V4 Engine Manifold Design: Pressure vs Flow Efficiency

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Manifold Evolution and Design Objectives

The V4 engine manifold design has evolved significantly since the early days of internal combustion engines. Initially, manifolds were simple conduits with minimal consideration for flow dynamics. The 1950s marked the beginning of scientific approaches to manifold design, with engineers starting to understand the relationship between pressure waves and volumetric efficiency. By the 1970s, computational fluid dynamics (CFD) began transforming manifold development, allowing for more precise modeling of airflow characteristics.

The 1980s and 1990s witnessed the integration of variable geometry systems, enabling manifolds to adapt to different engine operating conditions. This period also saw the emergence of tuned intake runners, which leveraged pressure wave harmonics to enhance cylinder filling at specific RPM ranges. The 2000s brought advanced materials and manufacturing techniques, facilitating more complex internal geometries previously impossible to produce.

Current V4 engine manifold design focuses on balancing two critical but often competing factors: pressure efficiency and flow efficiency. Pressure efficiency relates to the manifold's ability to maintain optimal pressure distribution across all cylinders, ensuring consistent combustion events. Flow efficiency concerns the minimization of resistance to airflow, reducing pumping losses and maximizing volumetric efficiency.

The technical objectives for modern V4 manifold design include achieving uniform air distribution across all cylinders while minimizing pressure drops. Engineers aim to optimize runner length and diameter to enhance torque characteristics across the engine's operating range. Additionally, there is a growing emphasis on reducing manifold volume to improve throttle response and transient performance.

Another critical objective is the integration of emissions control technologies directly into manifold designs, accommodating EGR systems and ensuring proper mixing of recirculated exhaust gases with fresh intake air. This integration must occur without compromising the manifold's primary flow characteristics.

Weight reduction represents another significant goal, with designers exploring composite materials and topology optimization to minimize mass while maintaining structural integrity under varying thermal and mechanical loads. The compact V4 configuration presents unique spatial constraints, requiring innovative packaging solutions that don't compromise performance.

Looking forward, the evolution of V4 manifold design is increasingly focused on adaptability, with systems capable of real-time geometry adjustments based on engine operating parameters. This includes variable runner lengths, adjustable plenum volumes, and intelligent flow control mechanisms that optimize the pressure-flow relationship across the entire operating envelope of modern high-performance V4 engines.

The 1980s and 1990s witnessed the integration of variable geometry systems, enabling manifolds to adapt to different engine operating conditions. This period also saw the emergence of tuned intake runners, which leveraged pressure wave harmonics to enhance cylinder filling at specific RPM ranges. The 2000s brought advanced materials and manufacturing techniques, facilitating more complex internal geometries previously impossible to produce.

Current V4 engine manifold design focuses on balancing two critical but often competing factors: pressure efficiency and flow efficiency. Pressure efficiency relates to the manifold's ability to maintain optimal pressure distribution across all cylinders, ensuring consistent combustion events. Flow efficiency concerns the minimization of resistance to airflow, reducing pumping losses and maximizing volumetric efficiency.

The technical objectives for modern V4 manifold design include achieving uniform air distribution across all cylinders while minimizing pressure drops. Engineers aim to optimize runner length and diameter to enhance torque characteristics across the engine's operating range. Additionally, there is a growing emphasis on reducing manifold volume to improve throttle response and transient performance.

Another critical objective is the integration of emissions control technologies directly into manifold designs, accommodating EGR systems and ensuring proper mixing of recirculated exhaust gases with fresh intake air. This integration must occur without compromising the manifold's primary flow characteristics.

Weight reduction represents another significant goal, with designers exploring composite materials and topology optimization to minimize mass while maintaining structural integrity under varying thermal and mechanical loads. The compact V4 configuration presents unique spatial constraints, requiring innovative packaging solutions that don't compromise performance.

Looking forward, the evolution of V4 manifold design is increasingly focused on adaptability, with systems capable of real-time geometry adjustments based on engine operating parameters. This includes variable runner lengths, adjustable plenum volumes, and intelligent flow control mechanisms that optimize the pressure-flow relationship across the entire operating envelope of modern high-performance V4 engines.

Market Requirements for Advanced V4 Engine Manifolds

The automotive industry is witnessing a significant shift toward more efficient and environmentally friendly engine designs, creating substantial market demand for advanced V4 engine manifolds. OEMs are increasingly prioritizing manifold systems that can optimize the balance between pressure maintenance and flow efficiency, as these components directly impact engine performance, fuel economy, and emissions compliance.

Market research indicates that the global automotive intake manifold market is projected to grow at a compound annual growth rate of 3.8% through 2028, with the advanced manifold segment showing even stronger growth potential. This acceleration is driven by stringent emission regulations in major markets including Europe, North America, and Asia, compelling manufacturers to develop manifold designs that can support more complete combustion and reduced pollutant formation.

Performance vehicle manufacturers represent a premium segment of this market, demanding manifold solutions that can deliver enhanced power output while maintaining reliability. These customers typically value flow efficiency that supports higher RPM performance, creating a distinct market niche with higher profit margins but specialized design requirements.

Conversely, the volume market for passenger vehicles prioritizes balanced performance with an emphasis on fuel economy. This segment requires manifold designs that optimize pressure dynamics across a broader RPM range, particularly enhancing low-end torque for everyday driving conditions. Market feedback indicates consumers increasingly value responsive acceleration from standstill and during overtaking maneuvers, directly influenced by manifold pressure characteristics.

Commercial vehicle applications constitute another significant market segment, where durability and consistent performance under load take precedence. These customers require manifold designs that maintain optimal pressure under varying load conditions, with particular emphasis on thermal management capabilities to ensure longevity.

Emerging markets present unique requirements, often demanding manifolds that can accommodate variable fuel quality while maintaining performance. Additionally, the aftermarket segment shows growing interest in customizable manifold solutions that can be tuned for specific performance profiles, representing a smaller but profitable market opportunity.

Manufacturing cost constraints remain a critical market consideration, with OEMs seeking manifold designs that achieve performance targets while minimizing material usage and production complexity. Market acceptance thresholds indicate that advanced manifold solutions must deliver at least 5-7% performance improvement to justify a 10% cost premium over conventional designs.

Market research indicates that the global automotive intake manifold market is projected to grow at a compound annual growth rate of 3.8% through 2028, with the advanced manifold segment showing even stronger growth potential. This acceleration is driven by stringent emission regulations in major markets including Europe, North America, and Asia, compelling manufacturers to develop manifold designs that can support more complete combustion and reduced pollutant formation.

Performance vehicle manufacturers represent a premium segment of this market, demanding manifold solutions that can deliver enhanced power output while maintaining reliability. These customers typically value flow efficiency that supports higher RPM performance, creating a distinct market niche with higher profit margins but specialized design requirements.

Conversely, the volume market for passenger vehicles prioritizes balanced performance with an emphasis on fuel economy. This segment requires manifold designs that optimize pressure dynamics across a broader RPM range, particularly enhancing low-end torque for everyday driving conditions. Market feedback indicates consumers increasingly value responsive acceleration from standstill and during overtaking maneuvers, directly influenced by manifold pressure characteristics.

Commercial vehicle applications constitute another significant market segment, where durability and consistent performance under load take precedence. These customers require manifold designs that maintain optimal pressure under varying load conditions, with particular emphasis on thermal management capabilities to ensure longevity.

Emerging markets present unique requirements, often demanding manifolds that can accommodate variable fuel quality while maintaining performance. Additionally, the aftermarket segment shows growing interest in customizable manifold solutions that can be tuned for specific performance profiles, representing a smaller but profitable market opportunity.

Manufacturing cost constraints remain a critical market consideration, with OEMs seeking manifold designs that achieve performance targets while minimizing material usage and production complexity. Market acceptance thresholds indicate that advanced manifold solutions must deliver at least 5-7% performance improvement to justify a 10% cost premium over conventional designs.

Current Manifold Technology Limitations and Challenges

Despite significant advancements in V4 engine manifold design, current technology faces several critical limitations that impede optimal performance balance between pressure maintenance and flow efficiency. Traditional manifold designs struggle with the inherent trade-off between these two parameters, often sacrificing one for the other. This fundamental challenge stems from the physical constraints of fluid dynamics within confined geometries and the complex interaction between pressure waves and flow characteristics.

The primary technical limitation lies in the geometric constraints of conventional manifold designs. Current plenum chambers and runner configurations cannot simultaneously optimize for both high-velocity flow and pressure preservation. When engineers design for maximum flow efficiency, pressure drops become inevitable at higher RPM ranges, resulting in torque inconsistencies across the power band. Conversely, designs that prioritize pressure maintenance often create flow restrictions that limit peak horsepower potential.

Material limitations present another significant challenge. While lightweight alloys reduce overall engine weight, they often lack the thermal stability required for maintaining precise dimensional tolerances under varying operating temperatures. This thermal expansion variability affects the critical cross-sectional areas of runners and transitions, altering the carefully calculated flow dynamics during real-world operation. Advanced composites and ceramics that could potentially address these issues remain prohibitively expensive for mass production.

Manufacturing precision represents a persistent challenge in manifold production. Even minor variations in internal surface finish can create turbulence points that disrupt laminar flow and generate pressure inconsistencies. Current manufacturing processes struggle to maintain the required tolerances consistently across production batches, leading to performance variations between otherwise identical engines.

Computational modeling limitations further complicate development efforts. While CFD (Computational Fluid Dynamics) software has advanced significantly, accurately predicting the complex, transient pressure wave dynamics in variable operating conditions remains challenging. This modeling gap forces designers to rely heavily on empirical testing, extending development cycles and increasing costs.

Packaging constraints in modern vehicle designs create additional challenges. The trend toward more compact engine compartments limits the available space for optimal runner lengths and plenum volumes. Engineers must often compromise theoretical ideal designs to accommodate these spatial limitations, resulting in sub-optimal flow characteristics.

Emissions compliance requirements add another layer of complexity. Modern manifolds must incorporate various sensors, EGR systems, and catalytic converter connections that can disrupt ideal flow paths. These regulatory necessities often force designs that prioritize emissions control over pure performance metrics, creating additional efficiency losses.

The primary technical limitation lies in the geometric constraints of conventional manifold designs. Current plenum chambers and runner configurations cannot simultaneously optimize for both high-velocity flow and pressure preservation. When engineers design for maximum flow efficiency, pressure drops become inevitable at higher RPM ranges, resulting in torque inconsistencies across the power band. Conversely, designs that prioritize pressure maintenance often create flow restrictions that limit peak horsepower potential.

Material limitations present another significant challenge. While lightweight alloys reduce overall engine weight, they often lack the thermal stability required for maintaining precise dimensional tolerances under varying operating temperatures. This thermal expansion variability affects the critical cross-sectional areas of runners and transitions, altering the carefully calculated flow dynamics during real-world operation. Advanced composites and ceramics that could potentially address these issues remain prohibitively expensive for mass production.

Manufacturing precision represents a persistent challenge in manifold production. Even minor variations in internal surface finish can create turbulence points that disrupt laminar flow and generate pressure inconsistencies. Current manufacturing processes struggle to maintain the required tolerances consistently across production batches, leading to performance variations between otherwise identical engines.

Computational modeling limitations further complicate development efforts. While CFD (Computational Fluid Dynamics) software has advanced significantly, accurately predicting the complex, transient pressure wave dynamics in variable operating conditions remains challenging. This modeling gap forces designers to rely heavily on empirical testing, extending development cycles and increasing costs.

Packaging constraints in modern vehicle designs create additional challenges. The trend toward more compact engine compartments limits the available space for optimal runner lengths and plenum volumes. Engineers must often compromise theoretical ideal designs to accommodate these spatial limitations, resulting in sub-optimal flow characteristics.

Emissions compliance requirements add another layer of complexity. Modern manifolds must incorporate various sensors, EGR systems, and catalytic converter connections that can disrupt ideal flow paths. These regulatory necessities often force designs that prioritize emissions control over pure performance metrics, creating additional efficiency losses.

Current Pressure-Flow Optimization Approaches

01 Manifold pressure measurement and monitoring systems

Various systems and methods for measuring and monitoring manifold pressure in V4 engines to optimize performance. These systems utilize pressure sensors placed at strategic locations within the intake manifold to provide real-time data on pressure variations. The collected data helps in diagnosing engine issues, optimizing fuel delivery, and ensuring efficient combustion processes. Advanced monitoring systems can also detect pressure anomalies that might indicate potential problems in the engine's operation.- Manifold pressure measurement and monitoring systems: Various systems and methods for measuring and monitoring manifold pressure in V4 engines to optimize performance. These systems include sensors that can accurately detect pressure changes within the intake manifold, providing real-time data for engine management systems. The monitoring systems help in maintaining optimal air-fuel ratios and can detect abnormalities in pressure that might indicate issues with engine performance or efficiency.

- Intake manifold design for improved flow efficiency: Innovative designs for intake manifolds that enhance airflow efficiency in V4 engines. These designs focus on optimizing the geometry of the manifold, including runner length, plenum volume, and cross-sectional area to reduce flow restrictions and improve volumetric efficiency. Some designs incorporate variable geometry features that can adapt to different engine operating conditions, providing optimal airflow across a wide range of RPM.

- Electronic control systems for manifold pressure optimization: Advanced electronic control systems that regulate manifold pressure to enhance engine efficiency and performance. These systems use input from various sensors to adjust parameters such as throttle position, valve timing, and boost pressure in turbocharged or supercharged V4 engines. By maintaining optimal manifold pressure across different operating conditions, these control systems can significantly improve fuel economy, power output, and emissions performance.

- Diagnostic methods for manifold pressure and flow issues: Diagnostic techniques and tools for identifying problems related to manifold pressure and airflow in V4 engines. These methods include pressure testing, flow bench analysis, and computational fluid dynamics simulations to detect restrictions, leaks, or design inefficiencies. Advanced diagnostic systems can pinpoint specific areas of concern within the intake system, allowing for targeted improvements to enhance overall engine performance and efficiency.

- Turbocharging and supercharging systems for pressure enhancement: Forced induction systems specifically designed for V4 engines to increase manifold pressure and improve volumetric efficiency. These systems include turbochargers and superchargers with specialized configurations to match the unique characteristics of V4 engines. Advanced features such as variable geometry turbines, electronic wastegates, and intercooling systems help optimize manifold pressure across the engine's operating range, resulting in improved power output and efficiency.

02 Intake manifold design for improved flow efficiency

Innovative designs of intake manifolds specifically for V4 engines that enhance airflow efficiency. These designs focus on optimizing the geometry of the manifold passages to reduce flow resistance and improve air distribution to each cylinder. Features include streamlined runners, variable length intake paths, and carefully calculated cross-sectional areas that maintain consistent flow velocity. These design improvements result in better volumetric efficiency, increased power output, and improved fuel economy.Expand Specific Solutions03 Electronic control systems for manifold pressure regulation

Electronic control systems that regulate manifold pressure in V4 engines to optimize performance under various operating conditions. These systems use input from multiple sensors to adjust throttle position, valve timing, and other parameters that affect manifold pressure. Advanced algorithms process real-time data to maintain optimal pressure levels for different driving scenarios, balancing power output with fuel efficiency. Some systems include adaptive learning capabilities that adjust parameters based on driving patterns and environmental conditions.Expand Specific Solutions04 Turbocharging and supercharging systems for pressure enhancement

Forced induction systems designed specifically for V4 engines to increase manifold pressure and enhance performance. These systems include turbochargers and superchargers that compress intake air before it enters the manifold, resulting in higher air density and improved combustion efficiency. Advanced designs feature variable geometry turbines, electronic wastegates, and intercooling systems to optimize pressure boost across different engine speeds. The integration of these systems with engine management controls allows for precise pressure regulation to maximize power while maintaining reliability.Expand Specific Solutions05 Flow testing and diagnostic methods for manifold efficiency

Methods and equipment for testing and diagnosing manifold flow efficiency in V4 engines. These approaches include specialized flow benches that can measure airflow characteristics through the manifold under controlled conditions, computational fluid dynamics simulations to predict flow patterns, and in-vehicle diagnostic tools that assess real-world performance. Testing procedures evaluate parameters such as flow rate, pressure drop, and distribution uniformity across cylinders. These diagnostic methods help identify restrictions, imbalances, or design flaws that may impact engine performance and efficiency.Expand Specific Solutions

Leading Manufacturers and Competitors in Manifold Technology

The V4 Engine Manifold Design market is currently in a growth phase, with increasing demand for optimized pressure-flow efficiency solutions across automotive applications. The market is estimated to reach significant value as manufacturers prioritize engine performance and emissions compliance. Leading players include established automotive giants like Toyota, Nissan, Honda, and Ford, alongside specialized component manufacturers such as MANN+HUMMEL and Bosch. These companies are advancing manifold technology through computational fluid dynamics, additive manufacturing, and variable geometry designs. Chinese manufacturers including SAIC, BYD, and Geely are rapidly gaining market share by investing in R&D capabilities to bridge the technological gap with traditional industry leaders.

GM Global Technology Operations LLC

Technical Solution: GM has developed an advanced V4 engine manifold design utilizing computational fluid dynamics (CFD) simulation to optimize the balance between pressure and flow efficiency. Their solution incorporates variable geometry intake runners that dynamically adjust based on engine load and RPM. This system features electronically controlled valves that modify the intake path length and cross-sectional area to optimize volumetric efficiency across the entire operating range. GM's design includes integrated pressure wave tuning technology that harnesses pressure pulses to improve cylinder filling at specific engine speeds. The manifold incorporates 3D-printed components with complex internal geometries impossible to achieve with traditional manufacturing methods, allowing for optimized flow paths with minimal pressure drops. Their design also features a dual-mode operation that prioritizes either maximum power output or fuel efficiency depending on driving conditions.

Strengths: Superior adaptability across varying engine loads and speeds, excellent balance of low-end torque and high-end power, and reduced pumping losses. Weaknesses: Higher manufacturing complexity and cost compared to fixed geometry designs, potential reliability concerns with moving components in the variable geometry system, and increased control system complexity.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has engineered an innovative V4 engine manifold design focusing on the critical balance between pressure retention and flow efficiency. Their solution features a continuously variable intake geometry system that adapts the effective runner length and volume based on real-time engine parameters. The manifold incorporates Nissan's proprietary Swirl Control Valve technology that creates optimized air movement patterns within the combustion chamber at different engine speeds. A key innovation is their resonance charging system that utilizes pressure wave dynamics to improve volumetric efficiency, with specially tuned runner lengths that create positive pressure waves arriving at the intake valve just as it opens. The design includes micro-perforated flow straighteners at strategic locations to reduce turbulence where detrimental while promoting it where beneficial for combustion. Nissan's manifold also features an integrated thermal management system that maintains optimal intake air temperature through active cooling channels, improving charge density across varying operating conditions.

Strengths: Exceptional volumetric efficiency across broad RPM range, superior thermal management leading to consistent performance, and excellent NVH (Noise, Vibration, Harshness) characteristics. Weaknesses: Complex control systems requiring sophisticated sensors and actuators, higher manufacturing precision requirements leading to increased costs, and potential for increased maintenance needs due to system complexity.

Critical Patents and Research in Manifold Fluid Dynamics

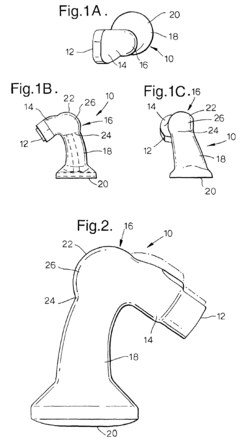

Exhaust manifold for an engine

PatentInactiveEP1473504A1

Innovation

- The exhaust manifold design includes an expanded elbow with a hemispherical concave inner surface and an adjacent inflexion at the outer radius, creating opposing pressure fields that minimize flow separation by reversing the flow of exhaust gases.

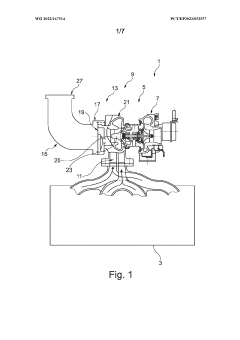

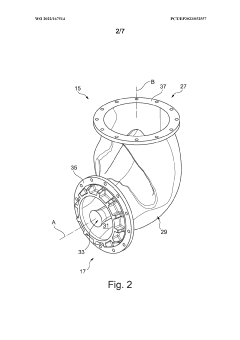

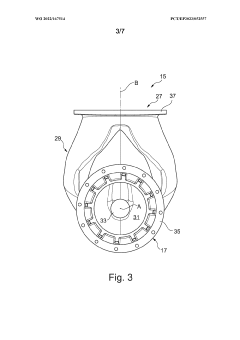

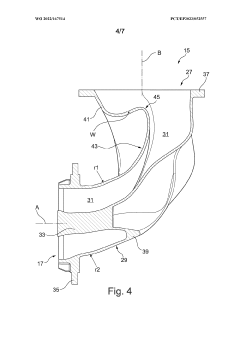

Manifold, turbomachine comprising such a manifold, turbocharger comprising such a turbomachine, and an internal combustion engine comprising such a manifold

PatentWO2022167514A1

Innovation

- A manifold design featuring a centrally arranged diffuser section, integrated with the wall and optimized for flow guidance, minimizes pressure loss and recirculation, while being structurally integrated with the turbine hub to enhance containment and prevent axial displacement of the turbine wheel.

Materials Science Advancements for Manifold Construction

Material science innovations have significantly transformed manifold design capabilities in V4 engines, addressing the critical balance between pressure maintenance and flow efficiency. Traditional materials like cast iron and aluminum alloys, while reliable, present inherent limitations in thermal management and weight optimization that directly impact engine performance metrics.

Recent advancements in composite materials have introduced carbon fiber reinforced polymers (CFRPs) specifically engineered for high-temperature engine environments. These materials offer superior strength-to-weight ratios compared to conventional metals, enabling thinner wall constructions that maintain structural integrity while reducing overall engine weight by up to 30%. The thermal expansion characteristics of these composites can be precisely tailored, minimizing warping under extreme temperature fluctuations.

Ceramic matrix composites (CMCs) represent another breakthrough, incorporating silicon carbide and aluminum oxide to create manifolds with exceptional heat resistance up to 1200°C. This thermal stability allows for more consistent pressure maintenance throughout the intake and exhaust cycles, particularly beneficial for turbocharged V4 configurations where temperature management directly impacts volumetric efficiency.

Surface treatment technologies have evolved to address internal flow dynamics. Plasma-sprayed coatings with controlled micro-texturing can reduce boundary layer disruption by up to 15%, decreasing flow resistance while maintaining optimal pressure characteristics. These treatments modify the effective surface roughness to minimize turbulence at critical junctions where flow direction changes.

Additive manufacturing has revolutionized manifold production capabilities, enabling complex internal geometries previously impossible with traditional casting methods. Direct metal laser sintering (DMLS) allows for the creation of variable wall thicknesses and integrated cooling channels that optimize both thermal management and flow characteristics simultaneously. This manufacturing approach permits rapid prototyping of designs with computational fluid dynamics (CFD) validated geometries.

Hybrid material systems combining metallic substrates with advanced ceramic thermal barriers represent the cutting edge of manifold construction. These systems leverage the structural properties of metals with the thermal insulation capabilities of ceramics, creating manifolds that can maintain more consistent internal temperatures and pressure conditions across varying engine loads and ambient conditions.

Recent advancements in composite materials have introduced carbon fiber reinforced polymers (CFRPs) specifically engineered for high-temperature engine environments. These materials offer superior strength-to-weight ratios compared to conventional metals, enabling thinner wall constructions that maintain structural integrity while reducing overall engine weight by up to 30%. The thermal expansion characteristics of these composites can be precisely tailored, minimizing warping under extreme temperature fluctuations.

Ceramic matrix composites (CMCs) represent another breakthrough, incorporating silicon carbide and aluminum oxide to create manifolds with exceptional heat resistance up to 1200°C. This thermal stability allows for more consistent pressure maintenance throughout the intake and exhaust cycles, particularly beneficial for turbocharged V4 configurations where temperature management directly impacts volumetric efficiency.

Surface treatment technologies have evolved to address internal flow dynamics. Plasma-sprayed coatings with controlled micro-texturing can reduce boundary layer disruption by up to 15%, decreasing flow resistance while maintaining optimal pressure characteristics. These treatments modify the effective surface roughness to minimize turbulence at critical junctions where flow direction changes.

Additive manufacturing has revolutionized manifold production capabilities, enabling complex internal geometries previously impossible with traditional casting methods. Direct metal laser sintering (DMLS) allows for the creation of variable wall thicknesses and integrated cooling channels that optimize both thermal management and flow characteristics simultaneously. This manufacturing approach permits rapid prototyping of designs with computational fluid dynamics (CFD) validated geometries.

Hybrid material systems combining metallic substrates with advanced ceramic thermal barriers represent the cutting edge of manifold construction. These systems leverage the structural properties of metals with the thermal insulation capabilities of ceramics, creating manifolds that can maintain more consistent internal temperatures and pressure conditions across varying engine loads and ambient conditions.

Environmental Regulations Impact on Manifold Design

Environmental regulations have become increasingly stringent worldwide, significantly influencing the design parameters of V4 engine manifolds. The primary regulatory frameworks, including Euro 7, EPA Tier 3, and China 6b standards, have established progressively lower emission thresholds for nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. These regulations have fundamentally altered the approach to manifold design, shifting focus from pure performance to a balance between performance and emissions control.

Manifold designers must now incorporate advanced flow modeling techniques to ensure optimal air-fuel mixture distribution while minimizing emissions formation. The traditional high-pressure designs that prioritized power output have given way to more sophisticated geometries that manage both pressure dynamics and emissions characteristics. This regulatory pressure has accelerated the development of variable geometry manifolds that can adapt to different engine operating conditions, optimizing both efficiency and emissions compliance.

The integration of exhaust gas recirculation (EGR) systems has become a critical consideration in modern manifold design. These systems require careful integration with the intake manifold to ensure proper mixing of recirculated exhaust gases with fresh intake air. The thermal management aspects of manifold design have also gained prominence, as temperature control plays a vital role in emissions formation, particularly NOx production during high-temperature combustion conditions.

Material selection for manifolds has evolved in response to regulatory requirements. Lightweight, thermally efficient materials that can withstand higher operating temperatures while maintaining dimensional stability are increasingly preferred. This shift has prompted research into advanced alloys, ceramics, and composite materials that offer superior thermal management properties while reducing overall engine weight.

Computational fluid dynamics (CFD) modeling has become an indispensable tool in regulatory-compliant manifold design. These sophisticated simulation techniques allow engineers to predict emissions formation within the manifold and combustion chamber, enabling iterative design optimization before physical prototyping. The integration of real-time sensors and electronic control systems with manifold design has further enhanced the ability to maintain optimal performance while meeting emissions targets across various operating conditions.

The cost implications of meeting environmental regulations have reshaped the economic considerations in manifold design. Manufacturers must balance the increased complexity and material costs against potential penalties for non-compliance and market access restrictions. This economic pressure has driven innovation in manufacturing processes, with techniques like 3D printing enabling more complex internal geometries that would be impossible with traditional casting methods.

Manifold designers must now incorporate advanced flow modeling techniques to ensure optimal air-fuel mixture distribution while minimizing emissions formation. The traditional high-pressure designs that prioritized power output have given way to more sophisticated geometries that manage both pressure dynamics and emissions characteristics. This regulatory pressure has accelerated the development of variable geometry manifolds that can adapt to different engine operating conditions, optimizing both efficiency and emissions compliance.

The integration of exhaust gas recirculation (EGR) systems has become a critical consideration in modern manifold design. These systems require careful integration with the intake manifold to ensure proper mixing of recirculated exhaust gases with fresh intake air. The thermal management aspects of manifold design have also gained prominence, as temperature control plays a vital role in emissions formation, particularly NOx production during high-temperature combustion conditions.

Material selection for manifolds has evolved in response to regulatory requirements. Lightweight, thermally efficient materials that can withstand higher operating temperatures while maintaining dimensional stability are increasingly preferred. This shift has prompted research into advanced alloys, ceramics, and composite materials that offer superior thermal management properties while reducing overall engine weight.

Computational fluid dynamics (CFD) modeling has become an indispensable tool in regulatory-compliant manifold design. These sophisticated simulation techniques allow engineers to predict emissions formation within the manifold and combustion chamber, enabling iterative design optimization before physical prototyping. The integration of real-time sensors and electronic control systems with manifold design has further enhanced the ability to maintain optimal performance while meeting emissions targets across various operating conditions.

The cost implications of meeting environmental regulations have reshaped the economic considerations in manifold design. Manufacturers must balance the increased complexity and material costs against potential penalties for non-compliance and market access restrictions. This economic pressure has driven innovation in manufacturing processes, with techniques like 3D printing enabling more complex internal geometries that would be impossible with traditional casting methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!