Trend Analysis for Ethylene Vinyl Acetate Research

EVA Research Background and Objectives

Ethylene Vinyl Acetate (EVA) has emerged as a versatile and significant material in various industries over the past few decades. This research aims to analyze the trends in EVA research, focusing on its technological evolution, market dynamics, and future prospects. The primary objective is to provide a comprehensive understanding of EVA's current status and potential developments in the coming years.

EVA, a copolymer of ethylene and vinyl acetate, was first developed in the 1950s. Since then, it has undergone continuous improvements in its properties and manufacturing processes. The material's unique combination of flexibility, toughness, and transparency has led to its widespread adoption in industries ranging from packaging and footwear to solar panel encapsulation and medical devices.

The global EVA market has experienced steady growth, driven by increasing demand in emerging economies and the material's expanding applications. This research aims to analyze the factors contributing to this growth, including technological advancements, changing consumer preferences, and regulatory influences. By examining these trends, we seek to identify potential opportunities and challenges for the EVA industry.

One of the key focuses of this research is the technological advancements in EVA production and applications. We will explore innovations in polymerization techniques, additives, and processing methods that have enhanced EVA's performance characteristics. Additionally, we will investigate emerging applications that are driving research and development efforts in the EVA field.

Sustainability has become a crucial factor in materials research, and EVA is no exception. This study will examine the ongoing efforts to improve the environmental profile of EVA, including research into bio-based alternatives, recycling technologies, and strategies to reduce the carbon footprint of EVA production.

The research will also delve into the competitive landscape of the EVA industry, analyzing the strategies of key players and identifying potential disruptors. By examining patent trends, research publications, and industry collaborations, we aim to provide insights into the direction of future innovations and market dynamics.

Furthermore, this study will explore the regional variations in EVA research and market trends. We will analyze how different geographical areas are contributing to EVA innovation and adoption, and how regional policies and economic factors are shaping the industry's landscape.

By conducting this comprehensive trend analysis, we aim to provide valuable insights for stakeholders in the EVA industry, including manufacturers, researchers, and policymakers. The findings of this research will serve as a foundation for strategic decision-making, guiding future research directions, and identifying potential investment opportunities in the evolving EVA market.

Market Demand Analysis for EVA Products

The global market for Ethylene Vinyl Acetate (EVA) products has been experiencing steady growth, driven by increasing demand across various industries. The versatility of EVA as a material has led to its widespread adoption in sectors such as packaging, footwear, solar panels, and automotive components. In the packaging industry, EVA is widely used for flexible packaging solutions, offering excellent sealing properties and durability. The growing e-commerce sector has further boosted the demand for EVA-based packaging materials.

The footwear industry represents another significant market for EVA products. The material's lightweight nature, cushioning properties, and resistance to wear and tear make it ideal for shoe soles and insoles. As consumer preferences shift towards comfortable and durable footwear, the demand for EVA in this sector continues to rise.

In the renewable energy sector, EVA plays a crucial role in the production of solar panels. The material is used as an encapsulant to protect solar cells from environmental factors and enhance their efficiency. With the global push towards sustainable energy solutions, the demand for EVA in solar panel manufacturing is expected to grow substantially in the coming years.

The automotive industry is another key consumer of EVA products. The material is used in various applications, including wire and cable insulation, gaskets, and interior components. As vehicle manufacturers focus on lightweight materials to improve fuel efficiency and reduce emissions, the demand for EVA in automotive applications is projected to increase.

Geographically, Asia-Pacific dominates the EVA market, with China being the largest consumer and producer. The region's robust manufacturing sector, coupled with rapid industrialization and urbanization, drives the demand for EVA products. North America and Europe also represent significant markets, particularly in high-value applications such as solar panels and specialty packaging.

The market for EVA products is influenced by several factors, including raw material prices, technological advancements, and regulatory policies. The volatility in ethylene and vinyl acetate prices can impact the overall cost of EVA production, affecting market dynamics. Additionally, ongoing research and development efforts are focused on improving EVA properties and expanding its applications, which could open up new market opportunities.

Environmental concerns and sustainability initiatives are also shaping the EVA market. There is a growing emphasis on developing bio-based and recyclable EVA alternatives to address environmental issues associated with traditional petroleum-based EVA. This trend is likely to influence future market dynamics and product development strategies in the EVA industry.

Current State and Challenges in EVA Technology

Ethylene Vinyl Acetate (EVA) technology has made significant strides in recent years, with its applications expanding across various industries. The current state of EVA technology is characterized by a growing demand for high-performance materials in sectors such as solar energy, packaging, and footwear. However, this increased demand has also brought to light several challenges that researchers and manufacturers must address.

One of the primary advancements in EVA technology is the development of enhanced copolymerization processes, allowing for better control over the vinyl acetate content and molecular weight distribution. This has resulted in EVA materials with improved thermal stability, flexibility, and adhesion properties. Additionally, the introduction of novel crosslinking agents and additives has further expanded the range of EVA's performance characteristics.

Despite these advancements, the EVA industry faces several technical challenges. One of the most pressing issues is the need for improved weatherability and UV resistance, particularly in outdoor applications such as solar panel encapsulation. Researchers are actively working on developing new stabilizer systems and surface treatments to enhance EVA's long-term durability under harsh environmental conditions.

Another significant challenge lies in the realm of recycling and sustainability. As environmental concerns grow, there is an increasing demand for recyclable and biodegradable EVA formulations. However, the complex nature of EVA copolymers and the presence of various additives make recycling a difficult task. Efforts are underway to develop more eco-friendly EVA compositions and improved recycling technologies, but progress in this area remains slow.

The EVA industry is also grappling with the challenge of balancing performance with cost-effectiveness. As raw material prices fluctuate and competition intensifies, manufacturers are under pressure to optimize their production processes and formulations. This has led to increased research into alternative feedstocks and more efficient polymerization techniques.

From a geographical perspective, EVA technology development is concentrated in regions with strong chemical and polymer industries, such as East Asia, North America, and Europe. China, in particular, has emerged as a major player in EVA production and research, driven by its growing domestic demand and export-oriented economy.

In conclusion, while EVA technology has made significant progress, it continues to face challenges in areas such as durability, sustainability, and cost-effectiveness. Overcoming these hurdles will require continued innovation in material science, process engineering, and application development. The future of EVA technology will likely be shaped by advancements in these key areas, as well as by evolving market demands and regulatory landscapes.

Current EVA Production Methods

01 Composition and properties of EVA

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to UV radiation and stress-cracking. The ratio of ethylene to vinyl acetate in the copolymer can be adjusted to modify its characteristics, making it suitable for various applications.- Composition and properties of EVA: Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to UV radiation and stress-cracking. The ratio of ethylene to vinyl acetate in the copolymer can be varied to achieve different characteristics, making it suitable for various applications.

- EVA in adhesive applications: EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is used in hot melt adhesives, pressure-sensitive adhesives, and sealants. The adhesive strength and flexibility of EVA-based adhesives can be tailored by adjusting the vinyl acetate content and molecular weight of the copolymer.

- EVA in foam and insulation materials: EVA is utilized in the production of foam and insulation materials due to its low density, good thermal insulation properties, and ability to be crosslinked. It is used in the manufacture of shoe soles, sports equipment padding, and building insulation. The foam properties can be modified by adjusting the blowing agent and crosslinking degree.

- EVA in solar panel encapsulation: EVA is a popular material for solar panel encapsulation due to its transparency, weather resistance, and ability to protect solar cells from environmental factors. It helps in improving the efficiency and longevity of solar panels by providing a protective barrier against moisture and UV radiation.

- Modifications and blends of EVA: EVA can be modified or blended with other polymers to enhance its properties for specific applications. This includes the addition of fillers, crosslinking agents, or blending with other polymers to improve mechanical strength, flame retardancy, or processability. These modifications expand the range of applications for EVA-based materials.

02 EVA in adhesive applications

EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is particularly useful in hot melt adhesives, where it provides good thermal stability and adhesion strength. EVA-based adhesives find applications in packaging, bookbinding, and construction industries.Expand Specific Solutions03 EVA in foam and insulation materials

EVA is utilized in the production of foam and insulation materials due to its low density, good cushioning properties, and thermal insulation characteristics. It is commonly used in the manufacture of shoe soles, sports equipment padding, and building insulation. The foam can be crosslinked to enhance its properties further.Expand Specific Solutions04 EVA in solar panel encapsulation

EVA is a preferred material for solar panel encapsulation due to its transparency, weather resistance, and electrical insulation properties. It helps protect the solar cells from environmental factors and ensures long-term performance of photovoltaic modules. The material can be modified to enhance its UV stability and adhesion to glass and backsheet materials.Expand Specific Solutions05 EVA in wire and cable insulation

EVA is used in wire and cable insulation applications due to its excellent electrical properties, flexibility, and resistance to environmental stress cracking. It can be compounded with various additives to enhance its flame retardancy and other specific properties required for different cable applications in industries such as automotive and telecommunications.Expand Specific Solutions

Key Players in EVA Industry

The trend analysis for Ethylene Vinyl Acetate (EVA) research reveals a competitive landscape in a mature industry with steady growth. The global EVA market is substantial, driven by diverse applications in sectors like packaging, footwear, and solar panels. Technologically, the field is well-established, with major players like China Petroleum & Chemical Corp., Celanese International Corp., and LyondellBasell Acetyls LLC leading innovation. Research institutions such as Shanghai Petrochemical Research Institute and Tianjin University contribute to advancements. The involvement of multinational corporations like Henkel AG & Co. KGaA and Solvay SA indicates the industry's global significance and potential for further development in specialized applications and sustainability.

China Petroleum & Chemical Corp.

Celanese International Corp.

Key Innovations in EVA Research

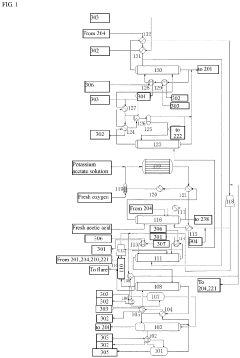

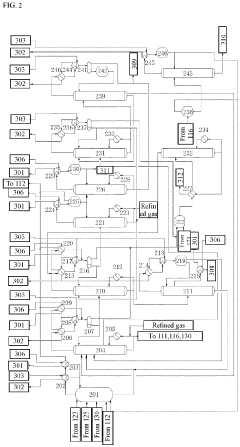

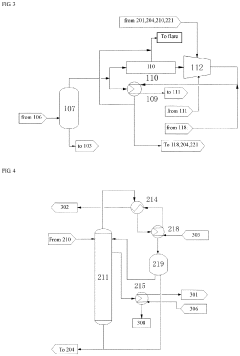

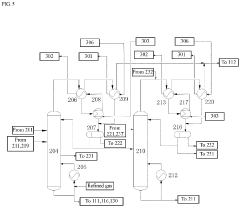

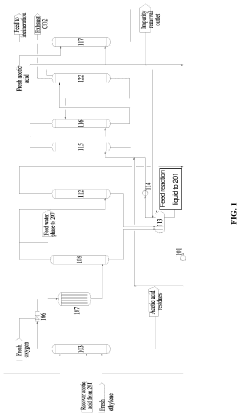

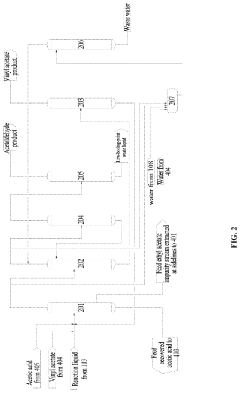

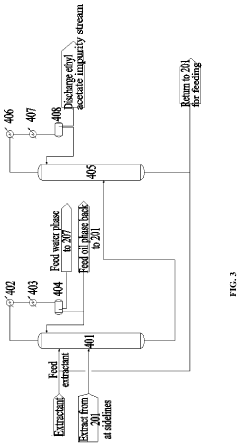

- A novel process incorporating an ethylene recovery membrane assembly, refined VAC tower side-draw stream additions, and improved cooling methods using circulating and chilled water for high-purity vinyl acetate production, reducing emissions and preventing material leakage by recovering ethylene and optimizing the distillation process.

- A method involving a gas phase oxidation process with a system integration that includes specific towers and reactors for ethylene recovery, acetic acid evaporation, oxygen mixing, and separation processes, utilizing acetic acid as an extractant in the rectifying and separating towers to enhance the separation of vinyl acetate from ethyl acetate.

Environmental Impact of EVA Production

The production of Ethylene Vinyl Acetate (EVA) has significant environmental implications that warrant careful consideration. The manufacturing process involves the use of petrochemical feedstocks, which are derived from non-renewable resources and contribute to greenhouse gas emissions. The polymerization reaction requires high temperatures and pressures, consuming substantial energy and potentially releasing volatile organic compounds (VOCs) into the atmosphere.

Water pollution is another concern associated with EVA production. The process generates wastewater containing various chemicals, including unreacted monomers and additives. If not properly treated, these effluents can harm aquatic ecosystems and contaminate water sources. Additionally, the use of catalysts and other chemical additives in EVA production may lead to the generation of hazardous waste that requires specialized disposal methods.

The environmental impact of EVA extends beyond its production phase. The material's durability and resistance to degradation, while beneficial for many applications, pose challenges for end-of-life management. EVA products often end up in landfills, where they persist for extended periods, contributing to long-term environmental pollution. Recycling EVA can be challenging due to its cross-linked structure, limiting the potential for circular economy practices.

However, recent trends in EVA research and production show a growing focus on sustainability. Manufacturers are exploring bio-based feedstocks as alternatives to petroleum-derived monomers, aiming to reduce the carbon footprint of EVA production. Advanced process technologies are being developed to improve energy efficiency and minimize emissions during manufacturing. These innovations include the use of more efficient catalysts, optimized reactor designs, and improved heat recovery systems.

Efforts are also being made to enhance the recyclability of EVA products. Research is underway to develop EVA formulations that maintain desirable properties while being more amenable to recycling processes. Some companies are investigating chemical recycling methods that can break down EVA into its constituent monomers, enabling the production of new EVA or other valuable chemicals.

The environmental impact of EVA production is increasingly influencing market dynamics and regulatory landscapes. Stricter environmental regulations are driving investments in cleaner production technologies and waste management practices. Consumers and industries are showing a growing preference for sustainable materials, creating opportunities for eco-friendly EVA alternatives and driving research into more environmentally benign production methods.

Regulatory Framework for EVA Applications

The regulatory framework for Ethylene Vinyl Acetate (EVA) applications is a complex and evolving landscape that significantly impacts the research and development trends in this field. As EVA finds increasing use in various industries, including solar panel manufacturing, packaging, and medical devices, regulatory bodies worldwide have implemented stringent guidelines to ensure product safety and environmental compliance.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating EVA applications in food contact materials and medical devices. The FDA's 21 CFR 177.1350 specifically addresses the use of EVA copolymers in food packaging, setting limits on the vinyl acetate content and specifying extraction tests for safety assessment. For medical applications, EVA must meet the requirements outlined in the ISO 10993 series for biocompatibility testing.

The European Union has established comprehensive regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. Under REACH, manufacturers and importers of EVA products must register their substances and provide detailed safety information. The European Food Safety Authority (EFSA) also regulates EVA use in food contact materials, setting specific migration limits for vinyl acetate monomers.

In the renewable energy sector, EVA's use in solar panel encapsulation is subject to IEC 61730 and UL 61730 standards, which focus on photovoltaic module safety qualification. These standards ensure that EVA-based encapsulants meet rigorous durability and performance criteria under various environmental conditions.

Environmental regulations have also shaped EVA research trends, with a growing emphasis on sustainable production methods and end-of-life considerations. The EU's Waste Electrical and Electronic Equipment (WEEE) Directive and similar regulations in other regions have spurred research into recyclable and biodegradable EVA formulations.

As global concerns about plastic pollution intensify, several countries have implemented or proposed regulations targeting single-use plastics, which may affect certain EVA applications. This regulatory pressure has driven innovation in EVA research, focusing on developing more environmentally friendly alternatives and improving recycling technologies for EVA-based products.

The automotive industry, another significant user of EVA, faces stringent regulations regarding vehicle emissions and fuel efficiency. This has led to increased research in lightweight EVA composites that can contribute to overall vehicle weight reduction while maintaining safety standards set by organizations like the National Highway Traffic Safety Administration (NHTSA) in the United States.

As the regulatory landscape continues to evolve, EVA researchers and manufacturers must stay abreast of new and upcoming regulations. This includes monitoring proposed changes to existing frameworks and participating in public consultations to ensure that future regulations are both scientifically sound and practically implementable.