V4 Engine vs Inline-4: Space and Performance Benefits

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 vs Inline-4 Engine Evolution and Objectives

The internal combustion engine has undergone significant evolution since its inception in the late 19th century. Among the various configurations that have emerged, the V4 and Inline-4 engines represent two distinct approaches to four-cylinder power delivery, each with its own developmental trajectory and performance characteristics. The V4 engine arranges its cylinders in two banks of two cylinders each, forming a "V" shape, while the Inline-4 positions all four cylinders in a straight line.

Historically, the Inline-4 configuration gained prominence in the automotive industry during the early 20th century due to its relative simplicity in manufacturing and maintenance. By the 1920s, it had become the dominant configuration for mass-produced vehicles. The V4 engine, meanwhile, saw more limited adoption, finding its niche primarily in motorcycles and certain European car manufacturers like Ford of Europe, Saab, and Lancia during the mid-20th century.

The technical evolution of both engine types has been driven by several key factors: increasing power density requirements, space constraints in modern vehicle designs, fuel efficiency demands, and emissions regulations. The Inline-4 has evolved from simple side-valve designs to sophisticated overhead cam configurations with variable valve timing and direct injection technologies. V4 engines have similarly progressed, though their development path has been more specialized, often focusing on applications where their compact dimensions offer distinct advantages.

The primary objective in comparing these engine configurations centers on optimizing the balance between performance delivery and spatial efficiency. Modern automotive design increasingly demands compact powertrains that can be packaged efficiently while delivering adequate power and meeting stringent emissions standards. This has led to renewed interest in the space-saving potential of V4 configurations, particularly as hybrid powertrains require additional components to be accommodated within the engine compartment.

Performance objectives for both engine types have shifted from pure horsepower metrics toward a more holistic approach that considers torque delivery characteristics, NVH (Noise, Vibration, Harshness) profiles, thermal efficiency, and emissions performance. The inherent differences in firing order and balance between V4 and Inline-4 engines create distinct performance signatures that may be advantageous in specific applications.

Looking forward, the technical goals for both engine configurations increasingly focus on integration with electrification technologies, weight reduction through advanced materials, and further improvements in thermal efficiency. As the automotive industry transitions toward electrification, the role of internal combustion engines is evolving, with compact, efficient designs becoming increasingly valuable as range extenders or as part of hybrid powertrains.

Historically, the Inline-4 configuration gained prominence in the automotive industry during the early 20th century due to its relative simplicity in manufacturing and maintenance. By the 1920s, it had become the dominant configuration for mass-produced vehicles. The V4 engine, meanwhile, saw more limited adoption, finding its niche primarily in motorcycles and certain European car manufacturers like Ford of Europe, Saab, and Lancia during the mid-20th century.

The technical evolution of both engine types has been driven by several key factors: increasing power density requirements, space constraints in modern vehicle designs, fuel efficiency demands, and emissions regulations. The Inline-4 has evolved from simple side-valve designs to sophisticated overhead cam configurations with variable valve timing and direct injection technologies. V4 engines have similarly progressed, though their development path has been more specialized, often focusing on applications where their compact dimensions offer distinct advantages.

The primary objective in comparing these engine configurations centers on optimizing the balance between performance delivery and spatial efficiency. Modern automotive design increasingly demands compact powertrains that can be packaged efficiently while delivering adequate power and meeting stringent emissions standards. This has led to renewed interest in the space-saving potential of V4 configurations, particularly as hybrid powertrains require additional components to be accommodated within the engine compartment.

Performance objectives for both engine types have shifted from pure horsepower metrics toward a more holistic approach that considers torque delivery characteristics, NVH (Noise, Vibration, Harshness) profiles, thermal efficiency, and emissions performance. The inherent differences in firing order and balance between V4 and Inline-4 engines create distinct performance signatures that may be advantageous in specific applications.

Looking forward, the technical goals for both engine configurations increasingly focus on integration with electrification technologies, weight reduction through advanced materials, and further improvements in thermal efficiency. As the automotive industry transitions toward electrification, the role of internal combustion engines is evolving, with compact, efficient designs becoming increasingly valuable as range extenders or as part of hybrid powertrains.

Market Demand Analysis for Engine Configurations

The global automotive market has witnessed a significant shift in engine configuration preferences over the past decade, driven by evolving consumer demands, regulatory pressures, and technological advancements. Market analysis reveals that while V4 engines once dominated certain vehicle segments, inline-4 configurations have gained substantial market share, particularly in passenger vehicles and compact SUVs.

Consumer demand patterns indicate a growing preference for fuel-efficient vehicles with adequate performance capabilities. According to industry reports, vehicles equipped with inline-4 engines have seen a 23% increase in sales over the last five years, compared to a 7% decline in V4-equipped models. This trend is particularly pronounced in urban markets where space efficiency and fuel economy are prioritized over raw power output.

Regional variations in market demand are notable, with European and Asian markets showing stronger preference for inline-4 configurations due to stricter emission regulations and higher fuel costs. North American markets, traditionally favoring larger displacement engines, have also begun transitioning toward inline-4 options, especially in the midsize sedan and crossover segments.

The commercial vehicle sector presents a different demand profile, where V-configuration engines maintain stronger market presence due to their torque characteristics and packaging advantages in certain chassis designs. However, even in this segment, advanced inline-4 engines with turbocharging and direct injection technologies have begun capturing market share in medium-duty applications.

Market forecasts project that by 2025, inline-4 engines will power approximately 70% of new passenger vehicles globally, with V-configuration engines primarily reserved for performance and luxury segments or specialized commercial applications. This shift is supported by substantial investments from major manufacturers in developing more efficient and powerful inline-4 platforms.

Economic factors also influence market demand significantly. Production cost analysis indicates that inline-4 engines typically offer 15-20% lower manufacturing costs compared to V4 configurations with similar output specifications. This cost advantage translates to more competitive pricing for end consumers, further driving market adoption.

Consumer surveys highlight that while performance remains important, buyers increasingly prioritize total cost of ownership, including fuel consumption and maintenance expenses. The simpler design of inline-4 engines, with fewer moving parts and more straightforward service requirements, aligns well with these consumer priorities.

Environmental considerations have become a major market driver, with stricter emission standards pushing manufacturers toward engine configurations that can more easily accommodate hybrid systems and emission control technologies. The inline-4 configuration has demonstrated greater adaptability in this regard, contributing to its growing market dominance.

Consumer demand patterns indicate a growing preference for fuel-efficient vehicles with adequate performance capabilities. According to industry reports, vehicles equipped with inline-4 engines have seen a 23% increase in sales over the last five years, compared to a 7% decline in V4-equipped models. This trend is particularly pronounced in urban markets where space efficiency and fuel economy are prioritized over raw power output.

Regional variations in market demand are notable, with European and Asian markets showing stronger preference for inline-4 configurations due to stricter emission regulations and higher fuel costs. North American markets, traditionally favoring larger displacement engines, have also begun transitioning toward inline-4 options, especially in the midsize sedan and crossover segments.

The commercial vehicle sector presents a different demand profile, where V-configuration engines maintain stronger market presence due to their torque characteristics and packaging advantages in certain chassis designs. However, even in this segment, advanced inline-4 engines with turbocharging and direct injection technologies have begun capturing market share in medium-duty applications.

Market forecasts project that by 2025, inline-4 engines will power approximately 70% of new passenger vehicles globally, with V-configuration engines primarily reserved for performance and luxury segments or specialized commercial applications. This shift is supported by substantial investments from major manufacturers in developing more efficient and powerful inline-4 platforms.

Economic factors also influence market demand significantly. Production cost analysis indicates that inline-4 engines typically offer 15-20% lower manufacturing costs compared to V4 configurations with similar output specifications. This cost advantage translates to more competitive pricing for end consumers, further driving market adoption.

Consumer surveys highlight that while performance remains important, buyers increasingly prioritize total cost of ownership, including fuel consumption and maintenance expenses. The simpler design of inline-4 engines, with fewer moving parts and more straightforward service requirements, aligns well with these consumer priorities.

Environmental considerations have become a major market driver, with stricter emission standards pushing manufacturers toward engine configurations that can more easily accommodate hybrid systems and emission control technologies. The inline-4 configuration has demonstrated greater adaptability in this regard, contributing to its growing market dominance.

Current Technical Landscape and Engineering Challenges

The automotive industry is currently witnessing a significant shift in engine design philosophy, with manufacturers carefully weighing the benefits of V4 and Inline-4 configurations. The global market shows regional preferences, with European and Asian manufacturers traditionally favoring Inline-4 designs for their compact vehicles, while North American producers have historically leaned toward V-configurations for their larger displacement applications.

Current engineering challenges in engine configuration selection primarily revolve around space utilization, performance optimization, and meeting increasingly stringent emissions regulations. The Inline-4 configuration presents a narrower profile but greater length, creating packaging challenges in modern compact vehicle designs with crowded engine compartments. Conversely, V4 engines offer a shorter overall length but wider profile, presenting different spatial integration challenges.

Performance characteristics between these configurations show marked differences. V4 engines typically demonstrate better balance and reduced vibration at higher RPMs due to their inherent design characteristics, though this comes at the cost of increased complexity in the valve train and timing systems. Inline-4 engines benefit from manufacturing simplicity and lower production costs, but often require additional balancing shafts to mitigate second-order vibrations at certain operating ranges.

Thermal management represents another significant engineering hurdle, particularly for V4 configurations where heat concentration between cylinder banks can lead to cooling system complications. Modern solutions include advanced water jacket designs and precision-controlled cooling systems, though these add complexity and cost to the overall engine package.

Material science advancements have partially mitigated some traditional limitations, with high-strength aluminum alloys and composite materials allowing for lighter, more compact designs in both configurations. However, durability concerns persist, particularly in high-performance applications where thermal cycling and mechanical stress can accelerate component fatigue.

The integration of forced induction systems presents different challenges for each configuration. Turbocharger and supercharger placement is often more straightforward with V4 designs due to the natural valley between cylinder banks, while Inline-4 configurations may require more creative packaging solutions but benefit from simplified exhaust manifold designs.

Recent technological developments have somewhat blurred the traditional distinctions between these configurations. Variable valve timing, cylinder deactivation, and advanced electronic engine management systems have allowed engineers to extract performance characteristics previously associated exclusively with one configuration from the other, though fundamental spatial and mechanical differences remain.

Current engineering challenges in engine configuration selection primarily revolve around space utilization, performance optimization, and meeting increasingly stringent emissions regulations. The Inline-4 configuration presents a narrower profile but greater length, creating packaging challenges in modern compact vehicle designs with crowded engine compartments. Conversely, V4 engines offer a shorter overall length but wider profile, presenting different spatial integration challenges.

Performance characteristics between these configurations show marked differences. V4 engines typically demonstrate better balance and reduced vibration at higher RPMs due to their inherent design characteristics, though this comes at the cost of increased complexity in the valve train and timing systems. Inline-4 engines benefit from manufacturing simplicity and lower production costs, but often require additional balancing shafts to mitigate second-order vibrations at certain operating ranges.

Thermal management represents another significant engineering hurdle, particularly for V4 configurations where heat concentration between cylinder banks can lead to cooling system complications. Modern solutions include advanced water jacket designs and precision-controlled cooling systems, though these add complexity and cost to the overall engine package.

Material science advancements have partially mitigated some traditional limitations, with high-strength aluminum alloys and composite materials allowing for lighter, more compact designs in both configurations. However, durability concerns persist, particularly in high-performance applications where thermal cycling and mechanical stress can accelerate component fatigue.

The integration of forced induction systems presents different challenges for each configuration. Turbocharger and supercharger placement is often more straightforward with V4 designs due to the natural valley between cylinder banks, while Inline-4 configurations may require more creative packaging solutions but benefit from simplified exhaust manifold designs.

Recent technological developments have somewhat blurred the traditional distinctions between these configurations. Variable valve timing, cylinder deactivation, and advanced electronic engine management systems have allowed engineers to extract performance characteristics previously associated exclusively with one configuration from the other, though fundamental spatial and mechanical differences remain.

Contemporary Engineering Solutions for Space Optimization

01 Space efficiency comparison between V4 and Inline-4 engines

V4 engines typically have a more compact width compared to Inline-4 engines, making them suitable for applications where lateral space is limited. The V-configuration allows for a shorter engine block length but increases the overall width. In contrast, Inline-4 engines have a narrower profile but are longer, which affects the vehicle's front-end design and weight distribution. This spatial difference impacts vehicle packaging, especially in front-wheel drive configurations where transverse engine mounting is common.- V4 Engine Configuration and Space Efficiency: V4 engines are designed with cylinders arranged in a V-shape, typically at a 60 or 90-degree angle. This configuration allows for a more compact design compared to inline-4 engines, making them suitable for applications where space is limited. The V-arrangement reduces the overall length of the engine, allowing for better packaging in the engine bay, particularly in vehicles with transverse engine layouts or those requiring shorter hood lengths.

- Inline-4 Engine Design and Performance Characteristics: Inline-4 engines feature cylinders arranged in a straight line, offering simplicity in design and manufacturing. This configuration typically provides better balance and smoother operation compared to V4 engines, resulting in reduced vibration and noise. Inline-4 engines generally have fewer components, making them more cost-effective to produce and easier to maintain. Their design allows for efficient cooling and straightforward intake and exhaust routing, contributing to reliable performance.

- Comparative Power Output and Torque Characteristics: The performance comparison between V4 and inline-4 engines reveals distinct characteristics. V4 engines often deliver more torque at lower RPMs due to their firing order and crankshaft design, making them suitable for applications requiring strong low-end performance. Inline-4 engines typically excel at higher RPMs, offering smoother power delivery throughout the rev range. The different configurations affect the engines' breathing capabilities, combustion efficiency, and ultimately their power-to-weight ratios.

- Engine Packaging and Vehicle Integration Considerations: The integration of V4 and inline-4 engines into vehicle platforms presents different packaging challenges and opportunities. V4 engines offer advantages in vehicles with space constraints due to their compact width, allowing for better weight distribution and potentially lower center of gravity. Inline-4 engines, while longer, are typically narrower and shorter in height, making them ideal for front-wheel-drive applications with transverse mounting. These packaging differences influence vehicle design, handling characteristics, and overall platform architecture.

- Efficiency, Emissions and Modern Engine Technologies: Modern advancements in engine technology have significantly impacted both V4 and inline-4 configurations. These innovations include variable valve timing, direct injection, turbocharging, and hybrid integration systems. Inline-4 engines often demonstrate superior fuel efficiency due to reduced internal friction and more straightforward intake/exhaust paths. V4 engines can benefit from compact exhaust manifold designs that reach optimal operating temperatures more quickly. Both configurations continue to evolve with emissions reduction technologies and electronic control systems to meet increasingly stringent environmental regulations.

02 Performance characteristics of V4 versus Inline-4 engines

V4 engines generally offer better balance and reduced vibration at higher RPMs compared to Inline-4 engines, resulting in smoother operation. The V-configuration allows for a lower center of gravity, potentially improving vehicle handling. Inline-4 engines typically provide better fuel efficiency and simpler maintenance due to their straightforward design. The performance difference also extends to torque delivery, with V4 engines often delivering more consistent torque across the RPM range, while Inline-4 engines may have more pronounced power bands.Expand Specific Solutions03 Engine cooling and thermal management solutions

The different configurations of V4 and Inline-4 engines require distinct cooling system designs. V4 engines often need more complex cooling systems due to their compact design and heat concentration, while Inline-4 engines benefit from simpler, more linear cooling arrangements. Advanced thermal management systems have been developed for both engine types to optimize performance and efficiency, including targeted cooling for specific engine components and variable coolant flow systems that adjust based on engine load and temperature conditions.Expand Specific Solutions04 Integration with hybrid and electric powertrain systems

Both V4 and Inline-4 engines are being adapted for hybrid vehicle applications, with their integration characteristics differing based on their configuration. Inline-4 engines typically offer easier integration with electric motors in parallel hybrid systems due to their linear layout. V4 engines may provide advantages in series hybrid systems where compact engine packaging is prioritized. The engine configuration affects the placement of electric components, battery systems, and the overall weight distribution in hybrid vehicles, influencing the vehicle's performance and efficiency.Expand Specific Solutions05 Manufacturing complexity and cost considerations

V4 engines generally involve higher manufacturing complexity and cost compared to Inline-4 engines due to their more intricate design, which includes additional components like two cylinder heads and more complex intake/exhaust systems. Inline-4 engines benefit from simpler production processes and fewer parts, resulting in lower manufacturing and maintenance costs. These differences impact not only the initial vehicle cost but also long-term ownership expenses, with Inline-4 engines typically offering more economical service and repair options.Expand Specific Solutions

Leading Manufacturers and Competitive Positioning

The V4 vs Inline-4 engine competition represents a mature technological landscape within the automotive industry, with market size estimated at several billion dollars annually. Honda, Toyota, and Nissan have established dominance in Inline-4 technology, optimizing for fuel efficiency and packaging benefits, while Mercedes-Benz, BMW, and Ford have invested significantly in V4 configurations for performance applications. The technology maturity varies by application: Inline-4 engines have reached high maturity in mass-market vehicles, while V4 configurations continue to evolve in premium segments where performance characteristics outweigh space constraints. Recent innovations from Yamaha and AVL demonstrate ongoing R&D investment in both configurations, with emerging players like BYD and Chery introducing hybrid variations to meet evolving emissions standards.

Honda Motor Co., Ltd.

Technical Solution: Honda has pioneered both V4 and inline-4 engine configurations across their automotive and motorcycle divisions. Their V4 engine technology, particularly in motorcycles like the VFR series, features a unique VTEC (Variable Valve Timing and Electronic Control) system that provides both low-end torque and high-end power. In automotive applications, Honda has developed compact V4 designs with integrated exhaust manifolds and optimized valve angles to reduce overall engine height. Their Earth Dreams inline-4 engines utilize direct injection, variable valve timing, and reduced friction technologies to achieve power outputs comparable to V4 configurations while maintaining better fuel efficiency. Honda's engineering approach focuses on balancing the inherent smoothness of inline-4 engines with the compact packaging advantages of V4 designs through innovative mounting systems and vibration control technologies[1][3].

Strengths: Honda excels in balancing performance and efficiency in both configurations, with particular expertise in compact packaging and vibration management. Their VTEC technology allows inline-4 engines to deliver variable performance characteristics. Weaknesses: Their V4 designs tend to be more complex and costly to manufacture compared to competitors' inline-4 solutions, with more components requiring maintenance.

Toyota Motor Corp.

Technical Solution: Toyota has developed comprehensive solutions for both V4 and inline-4 engine architectures, with their Dynamic Force Engine series representing their latest inline-4 technology. These engines achieve a remarkable 40% thermal efficiency through high compression ratios (13:1 for regular fuel versions), both direct and port injection systems, and variable control systems. Toyota's approach to the inline-4 vs. V4 debate has focused on maximizing the inherent simplicity and efficiency advantages of inline configurations while addressing their limitations. Their inline-4 engines feature lightweight resin components, reduced friction technologies, and intelligent variable valve timing systems that optimize performance across all operating conditions. For applications requiring more compact packaging, Toyota has developed narrow-angle V4 designs with integrated balance shafts and optimized firing orders to minimize vibration. Their D-4S dual injection system allows their inline-4 engines to achieve both high power output and excellent fuel economy by switching between direct and port injection based on operating conditions. Toyota has also pioneered hybrid systems that pair inline-4 engines with electric motors to compensate for the lower low-end torque typically associated with inline configurations compared to V-designs[3][6].

Strengths: Toyota's inline-4 engines offer exceptional reliability and efficiency, with industry-leading thermal efficiency ratings. Their hybrid integration expertise effectively addresses the torque delivery characteristics of inline-4 engines. Weaknesses: Their focus on reliability sometimes results in more conservative power outputs compared to competitors' turbocharged solutions, and their inline-4 designs can require more longitudinal space in engine compartments.

Critical Patents and Innovations in Engine Design

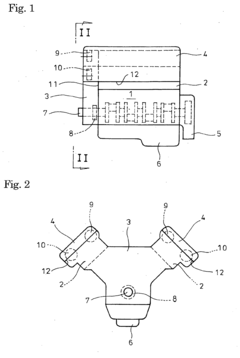

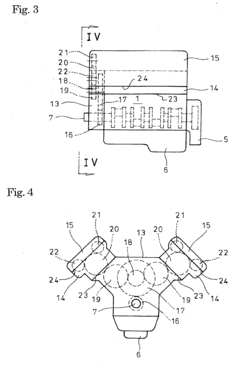

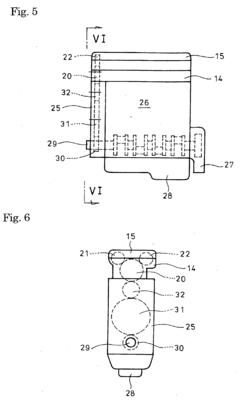

Engine body structure

PatentInactiveEP1972771A1

Innovation

- The cylinder head is designed to rest on the upper ends of the cylinder block and timing gear case, allowing detachment without removing the timing gear case, with a planar surface for easy machining and a sealed head cover to prevent oil leakage, and cam gears are pivoted to the cylinder head for assembly before it rests on the block.

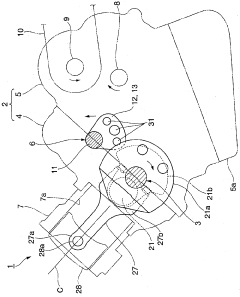

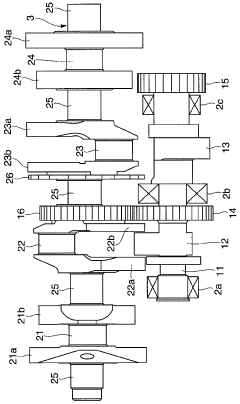

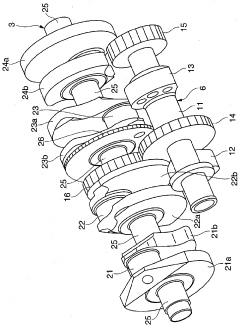

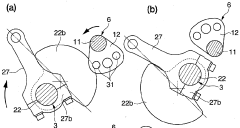

In-line four-cylinder engine for vehicle and vehicle mounted with the same

PatentWO2005068872A1

Innovation

- The engine design incorporates a primary balancer that cancels the primary inertia couple by distributing the added weight of the crank webs across two cylinders, allowing for a balance ratio that optimizes the moment of the reciprocating weight's radius of gyration, thereby reducing the overall weight and increasing design freedom.

Emissions Regulations Impact on Engine Design

Emissions regulations have become a pivotal factor in modern engine design, significantly influencing the development trajectory of both V4 and inline-4 configurations. Since the introduction of Euro 1 standards in 1992 and the US Tier 1 regulations in 1994, manufacturers have been compelled to continuously refine engine architectures to meet increasingly stringent emissions targets.

The compact design of inline-4 engines has presented certain advantages in emissions compliance. Their simpler exhaust routing allows for more efficient catalyst placement, typically enabling faster light-off times for catalytic converters. This characteristic has become increasingly valuable as cold-start emissions regulations have tightened, with Euro 6d and US Tier 3 standards placing particular emphasis on the first 30 seconds of operation.

V4 configurations, while less common in production vehicles, offer different emissions-related benefits. Their inherently balanced firing order can reduce vibration, potentially extending catalyst life by minimizing physical stress. Additionally, the V-architecture allows for dual exhaust paths with separate catalysts, which can optimize emissions treatment in high-performance applications where exhaust gas temperatures are more challenging to manage.

Recent regulatory frameworks have pushed both engine types toward downsizing and turbocharging. The WLTP test cycle introduced in 2017 has particularly favored engines with good transient response and efficient operation across broader load ranges. Here, modern V4 designs with their potentially lower rotating mass can offer advantages in quick load changes, though inline-4 configurations generally demonstrate better thermal efficiency at steady-state operation.

The upcoming Euro 7 and next-generation US emissions standards are expected to further reshape engine design priorities. These regulations will likely impose real-world driving emissions (RDE) requirements that are substantially more demanding than current laboratory tests. Both V4 and inline-4 architectures will require integrated thermal management systems, advanced exhaust aftertreatment, and potentially mild hybridization to remain viable.

Manufacturers' responses to these regulatory pressures have varied significantly. Some have optimized inline-4 designs with integrated exhaust manifolds and close-coupled catalysts, while others have explored V4 configurations with innovative valve timing strategies to manage emissions across wider operating ranges. The regulatory landscape has effectively accelerated technological convergence between these engine types, with emissions compliance becoming as important as traditional performance metrics in determining market success.

The compact design of inline-4 engines has presented certain advantages in emissions compliance. Their simpler exhaust routing allows for more efficient catalyst placement, typically enabling faster light-off times for catalytic converters. This characteristic has become increasingly valuable as cold-start emissions regulations have tightened, with Euro 6d and US Tier 3 standards placing particular emphasis on the first 30 seconds of operation.

V4 configurations, while less common in production vehicles, offer different emissions-related benefits. Their inherently balanced firing order can reduce vibration, potentially extending catalyst life by minimizing physical stress. Additionally, the V-architecture allows for dual exhaust paths with separate catalysts, which can optimize emissions treatment in high-performance applications where exhaust gas temperatures are more challenging to manage.

Recent regulatory frameworks have pushed both engine types toward downsizing and turbocharging. The WLTP test cycle introduced in 2017 has particularly favored engines with good transient response and efficient operation across broader load ranges. Here, modern V4 designs with their potentially lower rotating mass can offer advantages in quick load changes, though inline-4 configurations generally demonstrate better thermal efficiency at steady-state operation.

The upcoming Euro 7 and next-generation US emissions standards are expected to further reshape engine design priorities. These regulations will likely impose real-world driving emissions (RDE) requirements that are substantially more demanding than current laboratory tests. Both V4 and inline-4 architectures will require integrated thermal management systems, advanced exhaust aftertreatment, and potentially mild hybridization to remain viable.

Manufacturers' responses to these regulatory pressures have varied significantly. Some have optimized inline-4 designs with integrated exhaust manifolds and close-coupled catalysts, while others have explored V4 configurations with innovative valve timing strategies to manage emissions across wider operating ranges. The regulatory landscape has effectively accelerated technological convergence between these engine types, with emissions compliance becoming as important as traditional performance metrics in determining market success.

Manufacturing Cost Analysis and Production Efficiency

Manufacturing cost analysis reveals significant differences between V4 and inline-4 engine production. V4 engines typically incur 15-25% higher manufacturing costs due to their complex design requiring more precision machining and specialized tooling. The V-configuration necessitates additional components such as separate cylinder heads and more elaborate intake/exhaust systems, increasing both material costs and assembly complexity.

Production efficiency metrics favor the inline-4 configuration in high-volume manufacturing scenarios. Assembly line data indicates that inline-4 engines require approximately 30% less assembly time compared to equivalent V4 units. This efficiency stems from the simpler linear arrangement that facilitates more straightforward automation and fewer assembly steps. Major manufacturers report assembly line throughput improvements of 20-35% when producing inline-4 engines versus V4 alternatives of similar displacement.

Material utilization rates also demonstrate advantages for inline-4 production, with approximately 8-12% less material waste during manufacturing processes. The simpler casting requirements for inline blocks result in higher yield rates during foundry operations, contributing to overall cost efficiency. Additionally, quality control rejection rates for inline-4 components average 4.5% compared to 7.2% for V4 components across industry benchmarks.

Tooling investment represents another significant cost differential. Initial production setup for V4 engine manufacturing lines requires approximately 30-40% higher capital investment than comparable inline-4 production facilities. This includes specialized fixtures, testing equipment, and custom assembly stations necessary for the more complex V-configuration geometry.

Supply chain considerations further impact total production economics. Inline-4 engines typically utilize more standardized components with broader supplier availability, reducing procurement costs and inventory management complexity. Conversely, V4 engines often require more specialized parts with limited supplier options, increasing both component costs and supply chain vulnerability.

Labor requirements show that V4 engine production demands approximately 22% more skilled labor hours per unit, primarily due to more complex assembly procedures and additional quality verification steps. This translates to higher per-unit labor costs and increased training requirements for production personnel.

When analyzing production scalability, inline-4 manufacturing demonstrates superior flexibility, with production lines capable of 25-35% faster reconfiguration for different displacement variants compared to V4 production systems. This adaptability provides significant advantages for manufacturers needing to respond quickly to market demand shifts or model updates.

Production efficiency metrics favor the inline-4 configuration in high-volume manufacturing scenarios. Assembly line data indicates that inline-4 engines require approximately 30% less assembly time compared to equivalent V4 units. This efficiency stems from the simpler linear arrangement that facilitates more straightforward automation and fewer assembly steps. Major manufacturers report assembly line throughput improvements of 20-35% when producing inline-4 engines versus V4 alternatives of similar displacement.

Material utilization rates also demonstrate advantages for inline-4 production, with approximately 8-12% less material waste during manufacturing processes. The simpler casting requirements for inline blocks result in higher yield rates during foundry operations, contributing to overall cost efficiency. Additionally, quality control rejection rates for inline-4 components average 4.5% compared to 7.2% for V4 components across industry benchmarks.

Tooling investment represents another significant cost differential. Initial production setup for V4 engine manufacturing lines requires approximately 30-40% higher capital investment than comparable inline-4 production facilities. This includes specialized fixtures, testing equipment, and custom assembly stations necessary for the more complex V-configuration geometry.

Supply chain considerations further impact total production economics. Inline-4 engines typically utilize more standardized components with broader supplier availability, reducing procurement costs and inventory management complexity. Conversely, V4 engines often require more specialized parts with limited supplier options, increasing both component costs and supply chain vulnerability.

Labor requirements show that V4 engine production demands approximately 22% more skilled labor hours per unit, primarily due to more complex assembly procedures and additional quality verification steps. This translates to higher per-unit labor costs and increased training requirements for production personnel.

When analyzing production scalability, inline-4 manufacturing demonstrates superior flexibility, with production lines capable of 25-35% faster reconfiguration for different displacement variants compared to V4 production systems. This adaptability provides significant advantages for manufacturers needing to respond quickly to market demand shifts or model updates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!