Transformational Use Cases for Ethylene Vinyl Acetate

JUL 9, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA Technology Evolution

Ethylene Vinyl Acetate (EVA) has undergone significant technological evolution since its introduction in the 1950s. Initially developed as a copolymer of ethylene and vinyl acetate, EVA's unique properties have driven its continuous improvement and diversification of applications over the decades.

In the early stages, EVA was primarily used in flexible packaging and as a hot melt adhesive. The 1960s and 1970s saw advancements in polymerization techniques, leading to better control over the vinyl acetate content and molecular weight distribution. This enabled the production of EVA with tailored properties for specific applications, expanding its use in footwear, wire and cable insulation, and solar panel encapsulation.

The 1980s marked a significant milestone in EVA technology with the development of crosslinking techniques. This innovation greatly enhanced the material's heat resistance and mechanical properties, opening up new possibilities in high-performance applications such as automotive components and specialty films.

The 1990s and early 2000s witnessed a focus on improving EVA's processing characteristics. Advancements in extrusion and molding technologies allowed for more efficient production of EVA-based products, reducing manufacturing costs and expanding market reach. During this period, EVA also gained traction in the medical field, with the development of biocompatible grades for medical devices and pharmaceutical packaging.

In recent years, the evolution of EVA technology has been driven by sustainability concerns and the demand for high-performance materials. Research has focused on developing bio-based EVA alternatives and improving the material's recyclability. Additionally, nanotechnology has been employed to create EVA nanocomposites with enhanced properties, such as improved barrier characteristics and flame retardancy.

The latest frontier in EVA technology involves its integration with smart materials and IoT applications. Researchers are exploring the potential of EVA as a substrate for flexible electronics and sensors, paving the way for innovative applications in wearable technology and smart packaging.

Throughout its evolution, EVA has consistently demonstrated its versatility and adaptability to changing market demands. From its humble beginnings as a simple copolymer to its current status as a high-tech material with transformative potential, EVA continues to be at the forefront of polymer innovation. The ongoing research and development in EVA technology promise to unlock even more transformational use cases in the future, cementing its position as a crucial material in various industries.

In the early stages, EVA was primarily used in flexible packaging and as a hot melt adhesive. The 1960s and 1970s saw advancements in polymerization techniques, leading to better control over the vinyl acetate content and molecular weight distribution. This enabled the production of EVA with tailored properties for specific applications, expanding its use in footwear, wire and cable insulation, and solar panel encapsulation.

The 1980s marked a significant milestone in EVA technology with the development of crosslinking techniques. This innovation greatly enhanced the material's heat resistance and mechanical properties, opening up new possibilities in high-performance applications such as automotive components and specialty films.

The 1990s and early 2000s witnessed a focus on improving EVA's processing characteristics. Advancements in extrusion and molding technologies allowed for more efficient production of EVA-based products, reducing manufacturing costs and expanding market reach. During this period, EVA also gained traction in the medical field, with the development of biocompatible grades for medical devices and pharmaceutical packaging.

In recent years, the evolution of EVA technology has been driven by sustainability concerns and the demand for high-performance materials. Research has focused on developing bio-based EVA alternatives and improving the material's recyclability. Additionally, nanotechnology has been employed to create EVA nanocomposites with enhanced properties, such as improved barrier characteristics and flame retardancy.

The latest frontier in EVA technology involves its integration with smart materials and IoT applications. Researchers are exploring the potential of EVA as a substrate for flexible electronics and sensors, paving the way for innovative applications in wearable technology and smart packaging.

Throughout its evolution, EVA has consistently demonstrated its versatility and adaptability to changing market demands. From its humble beginnings as a simple copolymer to its current status as a high-tech material with transformative potential, EVA continues to be at the forefront of polymer innovation. The ongoing research and development in EVA technology promise to unlock even more transformational use cases in the future, cementing its position as a crucial material in various industries.

Market Demand Analysis

The market demand for Ethylene Vinyl Acetate (EVA) has been experiencing significant growth across various industries due to its versatile properties and wide range of applications. The global EVA market size was valued at over $7 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of around 4% from 2021 to 2028.

One of the primary drivers of market demand is the increasing use of EVA in the solar photovoltaic industry. EVA is extensively used as an encapsulant material in solar panels, providing excellent protection against environmental factors and enhancing the overall efficiency of solar cells. With the growing emphasis on renewable energy sources and the rapid expansion of solar power installations worldwide, the demand for EVA in this sector is expected to surge.

The packaging industry represents another significant market for EVA, particularly in flexible packaging applications. EVA's properties, such as flexibility, transparency, and heat-sealing capabilities, make it an ideal material for food packaging, shrink wrap, and other packaging solutions. The rising demand for convenient and sustainable packaging options is fueling the growth of EVA in this sector.

In the footwear industry, EVA has gained popularity as a material for shoe soles and insoles due to its lightweight nature, cushioning properties, and durability. The increasing focus on comfort and performance in athletic and casual footwear is driving the demand for EVA-based components.

The automotive sector is also contributing to the growing market demand for EVA. It is used in various automotive applications, including wire and cable insulation, gaskets, and interior components. The trend towards lightweight materials in vehicle manufacturing to improve fuel efficiency is expected to boost the adoption of EVA in this industry.

The construction industry is another key market for EVA, particularly in the production of adhesives, sealants, and waterproofing materials. The growth in construction activities, especially in developing economies, is likely to drive the demand for EVA-based products in this sector.

Geographically, Asia Pacific is expected to dominate the EVA market, driven by rapid industrialization, urbanization, and the presence of major manufacturing hubs in countries like China and India. North America and Europe are also significant markets, with steady growth anticipated due to technological advancements and increasing applications in various industries.

The market demand for EVA is further influenced by factors such as technological innovations, evolving consumer preferences, and regulatory policies promoting sustainable materials. As industries continue to explore new applications and transformational use cases for EVA, the market is poised for sustained growth in the coming years.

One of the primary drivers of market demand is the increasing use of EVA in the solar photovoltaic industry. EVA is extensively used as an encapsulant material in solar panels, providing excellent protection against environmental factors and enhancing the overall efficiency of solar cells. With the growing emphasis on renewable energy sources and the rapid expansion of solar power installations worldwide, the demand for EVA in this sector is expected to surge.

The packaging industry represents another significant market for EVA, particularly in flexible packaging applications. EVA's properties, such as flexibility, transparency, and heat-sealing capabilities, make it an ideal material for food packaging, shrink wrap, and other packaging solutions. The rising demand for convenient and sustainable packaging options is fueling the growth of EVA in this sector.

In the footwear industry, EVA has gained popularity as a material for shoe soles and insoles due to its lightweight nature, cushioning properties, and durability. The increasing focus on comfort and performance in athletic and casual footwear is driving the demand for EVA-based components.

The automotive sector is also contributing to the growing market demand for EVA. It is used in various automotive applications, including wire and cable insulation, gaskets, and interior components. The trend towards lightweight materials in vehicle manufacturing to improve fuel efficiency is expected to boost the adoption of EVA in this industry.

The construction industry is another key market for EVA, particularly in the production of adhesives, sealants, and waterproofing materials. The growth in construction activities, especially in developing economies, is likely to drive the demand for EVA-based products in this sector.

Geographically, Asia Pacific is expected to dominate the EVA market, driven by rapid industrialization, urbanization, and the presence of major manufacturing hubs in countries like China and India. North America and Europe are also significant markets, with steady growth anticipated due to technological advancements and increasing applications in various industries.

The market demand for EVA is further influenced by factors such as technological innovations, evolving consumer preferences, and regulatory policies promoting sustainable materials. As industries continue to explore new applications and transformational use cases for EVA, the market is poised for sustained growth in the coming years.

Technical Challenges

Ethylene Vinyl Acetate (EVA) has emerged as a versatile material with transformative potential across various industries. However, its widespread adoption and application face several technical challenges that require innovative solutions.

One of the primary challenges in EVA production is achieving precise control over the vinyl acetate content, which directly influences the material's properties. Variations in VA content can lead to inconsistencies in product performance, affecting applications ranging from solar panel encapsulation to footwear manufacturing. Developing advanced polymerization techniques and real-time monitoring systems is crucial to maintain consistent VA levels throughout production.

The thermal stability of EVA presents another significant challenge, particularly in high-temperature applications. As EVA degrades at elevated temperatures, it can release acetic acid, potentially compromising the integrity of the final product. This issue is particularly critical in solar panel encapsulation, where long-term exposure to sunlight can accelerate degradation. Research into heat-resistant additives and cross-linking agents is ongoing to enhance EVA's thermal stability without sacrificing its desirable properties.

Adhesion properties of EVA, while generally good, can be inconsistent across different substrates. This variability poses challenges in applications such as packaging and automotive components, where strong and reliable bonding is essential. Developing surface treatment techniques and adhesion promoters specific to EVA could significantly improve its performance in these areas.

The recyclability of EVA-based products remains a technical hurdle, particularly for multi-layer structures common in packaging and footwear. Separating EVA from other materials in composite structures is often difficult, hindering efficient recycling processes. Innovations in material design and recycling technologies are needed to address this challenge and improve the circular economy potential of EVA products.

Moisture sensitivity is another area of concern for certain EVA applications, especially in electronics and outdoor products. While EVA offers good water resistance, prolonged exposure to moisture can lead to degradation and loss of mechanical properties. Developing advanced moisture barrier technologies and hydrophobic treatments for EVA could expand its applicability in harsh environments.

Lastly, the processing of EVA, particularly in complex shapes and structures, presents technical challenges. Achieving uniform thickness and properties in injection molding and extrusion processes can be difficult, especially for high-VA content grades. Advancements in processing equipment and techniques, such as improved die designs and temperature control systems, are necessary to overcome these limitations and expand EVA's use in complex manufacturing processes.

One of the primary challenges in EVA production is achieving precise control over the vinyl acetate content, which directly influences the material's properties. Variations in VA content can lead to inconsistencies in product performance, affecting applications ranging from solar panel encapsulation to footwear manufacturing. Developing advanced polymerization techniques and real-time monitoring systems is crucial to maintain consistent VA levels throughout production.

The thermal stability of EVA presents another significant challenge, particularly in high-temperature applications. As EVA degrades at elevated temperatures, it can release acetic acid, potentially compromising the integrity of the final product. This issue is particularly critical in solar panel encapsulation, where long-term exposure to sunlight can accelerate degradation. Research into heat-resistant additives and cross-linking agents is ongoing to enhance EVA's thermal stability without sacrificing its desirable properties.

Adhesion properties of EVA, while generally good, can be inconsistent across different substrates. This variability poses challenges in applications such as packaging and automotive components, where strong and reliable bonding is essential. Developing surface treatment techniques and adhesion promoters specific to EVA could significantly improve its performance in these areas.

The recyclability of EVA-based products remains a technical hurdle, particularly for multi-layer structures common in packaging and footwear. Separating EVA from other materials in composite structures is often difficult, hindering efficient recycling processes. Innovations in material design and recycling technologies are needed to address this challenge and improve the circular economy potential of EVA products.

Moisture sensitivity is another area of concern for certain EVA applications, especially in electronics and outdoor products. While EVA offers good water resistance, prolonged exposure to moisture can lead to degradation and loss of mechanical properties. Developing advanced moisture barrier technologies and hydrophobic treatments for EVA could expand its applicability in harsh environments.

Lastly, the processing of EVA, particularly in complex shapes and structures, presents technical challenges. Achieving uniform thickness and properties in injection molding and extrusion processes can be difficult, especially for high-VA content grades. Advancements in processing equipment and techniques, such as improved die designs and temperature control systems, are necessary to overcome these limitations and expand EVA's use in complex manufacturing processes.

Current EVA Applications

01 Composition and synthesis of EVA copolymers

Ethylene Vinyl Acetate (EVA) copolymers are synthesized through the copolymerization of ethylene and vinyl acetate monomers. The composition and ratio of these monomers can be adjusted to achieve desired properties such as flexibility, toughness, and adhesion. Various polymerization methods and catalysts are employed to control the molecular weight and distribution of the copolymer.- Composition and synthesis of EVA copolymers: Ethylene Vinyl Acetate (EVA) copolymers are synthesized through the copolymerization of ethylene and vinyl acetate monomers. The composition and properties of EVA can be tailored by adjusting the ratio of these monomers and the polymerization conditions. This versatility allows for the production of EVA with varying degrees of flexibility, toughness, and adhesion properties.

- EVA blends and modifications: EVA copolymers can be blended with other polymers or modified with additives to enhance their properties. These blends and modifications can improve characteristics such as impact resistance, thermal stability, and processability. Common blend partners include polyethylene, polypropylene, and various elastomers. Modifications may involve crosslinking or the addition of fillers and stabilizers.

- Applications of EVA in adhesives and sealants: EVA copolymers are widely used in the production of hot melt adhesives and sealants. Their low melting point, good adhesion to various substrates, and flexibility make them ideal for these applications. EVA-based adhesives are used in packaging, bookbinding, and product assembly across various industries.

- EVA in foam and film production: EVA copolymers are utilized in the manufacture of foams and films for various applications. EVA foams offer excellent shock absorption and cushioning properties, making them suitable for sports equipment and packaging. EVA films are used in solar panel encapsulation, packaging, and agricultural applications due to their transparency, flexibility, and weather resistance.

- Recycling and sustainability of EVA products: As environmental concerns grow, there is increasing focus on the recycling and sustainability of EVA products. Research is being conducted on methods to efficiently recycle EVA materials, particularly from products like shoe soles and solar panels. Additionally, efforts are being made to develop bio-based or biodegradable alternatives to traditional EVA copolymers.

02 EVA blends and modifications

EVA copolymers can be blended with other polymers or modified with additives to enhance specific properties. These blends and modifications can improve characteristics such as impact resistance, thermal stability, and processability. Techniques like crosslinking, grafting, and the addition of fillers or compatibilizers are used to create tailored EVA-based materials for various applications.Expand Specific Solutions03 EVA foam production and properties

EVA foams are produced by incorporating blowing agents into the polymer matrix and subjecting it to specific processing conditions. The resulting foam structures exhibit properties such as low density, excellent cushioning, and good thermal insulation. Various techniques are employed to control cell size, distribution, and overall foam morphology to suit different applications.Expand Specific Solutions04 EVA in adhesive and sealant applications

EVA copolymers are widely used in adhesive and sealant formulations due to their excellent adhesion properties, flexibility, and compatibility with various substrates. The vinyl acetate content and molecular weight of the EVA can be tailored to achieve specific adhesive characteristics. Hot melt adhesives, pressure-sensitive adhesives, and sealants for packaging and construction applications often incorporate EVA as a key component.Expand Specific Solutions05 EVA in film and packaging applications

EVA copolymers are extensively used in the production of flexible films and packaging materials. The copolymer's properties, such as clarity, toughness, and low-temperature flexibility, make it suitable for various packaging applications. EVA films can be produced through extrusion or coextrusion processes, and their properties can be further enhanced through orientation or lamination with other materials.Expand Specific Solutions

Key Industry Players

The market for Ethylene Vinyl Acetate (EVA) is in a mature growth stage, with a global market size expected to reach $10.5 billion by 2027. The technology is well-established, with major players like DuPont, Celanese, and Mitsui Chemicals having extensive experience in EVA production. However, there's ongoing innovation in transformational applications, particularly in renewable energy, healthcare, and advanced packaging. Chinese companies like Sinopec are increasingly competitive, leveraging their petrochemical expertise. The industry is seeing a shift towards bio-based and recyclable EVA formulations, driven by sustainability trends, with companies like Kuraray and Wacker Chemie at the forefront of these developments.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced EVA production technologies, including a proprietary high-pressure tubular reactor process. This technology allows for precise control of vinyl acetate content and molecular weight distribution, resulting in EVA with tailored properties for specific applications[1]. Sinopec has also invested in research on EVA-based photovoltaic encapsulant materials, improving the durability and efficiency of solar panels[2]. Their transformational use cases include developing EVA-based materials for 3D printing, which offer improved flexibility and impact resistance compared to traditional filaments[3].

Strengths: Vertically integrated production, strong R&D capabilities, and a wide range of EVA grades. Weaknesses: Potential environmental concerns associated with petrochemical production and limited global market presence outside of Asia.

Mitsui Chemicals, Inc.

Technical Solution: Mitsui Chemicals has developed innovative EVA-based materials for transformational applications. Their Milastomer™ series combines EVA with other elastomers to create thermoplastic elastomers with enhanced properties[4]. These materials find use in automotive interiors, consumer electronics, and medical devices. Mitsui has also pioneered the use of EVA in advanced packaging solutions, developing high-barrier EVA films that extend food shelf life and reduce plastic waste[5]. In the renewable energy sector, Mitsui's EVA encapsulants for photovoltaic modules offer improved weatherability and power output stability[6].

Strengths: Strong focus on sustainability, diverse product portfolio, and global market presence. Weaknesses: Relatively high production costs and potential competition from bio-based alternatives.

Breakthrough EVA Patents

Graft ethylene-vinyl acetate copolymer and resin composition containing the same

PatentWO1997002302A1

Innovation

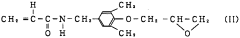

- A graft-modified ethylene-vinyl acetate copolymer is developed by incorporating a glycidyl group-containing compound and unsaturated glycidyl ester, along with a radical initiator, to enhance thermal stability and adhesion, and is blended with polyamide or polyester resins to improve mechanical and thermal properties.

Method for preparing ethylene-vinyl acetate with low melt index

PatentWO2014181991A1

Innovation

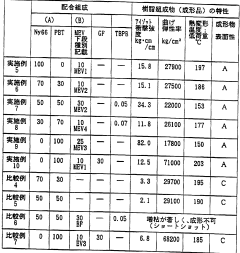

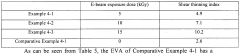

- Applying an electron beam with a defined exposure dose to an ethylene-vinyl acetate resin composition with a vinyl acetate content of 15 to 50 wt% to reduce the melt index to 10 g/10 min or less, thereby enhancing mechanical properties and processability without the need for additional modifiers like peroxides.

Environmental Impact

The environmental impact of Ethylene Vinyl Acetate (EVA) is a critical consideration in its transformational use cases. EVA, a copolymer of ethylene and vinyl acetate, has gained significant attention due to its versatile properties and wide range of applications. However, its production and disposal processes have raised concerns about potential environmental consequences.

In the manufacturing phase, EVA production involves the use of petrochemical feedstocks, which contribute to greenhouse gas emissions and resource depletion. The polymerization process requires substantial energy input, further increasing its carbon footprint. Additionally, the use of solvents and additives in EVA production can lead to air and water pollution if not properly managed.

During its use phase, EVA demonstrates some positive environmental attributes. Its durability and resistance to weathering can lead to longer product lifespans, potentially reducing waste generation. In certain applications, such as solar panel encapsulation, EVA contributes to the production of renewable energy, indirectly offsetting carbon emissions.

However, the end-of-life stage presents significant environmental challenges. EVA is not biodegradable and can persist in the environment for extended periods. Improper disposal can lead to soil and water contamination. Recycling EVA is complex due to its cross-linked structure, often resulting in downcycling rather than true recycling.

Recent innovations in EVA formulations have focused on improving its environmental profile. Bio-based EVA, derived partially from renewable resources, has emerged as a more sustainable alternative. These formulations aim to reduce reliance on fossil fuels and decrease the overall carbon footprint of EVA products.

Efforts to enhance the recyclability of EVA are also underway. Advanced recycling technologies, such as chemical recycling and depolymerization, show promise in breaking down EVA into its constituent monomers, enabling true circular economy practices. However, these technologies are still in the early stages of development and face challenges in scaling up to industrial levels.

The transformational use cases of EVA must consider these environmental impacts. Industries are increasingly adopting life cycle assessment approaches to evaluate the full environmental implications of EVA applications. This holistic view helps in identifying areas for improvement and drives innovation towards more sustainable EVA formulations and processing methods.

In the manufacturing phase, EVA production involves the use of petrochemical feedstocks, which contribute to greenhouse gas emissions and resource depletion. The polymerization process requires substantial energy input, further increasing its carbon footprint. Additionally, the use of solvents and additives in EVA production can lead to air and water pollution if not properly managed.

During its use phase, EVA demonstrates some positive environmental attributes. Its durability and resistance to weathering can lead to longer product lifespans, potentially reducing waste generation. In certain applications, such as solar panel encapsulation, EVA contributes to the production of renewable energy, indirectly offsetting carbon emissions.

However, the end-of-life stage presents significant environmental challenges. EVA is not biodegradable and can persist in the environment for extended periods. Improper disposal can lead to soil and water contamination. Recycling EVA is complex due to its cross-linked structure, often resulting in downcycling rather than true recycling.

Recent innovations in EVA formulations have focused on improving its environmental profile. Bio-based EVA, derived partially from renewable resources, has emerged as a more sustainable alternative. These formulations aim to reduce reliance on fossil fuels and decrease the overall carbon footprint of EVA products.

Efforts to enhance the recyclability of EVA are also underway. Advanced recycling technologies, such as chemical recycling and depolymerization, show promise in breaking down EVA into its constituent monomers, enabling true circular economy practices. However, these technologies are still in the early stages of development and face challenges in scaling up to industrial levels.

The transformational use cases of EVA must consider these environmental impacts. Industries are increasingly adopting life cycle assessment approaches to evaluate the full environmental implications of EVA applications. This holistic view helps in identifying areas for improvement and drives innovation towards more sustainable EVA formulations and processing methods.

Regulatory Considerations

The regulatory landscape for Ethylene Vinyl Acetate (EVA) is complex and multifaceted, reflecting its diverse applications across various industries. In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating EVA's use in food contact materials and medical devices. The FDA has established specific guidelines for EVA copolymers used in food packaging, ensuring they meet safety standards and do not leach harmful substances into food products.

In the European Union, the European Chemicals Agency (ECHA) oversees the regulation of EVA under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) framework. This comprehensive regulatory system requires manufacturers and importers to register EVA and provide detailed safety information, particularly when used in quantities exceeding one tonne per year.

For the construction industry, building codes and standards in many countries have specific requirements for EVA-based materials, especially concerning fire safety and thermal insulation properties. These regulations often vary by region and application, necessitating careful consideration in product development and marketing strategies.

In the renewable energy sector, particularly for solar panel encapsulation, EVA must comply with international standards such as IEC 61730 and UL 1703. These standards ensure the long-term reliability and safety of photovoltaic modules, addressing aspects like weatherability and electrical insulation properties of EVA encapsulants.

The automotive industry faces stringent regulations regarding the use of EVA in vehicle components. In many jurisdictions, EVA-based materials must meet specific flammability and emissions standards, as outlined in regulations like the Federal Motor Vehicle Safety Standards (FMVSS) in the United States.

Environmental regulations also significantly impact EVA production and use. Many countries have implemented policies to reduce volatile organic compound (VOC) emissions associated with EVA processing. Additionally, there is growing pressure to develop sustainable and recyclable EVA formulations to align with circular economy principles and reduce environmental impact.

As EVA finds new applications in emerging technologies, regulatory bodies are continually updating their guidelines. For instance, the use of EVA in 3D printing materials has prompted discussions about potential health and safety regulations, particularly for consumer-grade products.

In the European Union, the European Chemicals Agency (ECHA) oversees the regulation of EVA under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) framework. This comprehensive regulatory system requires manufacturers and importers to register EVA and provide detailed safety information, particularly when used in quantities exceeding one tonne per year.

For the construction industry, building codes and standards in many countries have specific requirements for EVA-based materials, especially concerning fire safety and thermal insulation properties. These regulations often vary by region and application, necessitating careful consideration in product development and marketing strategies.

In the renewable energy sector, particularly for solar panel encapsulation, EVA must comply with international standards such as IEC 61730 and UL 1703. These standards ensure the long-term reliability and safety of photovoltaic modules, addressing aspects like weatherability and electrical insulation properties of EVA encapsulants.

The automotive industry faces stringent regulations regarding the use of EVA in vehicle components. In many jurisdictions, EVA-based materials must meet specific flammability and emissions standards, as outlined in regulations like the Federal Motor Vehicle Safety Standards (FMVSS) in the United States.

Environmental regulations also significantly impact EVA production and use. Many countries have implemented policies to reduce volatile organic compound (VOC) emissions associated with EVA processing. Additionally, there is growing pressure to develop sustainable and recyclable EVA formulations to align with circular economy principles and reduce environmental impact.

As EVA finds new applications in emerging technologies, regulatory bodies are continually updating their guidelines. For instance, the use of EVA in 3D printing materials has prompted discussions about potential health and safety regulations, particularly for consumer-grade products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!