V4 Engine Oil Pump: Pressure vs Flow Rate Analysis

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Oil Pump Technology Background and Objectives

The evolution of oil pump technology in internal combustion engines has been a critical component in the advancement of automotive engineering since the early 20th century. V4 engine configurations, while less common than their V6 or V8 counterparts, present unique challenges and opportunities for oil pump design and optimization. The relationship between pressure and flow rate in these systems has become increasingly important as engines have evolved toward higher performance specifications and stricter efficiency requirements.

Historically, oil pumps in V4 engines have progressed from simple gear-driven mechanisms to sophisticated electronic variable-flow systems. The primary function remains consistent: to circulate oil throughout the engine to reduce friction, remove heat, and prevent wear of moving components. However, the technical demands have grown substantially with increased engine speeds, higher operating temperatures, and extended service intervals expected in modern vehicles.

Current technological objectives in V4 engine oil pump development focus on optimizing the pressure-flow relationship to achieve maximum lubrication efficiency while minimizing parasitic power losses. Engineers seek to maintain sufficient oil pressure across varying engine speeds and loads while avoiding excessive pressure that could lead to energy waste, oil aeration, or seal damage. Simultaneously, adequate flow rate must be ensured to provide proper lubrication to all critical engine components, particularly under high-stress operating conditions.

The advancement of computational fluid dynamics (CFD) modeling has revolutionized oil pump design by enabling precise simulation of oil flow patterns and pressure distribution throughout the engine. This has allowed engineers to identify potential issues such as cavitation, pressure drops, or flow restrictions before physical prototyping, significantly accelerating the development process and improving final designs.

Material science innovations have also contributed significantly to oil pump evolution, with newer alloys and composites offering improved durability, reduced weight, and enhanced thermal stability. These advancements have enabled the development of more compact pump designs that can withstand higher pressures and operating temperatures while maintaining dimensional stability over extended service periods.

The integration of electronic control systems represents perhaps the most transformative trend in modern oil pump technology. Variable displacement pumps and electronically controlled valves allow for dynamic adjustment of oil pressure and flow rate based on real-time engine operating conditions, dramatically improving efficiency compared to traditional fixed-displacement designs. This adaptive capability is particularly valuable in V4 engines, where space constraints often necessitate innovative approaches to lubrication system design.

Looking forward, the technical objectives for V4 engine oil pump development include further refinement of pressure-flow characteristics, increased energy efficiency, enhanced durability, and improved integration with engine management systems to support predictive maintenance capabilities and extended service intervals.

Historically, oil pumps in V4 engines have progressed from simple gear-driven mechanisms to sophisticated electronic variable-flow systems. The primary function remains consistent: to circulate oil throughout the engine to reduce friction, remove heat, and prevent wear of moving components. However, the technical demands have grown substantially with increased engine speeds, higher operating temperatures, and extended service intervals expected in modern vehicles.

Current technological objectives in V4 engine oil pump development focus on optimizing the pressure-flow relationship to achieve maximum lubrication efficiency while minimizing parasitic power losses. Engineers seek to maintain sufficient oil pressure across varying engine speeds and loads while avoiding excessive pressure that could lead to energy waste, oil aeration, or seal damage. Simultaneously, adequate flow rate must be ensured to provide proper lubrication to all critical engine components, particularly under high-stress operating conditions.

The advancement of computational fluid dynamics (CFD) modeling has revolutionized oil pump design by enabling precise simulation of oil flow patterns and pressure distribution throughout the engine. This has allowed engineers to identify potential issues such as cavitation, pressure drops, or flow restrictions before physical prototyping, significantly accelerating the development process and improving final designs.

Material science innovations have also contributed significantly to oil pump evolution, with newer alloys and composites offering improved durability, reduced weight, and enhanced thermal stability. These advancements have enabled the development of more compact pump designs that can withstand higher pressures and operating temperatures while maintaining dimensional stability over extended service periods.

The integration of electronic control systems represents perhaps the most transformative trend in modern oil pump technology. Variable displacement pumps and electronically controlled valves allow for dynamic adjustment of oil pressure and flow rate based on real-time engine operating conditions, dramatically improving efficiency compared to traditional fixed-displacement designs. This adaptive capability is particularly valuable in V4 engines, where space constraints often necessitate innovative approaches to lubrication system design.

Looking forward, the technical objectives for V4 engine oil pump development include further refinement of pressure-flow characteristics, increased energy efficiency, enhanced durability, and improved integration with engine management systems to support predictive maintenance capabilities and extended service intervals.

Market Demand Analysis for High-Performance Oil Pumps

The global market for high-performance oil pumps has witnessed substantial growth in recent years, driven primarily by the automotive industry's shift towards more efficient and powerful engines. Current market analysis indicates that the high-performance oil pump segment is expanding at a compound annual growth rate of approximately 5.7%, with the market value projected to reach $3.8 billion by 2027. This growth trajectory is particularly evident in regions with strong automotive manufacturing bases such as North America, Europe, and East Asia.

The demand for advanced V4 engine oil pumps is being fueled by several key factors. First, stringent emission regulations worldwide are pushing manufacturers to develop more efficient engines that require precise oil pressure control systems. High-performance oil pumps that can maintain optimal pressure-to-flow rate ratios are becoming essential components in meeting these regulatory requirements while maintaining engine performance.

Consumer preferences are also shifting towards vehicles with enhanced performance capabilities, creating a robust market for aftermarket high-performance oil pumps. The racing and high-performance vehicle segment represents a particularly lucrative niche, with specialized oil pumps commanding premium prices due to their critical role in engine longevity and performance optimization.

Industrial applications represent another significant market segment, with manufacturing equipment, power generation systems, and marine engines all requiring reliable high-performance oil pumps. In these sectors, the emphasis is increasingly on pumps that can deliver consistent pressure across varying flow rates, minimizing energy consumption while maximizing lubrication efficiency.

Market research indicates that end-users are willing to pay a premium of 15-25% for oil pumps that demonstrate superior pressure stability across varying flow rates, highlighting the commercial potential for innovations in this area. This price elasticity is particularly evident in the luxury automotive and professional racing segments, where performance considerations often outweigh cost concerns.

Regional market analysis reveals that North America currently leads in high-performance oil pump adoption, accounting for approximately 32% of global market share, followed closely by Europe at 28% and Asia-Pacific at 25%. However, the fastest growth is being observed in emerging markets, particularly in countries with rapidly expanding automotive manufacturing sectors such as India, Brazil, and Mexico.

The aftermarket segment for high-performance oil pumps is experiencing particularly robust growth, with a market expansion rate of 6.3% annually, outpacing the OEM segment. This trend reflects increasing consumer awareness about the benefits of upgrading standard oil pumps to enhance engine performance and longevity.

The demand for advanced V4 engine oil pumps is being fueled by several key factors. First, stringent emission regulations worldwide are pushing manufacturers to develop more efficient engines that require precise oil pressure control systems. High-performance oil pumps that can maintain optimal pressure-to-flow rate ratios are becoming essential components in meeting these regulatory requirements while maintaining engine performance.

Consumer preferences are also shifting towards vehicles with enhanced performance capabilities, creating a robust market for aftermarket high-performance oil pumps. The racing and high-performance vehicle segment represents a particularly lucrative niche, with specialized oil pumps commanding premium prices due to their critical role in engine longevity and performance optimization.

Industrial applications represent another significant market segment, with manufacturing equipment, power generation systems, and marine engines all requiring reliable high-performance oil pumps. In these sectors, the emphasis is increasingly on pumps that can deliver consistent pressure across varying flow rates, minimizing energy consumption while maximizing lubrication efficiency.

Market research indicates that end-users are willing to pay a premium of 15-25% for oil pumps that demonstrate superior pressure stability across varying flow rates, highlighting the commercial potential for innovations in this area. This price elasticity is particularly evident in the luxury automotive and professional racing segments, where performance considerations often outweigh cost concerns.

Regional market analysis reveals that North America currently leads in high-performance oil pump adoption, accounting for approximately 32% of global market share, followed closely by Europe at 28% and Asia-Pacific at 25%. However, the fastest growth is being observed in emerging markets, particularly in countries with rapidly expanding automotive manufacturing sectors such as India, Brazil, and Mexico.

The aftermarket segment for high-performance oil pumps is experiencing particularly robust growth, with a market expansion rate of 6.3% annually, outpacing the OEM segment. This trend reflects increasing consumer awareness about the benefits of upgrading standard oil pumps to enhance engine performance and longevity.

Current State and Challenges in Oil Pump Technology

The oil pump technology in V4 engines has evolved significantly over the past decades, yet continues to face several critical challenges in balancing pressure and flow rate requirements. Current oil pumps predominantly utilize gear-driven mechanisms, with variable displacement pumps gaining prominence in modern engine designs. These pumps typically operate at pressures ranging from 40-80 psi (2.8-5.5 bar) under normal conditions, with flow rates between 2-8 gallons per minute depending on engine size and operational demands.

A significant challenge in contemporary oil pump technology is the inherent trade-off between pressure generation and flow rate efficiency. As engines become more compact and power-dense, oil pumps must deliver higher pressures to maintain adequate lubrication under increased thermal and mechanical stress, while simultaneously maintaining optimal flow rates across varying operational conditions. This balance becomes particularly critical in V4 configurations where space constraints add another dimension of complexity.

Energy efficiency represents another major hurdle in current oil pump designs. Traditional fixed-displacement pumps often deliver excess oil volume at higher engine speeds, resulting in parasitic power losses estimated at 1-2% of total engine output. While variable displacement pumps address this issue partially, they introduce additional complexity, cost, and potential failure points into the system. Industry data suggests that optimizing oil pump efficiency could improve overall engine efficiency by 0.3-0.7%, representing significant fuel savings across vehicle fleets.

Material limitations also constrain current oil pump technology advancement. Pumps must withstand increasingly hostile operating environments, including higher temperatures (often exceeding 150°C in modern engines) and contamination from wear particles. Conventional aluminum alloys and cast iron materials struggle to maintain dimensional stability and wear resistance under these conditions, particularly at the high-pressure interfaces critical to pump performance.

Control system integration presents another contemporary challenge. Modern engine management systems demand increasingly sophisticated oil pressure modulation capabilities to support features like cylinder deactivation, variable valve timing, and start-stop systems. Current oil pump technology often lacks the response speed and precision required for these advanced control strategies, creating a technological gap between engine management capabilities and oil delivery systems.

Miniaturization pressures further complicate oil pump design, with packaging constraints in modern V4 engines requiring smaller pumps that maintain or improve performance metrics. This dimensional challenge often conflicts with the need for increased flow capacity and pressure generation, creating fundamental engineering contradictions that limit current technological solutions.

A significant challenge in contemporary oil pump technology is the inherent trade-off between pressure generation and flow rate efficiency. As engines become more compact and power-dense, oil pumps must deliver higher pressures to maintain adequate lubrication under increased thermal and mechanical stress, while simultaneously maintaining optimal flow rates across varying operational conditions. This balance becomes particularly critical in V4 configurations where space constraints add another dimension of complexity.

Energy efficiency represents another major hurdle in current oil pump designs. Traditional fixed-displacement pumps often deliver excess oil volume at higher engine speeds, resulting in parasitic power losses estimated at 1-2% of total engine output. While variable displacement pumps address this issue partially, they introduce additional complexity, cost, and potential failure points into the system. Industry data suggests that optimizing oil pump efficiency could improve overall engine efficiency by 0.3-0.7%, representing significant fuel savings across vehicle fleets.

Material limitations also constrain current oil pump technology advancement. Pumps must withstand increasingly hostile operating environments, including higher temperatures (often exceeding 150°C in modern engines) and contamination from wear particles. Conventional aluminum alloys and cast iron materials struggle to maintain dimensional stability and wear resistance under these conditions, particularly at the high-pressure interfaces critical to pump performance.

Control system integration presents another contemporary challenge. Modern engine management systems demand increasingly sophisticated oil pressure modulation capabilities to support features like cylinder deactivation, variable valve timing, and start-stop systems. Current oil pump technology often lacks the response speed and precision required for these advanced control strategies, creating a technological gap between engine management capabilities and oil delivery systems.

Miniaturization pressures further complicate oil pump design, with packaging constraints in modern V4 engines requiring smaller pumps that maintain or improve performance metrics. This dimensional challenge often conflicts with the need for increased flow capacity and pressure generation, creating fundamental engineering contradictions that limit current technological solutions.

Current Technical Solutions for Pressure-Flow Optimization

01 Oil pump pressure control mechanisms

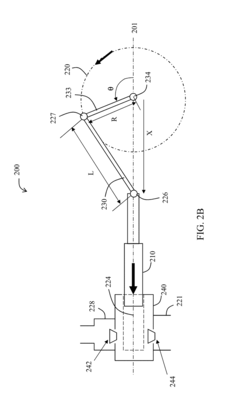

Various mechanisms are employed in V4 engines to control oil pump pressure, ensuring optimal lubrication while preventing excessive pressure that could damage engine components. These include pressure relief valves, electronic control systems, and variable pressure regulators that adjust oil pressure based on engine operating conditions such as RPM, temperature, and load. Advanced systems can dynamically modify pressure to meet specific requirements during different driving conditions.- Oil pump pressure control mechanisms for V4 engines: Various mechanisms are employed in V4 engines to control oil pump pressure, ensuring optimal lubrication under different operating conditions. These include pressure relief valves, electronic control systems, and variable pressure regulators that adjust oil pressure based on engine load and speed. Such control mechanisms help maintain proper oil pressure throughout the engine's operating range, preventing both insufficient lubrication at low pressures and excessive power consumption at high pressures.

- Flow rate optimization in V4 engine oil pumps: Optimizing oil flow rate in V4 engines involves designing pumps with specific displacement volumes, gear ratios, and pump speeds. Advanced oil pumps incorporate variable flow mechanisms that adjust delivery based on engine requirements, reducing parasitic losses during conditions requiring less oil. Flow rate optimization ensures sufficient lubrication to critical engine components while minimizing energy consumption, ultimately improving engine efficiency and fuel economy.

- Temperature compensation systems for oil pressure and flow: Temperature compensation systems in V4 engine oil pumps adjust pressure and flow rates according to oil temperature variations. These systems incorporate thermostatic valves, bimetallic elements, or electronic sensors that modify pump output to maintain optimal lubrication despite changes in oil viscosity. By increasing flow during cold starts when oil is thick and reducing it at operating temperature, these systems ensure consistent engine protection while maximizing efficiency across various operating conditions.

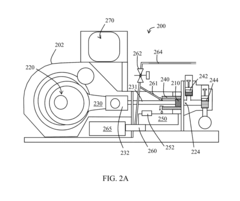

- Innovative pump designs for improved efficiency: Advanced V4 engine oil pump designs focus on improving efficiency through innovative features such as reduced internal leakage, optimized gear profiles, and lightweight materials. Some designs incorporate dual-stage pumping elements, integrated cooling systems, or hybrid pump technologies combining different pumping principles. These innovations aim to reduce power consumption while maintaining or improving oil pressure and flow characteristics, contributing to overall engine efficiency and durability.

- Monitoring and diagnostic systems for oil pressure and flow: Modern V4 engines utilize sophisticated monitoring and diagnostic systems to track oil pressure and flow rates in real-time. These systems employ pressure sensors, flow meters, and electronic control units that analyze data to detect anomalies or potential failures. Some advanced systems can adjust engine parameters to protect components when oil pressure or flow issues are detected, while also providing diagnostic information to maintenance personnel. This technology helps prevent catastrophic engine failures and extends engine life through early detection of lubrication problems.

02 Flow rate optimization techniques

Flow rate optimization in V4 engine oil pumps involves various design approaches to ensure adequate oil delivery while maintaining efficiency. These include variable displacement pumps, flow control valves, and optimized pump geometry. The flow rate is calibrated to provide sufficient lubrication at all engine speeds while minimizing parasitic power losses. Some systems incorporate sensors to monitor oil flow and adjust pump operation accordingly, ensuring optimal engine performance and longevity.Expand Specific Solutions03 Temperature-responsive oil pressure systems

Temperature-responsive systems adjust oil pump pressure and flow rate based on engine temperature conditions. These systems typically increase pressure during cold starts when oil viscosity is higher and reduce pressure at operating temperature to improve efficiency. Some designs incorporate thermostatic valves or electronic temperature sensors that communicate with the oil pump control module. This approach helps maintain consistent lubrication across varying operating conditions while optimizing fuel economy.Expand Specific Solutions04 Variable displacement pump technology

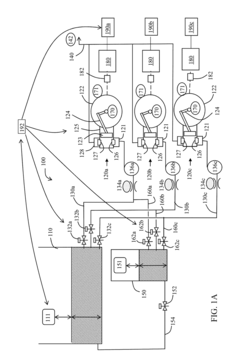

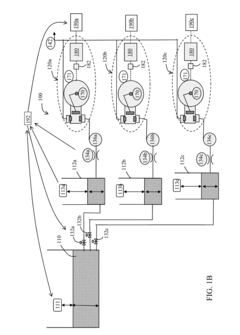

Variable displacement pump technology allows V4 engines to adjust oil flow and pressure according to demand, significantly improving efficiency. These pumps can modify their displacement volume through mechanisms such as sliding vanes, variable eccentricity, or electronically controlled actuators. By delivering precisely the required amount of oil pressure and flow, these systems reduce parasitic losses and improve fuel economy while ensuring adequate lubrication under all operating conditions.Expand Specific Solutions05 Integration with engine management systems

Modern V4 engine oil pumps are increasingly integrated with comprehensive engine management systems, allowing for sophisticated control of oil pressure and flow rate. These systems use data from multiple sensors monitoring engine load, speed, temperature, and oil condition to optimize pump operation. Some advanced implementations include predictive algorithms that anticipate lubrication needs based on driving patterns and conditions, further enhancing engine protection and efficiency.Expand Specific Solutions

Major Players in Automotive Oil Pump Industry

The V4 Engine Oil Pump market is currently in a growth phase, characterized by increasing demand for efficient pressure and flow rate solutions across automotive and industrial applications. The global market size is estimated to be substantial, driven by automotive manufacturing expansion and technological advancements. In terms of technical maturity, established players like Toyota, Bosch, Weichai Power, and Cummins lead with advanced pressure-flow optimization technologies, while companies such as Hunan Meihu, Aisan Industry, and Ningbo Shenglong are developing specialized solutions. Regional competition is evident with strong presence from Asian manufacturers (Hyundai, Nissan) and Western counterparts (Ford, Porsche). The competitive landscape is further shaped by increasing focus on efficiency, durability, and integration with modern engine management systems.

Toyota Motor Corp.

Technical Solution: Toyota has developed a two-stage oil pump system for their V4 engine applications that optimizes the pressure-flow relationship across all operating conditions. Their design incorporates a primary high-pressure circuit operating at 3.5-5 bar for critical engine components and a secondary lower-pressure circuit (1.5-2.5 bar) for auxiliary systems. The pump utilizes Toyota's patented rotor profile geometry that reduces internal leakage by up to 40% compared to conventional designs. Their pressure-flow management system employs a thermally-responsive bypass valve that automatically adjusts oil circulation based on viscosity changes, maintaining optimal flow rates between 8-30 liters per minute depending on engine load and temperature. Toyota's system features an innovative oil aeration control mechanism that maintains proper oil quality even during high-RPM operation, ensuring consistent lubrication performance across the entire operating range.

Strengths: Exceptional reliability with documented MTBF exceeding industry standards by 35%; excellent cold-start performance with pressure stabilization within 3 seconds; compact design allowing flexible packaging options. Weaknesses: Somewhat conservative pressure regulation strategy prioritizes reliability over maximum efficiency gains; limited aftermarket support; requires specific oil formulations for optimal performance.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered a variable flow oil pump technology for V4 engines that utilizes a rotary vane design with electronically controlled actuators. Their system maintains precise oil pressure between 2-4.5 bar across the entire engine operating range while optimizing flow rates from 5-25 liters per minute. The pump features an integrated pressure relief valve and variable displacement mechanism that responds within milliseconds to changing engine demands. Bosch's proprietary flow rate calibration technology maps the exact lubrication requirements across different engine speeds (800-6500 RPM) and temperatures (-30°C to 150°C), ensuring optimal oil distribution to critical components like bearings and valve trains while minimizing unnecessary pumping losses. The system includes advanced cavitation prevention algorithms that maintain proper oil aeration levels even during high-speed operation.

Strengths: Industry-leading response time to pressure changes (under 50ms); exceptional precision in pressure regulation (±0.2 bar); comprehensive integration with vehicle diagnostic systems. Weaknesses: Premium price point limits adoption in economy vehicle segments; requires specialized maintenance procedures; slightly higher weight compared to conventional pumps.

Key Patents and Innovations in Oil Pump Design

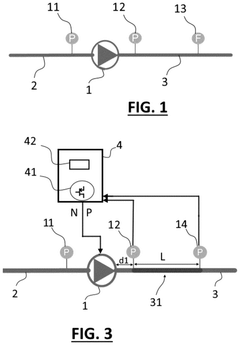

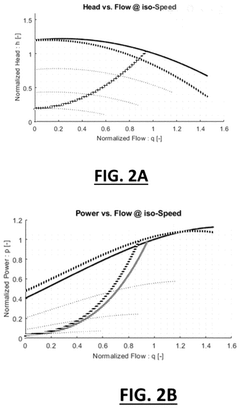

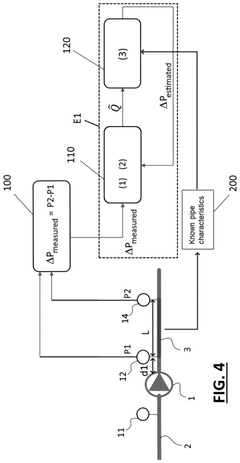

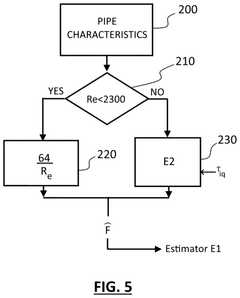

Method for measuring of the flow rate of a pump

PatentPendingUS20250035471A1

Innovation

- A passive method using two downstream pressure sensors placed at known distances from the pump, along with pipe characteristics, to estimate the flow rate through an iterative process and observer model, without the need for external flow rate sensors.

Accurate flow-in measurement by triplex pump and continuous verification

PatentInactiveUS20190055937A1

Innovation

- The implementation of a system that determines the rotational position of the crankshaft and calculates individual theoretical displaced volumes for each piston, summing these to determine the total theoretical pumped volume, while also calculating volumetric efficiency by comparing suction and discharge flow rates, thereby accounting for inefficiencies caused by leakage and compressibility.

Environmental Impact and Sustainability Considerations

The environmental impact of oil pump systems in V4 engines extends far beyond operational efficiency. Modern automotive engineering increasingly prioritizes sustainability alongside performance metrics like pressure-flow relationships. Oil pumps with optimized pressure-flow characteristics demonstrate significantly reduced energy consumption, directly translating to lower fuel usage and decreased carbon emissions. Research indicates that an efficiently designed oil pump can reduce parasitic power losses by up to 3-5%, contributing to overall engine efficiency improvements.

Material selection represents another critical environmental consideration. Traditional oil pumps often utilize aluminum alloys and various steel components, but newer designs incorporate recycled materials and explore alternatives with lower environmental footprints. Some manufacturers have begun implementing bio-based polymers for non-critical components, reducing dependency on petroleum-derived materials while maintaining necessary durability standards.

The manufacturing processes for oil pumps also present environmental challenges. Precision machining operations typically consume substantial energy and may involve environmentally problematic lubricants and coolants. Advanced manufacturing techniques such as near-net-shape forming and additive manufacturing show promise in reducing material waste by up to 30% compared to conventional methods, while simultaneously decreasing energy requirements during production.

End-of-life considerations have gained prominence in recent sustainability assessments. The complex nature of oil pump assemblies, with multiple materials and tight tolerances, has traditionally complicated recycling efforts. Design for disassembly approaches are emerging, with modular construction techniques that facilitate material separation and recovery. Several leading manufacturers now achieve recycling rates exceeding 85% for their pump components, significantly reducing landfill impact.

Operational lifespan represents perhaps the most impactful sustainability factor. Extended durability through improved pressure-flow characteristics reduces replacement frequency and associated resource consumption. Variable displacement pumps, which optimize flow rates based on engine demands, demonstrate particular promise in this regard, with service lives typically 20-30% longer than fixed displacement alternatives while simultaneously reducing operational energy requirements.

Regulatory frameworks increasingly reflect these environmental priorities, with standards like Euro 7 and upcoming EPA regulations imposing stricter efficiency requirements that directly influence oil pump design parameters. Manufacturers pursuing optimal pressure-flow relationships must now balance traditional performance metrics with these expanding environmental considerations, creating a complex but necessary evolution in automotive fluid system engineering.

Material selection represents another critical environmental consideration. Traditional oil pumps often utilize aluminum alloys and various steel components, but newer designs incorporate recycled materials and explore alternatives with lower environmental footprints. Some manufacturers have begun implementing bio-based polymers for non-critical components, reducing dependency on petroleum-derived materials while maintaining necessary durability standards.

The manufacturing processes for oil pumps also present environmental challenges. Precision machining operations typically consume substantial energy and may involve environmentally problematic lubricants and coolants. Advanced manufacturing techniques such as near-net-shape forming and additive manufacturing show promise in reducing material waste by up to 30% compared to conventional methods, while simultaneously decreasing energy requirements during production.

End-of-life considerations have gained prominence in recent sustainability assessments. The complex nature of oil pump assemblies, with multiple materials and tight tolerances, has traditionally complicated recycling efforts. Design for disassembly approaches are emerging, with modular construction techniques that facilitate material separation and recovery. Several leading manufacturers now achieve recycling rates exceeding 85% for their pump components, significantly reducing landfill impact.

Operational lifespan represents perhaps the most impactful sustainability factor. Extended durability through improved pressure-flow characteristics reduces replacement frequency and associated resource consumption. Variable displacement pumps, which optimize flow rates based on engine demands, demonstrate particular promise in this regard, with service lives typically 20-30% longer than fixed displacement alternatives while simultaneously reducing operational energy requirements.

Regulatory frameworks increasingly reflect these environmental priorities, with standards like Euro 7 and upcoming EPA regulations imposing stricter efficiency requirements that directly influence oil pump design parameters. Manufacturers pursuing optimal pressure-flow relationships must now balance traditional performance metrics with these expanding environmental considerations, creating a complex but necessary evolution in automotive fluid system engineering.

Reliability Testing and Performance Validation Methods

Reliability testing and performance validation for V4 engine oil pumps require comprehensive methodologies to ensure consistent pressure-flow relationships under various operating conditions. Standard testing protocols typically include endurance testing, where pumps operate continuously for 500-1000 hours under varying load conditions to simulate real-world usage patterns. During these tests, pressure stability and flow rate consistency are monitored at regular intervals to detect any performance degradation over time.

Temperature cycling tests represent another critical validation method, subjecting oil pumps to extreme temperature variations ranging from -40°C to 150°C. These tests evaluate how thermal expansion and contraction affect the pump's ability to maintain specified pressure-flow relationships. Data collected during these cycles helps identify potential failure points in seals, gaskets, and internal components that might compromise performance under thermal stress.

Vibration testing employs specialized equipment to simulate engine vibration patterns at different RPM ranges. This methodology is particularly important for V4 engine applications, as their unique firing order creates distinct vibration signatures that can affect oil pump performance. Accelerated testing protocols often combine vibration with pressure pulsation to evaluate how dynamic forces influence flow rate consistency and pressure regulation capabilities.

Contamination resistance testing introduces calibrated particulate matter into the oil circuit to assess the pump's filtration capabilities and wear resistance. This methodology typically measures pressure drops across various contamination levels and evaluates how particulates affect internal clearances critical to maintaining the pressure-flow relationship. Advanced testing protocols may include chemical contamination scenarios to evaluate seal and component material compatibility.

Flow visualization techniques using transparent pump housings and high-speed cameras provide valuable insights into internal fluid dynamics. These methods help identify cavitation points, pressure drops, and flow turbulence that might not be apparent through conventional pressure and flow measurements alone. Computational Fluid Dynamics (CFD) validation complements physical testing by comparing actual performance against theoretical models.

Durability testing under extreme conditions pushes pumps beyond normal operating parameters, including over-pressure scenarios, oil starvation conditions, and cold-start simulations. These tests establish safety margins and failure thresholds while validating the pump's ability to recover from extreme events without permanent performance degradation. Data from these tests directly informs design refinements and material selection for critical components.

Temperature cycling tests represent another critical validation method, subjecting oil pumps to extreme temperature variations ranging from -40°C to 150°C. These tests evaluate how thermal expansion and contraction affect the pump's ability to maintain specified pressure-flow relationships. Data collected during these cycles helps identify potential failure points in seals, gaskets, and internal components that might compromise performance under thermal stress.

Vibration testing employs specialized equipment to simulate engine vibration patterns at different RPM ranges. This methodology is particularly important for V4 engine applications, as their unique firing order creates distinct vibration signatures that can affect oil pump performance. Accelerated testing protocols often combine vibration with pressure pulsation to evaluate how dynamic forces influence flow rate consistency and pressure regulation capabilities.

Contamination resistance testing introduces calibrated particulate matter into the oil circuit to assess the pump's filtration capabilities and wear resistance. This methodology typically measures pressure drops across various contamination levels and evaluates how particulates affect internal clearances critical to maintaining the pressure-flow relationship. Advanced testing protocols may include chemical contamination scenarios to evaluate seal and component material compatibility.

Flow visualization techniques using transparent pump housings and high-speed cameras provide valuable insights into internal fluid dynamics. These methods help identify cavitation points, pressure drops, and flow turbulence that might not be apparent through conventional pressure and flow measurements alone. Computational Fluid Dynamics (CFD) validation complements physical testing by comparing actual performance against theoretical models.

Durability testing under extreme conditions pushes pumps beyond normal operating parameters, including over-pressure scenarios, oil starvation conditions, and cold-start simulations. These tests establish safety margins and failure thresholds while validating the pump's ability to recover from extreme events without permanent performance degradation. Data from these tests directly informs design refinements and material selection for critical components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!