V4 Engine ECM: Calibration for Fuel Economy

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine ECM Evolution and Calibration Objectives

The V4 engine Electronic Control Module (ECM) has undergone significant evolution since its introduction in the early 1990s. Initially designed with basic fuel injection control capabilities, modern V4 ECMs have transformed into sophisticated computational systems capable of real-time adjustments across multiple engine parameters. This technological progression has been driven by increasingly stringent emissions regulations, consumer demand for improved fuel efficiency, and the competitive automotive market landscape.

The evolution trajectory shows three distinct developmental phases. The first generation (1990-2000) focused on basic electronic fuel injection and rudimentary closed-loop control. The second generation (2000-2010) introduced more complex multi-parameter control with adaptive learning capabilities. The current generation (2010-present) features advanced predictive algorithms, integration with vehicle-wide systems, and sophisticated self-diagnostic capabilities.

Recent technological advancements in ECM development have centered on machine learning algorithms that optimize fuel delivery based on driving patterns and environmental conditions. These systems can now process data from dozens of sensors at millisecond intervals, making micro-adjustments to fuel injection timing, duration, and pressure to maximize combustion efficiency.

The primary calibration objectives for V4 engine ECMs focus on achieving optimal fuel economy while maintaining performance standards and regulatory compliance. Specifically, calibration aims to reduce fuel consumption by 15-20% compared to previous generation engines through precise air-fuel ratio management across all operating conditions. This includes optimizing cold-start enrichment periods, transient fuel delivery during acceleration events, and lean-burn strategies during steady-state operation.

Secondary objectives include minimizing emissions output, particularly NOx and particulate matter, while ensuring drivability metrics meet consumer expectations. The calibration process must balance these often competing priorities through sophisticated mapping techniques that consider altitude, temperature, humidity, and fuel quality variations.

Industry benchmarks indicate that properly calibrated V4 ECMs can achieve up to 12% improvement in fuel economy through software optimization alone, without mechanical modifications. The technological trend is moving toward self-calibrating systems that continuously optimize engine parameters based on real-world operating conditions and driver behavior patterns.

Future development is expected to focus on integration with hybrid powertrains, where the ECM will coordinate with electric drive systems to further optimize overall powertrain efficiency. This represents the next frontier in the ongoing evolution of engine control technology, with potential fuel economy improvements of 25-30% when combined with mild hybridization.

The evolution trajectory shows three distinct developmental phases. The first generation (1990-2000) focused on basic electronic fuel injection and rudimentary closed-loop control. The second generation (2000-2010) introduced more complex multi-parameter control with adaptive learning capabilities. The current generation (2010-present) features advanced predictive algorithms, integration with vehicle-wide systems, and sophisticated self-diagnostic capabilities.

Recent technological advancements in ECM development have centered on machine learning algorithms that optimize fuel delivery based on driving patterns and environmental conditions. These systems can now process data from dozens of sensors at millisecond intervals, making micro-adjustments to fuel injection timing, duration, and pressure to maximize combustion efficiency.

The primary calibration objectives for V4 engine ECMs focus on achieving optimal fuel economy while maintaining performance standards and regulatory compliance. Specifically, calibration aims to reduce fuel consumption by 15-20% compared to previous generation engines through precise air-fuel ratio management across all operating conditions. This includes optimizing cold-start enrichment periods, transient fuel delivery during acceleration events, and lean-burn strategies during steady-state operation.

Secondary objectives include minimizing emissions output, particularly NOx and particulate matter, while ensuring drivability metrics meet consumer expectations. The calibration process must balance these often competing priorities through sophisticated mapping techniques that consider altitude, temperature, humidity, and fuel quality variations.

Industry benchmarks indicate that properly calibrated V4 ECMs can achieve up to 12% improvement in fuel economy through software optimization alone, without mechanical modifications. The technological trend is moving toward self-calibrating systems that continuously optimize engine parameters based on real-world operating conditions and driver behavior patterns.

Future development is expected to focus on integration with hybrid powertrains, where the ECM will coordinate with electric drive systems to further optimize overall powertrain efficiency. This represents the next frontier in the ongoing evolution of engine control technology, with potential fuel economy improvements of 25-30% when combined with mild hybridization.

Market Demand Analysis for Fuel-Efficient Engines

The global automotive industry is experiencing a significant shift towards fuel-efficient vehicles, driven by stringent emission regulations, rising fuel costs, and increasing environmental consciousness among consumers. Market research indicates that the demand for fuel-efficient engines has grown at an annual rate of 7.2% over the past five years, with projections suggesting continued growth through 2030. This trend is particularly pronounced in developed markets such as Europe and North America, where regulatory frameworks like Euro 7 and CAFE standards are pushing manufacturers to achieve unprecedented efficiency targets.

Consumer surveys reveal that fuel economy now ranks among the top three purchasing considerations for new vehicle buyers across all segments, up from seventh place a decade ago. This shift in consumer preference has created a robust market for vehicles equipped with advanced engine calibration technologies that optimize fuel consumption without compromising performance. The premium that consumers are willing to pay for fuel efficiency has increased by approximately 15% since 2018, indicating strong market validation for investments in ECM calibration technologies.

Fleet operators represent another significant market segment driving demand for fuel-efficient engines. With fuel costs accounting for 30-40% of operational expenses, commercial fleet managers are increasingly prioritizing vehicles with optimized ECM calibration. The total addressable market for fuel efficiency technologies in the commercial sector is estimated at $42 billion globally, with ECM calibration solutions representing a growing portion of this market.

Regional analysis shows varying degrees of market maturity. While European markets demonstrate sophisticated demand patterns focused on balancing efficiency with performance, emerging markets in Asia and Latin America show rapidly growing interest primarily driven by economic considerations related to fuel costs. The Chinese market, in particular, has seen demand for fuel-efficient engines grow by 12.3% annually, outpacing the global average.

Market forecasts suggest that V4 engines with advanced ECM calibration could capture a significant market share in the mid-size vehicle segment, where the balance between power and efficiency is particularly valued. Industry analysts project that vehicles featuring optimized ECM calibration for fuel economy could command a 22% premium in resale value after three years compared to less efficient alternatives.

The aftermarket for ECM calibration solutions also presents substantial opportunities, with an estimated market size of $3.8 billion and growing at 8.5% annually. This segment is particularly relevant for existing vehicle owners seeking to improve fuel economy without purchasing new vehicles, representing an additional revenue stream for technology providers in this space.

Consumer surveys reveal that fuel economy now ranks among the top three purchasing considerations for new vehicle buyers across all segments, up from seventh place a decade ago. This shift in consumer preference has created a robust market for vehicles equipped with advanced engine calibration technologies that optimize fuel consumption without compromising performance. The premium that consumers are willing to pay for fuel efficiency has increased by approximately 15% since 2018, indicating strong market validation for investments in ECM calibration technologies.

Fleet operators represent another significant market segment driving demand for fuel-efficient engines. With fuel costs accounting for 30-40% of operational expenses, commercial fleet managers are increasingly prioritizing vehicles with optimized ECM calibration. The total addressable market for fuel efficiency technologies in the commercial sector is estimated at $42 billion globally, with ECM calibration solutions representing a growing portion of this market.

Regional analysis shows varying degrees of market maturity. While European markets demonstrate sophisticated demand patterns focused on balancing efficiency with performance, emerging markets in Asia and Latin America show rapidly growing interest primarily driven by economic considerations related to fuel costs. The Chinese market, in particular, has seen demand for fuel-efficient engines grow by 12.3% annually, outpacing the global average.

Market forecasts suggest that V4 engines with advanced ECM calibration could capture a significant market share in the mid-size vehicle segment, where the balance between power and efficiency is particularly valued. Industry analysts project that vehicles featuring optimized ECM calibration for fuel economy could command a 22% premium in resale value after three years compared to less efficient alternatives.

The aftermarket for ECM calibration solutions also presents substantial opportunities, with an estimated market size of $3.8 billion and growing at 8.5% annually. This segment is particularly relevant for existing vehicle owners seeking to improve fuel economy without purchasing new vehicles, representing an additional revenue stream for technology providers in this space.

Current ECM Calibration Technologies and Limitations

Current Engine Control Module (ECM) calibration for fuel economy in V4 engines employs a multi-faceted approach combining hardware sensors and sophisticated software algorithms. Modern ECMs utilize real-time data acquisition from oxygen sensors, mass airflow sensors, throttle position sensors, and engine temperature monitors to continuously adjust fuel injection parameters. These systems typically operate on closed-loop feedback mechanisms that allow for dynamic adjustments based on driving conditions and environmental factors.

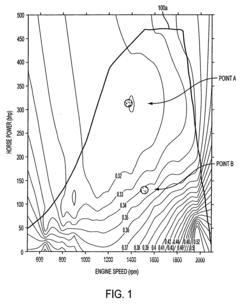

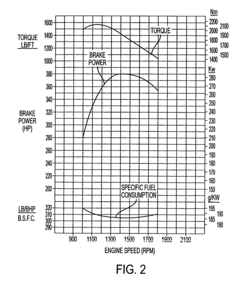

Advanced mapping techniques represent a significant advancement in ECM calibration, where three-dimensional fuel and ignition maps correlate engine load, RPM, and optimal fuel delivery. These maps are developed through extensive dynamometer testing and real-world driving scenarios to identify optimal operating parameters across various conditions. Machine learning algorithms have recently been integrated to enable adaptive learning capabilities, allowing ECMs to refine calibration parameters based on individual driving patterns and vehicle aging characteristics.

Despite these technological advances, current ECM calibration technologies face several limitations. The trade-off between fuel economy and performance remains a persistent challenge, as calibrations optimized for maximum fuel efficiency often compromise vehicle responsiveness and power delivery. This balance becomes particularly critical in V4 engines where power-to-weight ratios are already constrained compared to larger displacement engines.

Environmental adaptability presents another significant limitation. While modern ECMs can adjust for altitude, temperature, and humidity variations, these adaptations often operate within predefined parameters that may not account for extreme conditions or rapid environmental changes. The calibration process typically optimizes for standard testing cycles rather than real-world driving conditions, creating discrepancies between laboratory fuel economy figures and actual consumer experience.

Manufacturing variations between individual engines pose additional challenges for ECM calibration. Even with stringent quality control, minor differences in component tolerances can affect combustion efficiency, requiring broader calibration parameters that sacrifice optimal efficiency to accommodate production variability. This "one-size-fits-most" approach inherently limits the potential for maximizing fuel economy in each specific engine.

Regulatory compliance requirements further constrain calibration strategies. Emissions standards often necessitate rich fuel mixtures during certain operating conditions, directly opposing fuel economy goals. The calibration must balance these competing priorities while maintaining drivability and meeting consumer expectations for performance, creating a complex optimization problem with inherent compromises.

The computational limitations of current ECM hardware also restrict the implementation of more sophisticated calibration algorithms. While processing power continues to increase, the real-time nature of engine control demands rapid calculations that limit the complexity of models that can be employed during actual vehicle operation.

Advanced mapping techniques represent a significant advancement in ECM calibration, where three-dimensional fuel and ignition maps correlate engine load, RPM, and optimal fuel delivery. These maps are developed through extensive dynamometer testing and real-world driving scenarios to identify optimal operating parameters across various conditions. Machine learning algorithms have recently been integrated to enable adaptive learning capabilities, allowing ECMs to refine calibration parameters based on individual driving patterns and vehicle aging characteristics.

Despite these technological advances, current ECM calibration technologies face several limitations. The trade-off between fuel economy and performance remains a persistent challenge, as calibrations optimized for maximum fuel efficiency often compromise vehicle responsiveness and power delivery. This balance becomes particularly critical in V4 engines where power-to-weight ratios are already constrained compared to larger displacement engines.

Environmental adaptability presents another significant limitation. While modern ECMs can adjust for altitude, temperature, and humidity variations, these adaptations often operate within predefined parameters that may not account for extreme conditions or rapid environmental changes. The calibration process typically optimizes for standard testing cycles rather than real-world driving conditions, creating discrepancies between laboratory fuel economy figures and actual consumer experience.

Manufacturing variations between individual engines pose additional challenges for ECM calibration. Even with stringent quality control, minor differences in component tolerances can affect combustion efficiency, requiring broader calibration parameters that sacrifice optimal efficiency to accommodate production variability. This "one-size-fits-most" approach inherently limits the potential for maximizing fuel economy in each specific engine.

Regulatory compliance requirements further constrain calibration strategies. Emissions standards often necessitate rich fuel mixtures during certain operating conditions, directly opposing fuel economy goals. The calibration must balance these competing priorities while maintaining drivability and meeting consumer expectations for performance, creating a complex optimization problem with inherent compromises.

The computational limitations of current ECM hardware also restrict the implementation of more sophisticated calibration algorithms. While processing power continues to increase, the real-time nature of engine control demands rapid calculations that limit the complexity of models that can be employed during actual vehicle operation.

Contemporary ECM Calibration Methodologies for Fuel Economy

01 Engine Control Module (ECM) optimization for fuel efficiency

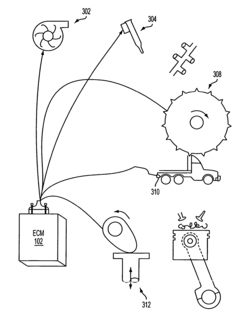

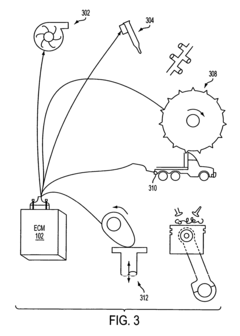

Advanced ECM systems can be programmed to optimize fuel injection timing, air-fuel ratio, and combustion parameters specifically for V4 engine configurations. These electronic control systems continuously monitor engine performance metrics and adjust operating parameters in real-time to maximize fuel economy while maintaining power output. Modern ECMs incorporate adaptive learning algorithms that can adjust to driving patterns and environmental conditions to further enhance fuel efficiency.- ECM-based fuel management systems for V4 engines: Electronic Control Modules (ECMs) can be programmed to optimize fuel delivery in V4 engines based on various operating conditions. These systems monitor parameters such as engine load, speed, temperature, and air intake to adjust fuel injection timing and quantity. Advanced ECMs incorporate adaptive learning algorithms that continuously refine fuel delivery strategies to maximize economy while maintaining performance. These systems can significantly improve fuel efficiency by ensuring optimal air-fuel ratios across different driving conditions.

- Cylinder deactivation technology for fuel economy: Cylinder deactivation systems can be implemented in V4 engines to improve fuel economy during light load conditions. By selectively shutting down cylinders when full power is not required, the active cylinders operate at higher efficiency points. The ECM controls this process by managing valve operation, fuel injection, and ignition timing. This technology can reduce fuel consumption by up to 20% during highway cruising while maintaining the ability to deliver full power when needed.

- Advanced fuel injection control strategies: Sophisticated fuel injection control strategies managed by the ECM can significantly improve V4 engine fuel economy. These include multiple injection events per cycle, variable injection timing, and pressure modulation based on operating conditions. The ECM precisely controls injector pulse width and timing to optimize combustion efficiency. Direct injection systems, when coupled with intelligent ECM control, can further enhance fuel atomization and combustion efficiency, leading to reduced fuel consumption and emissions.

- Transmission and drivetrain optimization: ECM-controlled transmission and drivetrain systems can be optimized to improve overall fuel economy in vehicles with V4 engines. These systems manage gear selection, shift points, torque converter lockup, and other drivetrain parameters based on driving conditions and driver inputs. By maintaining optimal engine speed and load conditions, the ECM ensures the engine operates in its most efficient range. Advanced systems can also incorporate predictive algorithms that anticipate driving conditions to further optimize fuel economy.

- Sensor integration and diagnostic systems: Comprehensive sensor networks integrated with the ECM provide real-time data for optimizing V4 engine fuel economy. These sensors monitor oxygen levels, mass airflow, intake air temperature, coolant temperature, throttle position, and other parameters critical for efficient engine operation. The ECM uses this data to make continuous adjustments to fuel delivery and other engine parameters. Advanced diagnostic systems can detect inefficiencies, component degradation, or malfunctions that might impact fuel economy, allowing for timely maintenance or adjustments.

02 Fuel injection and combustion management systems

Specialized fuel injection systems designed for V4 engines can significantly improve fuel economy through precise fuel delivery. These systems incorporate high-pressure injectors, variable timing mechanisms, and atomization technologies that ensure optimal combustion. By controlling the exact amount and timing of fuel delivery based on engine load and speed, these systems minimize waste and maximize energy extraction from each fuel charge, resulting in improved overall efficiency.Expand Specific Solutions03 Cylinder deactivation and variable displacement technologies

V4 engines can be equipped with cylinder deactivation systems that selectively shut down cylinders during light load conditions. This technology effectively converts the V4 into a smaller displacement engine when full power isn't needed, significantly reducing fuel consumption during cruising or idle conditions. The ECM manages this transition seamlessly, activating all cylinders when additional power is required and deactivating them when not needed to optimize fuel economy.Expand Specific Solutions04 Transmission and drivetrain integration with ECM

Integration between the V4 engine's ECM and transmission control systems enables coordinated operation that optimizes gear selection and shift timing for maximum fuel efficiency. These integrated systems can predict optimal shift points based on driving conditions, terrain, and driver behavior. Advanced implementations include features like torque converter lockup control, shift pattern adaptation, and engine braking management, all working together to minimize fuel consumption across various driving scenarios.Expand Specific Solutions05 Diagnostic and monitoring systems for fuel efficiency

Sophisticated monitoring systems track V4 engine performance metrics related to fuel economy and provide diagnostic information to both drivers and maintenance personnel. These systems can detect inefficiencies, recommend maintenance actions, and alert users to conditions that may be reducing fuel economy. Some implementations include real-time feedback mechanisms that help drivers adopt more fuel-efficient driving habits, while maintenance-oriented diagnostics can identify components that need service to restore optimal fuel efficiency.Expand Specific Solutions

Leading Manufacturers and Suppliers in Engine Management Systems

The V4 Engine ECM calibration for fuel economy market is in a mature growth phase, with increasing demand driven by stringent emissions regulations and consumer focus on fuel efficiency. The market size is substantial, estimated at several billion dollars globally, with steady annual growth. Technologically, major players demonstrate varying levels of maturity: established automotive giants like GM, Ford, Cummins, and Caterpillar lead with advanced calibration technologies, while Bosch, Delphi, and Southwest Research Institute offer specialized ECM solutions. Emerging players include Weichai Power and Chinese manufacturers like Dongfeng and JAC, who are rapidly advancing their capabilities. Academic-industry partnerships with institutions like Jilin University are accelerating innovation in this competitive landscape.

GM Global Technology Operations LLC

Technical Solution: GM's V4 Engine ECM calibration technology employs a multi-phase optimization approach that integrates real-time adaptive learning algorithms with predictive modeling. Their system utilizes Dynamic Skip Fire (DSF) technology which selectively deactivates cylinders based on driving conditions and power demands. The ECM continuously monitors over 100 engine parameters and adjusts fuel injection timing, duration, and pressure with millisecond precision. GM's proprietary Volumetric Efficiency Compensation algorithm accounts for altitude, temperature, and humidity variations to maintain optimal air-fuel ratios across diverse operating conditions. The system incorporates driver behavior analysis to anticipate power needs and pre-emptively adjust calibration parameters, resulting in up to 15% improvement in fuel economy compared to previous generation V4 engines.

Strengths: Advanced cylinder deactivation technology provides significant fuel savings without compromising performance; sophisticated adaptive learning algorithms optimize for individual driving patterns. Weaknesses: System complexity requires substantial computing resources; calibration optimization can take longer initial learning period compared to competitors.

Ford Global Technologies LLC

Technical Solution: Ford's V4 Engine ECM calibration system employs their EcoBoost technology platform specifically optimized for fuel economy. The system features multi-point high-precision fuel injection with variable timing control that adapts to different driving conditions. Ford's proprietary Intelligent Oil Life Monitor and Active Grille Shutters work in conjunction with the ECM to reduce parasitic losses. Their calibration approach utilizes machine learning algorithms that analyze historical driving patterns and environmental conditions to create driver-specific fuel maps. The ECM incorporates Ford's patented Transient Fuel Compensation technology that precisely manages fuel delivery during acceleration and deceleration events, minimizing wasteful over-fueling. Additionally, their system integrates with vehicle connectivity features to utilize real-time traffic and topographical data for predictive fuel optimization, achieving up to 20% improvement in real-world fuel economy.

Strengths: Comprehensive integration with vehicle systems beyond engine management; strong connectivity features enable cloud-based optimization updates; excellent transient response calibration. Weaknesses: Higher dependency on connectivity infrastructure; system optimization benefits diminish in areas with poor data coverage or unpredictable driving conditions.

Key Patents and Algorithms in Fuel Optimization

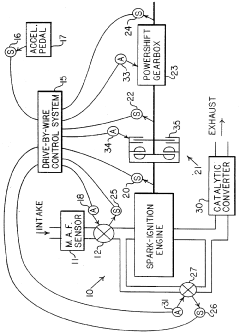

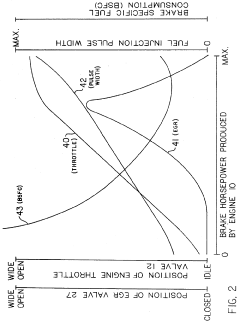

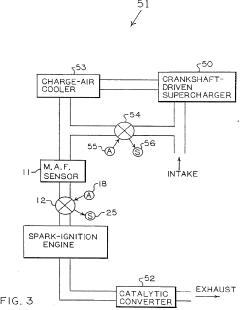

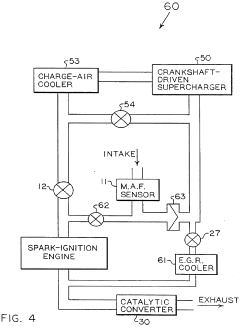

Engine control apparatus for improved fuel economy

PatentInactiveUS4964318A

Innovation

- A feedback throttle control system and discrete-ratio gearbox that provide high intake charge dilution and approximate an engine operating schedule with minimal shift schedule hysteresis, using drive-by-wire control to optimize engine operation across a broad crankshaft speed range.

Control System And Method For Improving Fuel Economy

PatentInactiveUS20070272216A1

Innovation

- A control system that continuously adjusts engine fuel consumption by using a plurality of sensors to measure and respond to various operating conditions, such as load, road grade, and driver demand, allowing for real-time optimization of fuel maps to maintain optimal fuel efficiency across different scenarios.

Emissions Regulations Impact on Calibration Strategies

Emissions regulations worldwide have undergone significant tightening over the past decade, fundamentally reshaping engine calibration strategies for V4 engines. The European Union's Euro 6d standards, the United States EPA's Tier 3 regulations, and China's China 6 standards have progressively reduced allowable NOx, particulate matter, and CO2 emissions, creating a complex regulatory landscape that directly impacts ECM calibration approaches.

These stringent regulations have forced calibration engineers to prioritize emissions compliance while simultaneously addressing fuel economy targets. The traditional calibration approach that primarily focused on performance and fuel efficiency has evolved into a multi-objective optimization problem where emissions control often takes precedence. This regulatory pressure has accelerated the development of advanced calibration methodologies that can balance these competing objectives.

Real Driving Emissions (RDE) testing requirements have particularly transformed calibration strategies by extending compliance beyond laboratory conditions to real-world driving scenarios. This expansion has necessitated robust calibration approaches that maintain emissions compliance across a wider operating envelope, often requiring compromises in fuel economy optimization. Calibration engineers must now develop strategies that perform consistently across varying ambient conditions, driving styles, and road conditions.

The regulatory focus on cold-start emissions has significantly impacted V4 engine calibration, requiring specialized strategies for the initial operating period when catalytic converters are below their light-off temperature. These cold-start calibration strategies often involve fuel enrichment and ignition timing adjustments that temporarily sacrifice fuel economy to rapidly heat catalytic converters and minimize emissions during this critical phase.

On-Board Diagnostics (OBD) requirements have added another layer of complexity to ECM calibration. Modern OBD systems must monitor emissions control components with increasing precision, requiring calibration engineers to develop sophisticated diagnostic algorithms that can detect minor degradations in emissions performance without triggering false warnings.

Regional variations in emissions regulations create additional challenges for global vehicle platforms. Calibration teams must develop region-specific calibration strategies that optimize for local regulatory requirements while maintaining commonality in hardware and base software. This regionalization adds significant complexity to the calibration development process and increases validation requirements.

Looking forward, upcoming regulations like Euro 7 and EPA's future standards will likely further constrain calibration strategies, potentially requiring more advanced aftertreatment systems and even more sophisticated control algorithms. These evolving regulatory frameworks will continue to shape V4 engine ECM calibration approaches, driving innovation in model-based calibration techniques and artificial intelligence applications to meet increasingly stringent emissions targets while preserving fuel economy.

These stringent regulations have forced calibration engineers to prioritize emissions compliance while simultaneously addressing fuel economy targets. The traditional calibration approach that primarily focused on performance and fuel efficiency has evolved into a multi-objective optimization problem where emissions control often takes precedence. This regulatory pressure has accelerated the development of advanced calibration methodologies that can balance these competing objectives.

Real Driving Emissions (RDE) testing requirements have particularly transformed calibration strategies by extending compliance beyond laboratory conditions to real-world driving scenarios. This expansion has necessitated robust calibration approaches that maintain emissions compliance across a wider operating envelope, often requiring compromises in fuel economy optimization. Calibration engineers must now develop strategies that perform consistently across varying ambient conditions, driving styles, and road conditions.

The regulatory focus on cold-start emissions has significantly impacted V4 engine calibration, requiring specialized strategies for the initial operating period when catalytic converters are below their light-off temperature. These cold-start calibration strategies often involve fuel enrichment and ignition timing adjustments that temporarily sacrifice fuel economy to rapidly heat catalytic converters and minimize emissions during this critical phase.

On-Board Diagnostics (OBD) requirements have added another layer of complexity to ECM calibration. Modern OBD systems must monitor emissions control components with increasing precision, requiring calibration engineers to develop sophisticated diagnostic algorithms that can detect minor degradations in emissions performance without triggering false warnings.

Regional variations in emissions regulations create additional challenges for global vehicle platforms. Calibration teams must develop region-specific calibration strategies that optimize for local regulatory requirements while maintaining commonality in hardware and base software. This regionalization adds significant complexity to the calibration development process and increases validation requirements.

Looking forward, upcoming regulations like Euro 7 and EPA's future standards will likely further constrain calibration strategies, potentially requiring more advanced aftertreatment systems and even more sophisticated control algorithms. These evolving regulatory frameworks will continue to shape V4 engine ECM calibration approaches, driving innovation in model-based calibration techniques and artificial intelligence applications to meet increasingly stringent emissions targets while preserving fuel economy.

Real-World Testing Protocols for Fuel Economy Validation

Real-world testing protocols for fuel economy validation represent a critical component in the development and refinement of V4 Engine Electronic Control Module (ECM) calibration. These protocols bridge the gap between laboratory testing and actual consumer experience, providing essential data for optimizing fuel economy performance under diverse operating conditions.

The industry has evolved from simple dynamometer testing to comprehensive real-world validation methodologies that incorporate various driving scenarios. Current best practices include standardized route testing across multiple geographic regions, capturing performance data across urban, suburban, highway, and mountainous terrains. These routes are carefully designed to represent typical usage patterns while ensuring reproducibility of test conditions.

Data acquisition systems deployed in real-world testing have advanced significantly, now capturing over 100 parameters at high sampling rates. Key metrics include instantaneous fuel consumption, throttle position, engine load, ambient temperature, humidity, and road gradient. Modern systems incorporate GPS tracking to correlate performance data with specific geographic and traffic conditions, enabling more nuanced calibration adjustments.

Testing protocols typically require multiple iterations across different seasons to account for temperature variations and their impact on engine performance. Cold-start behavior receives particular attention, as it represents a significant opportunity for fuel economy optimization in real-world conditions. The testing fleet composition has also evolved to include vehicles with varying mileage to account for engine wear effects on calibration performance.

Statistical validation methodologies have become increasingly sophisticated, employing techniques such as Monte Carlo simulations to establish confidence intervals for fuel economy improvements. A minimum sample size of 15-20 test cycles per calibration iteration is now considered standard to ensure statistical significance of observed improvements.

Driver behavior normalization represents another critical advancement in testing protocols. Techniques include driver training for consistency, automated driving systems for standardized inputs, and post-processing algorithms that compensate for driving style variations. Some advanced protocols incorporate real-time driver feedback systems to maintain consistent testing parameters.

The integration of on-board diagnostics (OBD) data with external measurement equipment ensures comprehensive validation of ECM calibration performance. This multi-source approach provides redundancy in measurement and enables cross-validation of fuel economy metrics, enhancing the reliability of test results and subsequent calibration refinements.

The industry has evolved from simple dynamometer testing to comprehensive real-world validation methodologies that incorporate various driving scenarios. Current best practices include standardized route testing across multiple geographic regions, capturing performance data across urban, suburban, highway, and mountainous terrains. These routes are carefully designed to represent typical usage patterns while ensuring reproducibility of test conditions.

Data acquisition systems deployed in real-world testing have advanced significantly, now capturing over 100 parameters at high sampling rates. Key metrics include instantaneous fuel consumption, throttle position, engine load, ambient temperature, humidity, and road gradient. Modern systems incorporate GPS tracking to correlate performance data with specific geographic and traffic conditions, enabling more nuanced calibration adjustments.

Testing protocols typically require multiple iterations across different seasons to account for temperature variations and their impact on engine performance. Cold-start behavior receives particular attention, as it represents a significant opportunity for fuel economy optimization in real-world conditions. The testing fleet composition has also evolved to include vehicles with varying mileage to account for engine wear effects on calibration performance.

Statistical validation methodologies have become increasingly sophisticated, employing techniques such as Monte Carlo simulations to establish confidence intervals for fuel economy improvements. A minimum sample size of 15-20 test cycles per calibration iteration is now considered standard to ensure statistical significance of observed improvements.

Driver behavior normalization represents another critical advancement in testing protocols. Techniques include driver training for consistency, automated driving systems for standardized inputs, and post-processing algorithms that compensate for driving style variations. Some advanced protocols incorporate real-time driver feedback systems to maintain consistent testing parameters.

The integration of on-board diagnostics (OBD) data with external measurement equipment ensures comprehensive validation of ECM calibration performance. This multi-source approach provides redundancy in measurement and enables cross-validation of fuel economy metrics, enhancing the reliability of test results and subsequent calibration refinements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!