower energy density compared to some competing technologies, higher production costs due to specialized nanoscale materials.

Hefei Guoxuan High-Tech Power Energy Co., Ltd.

Technical Solution: Guoxuan High-Tech has developed LFP batteries specifically tailored for hydrogen economy applications. Their batteries feature a unique doping process that enhances the conductivity and stability of the LFP cathode material. Guoxuan's LFP batteries are being used in large-scale energy storage systems that support hydrogen production facilities, helping to balance the intermittent nature of renewable energy sources. The company has also introduced a modular battery design that allows for easy scaling and integration with hydrogen electrolyzers[8]. Guoxuan is working on improving the energy density of their LFP batteries through advanced electrode manufacturing techniques and optimized cell design[9].

Strengths: Enhanced conductivity and stability, modular design for easy integration, scalability for large energy storage systems. Weaknesses: Relatively new entrant in the global market, potential challenges in international expansion.

Core Innovations in LFP Batteries for Hydrogen Economy

Lithium iron phosphate material and preparation method therefor

PatentActiveUS20240140799A1

Innovation

- A method involving the mixing of zinc and copper sources with a complexing agent, followed by sintering with an iron source and phosphoric acid to form a solid-phase material, which is then mixed with a lithium source and further sintered to produce a ferrous lithium phosphate material with enhanced electrochemical properties.

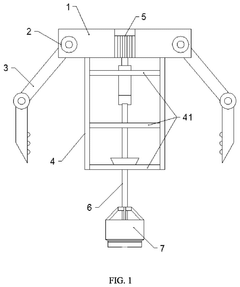

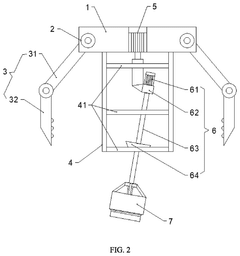

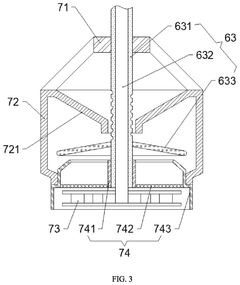

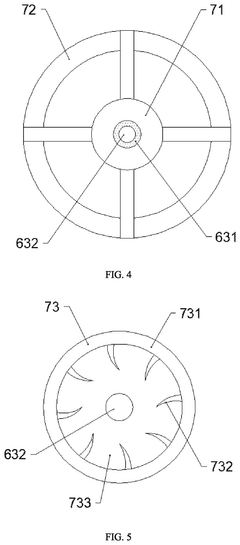

Stirring mechanism for extracting lithium from waste liquid of lithium iron phosphate battery

PatentActiveUS20240332659A1

Innovation

- A stirring mechanism with a rotatable design, including a pedestal, clamping jaws, and a stirring member with a rotating shaft and motor, which forms an angle with the container axis to enhance mixing and precipitation, using a jaw-shaped connecting base, material guide wheel, and collecting frame to facilitate quick separation of metal elements.

Environmental Impact of LFP Batteries in Hydrogen Economy

The environmental impact of Lithium Iron Phosphate (LFP) batteries in the hydrogen economy is a critical consideration as we transition towards more sustainable energy solutions. LFP batteries, known for their stability and long cycle life, play a significant role in supporting the hydrogen economy by enabling efficient energy storage and distribution.

One of the primary environmental benefits of LFP batteries in the hydrogen economy is their contribution to reducing greenhouse gas emissions. By facilitating the storage of renewable energy sources such as solar and wind power, LFP batteries help mitigate the intermittency issues associated with these clean energy sources. This stored energy can then be used to power electrolyzers for hydrogen production during periods of low renewable energy generation, ensuring a consistent supply of green hydrogen.

The production of LFP batteries, however, does have environmental implications. The mining and processing of lithium, iron, and phosphate can lead to land degradation, water pollution, and habitat disruption. Nevertheless, compared to other battery chemistries, LFP batteries have a lower environmental footprint due to the abundance and relatively low toxicity of their constituent materials.

In the context of the hydrogen economy, LFP batteries contribute to the overall efficiency of hydrogen production and distribution systems. By enabling load balancing and grid stabilization, these batteries help optimize the use of renewable energy for hydrogen production, reducing the need for fossil fuel-based electricity and consequently lowering carbon emissions.

The end-of-life management of LFP batteries is another crucial aspect of their environmental impact. Fortunately, LFP batteries are highly recyclable, with up to 95% of their materials recoverable through advanced recycling processes. This high recyclability rate not only reduces waste but also decreases the demand for raw materials, further minimizing the environmental impact of battery production.

When considering the full lifecycle of LFP batteries in the hydrogen economy, it's important to note their long lifespan and high cycle count. This durability translates to less frequent replacements and reduced waste generation over time, contributing to a more sustainable energy storage solution for hydrogen-based systems.

The integration of LFP batteries in hydrogen refueling stations and hydrogen-powered vehicles also presents environmental benefits. By providing a stable power source for compression and cooling systems in refueling stations, LFP batteries help optimize hydrogen distribution infrastructure, potentially reducing energy waste and improving overall system efficiency.

In conclusion, while the production of LFP batteries does have some environmental impacts, their role in supporting the hydrogen economy offers significant net positive environmental effects. By enabling more efficient use of renewable energy, facilitating green hydrogen production, and providing a recyclable and durable energy storage solution, LFP batteries contribute to the overall sustainability and reduced carbon footprint of the hydrogen economy.

One of the primary environmental benefits of LFP batteries in the hydrogen economy is their contribution to reducing greenhouse gas emissions. By facilitating the storage of renewable energy sources such as solar and wind power, LFP batteries help mitigate the intermittency issues associated with these clean energy sources. This stored energy can then be used to power electrolyzers for hydrogen production during periods of low renewable energy generation, ensuring a consistent supply of green hydrogen.

The production of LFP batteries, however, does have environmental implications. The mining and processing of lithium, iron, and phosphate can lead to land degradation, water pollution, and habitat disruption. Nevertheless, compared to other battery chemistries, LFP batteries have a lower environmental footprint due to the abundance and relatively low toxicity of their constituent materials.

In the context of the hydrogen economy, LFP batteries contribute to the overall efficiency of hydrogen production and distribution systems. By enabling load balancing and grid stabilization, these batteries help optimize the use of renewable energy for hydrogen production, reducing the need for fossil fuel-based electricity and consequently lowering carbon emissions.

The end-of-life management of LFP batteries is another crucial aspect of their environmental impact. Fortunately, LFP batteries are highly recyclable, with up to 95% of their materials recoverable through advanced recycling processes. This high recyclability rate not only reduces waste but also decreases the demand for raw materials, further minimizing the environmental impact of battery production.

When considering the full lifecycle of LFP batteries in the hydrogen economy, it's important to note their long lifespan and high cycle count. This durability translates to less frequent replacements and reduced waste generation over time, contributing to a more sustainable energy storage solution for hydrogen-based systems.

The integration of LFP batteries in hydrogen refueling stations and hydrogen-powered vehicles also presents environmental benefits. By providing a stable power source for compression and cooling systems in refueling stations, LFP batteries help optimize hydrogen distribution infrastructure, potentially reducing energy waste and improving overall system efficiency.

In conclusion, while the production of LFP batteries does have some environmental impacts, their role in supporting the hydrogen economy offers significant net positive environmental effects. By enabling more efficient use of renewable energy, facilitating green hydrogen production, and providing a recyclable and durable energy storage solution, LFP batteries contribute to the overall sustainability and reduced carbon footprint of the hydrogen economy.

Policy and Regulatory Framework for LFP in H2 Applications

The policy and regulatory framework for Lithium Iron Phosphate (LFP) batteries in hydrogen applications is evolving rapidly as governments and industries recognize the potential synergies between these technologies in the emerging hydrogen economy. Many countries are implementing supportive policies to encourage the integration of LFP batteries with hydrogen systems, particularly in the transportation and energy storage sectors.

In the transportation domain, several nations have introduced incentives for vehicles that combine hydrogen fuel cells with LFP batteries. These hybrid systems leverage the high energy density of hydrogen for long-range travel and the rapid charge/discharge capabilities of LFP batteries for acceleration and regenerative braking. Regulatory bodies are adapting vehicle emission standards to account for the unique characteristics of these hybrid powertrains, often offering more favorable treatment compared to conventional internal combustion engines.

The energy storage sector is witnessing the development of regulations that promote the use of LFP batteries in conjunction with hydrogen production and storage facilities. Grid operators are being encouraged to incorporate these integrated systems to enhance grid stability and facilitate the integration of intermittent renewable energy sources. Some jurisdictions have introduced mandates for utilities to include a certain percentage of hydrogen-LFP hybrid storage in their energy mix, recognizing the complementary nature of these technologies in managing peak loads and seasonal variations.

Safety regulations are being updated to address the specific requirements of combined hydrogen and LFP battery systems. This includes new standards for installation, operation, and maintenance of these integrated technologies in both stationary and mobile applications. Certification processes are being established to ensure that components and systems meet stringent safety and performance criteria.

Research and development initiatives focused on LFP batteries in hydrogen applications are receiving increased government funding and tax incentives. Many countries have established dedicated programs to support collaborative projects between battery manufacturers, hydrogen technology developers, and end-users. These initiatives aim to accelerate innovation and commercialization of integrated hydrogen-LFP solutions.

International standardization efforts are underway to harmonize regulations and technical specifications for LFP batteries in hydrogen systems across different regions. This is crucial for fostering global market development and ensuring interoperability of components and systems. Organizations such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) are playing key roles in developing these standards.

As the hydrogen economy continues to grow, it is expected that the regulatory framework for LFP batteries in hydrogen applications will become more comprehensive and refined. Policymakers are likely to focus on creating a balanced approach that promotes innovation while ensuring safety and environmental protection. The success of these policies will play a crucial role in determining the extent to which LFP batteries contribute to the broader hydrogen economy.

In the transportation domain, several nations have introduced incentives for vehicles that combine hydrogen fuel cells with LFP batteries. These hybrid systems leverage the high energy density of hydrogen for long-range travel and the rapid charge/discharge capabilities of LFP batteries for acceleration and regenerative braking. Regulatory bodies are adapting vehicle emission standards to account for the unique characteristics of these hybrid powertrains, often offering more favorable treatment compared to conventional internal combustion engines.

The energy storage sector is witnessing the development of regulations that promote the use of LFP batteries in conjunction with hydrogen production and storage facilities. Grid operators are being encouraged to incorporate these integrated systems to enhance grid stability and facilitate the integration of intermittent renewable energy sources. Some jurisdictions have introduced mandates for utilities to include a certain percentage of hydrogen-LFP hybrid storage in their energy mix, recognizing the complementary nature of these technologies in managing peak loads and seasonal variations.

Safety regulations are being updated to address the specific requirements of combined hydrogen and LFP battery systems. This includes new standards for installation, operation, and maintenance of these integrated technologies in both stationary and mobile applications. Certification processes are being established to ensure that components and systems meet stringent safety and performance criteria.

Research and development initiatives focused on LFP batteries in hydrogen applications are receiving increased government funding and tax incentives. Many countries have established dedicated programs to support collaborative projects between battery manufacturers, hydrogen technology developers, and end-users. These initiatives aim to accelerate innovation and commercialization of integrated hydrogen-LFP solutions.

International standardization efforts are underway to harmonize regulations and technical specifications for LFP batteries in hydrogen systems across different regions. This is crucial for fostering global market development and ensuring interoperability of components and systems. Organizations such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) are playing key roles in developing these standards.

As the hydrogen economy continues to grow, it is expected that the regulatory framework for LFP batteries in hydrogen applications will become more comprehensive and refined. Policymakers are likely to focus on creating a balanced approach that promotes innovation while ensuring safety and environmental protection. The success of these policies will play a crucial role in determining the extent to which LFP batteries contribute to the broader hydrogen economy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!