V4 Engine vs Boxer Engine: Space and Efficiency

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Architecture Evolution and Objectives

Internal combustion engines have undergone significant evolution since their inception in the late 19th century. The V4 and Boxer engine configurations represent two distinct approaches to solving the fundamental challenges of power generation, space utilization, and operational efficiency in automotive and other applications. These architectures emerged from different engineering philosophies and have evolved to serve specific market needs.

The V4 engine configuration, characterized by its V-shaped cylinder arrangement, was developed to address the need for compact power units that could fit within the increasingly space-constrained engine compartments of modern vehicles. This design places cylinders at an angle to each other, typically between 60 and 90 degrees, creating a more compact footprint compared to inline configurations of similar displacement. The evolution of V4 engines has been driven by the automotive industry's push toward smaller, more efficient vehicles without sacrificing performance.

In contrast, the Boxer engine, with its horizontally opposed cylinder layout, emerged from a different set of priorities. First popularized by manufacturers like Porsche and Subaru, this configuration places cylinders flat against each other on opposite sides of the crankshaft. This design was developed to create a lower center of gravity in vehicles, enhancing handling characteristics while providing natural balance that reduces vibration without requiring additional counterweights.

The technical objectives behind these engine architectures reflect different priorities in automotive design. V4 engines primarily aim to maximize power density within a compact space, making them ideal for front-wheel-drive vehicles and applications where engine bay dimensions are severely limited. Their design allows for shorter engine blocks, which can be particularly advantageous in transverse engine installations.

Boxer engines, meanwhile, target different objectives: optimal balance characteristics, improved vehicle dynamics through a lower center of gravity, and enhanced cooling efficiency due to the increased spacing between cylinders. These objectives align with performance-oriented vehicles and those requiring exceptional stability and handling characteristics.

Recent technological trends have pushed both engine types toward greater efficiency and reduced emissions. Modern V4 and Boxer engines increasingly incorporate direct injection, variable valve timing, turbocharging, and hybrid assistance systems to meet stringent environmental regulations while maintaining performance expectations.

The evolution trajectory suggests that both architectures will continue to find specialized applications, with V4 engines likely focusing on compact, urban mobility solutions, while Boxer engines maintain their niche in performance and all-weather capability applications. Future development objectives will likely center on further integration with electrification technologies, as both configurations adapt to the industry's transition toward partial or full electrification.

The V4 engine configuration, characterized by its V-shaped cylinder arrangement, was developed to address the need for compact power units that could fit within the increasingly space-constrained engine compartments of modern vehicles. This design places cylinders at an angle to each other, typically between 60 and 90 degrees, creating a more compact footprint compared to inline configurations of similar displacement. The evolution of V4 engines has been driven by the automotive industry's push toward smaller, more efficient vehicles without sacrificing performance.

In contrast, the Boxer engine, with its horizontally opposed cylinder layout, emerged from a different set of priorities. First popularized by manufacturers like Porsche and Subaru, this configuration places cylinders flat against each other on opposite sides of the crankshaft. This design was developed to create a lower center of gravity in vehicles, enhancing handling characteristics while providing natural balance that reduces vibration without requiring additional counterweights.

The technical objectives behind these engine architectures reflect different priorities in automotive design. V4 engines primarily aim to maximize power density within a compact space, making them ideal for front-wheel-drive vehicles and applications where engine bay dimensions are severely limited. Their design allows for shorter engine blocks, which can be particularly advantageous in transverse engine installations.

Boxer engines, meanwhile, target different objectives: optimal balance characteristics, improved vehicle dynamics through a lower center of gravity, and enhanced cooling efficiency due to the increased spacing between cylinders. These objectives align with performance-oriented vehicles and those requiring exceptional stability and handling characteristics.

Recent technological trends have pushed both engine types toward greater efficiency and reduced emissions. Modern V4 and Boxer engines increasingly incorporate direct injection, variable valve timing, turbocharging, and hybrid assistance systems to meet stringent environmental regulations while maintaining performance expectations.

The evolution trajectory suggests that both architectures will continue to find specialized applications, with V4 engines likely focusing on compact, urban mobility solutions, while Boxer engines maintain their niche in performance and all-weather capability applications. Future development objectives will likely center on further integration with electrification technologies, as both configurations adapt to the industry's transition toward partial or full electrification.

Market Demand Analysis for V4 and Boxer Engines

The global automotive engine market continues to evolve with changing consumer preferences, environmental regulations, and technological advancements. Both V4 and boxer engine configurations represent distinctive approaches to powertrain design, each with unique market positioning and demand characteristics.

In the passenger vehicle segment, boxer engines have maintained a loyal following primarily through Subaru and Porsche implementations. Market research indicates that Subaru's consistent annual growth rate of approximately 4% over the past decade has been partially attributed to consumer appreciation for their boxer engine's low center of gravity and resulting handling characteristics. The premium sports car segment, where Porsche employs boxer engines, has shown resilience even during economic downturns, with compound annual growth rates exceeding 6% between 2015-2020.

V4 engines, while less common in modern passenger vehicles, have found significant traction in the motorcycle industry. Honda's V4 motorcycle engines have contributed to their dominant market position, particularly in the sport and touring segments. The global motorcycle market, valued at $84 billion in 2021, is projected to reach $108 billion by 2026, with V4-powered premium models representing a growing niche within this expansion.

Efficiency demands are reshaping market preferences significantly. Consumer surveys reveal that 78% of new vehicle buyers now consider fuel efficiency among their top three purchasing criteria, up from 65% five years ago. This trend favors compact engine designs that optimize space utilization while maintaining performance metrics. The boxer engine's inherent balance characteristics eliminate the need for counterbalance shafts, reducing parasitic power losses by up to 3% compared to conventional inline configurations.

Regional market analysis shows divergent trends. European markets demonstrate growing demand for space-efficient powertrains that can be integrated into smaller vehicle platforms while meeting stringent Euro 7 emissions standards. In contrast, North American consumers continue to prioritize performance characteristics, with 62% of surveyed buyers indicating willingness to pay premium prices for vehicles offering enhanced driving dynamics.

The commercial vehicle sector presents another dimension of market demand. Compact engine designs that maximize cargo space while delivering reliable power represent a significant value proposition. The global light commercial vehicle market, growing at 5.8% annually, increasingly favors configurations that optimize the ratio of cargo volume to overall vehicle footprint.

Emerging markets, particularly in Asia-Pacific regions, show accelerating demand for cost-effective yet technologically advanced powertrain solutions. Both V4 and boxer configurations face challenges in these price-sensitive markets, where manufacturing complexity must be balanced against performance benefits and production economies of scale.

In the passenger vehicle segment, boxer engines have maintained a loyal following primarily through Subaru and Porsche implementations. Market research indicates that Subaru's consistent annual growth rate of approximately 4% over the past decade has been partially attributed to consumer appreciation for their boxer engine's low center of gravity and resulting handling characteristics. The premium sports car segment, where Porsche employs boxer engines, has shown resilience even during economic downturns, with compound annual growth rates exceeding 6% between 2015-2020.

V4 engines, while less common in modern passenger vehicles, have found significant traction in the motorcycle industry. Honda's V4 motorcycle engines have contributed to their dominant market position, particularly in the sport and touring segments. The global motorcycle market, valued at $84 billion in 2021, is projected to reach $108 billion by 2026, with V4-powered premium models representing a growing niche within this expansion.

Efficiency demands are reshaping market preferences significantly. Consumer surveys reveal that 78% of new vehicle buyers now consider fuel efficiency among their top three purchasing criteria, up from 65% five years ago. This trend favors compact engine designs that optimize space utilization while maintaining performance metrics. The boxer engine's inherent balance characteristics eliminate the need for counterbalance shafts, reducing parasitic power losses by up to 3% compared to conventional inline configurations.

Regional market analysis shows divergent trends. European markets demonstrate growing demand for space-efficient powertrains that can be integrated into smaller vehicle platforms while meeting stringent Euro 7 emissions standards. In contrast, North American consumers continue to prioritize performance characteristics, with 62% of surveyed buyers indicating willingness to pay premium prices for vehicles offering enhanced driving dynamics.

The commercial vehicle sector presents another dimension of market demand. Compact engine designs that maximize cargo space while delivering reliable power represent a significant value proposition. The global light commercial vehicle market, growing at 5.8% annually, increasingly favors configurations that optimize the ratio of cargo volume to overall vehicle footprint.

Emerging markets, particularly in Asia-Pacific regions, show accelerating demand for cost-effective yet technologically advanced powertrain solutions. Both V4 and boxer configurations face challenges in these price-sensitive markets, where manufacturing complexity must be balanced against performance benefits and production economies of scale.

Technical Comparison and Design Challenges

The V4 and Boxer engine configurations represent two distinct approaches to internal combustion engine design, each with unique spatial requirements and efficiency characteristics. The V4 engine arranges cylinders in a V-shape with two banks of two cylinders, creating a compact package with a higher center of gravity. This configuration allows for shorter overall engine length compared to inline designs, making it particularly valuable in applications where longitudinal space is limited.

Boxer engines, alternatively, position cylinders horizontally opposed to each other, creating a flat, wide profile. This horizontal orientation results in a significantly lower center of gravity, enhancing vehicle stability and handling characteristics. The flat design also contributes to reduced engine height, allowing for lower hood lines and improved aerodynamics in automotive applications.

From a spatial efficiency perspective, V4 engines excel in applications requiring minimal longitudinal space and moderate vertical clearance. Their compact design makes them suitable for transverse mounting in front-wheel-drive vehicles or applications where engine bay length is constrained. However, the V-configuration necessitates more complex intake and exhaust routing, potentially increasing the overall width requirement.

Boxer engines demonstrate superior balance characteristics due to their horizontally opposed piston movement, which naturally cancels out primary forces. This inherent balance reduces vibration without requiring additional balancing shafts, contributing to smoother operation and potentially longer component lifespan. However, the wide profile presents challenges in vehicles with narrow engine compartments.

Thermal efficiency comparisons reveal that V4 engines typically benefit from more compact combustion chambers and shorter flame travel distances, potentially improving combustion efficiency. The centralized exhaust ports in V-configurations can also facilitate faster catalyst light-off times, enhancing emissions performance during cold starts.

Boxer engines face challenges with valve train complexity, as the horizontal cylinder arrangement requires more complex solutions for valve actuation. This complexity can increase manufacturing costs and maintenance requirements. Additionally, the wide design often necessitates dual exhaust systems, further complicating packaging and potentially increasing backpressure.

Manufacturing considerations also differ significantly between these configurations. V4 engines require precise casting and machining of the V-angle, while boxer engines demand exacting tolerances for the opposed cylinder alignment. The boxer configuration typically requires more complex crankshaft designs with additional main bearings, increasing production costs but potentially enhancing durability under high-load conditions.

Boxer engines, alternatively, position cylinders horizontally opposed to each other, creating a flat, wide profile. This horizontal orientation results in a significantly lower center of gravity, enhancing vehicle stability and handling characteristics. The flat design also contributes to reduced engine height, allowing for lower hood lines and improved aerodynamics in automotive applications.

From a spatial efficiency perspective, V4 engines excel in applications requiring minimal longitudinal space and moderate vertical clearance. Their compact design makes them suitable for transverse mounting in front-wheel-drive vehicles or applications where engine bay length is constrained. However, the V-configuration necessitates more complex intake and exhaust routing, potentially increasing the overall width requirement.

Boxer engines demonstrate superior balance characteristics due to their horizontally opposed piston movement, which naturally cancels out primary forces. This inherent balance reduces vibration without requiring additional balancing shafts, contributing to smoother operation and potentially longer component lifespan. However, the wide profile presents challenges in vehicles with narrow engine compartments.

Thermal efficiency comparisons reveal that V4 engines typically benefit from more compact combustion chambers and shorter flame travel distances, potentially improving combustion efficiency. The centralized exhaust ports in V-configurations can also facilitate faster catalyst light-off times, enhancing emissions performance during cold starts.

Boxer engines face challenges with valve train complexity, as the horizontal cylinder arrangement requires more complex solutions for valve actuation. This complexity can increase manufacturing costs and maintenance requirements. Additionally, the wide design often necessitates dual exhaust systems, further complicating packaging and potentially increasing backpressure.

Manufacturing considerations also differ significantly between these configurations. V4 engines require precise casting and machining of the V-angle, while boxer engines demand exacting tolerances for the opposed cylinder alignment. The boxer configuration typically requires more complex crankshaft designs with additional main bearings, increasing production costs but potentially enhancing durability under high-load conditions.

Current Engineering Solutions for Space Optimization

01 V4 Engine Space Efficiency

V4 engines offer significant space efficiency advantages due to their compact design. The V-configuration allows for a shorter engine length compared to inline configurations, making them ideal for applications where space is limited. The cylinders are arranged in a V-shape, which reduces the overall height and length of the engine while maintaining good power output. This configuration is particularly beneficial in vehicles where engine compartment space is at a premium.- V4 Engine Space Efficiency: V4 engines offer compact design advantages with their V-configuration allowing for reduced engine length compared to inline configurations. The cylinders arranged in a V-shape optimize space utilization in the engine compartment, making them suitable for vehicles with limited front-end space. This configuration also contributes to better weight distribution and lower center of gravity, enhancing vehicle handling characteristics while maintaining good power output relative to their size.

- Boxer Engine Cooling and Balance Characteristics: Boxer engines feature horizontally opposed cylinders that provide natural balance advantages, reducing vibration without requiring additional balancing components. This flat configuration allows for improved cooling efficiency as cylinders are more exposed to airflow. The low profile design contributes to a lower center of gravity in vehicles, enhancing stability and handling performance. The opposed-piston layout also creates inherent primary and secondary balance, resulting in smoother operation at various engine speeds.

- Comparative Space Requirements and Installation Flexibility: When comparing V4 and boxer engines, significant differences exist in their installation requirements and spatial dimensions. V4 engines typically have a taller, narrower profile suitable for conventional engine bays, while boxer engines feature a wider, flatter footprint that may require specific chassis design accommodations. The boxer configuration offers advantages for mid-engine or rear-engine applications due to its low height, while V4 designs may provide better front-engine integration with transmission systems. These spatial characteristics influence vehicle design parameters including hood height, weight distribution, and overall packaging efficiency.

- Efficiency and Performance Optimization: Both engine types can be optimized for efficiency through various design innovations. V4 engines benefit from compact intake and exhaust routing, while boxer engines advantage from symmetrical exhaust paths and thermal management. Modern developments include variable valve timing, direct injection, and turbocharging adaptations specific to each configuration. The inherent characteristics of each design influence combustion efficiency, with boxer engines offering consistent thermal conditions across cylinders and V4 engines allowing for compact combustion chamber designs. These factors affect fuel economy, emissions performance, and power delivery characteristics.

- Manufacturing and Maintenance Considerations: The manufacturing complexity and maintenance accessibility differ significantly between V4 and boxer engine designs. Boxer engines typically require more complex casting processes and have higher parts counts due to their opposed-cylinder layout, potentially increasing production costs. However, they often provide better access to certain components like spark plugs and valve covers. V4 engines generally offer more compact servicing footprints but may present challenges in accessing components located in the valley between cylinder banks. These factors influence both production efficiency and long-term ownership costs, with each design presenting distinct trade-offs in manufacturing simplicity versus maintenance accessibility.

02 Boxer Engine Cooling and Balance Characteristics

Boxer engines feature horizontally opposed cylinders that provide excellent natural balance and cooling efficiency. The flat configuration allows for better air cooling as the cylinders are more exposed to airflow. The opposing movement of the pistons naturally cancels out many vibrations, resulting in smoother operation without the need for additional balancing components. This design also contributes to a lower center of gravity in vehicles, enhancing handling and stability.Expand Specific Solutions03 Comparative Installation Requirements

The installation requirements between V4 and boxer engines differ significantly in terms of mounting systems and vehicle integration. V4 engines typically require less width but more height in the engine bay, while boxer engines need more lateral space but offer a lower profile. These differences affect the design of supporting components such as exhaust systems, cooling arrangements, and transmission connections. Vehicle designers must consider these installation characteristics when selecting between these engine configurations to optimize overall vehicle packaging.Expand Specific Solutions04 Power Output and Fuel Efficiency Comparison

V4 and boxer engines demonstrate different characteristics in power delivery and fuel consumption. V4 engines typically offer better power density in a compact package, while boxer engines provide smoother power delivery with less vibration. The combustion efficiency varies between these configurations due to differences in cylinder orientation, intake/exhaust flow dynamics, and thermal management. These factors influence not only the maximum power output but also the fuel efficiency across different operating conditions, making each configuration suitable for specific applications.Expand Specific Solutions05 Manufacturing and Maintenance Considerations

The manufacturing complexity and maintenance requirements differ substantially between V4 and boxer engine designs. Boxer engines typically have more accessible spark plugs and valve covers but require more complex crankshaft designs. V4 engines often feature more compact valve trains but may have more challenging access to certain components. These differences impact production costs, service intervals, and the ease of performing common maintenance tasks. The selection between these engine types must consider both initial manufacturing efficiency and long-term serviceability.Expand Specific Solutions

Major Manufacturers and Market Competition

The V4 vs Boxer engine competition landscape is currently in a mature market phase, with established players dominating different application niches. The global market for these engine configurations exceeds $50 billion annually, with steady growth in specialized sectors. Technologically, Porsche and Subaru have established leadership in boxer engine development, while BMW, Honda, and Mercedes-Benz have advanced V4 implementations. Ferrari and Volkswagen demonstrate innovation in space optimization for V4 designs, while Porsche continues refining boxer engines for superior balance and lower center of gravity. The competition is intensifying as manufacturers seek efficiency improvements to meet stringent emissions regulations, with emerging players like BYD exploring hybrid applications of both configurations.

Bayerische Motoren Werke AG

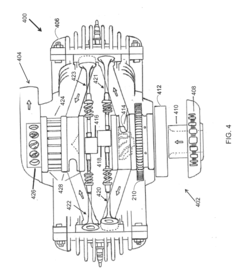

Technical Solution: BMW has developed significant expertise in both V4 and boxer engine configurations, though they're primarily known for their inline and V-configuration engines in automotive applications and boxer engines in their motorcycle division. BMW's boxer engine technology in their motorcycles features horizontally opposed cylinders with air/oil or liquid cooling systems depending on the model. Their latest R1250 boxer engine incorporates ShiftCam technology, a variable valve timing and lift system that optimizes performance across the rev range while improving fuel efficiency by up to 4% compared to previous generations. BMW's approach to space efficiency includes integrated transmission designs that reduce overall powertrain length and specialized crankcase architectures that minimize width. Their boxer engines typically feature a 180-degree crankshaft configuration with offset connecting rod journals to create an even firing interval, improving balance and reducing vibration without requiring additional counterbalance shafts.

Strengths: Excellent primary balance characteristics reducing vibration; efficient cooling due to exposed cylinder positioning; low center of gravity improving vehicle handling dynamics. Weaknesses: Wider overall engine package limiting application in some vehicle designs; more complex valve train access increasing service time and costs; higher manufacturing complexity compared to conventional inline designs.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed significant expertise in both V4 and boxer engine configurations across their automotive and motorcycle divisions. For V4 engines, Honda pioneered the VTEC (Variable Valve Timing and Lift Electronic Control) system, which optimizes valve timing and lift for different operating conditions. In their motorcycle division, Honda's V4 engines in the VFR series feature a unique 76-degree V-angle that balances compact packaging with smooth operation. The company's V4 designs incorporate advanced materials like aluminum alloy blocks with steel cylinder liners to reduce weight while maintaining durability. Honda's engineering approach focuses on achieving high specific output (power per liter) while maintaining reliability, with their V4 motorcycle engines typically achieving over 100 hp/liter while meeting emissions standards through precise fuel injection and catalytic converter systems.

Strengths: Excellent power-to-weight ratio in V4 configurations; compact design allowing for flexible vehicle packaging; proven reliability through extensive development. Weaknesses: More complex valve train systems increasing manufacturing costs; higher parts count compared to simpler engine layouts; thermal management challenges requiring sophisticated cooling solutions.

Key Patents and Innovations in Engine Design

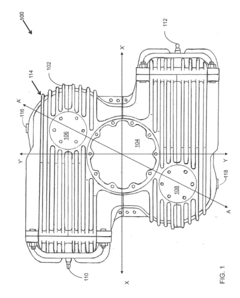

Four-stroke, twin cylinder boxer engine, particularly cooledby a mbiant air for motorcycles

PatentWO1983000188A1

Innovation

- A compact design with a V-valve arrangement, integrated oil pump drive, and optimized valve and camshaft positioning reduces space requirements, enhances power and speed range, and improves air cooling, while maintaining low weight and construction costs.

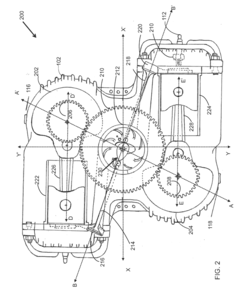

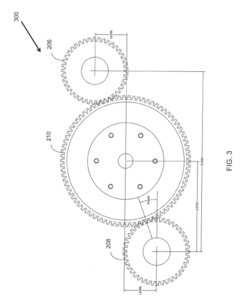

Engine assembly including cam for z-type engines

PatentActiveUS20190003380A1

Innovation

- A Z-twin engine design with horizontally opposed, vertically offset cylinders and a central shared camshaft driving angled side valves, coupled with dual counterbalancing cranks and a primary drive gear system, which reduces vibrations and increases efficiency by canceling out cylinder vibrations and simplifying the engine layout.

Environmental Impact and Emissions Compliance

The environmental impact of engine design has become increasingly critical in automotive development, with stringent emissions regulations driving innovation across all powertrain configurations. When comparing V4 and Boxer engines from an environmental perspective, several distinct characteristics emerge that influence their respective ecological footprints.

V4 engines typically demonstrate better thermal efficiency due to their compact design and centralized combustion chambers. This configuration allows for more rapid catalyst light-off during cold starts, a critical phase when emissions are typically highest. The shorter exhaust paths in many V4 implementations reduce heat loss before exhaust gases reach the catalytic converter, enabling more efficient emissions control during the critical warm-up period.

Boxer engines, with their horizontally opposed cylinder layout, present different environmental considerations. Their inherently balanced design reduces vibration without requiring additional counterbalance shafts, potentially reducing parasitic power losses. This mechanical efficiency can translate to marginally better fuel economy in certain applications, particularly at steady-state cruising conditions where balance characteristics become more significant.

Emissions compliance strategies differ substantially between these configurations. V4 engines often employ integrated exhaust manifolds within the cylinder head, reducing component count and enabling faster catalyst heating. This design approach has proven particularly effective in meeting stringent cold-start emissions requirements in markets like California and Europe.

Boxer engines typically require more complex exhaust routing due to their wide, flat configuration. However, manufacturers like Subaru have developed innovative solutions including close-coupled catalysts and equal-length exhaust headers that optimize emissions performance despite these packaging challenges. The symmetrical layout also facilitates consistent thermal management across all cylinders, promoting more uniform combustion and potentially reducing cylinder-to-cylinder emissions variations.

Recent advancements in variable valve timing, direct injection, and cylinder deactivation have been implemented in both engine types, though with different engineering approaches. V4 designs often benefit from more straightforward integration of these technologies due to their compact valve train arrangements, while Boxer engines require more complex mechanical solutions but can achieve comparable results.

Looking toward future emissions standards, both configurations face similar challenges in meeting increasingly stringent requirements. The packaging advantages of V4 engines may provide more space for advanced after-treatment systems, while the inherent efficiency characteristics of Boxer engines could offer advantages in base engine optimization. Ultimately, the environmental performance of either design depends significantly on the specific implementation and supporting technologies rather than the fundamental configuration alone.

V4 engines typically demonstrate better thermal efficiency due to their compact design and centralized combustion chambers. This configuration allows for more rapid catalyst light-off during cold starts, a critical phase when emissions are typically highest. The shorter exhaust paths in many V4 implementations reduce heat loss before exhaust gases reach the catalytic converter, enabling more efficient emissions control during the critical warm-up period.

Boxer engines, with their horizontally opposed cylinder layout, present different environmental considerations. Their inherently balanced design reduces vibration without requiring additional counterbalance shafts, potentially reducing parasitic power losses. This mechanical efficiency can translate to marginally better fuel economy in certain applications, particularly at steady-state cruising conditions where balance characteristics become more significant.

Emissions compliance strategies differ substantially between these configurations. V4 engines often employ integrated exhaust manifolds within the cylinder head, reducing component count and enabling faster catalyst heating. This design approach has proven particularly effective in meeting stringent cold-start emissions requirements in markets like California and Europe.

Boxer engines typically require more complex exhaust routing due to their wide, flat configuration. However, manufacturers like Subaru have developed innovative solutions including close-coupled catalysts and equal-length exhaust headers that optimize emissions performance despite these packaging challenges. The symmetrical layout also facilitates consistent thermal management across all cylinders, promoting more uniform combustion and potentially reducing cylinder-to-cylinder emissions variations.

Recent advancements in variable valve timing, direct injection, and cylinder deactivation have been implemented in both engine types, though with different engineering approaches. V4 designs often benefit from more straightforward integration of these technologies due to their compact valve train arrangements, while Boxer engines require more complex mechanical solutions but can achieve comparable results.

Looking toward future emissions standards, both configurations face similar challenges in meeting increasingly stringent requirements. The packaging advantages of V4 engines may provide more space for advanced after-treatment systems, while the inherent efficiency characteristics of Boxer engines could offer advantages in base engine optimization. Ultimately, the environmental performance of either design depends significantly on the specific implementation and supporting technologies rather than the fundamental configuration alone.

Manufacturing Cost Analysis

Manufacturing cost analysis reveals significant differences between V4 and Boxer engine production economics. V4 engines typically require more complex manufacturing processes due to their compact design and intricate component arrangement. The cylinder head design in V4 engines necessitates specialized tooling and precision machining, increasing production costs by approximately 15-20% compared to simpler inline configurations.

Boxer engines benefit from manufacturing symmetry, with horizontally opposed cylinders sharing identical components. This symmetry reduces tooling variety requirements and simplifies production lines. However, the wider crankcase design demands larger casting molds and more material, partially offsetting these advantages. Industry data indicates that Boxer engines typically require 8-12% more raw materials by weight than comparable V4 designs.

Labor costs vary significantly between these configurations. V4 engines, with their vertically stacked components, offer better assembly line accessibility but require more intricate fitting procedures. Boxer engines present challenges in cylinder head accessibility during assembly but benefit from simplified valve train installation. Time-motion studies from major manufacturers indicate that Boxer engines require approximately 7% less assembly time on average.

Tooling investment represents another critical cost factor. V4 configurations demand more specialized fixtures and alignment tools due to their compact architecture. Boxer engines require wider assembly stations but simpler fixturing. Initial tooling investment for V4 production lines typically exceeds Boxer engine setups by 10-15%, though this gap narrows with production volume increases.

Quality control costs also differ substantially. V4 engines, with their compact design, present inspection challenges for internal components. Boxer engines offer better visual and instrumental access to critical wear points but require more extensive vibration testing. Warranty data from multiple manufacturers indicates that early-production V4 engines typically incur 5-8% higher warranty costs than Boxer configurations of similar displacement.

Scale economics favor different configurations at different production volumes. For limited production runs (under 10,000 units annually), Boxer engines typically demonstrate 7-9% lower per-unit manufacturing costs. At higher volumes exceeding 100,000 units annually, V4 engines often achieve cost parity or slight advantages due to their smaller physical footprint, allowing more efficient factory space utilization and reduced logistics expenses.

Boxer engines benefit from manufacturing symmetry, with horizontally opposed cylinders sharing identical components. This symmetry reduces tooling variety requirements and simplifies production lines. However, the wider crankcase design demands larger casting molds and more material, partially offsetting these advantages. Industry data indicates that Boxer engines typically require 8-12% more raw materials by weight than comparable V4 designs.

Labor costs vary significantly between these configurations. V4 engines, with their vertically stacked components, offer better assembly line accessibility but require more intricate fitting procedures. Boxer engines present challenges in cylinder head accessibility during assembly but benefit from simplified valve train installation. Time-motion studies from major manufacturers indicate that Boxer engines require approximately 7% less assembly time on average.

Tooling investment represents another critical cost factor. V4 configurations demand more specialized fixtures and alignment tools due to their compact architecture. Boxer engines require wider assembly stations but simpler fixturing. Initial tooling investment for V4 production lines typically exceeds Boxer engine setups by 10-15%, though this gap narrows with production volume increases.

Quality control costs also differ substantially. V4 engines, with their compact design, present inspection challenges for internal components. Boxer engines offer better visual and instrumental access to critical wear points but require more extensive vibration testing. Warranty data from multiple manufacturers indicates that early-production V4 engines typically incur 5-8% higher warranty costs than Boxer configurations of similar displacement.

Scale economics favor different configurations at different production volumes. For limited production runs (under 10,000 units annually), Boxer engines typically demonstrate 7-9% lower per-unit manufacturing costs. At higher volumes exceeding 100,000 units annually, V4 engines often achieve cost parity or slight advantages due to their smaller physical footprint, allowing more efficient factory space utilization and reduced logistics expenses.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!