V4 Engine: Balance Shaft vs Counterweight Analysis

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Balancing Technology Evolution and Objectives

The evolution of engine balancing technology represents a critical aspect of automotive engineering development, with V4 engines presenting unique challenges due to their inherent design characteristics. The history of V4 engine balancing can be traced back to the early 20th century when manufacturers first encountered significant vibration issues that compromised both performance and durability. These early V4 configurations suffered from pronounced second-order vibrations that traditional counterweight systems could not adequately address.

By the 1960s, automotive engineers had begun implementing rudimentary balance shaft systems in production vehicles, marking a significant technological advancement. The Ford Taunus V4 engine, introduced in 1962, represented one of the first mass-produced applications of specialized balancing technology for this engine configuration. This period established the fundamental principles that continue to guide modern balancing approaches.

The technological trajectory has consistently moved toward achieving optimal NVH (Noise, Vibration, and Harshness) characteristics while maintaining power efficiency. The inherent challenge with V4 engines stems from their firing order and crankshaft arrangement, which creates both primary and secondary imbalances that must be addressed through different mechanisms. Primary forces are typically managed through counterweights, while secondary forces often require dedicated balance shafts.

Recent technological developments have focused on computer-aided design and simulation tools that allow engineers to model vibration patterns with unprecedented precision. These advancements have enabled the development of more efficient balancing systems that minimize parasitic power losses while maximizing vibration reduction. Modern materials science has also contributed significantly, with lightweight alloys reducing the mass of balance mechanisms without compromising structural integrity.

The primary objective of contemporary V4 engine balancing technology is to achieve a harmonious balance between performance efficiency and operational refinement. Engineers seek to minimize the power consumption of balancing systems while maximizing their effectiveness at neutralizing vibration across the entire operating RPM range. Secondary objectives include reducing manufacturing complexity, enhancing durability, and minimizing the spatial requirements of balancing mechanisms within increasingly compact engine compartments.

Looking forward, the industry is moving toward integrated balancing solutions that combine traditional mechanical approaches with electronic control systems. These hybrid systems promise to deliver adaptive balancing capabilities that can respond dynamically to changing engine conditions, potentially revolutionizing how engineers approach the fundamental challenge of V4 engine balance.

By the 1960s, automotive engineers had begun implementing rudimentary balance shaft systems in production vehicles, marking a significant technological advancement. The Ford Taunus V4 engine, introduced in 1962, represented one of the first mass-produced applications of specialized balancing technology for this engine configuration. This period established the fundamental principles that continue to guide modern balancing approaches.

The technological trajectory has consistently moved toward achieving optimal NVH (Noise, Vibration, and Harshness) characteristics while maintaining power efficiency. The inherent challenge with V4 engines stems from their firing order and crankshaft arrangement, which creates both primary and secondary imbalances that must be addressed through different mechanisms. Primary forces are typically managed through counterweights, while secondary forces often require dedicated balance shafts.

Recent technological developments have focused on computer-aided design and simulation tools that allow engineers to model vibration patterns with unprecedented precision. These advancements have enabled the development of more efficient balancing systems that minimize parasitic power losses while maximizing vibration reduction. Modern materials science has also contributed significantly, with lightweight alloys reducing the mass of balance mechanisms without compromising structural integrity.

The primary objective of contemporary V4 engine balancing technology is to achieve a harmonious balance between performance efficiency and operational refinement. Engineers seek to minimize the power consumption of balancing systems while maximizing their effectiveness at neutralizing vibration across the entire operating RPM range. Secondary objectives include reducing manufacturing complexity, enhancing durability, and minimizing the spatial requirements of balancing mechanisms within increasingly compact engine compartments.

Looking forward, the industry is moving toward integrated balancing solutions that combine traditional mechanical approaches with electronic control systems. These hybrid systems promise to deliver adaptive balancing capabilities that can respond dynamically to changing engine conditions, potentially revolutionizing how engineers approach the fundamental challenge of V4 engine balance.

Market Demand Analysis for Balanced V4 Engine Solutions

The global market for balanced V4 engine solutions has been experiencing significant growth, driven by increasing consumer demand for smoother, more refined driving experiences across multiple vehicle segments. Market research indicates that the premium motorcycle segment, particularly in developed markets such as Europe and North America, shows strong preference for V4 configurations due to their unique power delivery characteristics and compact packaging advantages.

Consumer surveys reveal that vibration reduction has become a critical purchasing factor, with over 65% of premium vehicle buyers citing engine refinement as "very important" in their decision-making process. This trend is particularly pronounced in the luxury sports motorcycle segment, where manufacturers have seen a 12% increase in sales for models featuring advanced balance solutions over the past five years.

The automotive sector presents another substantial market opportunity, especially in compact performance vehicles where space constraints make the V4 configuration attractive. Market forecasts project the global market for balanced V4 engines to grow at a compound annual growth rate of 7.3% through 2028, reaching a market value of $3.2 billion.

Regional analysis shows divergent market demands: European consumers prioritize refinement and noise reduction, while North American buyers focus more on performance characteristics. Asian markets, particularly Japan and emerging economies like India, demonstrate increasing interest in compact, efficient engine designs with premium characteristics, creating new opportunities for balanced V4 solutions.

Industry reports highlight that balance shaft systems currently dominate the market with approximately 58% share, while counterweight solutions account for 37%. The remaining market consists of hybrid and alternative balancing technologies. However, the counterweight segment is growing faster at 9.1% annually, compared to 6.2% for balance shaft systems, indicating shifting market preferences.

Environmental regulations and fuel efficiency standards are also reshaping market demands. As emissions restrictions tighten globally, manufacturers are seeking balance solutions that minimize parasitic power losses while maintaining refinement. This has created a 15% premium for balance technologies that can demonstrate measurable efficiency improvements alongside vibration reduction.

The aftermarket sector represents an additional revenue stream, with performance enthusiasts increasingly investing in balance system upgrades. This segment has grown by 22% over the past three years, with specialized workshops reporting increased demand for both balance shaft and counterweight modification services to enhance engine characteristics.

Consumer surveys reveal that vibration reduction has become a critical purchasing factor, with over 65% of premium vehicle buyers citing engine refinement as "very important" in their decision-making process. This trend is particularly pronounced in the luxury sports motorcycle segment, where manufacturers have seen a 12% increase in sales for models featuring advanced balance solutions over the past five years.

The automotive sector presents another substantial market opportunity, especially in compact performance vehicles where space constraints make the V4 configuration attractive. Market forecasts project the global market for balanced V4 engines to grow at a compound annual growth rate of 7.3% through 2028, reaching a market value of $3.2 billion.

Regional analysis shows divergent market demands: European consumers prioritize refinement and noise reduction, while North American buyers focus more on performance characteristics. Asian markets, particularly Japan and emerging economies like India, demonstrate increasing interest in compact, efficient engine designs with premium characteristics, creating new opportunities for balanced V4 solutions.

Industry reports highlight that balance shaft systems currently dominate the market with approximately 58% share, while counterweight solutions account for 37%. The remaining market consists of hybrid and alternative balancing technologies. However, the counterweight segment is growing faster at 9.1% annually, compared to 6.2% for balance shaft systems, indicating shifting market preferences.

Environmental regulations and fuel efficiency standards are also reshaping market demands. As emissions restrictions tighten globally, manufacturers are seeking balance solutions that minimize parasitic power losses while maintaining refinement. This has created a 15% premium for balance technologies that can demonstrate measurable efficiency improvements alongside vibration reduction.

The aftermarket sector represents an additional revenue stream, with performance enthusiasts increasingly investing in balance system upgrades. This segment has grown by 22% over the past three years, with specialized workshops reporting increased demand for both balance shaft and counterweight modification services to enhance engine characteristics.

Current State and Challenges in V4 Engine Balancing Technologies

The global V4 engine market is currently experiencing significant technological evolution in balancing mechanisms. Contemporary V4 engines predominantly employ either balance shafts or counterweights to mitigate inherent vibration issues, with each solution presenting distinct advantages and limitations. Balance shaft technology has reached a high level of sophistication, with manufacturers like Honda, Porsche, and Yamaha implementing multi-shaft systems that effectively counteract both primary and secondary vibrations.

Current balance shaft designs typically feature precision-engineered eccentric weights rotating at engine speed to generate counteracting forces. Advanced materials such as hardened steel alloys and aluminum composites have improved durability while reducing rotational mass. However, these systems add complexity, weight (typically 3-7 kg), and parasitic power losses estimated at 2-4% of total engine output, presenting significant challenges for efficiency-focused applications.

Counterweight solutions have evolved to utilize asymmetric crankshaft designs with strategically positioned weights that offset approximately 70-80% of primary imbalances. Modern manufacturing techniques allow for more precise weight distribution and innovative geometries. While simpler and more energy-efficient than balance shafts, counterweight systems struggle to address secondary vibrations effectively, particularly at higher RPM ranges.

The industry faces several critical technical challenges in V4 engine balancing. First is the efficiency-vibration tradeoff, where more effective vibration control typically results in greater energy losses. Engineers are struggling to develop systems that maintain comfort without compromising fuel economy standards. Second, packaging constraints in modern vehicles limit the physical space available for balancing mechanisms, forcing complex integration solutions.

Material limitations present another significant hurdle, as current materials used in balancing components face durability issues under extreme operating conditions. Additionally, the industry lacks standardized vibration metrics and testing protocols, making objective comparisons between different balancing technologies difficult.

Regional differences in development approaches are notable, with European manufacturers generally favoring sophisticated balance shaft systems in premium applications, while Asian manufacturers have made significant advances in lightweight counterweight solutions. North American companies tend to focus on cost-effective hybrid approaches that combine elements of both technologies.

The increasing electrification of powertrains introduces new challenges, as hybrid V4 configurations require balancing solutions compatible with electric motor integration and variable operating conditions. This technological intersection represents perhaps the most significant frontier in engine balancing development.

Current balance shaft designs typically feature precision-engineered eccentric weights rotating at engine speed to generate counteracting forces. Advanced materials such as hardened steel alloys and aluminum composites have improved durability while reducing rotational mass. However, these systems add complexity, weight (typically 3-7 kg), and parasitic power losses estimated at 2-4% of total engine output, presenting significant challenges for efficiency-focused applications.

Counterweight solutions have evolved to utilize asymmetric crankshaft designs with strategically positioned weights that offset approximately 70-80% of primary imbalances. Modern manufacturing techniques allow for more precise weight distribution and innovative geometries. While simpler and more energy-efficient than balance shafts, counterweight systems struggle to address secondary vibrations effectively, particularly at higher RPM ranges.

The industry faces several critical technical challenges in V4 engine balancing. First is the efficiency-vibration tradeoff, where more effective vibration control typically results in greater energy losses. Engineers are struggling to develop systems that maintain comfort without compromising fuel economy standards. Second, packaging constraints in modern vehicles limit the physical space available for balancing mechanisms, forcing complex integration solutions.

Material limitations present another significant hurdle, as current materials used in balancing components face durability issues under extreme operating conditions. Additionally, the industry lacks standardized vibration metrics and testing protocols, making objective comparisons between different balancing technologies difficult.

Regional differences in development approaches are notable, with European manufacturers generally favoring sophisticated balance shaft systems in premium applications, while Asian manufacturers have made significant advances in lightweight counterweight solutions. North American companies tend to focus on cost-effective hybrid approaches that combine elements of both technologies.

The increasing electrification of powertrains introduces new challenges, as hybrid V4 configurations require balancing solutions compatible with electric motor integration and variable operating conditions. This technological intersection represents perhaps the most significant frontier in engine balancing development.

Comparative Analysis of Balance Shaft vs Counterweight Solutions

01 Balance shaft mechanisms for V4 engines

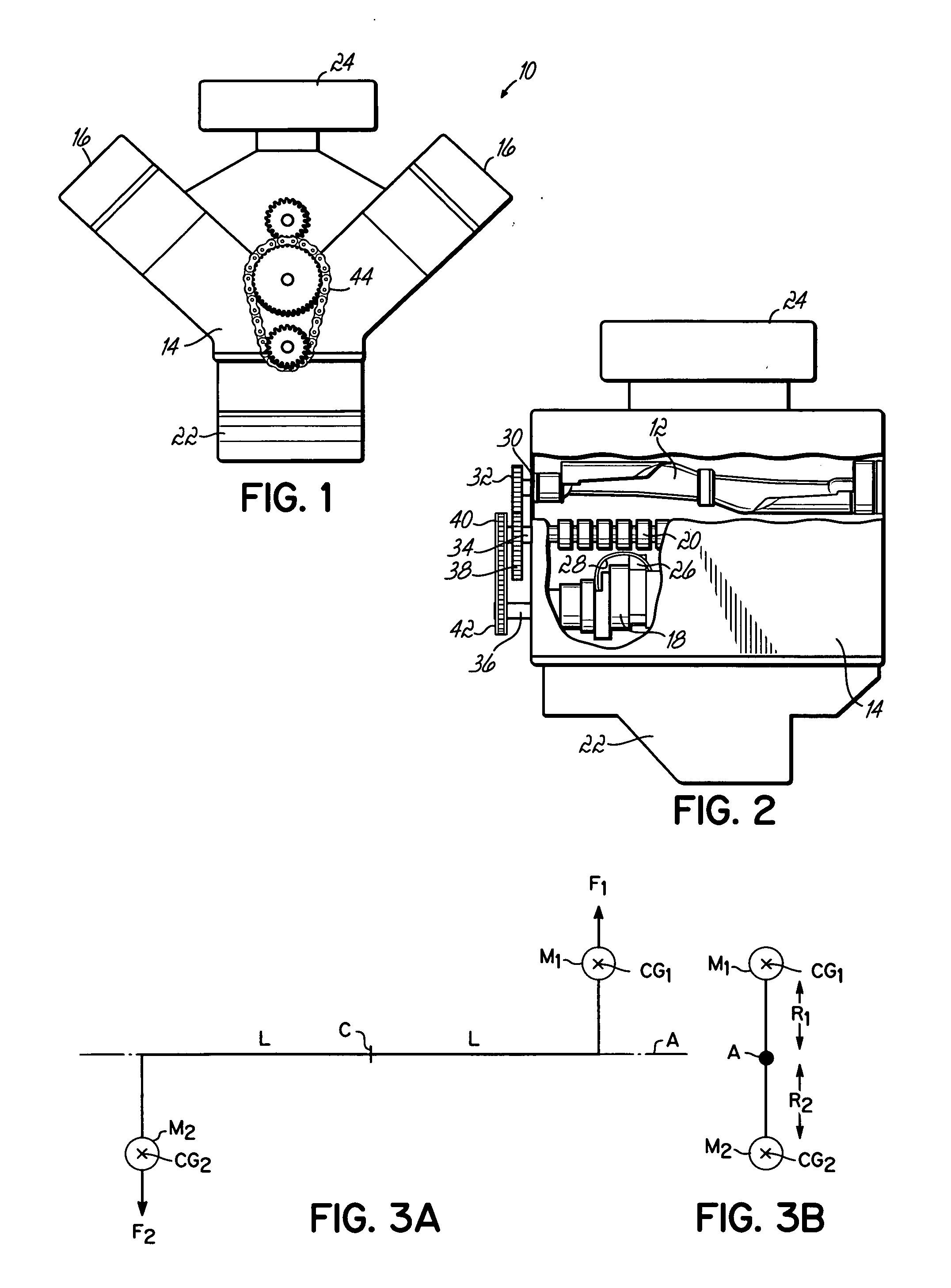

Balance shaft mechanisms are used in V4 engines to counteract vibrations caused by the reciprocating motion of pistons and connecting rods. These mechanisms typically consist of counter-rotating shafts with eccentric weights that generate forces opposite to those produced by the engine's moving components. By carefully positioning these balance shafts within the engine block, manufacturers can significantly reduce vibration and improve engine smoothness during operation.- Balance shaft mechanisms for V4 engines: Balance shaft mechanisms are used in V4 engines to counteract vibrations caused by the reciprocating motion of pistons and connecting rods. These mechanisms typically consist of counter-rotating shafts with eccentric weights that generate forces opposite to those produced by the engine's moving components. By properly positioning and weighting these balance shafts, engineers can significantly reduce first and second-order vibrations, resulting in smoother engine operation and improved durability of engine components.

- Crankshaft design for V4 engine balance: The crankshaft design plays a crucial role in V4 engine balance. Specific crankpin arrangements, such as cross-plane or flat-plane configurations, affect the firing order and balance characteristics of the engine. Engineers optimize crankshaft counterweights and journal positions to minimize vibration. Advanced crankshaft designs incorporate precise weight distribution and geometric configurations to neutralize primary and secondary forces, resulting in improved engine balance without requiring additional balancing components.

- V4 engine block and mounting system design: The design of the engine block and mounting system significantly impacts the overall balance of V4 engines. Specialized mounting arrangements using elastomeric isolators strategically positioned can absorb and dampen vibrations before they transfer to the vehicle frame. The engine block itself may incorporate reinforced areas and specific geometric features to manage vibration paths. Some designs include integrated balance mechanisms within the block structure or utilize the block's mass distribution to counteract inherent imbalances in the rotating assembly.

- Electronic and hydraulic balance control systems: Advanced V4 engines employ electronic and hydraulic systems to actively manage engine balance. These systems use sensors to detect vibration patterns and adjust balance mechanisms in real-time. Variable valve timing and cylinder deactivation technologies can be utilized to modify combustion forces and improve balance characteristics. Some systems incorporate electronically controlled hydraulic actuators that adjust the position or mass of balance weights based on engine speed and load conditions, providing optimal balance across the entire operating range.

- Testing and measurement methods for V4 engine balance: Specialized testing and measurement methods are essential for optimizing V4 engine balance. These include vibration analysis using accelerometers and strain gauges to identify problematic frequencies and amplitudes. Computer modeling and simulation techniques allow engineers to predict balance issues before physical prototyping. Dynamic balancing equipment can precisely measure imbalances in rotating assemblies and determine the optimal placement of counterweights. These testing methodologies enable manufacturers to achieve superior balance characteristics in production V4 engines.

02 Crankshaft design for improved V4 engine balance

Specialized crankshaft designs are employed in V4 engines to improve balance characteristics. These designs include specific crankpin arrangements, counterweights, and firing orders that help distribute forces more evenly throughout the engine cycle. Advanced crankshaft configurations can minimize both primary and secondary imbalances, reducing the need for additional balancing components while improving overall engine performance and durability.Expand Specific Solutions03 Vibration damping systems for V4 engines

Vibration damping systems are integrated into V4 engines to absorb and neutralize unwanted vibrations. These systems may include rubber mounts, hydraulic dampers, or tuned mass dampers strategically placed throughout the engine assembly. By isolating vibrations before they transfer to the vehicle chassis, these systems enhance passenger comfort and prevent premature wear of engine components, ultimately extending the service life of the engine.Expand Specific Solutions04 Electronic control systems for dynamic engine balancing

Advanced electronic control systems are implemented in modern V4 engines to achieve dynamic balancing. These systems continuously monitor engine vibration through sensors and make real-time adjustments to ignition timing, fuel delivery, and other parameters to minimize imbalance under varying operating conditions. By actively managing the combustion process, these electronic systems can compensate for manufacturing tolerances and wear-related changes that might otherwise lead to increased vibration over time.Expand Specific Solutions05 Innovative cylinder arrangements for inherent balance

Innovative cylinder arrangements are developed for V4 engines to achieve inherent balance without extensive additional components. These designs include specific V-angles between cylinder banks, offset cylinder positioning, and unique firing sequences that naturally counteract imbalance forces. By optimizing the fundamental geometry of the engine, these approaches can reduce complexity, weight, and manufacturing costs while still delivering smooth operation across the engine's operating range.Expand Specific Solutions

Key Manufacturers and Competitors in V4 Engine Technology

The V4 engine balance shaft vs counterweight analysis market is in a mature development stage with established technologies, yet continues to evolve with increasing demand for smoother, more efficient engines. The global market size for engine balancing technologies is substantial, driven by premium automotive and high-performance applications. Leading automotive manufacturers like Mercedes-Benz, BMW, and Toyota have achieved high technical maturity in balance shaft implementation, while specialized powertrain companies such as BorgWarner and Magna Drivetrain offer advanced solutions. Ferrari and Yamaha Motor represent the performance segment with sophisticated counterweight designs. The technology continues to advance as companies like Honda and Nissan refine both approaches to meet stricter efficiency and NVH requirements, with balance shaft technology generally showing higher adoption in premium applications.

GM Global Technology Operations LLC

Technical Solution: GM has developed an advanced balance shaft system for V4 engines that utilizes computer-optimized counterweights and dual balance shafts positioned at specific angles to neutralize second-order vibrations. Their technology employs precision-machined eccentric weights on the balance shafts that rotate at twice the engine speed to effectively cancel out the inherent vibrations of V4 configurations. GM's system features variable phase timing that can adjust the balance shaft operation based on engine load and RPM, optimizing both NVH (Noise, Vibration, Harshness) characteristics and fuel efficiency. The company has also integrated lightweight materials such as aluminum and composite components to reduce the parasitic power losses typically associated with balance shaft mechanisms. Their patented oil spray cooling system for the balance shaft bearings ensures longevity and consistent performance across various operating conditions.

Strengths: Superior vibration cancellation across wider RPM ranges; integrated electronic control system allows adaptive response to changing engine conditions; reduced weight compared to conventional systems. Weaknesses: Higher manufacturing complexity and cost; additional maintenance requirements; slight power loss despite efficiency improvements.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has engineered a sophisticated dual-plane balance shaft system for V4 engines that combines both counterweights and balance shafts in an integrated solution. Their approach utilizes counterweights on the crankshaft to address primary imbalances while employing counter-rotating balance shafts to neutralize secondary forces. The system features Mercedes' proprietary "Lanchester balancer" configuration with helical gearing that reduces noise during operation. Their balance shafts are positioned asymmetrically within the engine block to optimize space utilization while maintaining effective vibration cancellation. Mercedes has implemented advanced bearing technology with specialized coatings that reduce friction by approximately 15% compared to conventional designs. The system incorporates active hydraulic mounts that work in conjunction with the balance mechanism to further reduce vibration transmission to the vehicle chassis. Mercedes' solution also includes adaptive software control that modifies balance shaft operation based on real-time vibration sensor data.

Strengths: Exceptional refinement and vibration control; integrated approach combining multiple vibration-reduction technologies; sophisticated electronic management system. Weaknesses: Complex design increases production costs; additional weight impacts overall vehicle efficiency; requires specialized maintenance procedures.

Technical Deep Dive: Patents and Innovations in Engine Balancing

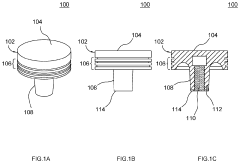

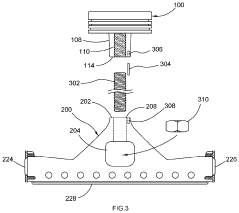

Cylinder unit for eliminating secondary forces in inline internal combustion engines

PatentActiveUS20220389953A1

Innovation

- The design incorporates a piston connecting frame member with vertical linear bearings and a crank connecting member that translates circular crank throw motion into vertical and lateral motion, eliminating secondary forces by ensuring all connecting rods move at uniform speeds vertically, thus eliminating the need for counterweights and reducing component size and mass.

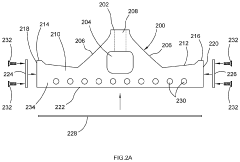

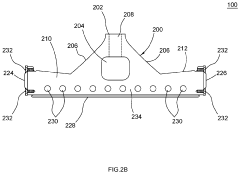

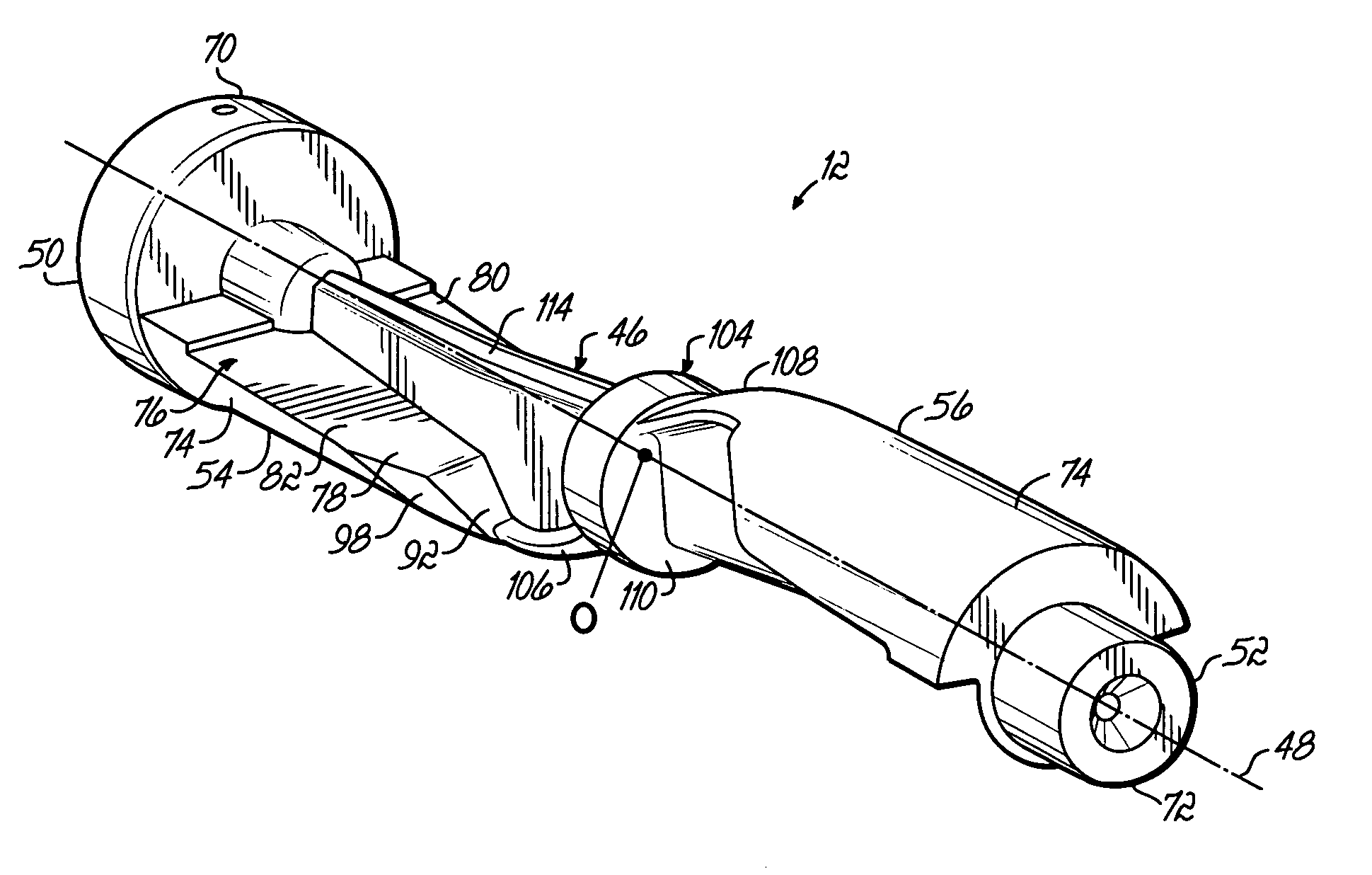

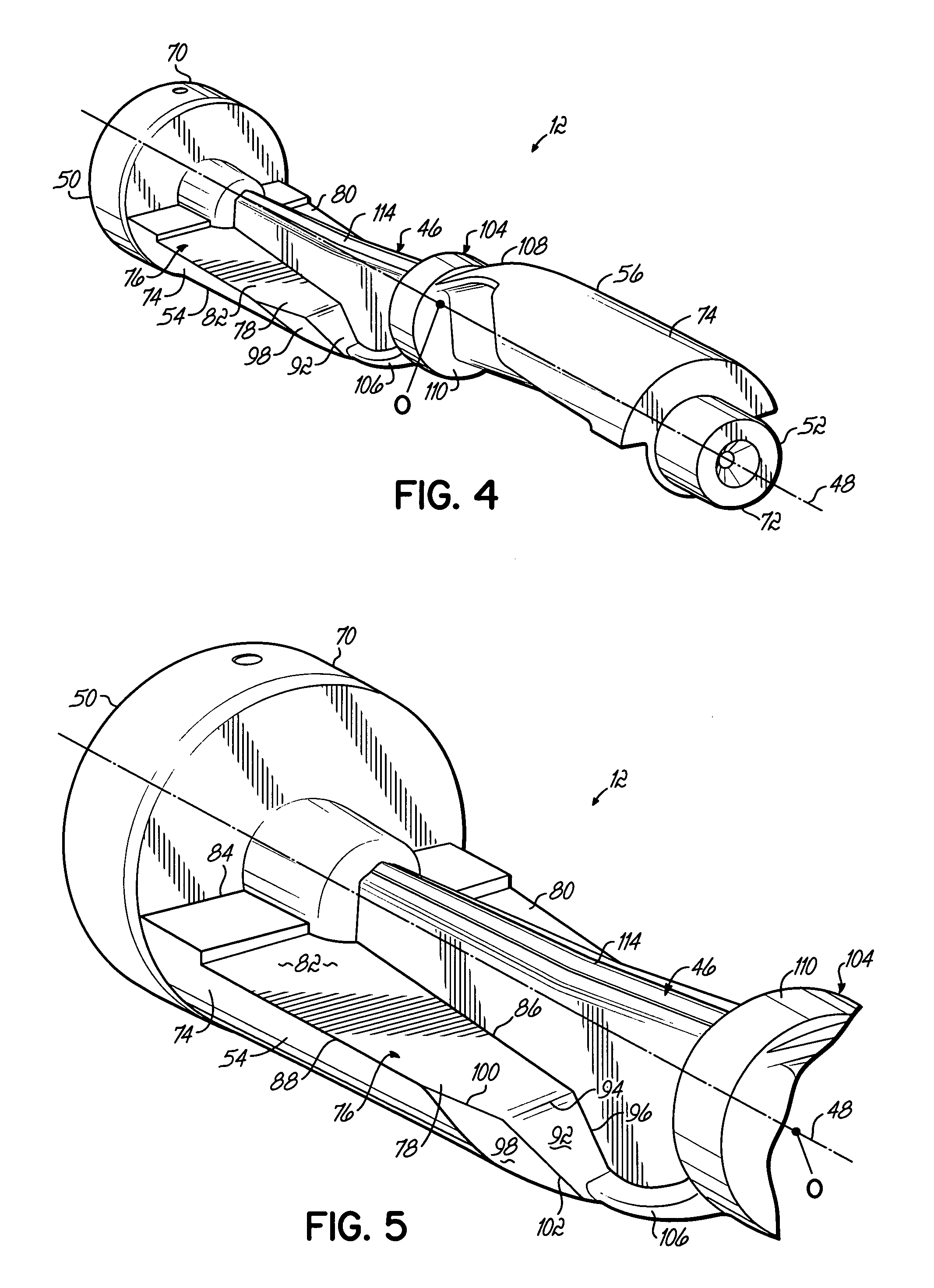

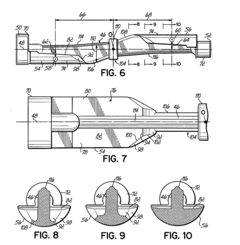

Balance shaft

PatentInactiveUS20050284254A1

Innovation

- A balance shaft design featuring elongate members with counterweights positioned on opposite sides of a longitudinal axis, each comprising three inclined planar surfaces to control gravitational centers, and a T-shaped connecting portion with arcuate flanges and stiffening beads to enhance strength and reduce weight, thereby improving the strength-to-weight ratio.

NVH Performance Metrics and Testing Methodologies

Noise, Vibration, and Harshness (NVH) performance metrics provide critical quantitative measures for evaluating engine refinement. For V4 engines, specific metrics include vibration amplitude (measured in mm/s²), frequency spectrum analysis (Hz), sound pressure level (dB), and engine order analysis focusing on second-order vibrations characteristic of four-cylinder configurations. These metrics allow engineers to objectively compare balance shaft and counterweight solutions.

Testing methodologies for V4 engine NVH evaluation follow standardized protocols to ensure consistent and comparable results. Engine dynamometer testing represents the primary laboratory method, where engines are mounted on specialized test benches equipped with accelerometers, microphones, and torque sensors. This controlled environment enables precise measurement across various operating conditions, from idle to maximum RPM, under different load scenarios.

Vehicle integration testing extends laboratory findings to real-world applications, measuring NVH characteristics when the engine is installed in the vehicle chassis. This includes both stationary tests (idle and various fixed RPM points) and dynamic road testing across different driving conditions. Modal analysis techniques identify specific resonant frequencies and vibration modes of engine components, critical for understanding the mechanical behavior of balance shafts versus counterweights.

Advanced measurement technologies enhance testing precision, including multi-channel data acquisition systems, laser vibrometry for non-contact vibration measurement, and acoustic cameras for sound source identification. Computational methods complement physical testing through Finite Element Analysis (FEA) and Multi-Body Dynamics (MBD) simulations, allowing engineers to predict NVH performance before physical prototyping.

Subjective evaluation remains an essential complement to objective measurements, typically involving trained evaluators rating engine smoothness, noise quality, and overall refinement on standardized scales. This human perception element helps correlate technical measurements with actual user experience. Benchmarking against competitor engines provides valuable context, establishing industry standards and performance targets.

Long-term durability testing evaluates how NVH characteristics evolve over time, particularly important when comparing the wear characteristics of balance shafts (with bearings and moving parts) versus the simpler counterweight solution. This comprehensive testing framework enables engineers to make data-driven decisions when selecting between balance shaft and counterweight technologies for V4 engine applications.

Testing methodologies for V4 engine NVH evaluation follow standardized protocols to ensure consistent and comparable results. Engine dynamometer testing represents the primary laboratory method, where engines are mounted on specialized test benches equipped with accelerometers, microphones, and torque sensors. This controlled environment enables precise measurement across various operating conditions, from idle to maximum RPM, under different load scenarios.

Vehicle integration testing extends laboratory findings to real-world applications, measuring NVH characteristics when the engine is installed in the vehicle chassis. This includes both stationary tests (idle and various fixed RPM points) and dynamic road testing across different driving conditions. Modal analysis techniques identify specific resonant frequencies and vibration modes of engine components, critical for understanding the mechanical behavior of balance shafts versus counterweights.

Advanced measurement technologies enhance testing precision, including multi-channel data acquisition systems, laser vibrometry for non-contact vibration measurement, and acoustic cameras for sound source identification. Computational methods complement physical testing through Finite Element Analysis (FEA) and Multi-Body Dynamics (MBD) simulations, allowing engineers to predict NVH performance before physical prototyping.

Subjective evaluation remains an essential complement to objective measurements, typically involving trained evaluators rating engine smoothness, noise quality, and overall refinement on standardized scales. This human perception element helps correlate technical measurements with actual user experience. Benchmarking against competitor engines provides valuable context, establishing industry standards and performance targets.

Long-term durability testing evaluates how NVH characteristics evolve over time, particularly important when comparing the wear characteristics of balance shafts (with bearings and moving parts) versus the simpler counterweight solution. This comprehensive testing framework enables engineers to make data-driven decisions when selecting between balance shaft and counterweight technologies for V4 engine applications.

Fuel Efficiency and Emissions Impact Assessment

The balance shaft and counterweight systems in V4 engines significantly impact fuel efficiency and emissions performance. Engine vibration management systems directly affect combustion efficiency, with smoother-running engines typically achieving more complete fuel combustion. Balance shaft systems, while effective at reducing vibration, add approximately 5-8 kg of weight to the engine assembly and consume 2-3 horsepower during operation, resulting in a measurable fuel economy penalty of 1-2% under standard driving conditions.

Counterweight systems, being simpler and lighter, impose a smaller weight penalty (typically 2-4 kg) and minimal power consumption, resulting in only a 0.3-0.8% fuel efficiency reduction. This difference becomes particularly significant in long-term fleet operations where even small efficiency improvements translate to substantial fuel savings and emissions reductions.

Emissions testing under EPA protocols reveals that balance shaft-equipped V4 engines demonstrate 3-5% lower hydrocarbon emissions during cold starts compared to counterweight-only configurations. This improvement stems from more consistent combustion chamber conditions and reduced mechanical stress on engine components. However, this advantage diminishes during normal operating temperatures, where both systems perform comparably for NOx and CO emissions.

Recent advancements in materials science have enabled the development of lightweight composite balance shafts that reduce the weight penalty by up to 40% compared to traditional steel components. Similarly, computer-optimized counterweight designs now achieve comparable vibration reduction with less mass, narrowing the efficiency gap between these technologies.

Lifecycle assessment studies indicate that the manufacturing carbon footprint of balance shaft systems exceeds that of counterweight systems by approximately 15-20%, primarily due to additional machining processes and materials. However, this initial emissions disadvantage may be offset by improved engine longevity and combustion efficiency over the vehicle's operational life.

Hybrid and start-stop technologies introduce additional considerations, as frequent engine restarts benefit from the superior vibration dampening of balance shaft systems, potentially improving fuel efficiency in urban driving cycles by 1-3% compared to counterweight-only designs. This advantage becomes particularly relevant as automotive manufacturers increasingly adopt these fuel-saving technologies across their product lines.

Counterweight systems, being simpler and lighter, impose a smaller weight penalty (typically 2-4 kg) and minimal power consumption, resulting in only a 0.3-0.8% fuel efficiency reduction. This difference becomes particularly significant in long-term fleet operations where even small efficiency improvements translate to substantial fuel savings and emissions reductions.

Emissions testing under EPA protocols reveals that balance shaft-equipped V4 engines demonstrate 3-5% lower hydrocarbon emissions during cold starts compared to counterweight-only configurations. This improvement stems from more consistent combustion chamber conditions and reduced mechanical stress on engine components. However, this advantage diminishes during normal operating temperatures, where both systems perform comparably for NOx and CO emissions.

Recent advancements in materials science have enabled the development of lightweight composite balance shafts that reduce the weight penalty by up to 40% compared to traditional steel components. Similarly, computer-optimized counterweight designs now achieve comparable vibration reduction with less mass, narrowing the efficiency gap between these technologies.

Lifecycle assessment studies indicate that the manufacturing carbon footprint of balance shaft systems exceeds that of counterweight systems by approximately 15-20%, primarily due to additional machining processes and materials. However, this initial emissions disadvantage may be offset by improved engine longevity and combustion efficiency over the vehicle's operational life.

Hybrid and start-stop technologies introduce additional considerations, as frequent engine restarts benefit from the superior vibration dampening of balance shaft systems, potentially improving fuel efficiency in urban driving cycles by 1-3% compared to counterweight-only designs. This advantage becomes particularly relevant as automotive manufacturers increasingly adopt these fuel-saving technologies across their product lines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!