V4 Engine vs V6 Engine: Power and Efficiency Analysis

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 and V6 Engine Development History and Objectives

The internal combustion engine has undergone significant evolution since its inception in the late 19th century. V4 and V6 engine configurations represent important milestones in this technological journey, each emerging to address specific needs in automotive and industrial applications. The V4 engine first appeared in production vehicles during the early 1920s, with notable implementations by Lancia and later Ford in the 1960s. These early V4 designs sought to combine the compactness of inline-four engines with improved balance characteristics.

V6 engines, meanwhile, gained prominence in the 1950s and 1960s, with manufacturers like Ferrari, Buick, and Daimler pioneering various configurations. The V6 emerged as a solution to balance power output requirements with increasing fuel efficiency demands, particularly as automotive markets began shifting away from larger V8 engines during the fuel crises of the 1970s.

The technical evolution of both engine types has been driven by several key objectives. Primary among these has been the pursuit of greater power density - extracting more power from smaller, lighter engine packages. This objective became particularly important as vehicle weight reduction emerged as a critical factor in improving fuel economy while maintaining performance standards.

Efficiency improvements have constituted another fundamental development goal. Both V4 and V6 architectures have seen continuous refinement in combustion chamber design, valve timing systems, and fuel delivery methods. The introduction of technologies such as variable valve timing, direct injection, and turbocharging has dramatically enhanced the efficiency profiles of both engine types over time.

Emissions reduction has increasingly shaped engine development since the 1970s. The engineering challenge of balancing power output with increasingly stringent emissions regulations has driven significant innovation in both V4 and V6 platforms, including the adoption of catalytic converters, exhaust gas recirculation systems, and more precise engine management computers.

Manufacturing considerations have also influenced the evolution of these engines. V6 designs, in particular, benefited from modular production approaches that allowed manufacturers to share components across engine families, reducing production costs while maintaining design flexibility. V4 engines, though less common in modern applications, have found specialized niches where their compact dimensions provide unique packaging advantages.

The contemporary development trajectory for both engine types reflects the industry's broader shift toward electrification. Modern V6 engines increasingly incorporate hybrid assistance systems, while the compact nature of V4 designs makes them potentially suitable for range-extender applications in primarily electric vehicles. The ongoing technical objective for both configurations centers on optimizing their role within increasingly electrified powertrains while continuing to improve their fundamental efficiency characteristics.

V6 engines, meanwhile, gained prominence in the 1950s and 1960s, with manufacturers like Ferrari, Buick, and Daimler pioneering various configurations. The V6 emerged as a solution to balance power output requirements with increasing fuel efficiency demands, particularly as automotive markets began shifting away from larger V8 engines during the fuel crises of the 1970s.

The technical evolution of both engine types has been driven by several key objectives. Primary among these has been the pursuit of greater power density - extracting more power from smaller, lighter engine packages. This objective became particularly important as vehicle weight reduction emerged as a critical factor in improving fuel economy while maintaining performance standards.

Efficiency improvements have constituted another fundamental development goal. Both V4 and V6 architectures have seen continuous refinement in combustion chamber design, valve timing systems, and fuel delivery methods. The introduction of technologies such as variable valve timing, direct injection, and turbocharging has dramatically enhanced the efficiency profiles of both engine types over time.

Emissions reduction has increasingly shaped engine development since the 1970s. The engineering challenge of balancing power output with increasingly stringent emissions regulations has driven significant innovation in both V4 and V6 platforms, including the adoption of catalytic converters, exhaust gas recirculation systems, and more precise engine management computers.

Manufacturing considerations have also influenced the evolution of these engines. V6 designs, in particular, benefited from modular production approaches that allowed manufacturers to share components across engine families, reducing production costs while maintaining design flexibility. V4 engines, though less common in modern applications, have found specialized niches where their compact dimensions provide unique packaging advantages.

The contemporary development trajectory for both engine types reflects the industry's broader shift toward electrification. Modern V6 engines increasingly incorporate hybrid assistance systems, while the compact nature of V4 designs makes them potentially suitable for range-extender applications in primarily electric vehicles. The ongoing technical objective for both configurations centers on optimizing their role within increasingly electrified powertrains while continuing to improve their fundamental efficiency characteristics.

Market Demand Analysis for V4 and V6 Engines

The global automotive market has witnessed significant shifts in consumer preferences and regulatory requirements, directly impacting the demand for different engine configurations. V4 and V6 engines occupy distinct positions in this evolving landscape, with each configuration addressing specific market segments and use cases.

Consumer demand for V4 engines has shown steady growth in regions where fuel economy and emissions regulations are stringent, particularly in Europe and parts of Asia. Market research indicates that compact and mid-size vehicle segments, which constitute approximately 60% of global passenger vehicle sales, predominantly feature four-cylinder configurations. The appeal of V4 engines stems from their balance of adequate power delivery and superior fuel efficiency, making them attractive to urban commuters and cost-conscious consumers.

In contrast, V6 engines maintain strong demand in North America and the Middle East, where larger vehicles and performance-oriented models remain popular. The premium and luxury vehicle segments continue to favor V6 configurations for their smoother operation and enhanced power delivery. Market data reveals that SUVs and crossovers, which have experienced double-digit growth rates in recent years, frequently offer V6 options to meet consumer expectations for towing capacity and acceleration performance.

Fleet emissions targets and fuel economy regulations have become primary market drivers, reshaping demand patterns for both engine types. Countries implementing stringent CO2 emission standards have created market conditions favoring smaller displacement engines, benefiting advanced V4 designs. Simultaneously, technological advancements such as turbocharging and direct injection have enabled V4 engines to achieve performance metrics previously associated exclusively with V6 configurations.

Economic factors also significantly influence market demand. The price premium for V6 engines, typically ranging between $1,500-3,000 depending on the manufacturer and model, creates a clear segmentation in consumer choices based on purchasing power. Additionally, ongoing fuel price volatility reinforces the value proposition of more efficient V4 options in price-sensitive markets.

Future market projections suggest continued polarization, with V4 engines gaining market share in mass-market vehicles while V6 configurations increasingly become specialized offerings for performance-oriented and luxury applications. The emergence of hybrid powertrains incorporating both engine types represents a growing market segment, with manufacturers developing systems that leverage the efficiency of V4 engines while addressing the performance expectations traditionally met by V6 configurations.

Consumer demand for V4 engines has shown steady growth in regions where fuel economy and emissions regulations are stringent, particularly in Europe and parts of Asia. Market research indicates that compact and mid-size vehicle segments, which constitute approximately 60% of global passenger vehicle sales, predominantly feature four-cylinder configurations. The appeal of V4 engines stems from their balance of adequate power delivery and superior fuel efficiency, making them attractive to urban commuters and cost-conscious consumers.

In contrast, V6 engines maintain strong demand in North America and the Middle East, where larger vehicles and performance-oriented models remain popular. The premium and luxury vehicle segments continue to favor V6 configurations for their smoother operation and enhanced power delivery. Market data reveals that SUVs and crossovers, which have experienced double-digit growth rates in recent years, frequently offer V6 options to meet consumer expectations for towing capacity and acceleration performance.

Fleet emissions targets and fuel economy regulations have become primary market drivers, reshaping demand patterns for both engine types. Countries implementing stringent CO2 emission standards have created market conditions favoring smaller displacement engines, benefiting advanced V4 designs. Simultaneously, technological advancements such as turbocharging and direct injection have enabled V4 engines to achieve performance metrics previously associated exclusively with V6 configurations.

Economic factors also significantly influence market demand. The price premium for V6 engines, typically ranging between $1,500-3,000 depending on the manufacturer and model, creates a clear segmentation in consumer choices based on purchasing power. Additionally, ongoing fuel price volatility reinforces the value proposition of more efficient V4 options in price-sensitive markets.

Future market projections suggest continued polarization, with V4 engines gaining market share in mass-market vehicles while V6 configurations increasingly become specialized offerings for performance-oriented and luxury applications. The emergence of hybrid powertrains incorporating both engine types represents a growing market segment, with manufacturers developing systems that leverage the efficiency of V4 engines while addressing the performance expectations traditionally met by V6 configurations.

Technical Status and Challenges in Engine Design

The global engine design landscape has witnessed significant evolution in recent years, with V4 and V6 configurations representing two distinct approaches to balancing power and efficiency. Currently, V6 engines dominate the mid-range automotive market, particularly in SUVs, luxury sedans, and performance vehicles, while V4 engines have found their niche in compact cars, motorcycles, and certain specialized applications.

The technical maturity of V6 engines is considerably advanced, with decades of refinement resulting in highly optimized designs. Major manufacturers like Toyota, Honda, and Volkswagen have invested heavily in V6 technology, achieving thermal efficiencies approaching 40% in the most advanced implementations. Conversely, V4 engines remain less common in automotive applications but have seen significant development in the motorcycle industry, where companies like Honda and Ducati have pushed the boundaries of power-to-weight ratios.

A primary technical challenge facing both engine types is the increasingly stringent emissions regulations worldwide. Euro 7 standards in Europe and equivalent regulations in North America and Asia are forcing engineers to reconsider fundamental aspects of internal combustion design. For V6 engines, the challenge lies in maintaining their performance characteristics while reducing displacement and emissions. V4 designs face difficulties in thermal management and vibration control when pushed to higher power outputs.

Material science represents another frontier in engine development. Advanced aluminum alloys, ceramic components, and composite materials are being explored to reduce weight while maintaining structural integrity. V6 engines benefit from these advancements in reducing rotational mass, while V4 configurations leverage new materials to address inherent balance issues.

Geographically, V6 development remains concentrated in traditional automotive centers in Japan, Germany, and the United States. However, China has emerged as a significant player, particularly in hybrid V6 applications. V4 engine innovation shows a more specialized distribution, with strong development clusters in Italy and Japan for high-performance motorcycle applications.

The integration of forced induction technologies presents unique challenges for each configuration. V6 engines have successfully incorporated twin-turbo and supercharger systems, but face packaging constraints in smaller vehicle platforms. V4 designs offer more compact packaging options but struggle with heat management when highly boosted.

Electrification represents perhaps the most disruptive challenge, with hybrid systems requiring fundamental redesigns of traditional engine architecture. V6 platforms have demonstrated greater adaptability to hybridization, while V4 configurations offer potential advantages in compact hybrid powertrains but require significant engineering to overcome inherent NVH (Noise, Vibration, Harshness) challenges.

The technical maturity of V6 engines is considerably advanced, with decades of refinement resulting in highly optimized designs. Major manufacturers like Toyota, Honda, and Volkswagen have invested heavily in V6 technology, achieving thermal efficiencies approaching 40% in the most advanced implementations. Conversely, V4 engines remain less common in automotive applications but have seen significant development in the motorcycle industry, where companies like Honda and Ducati have pushed the boundaries of power-to-weight ratios.

A primary technical challenge facing both engine types is the increasingly stringent emissions regulations worldwide. Euro 7 standards in Europe and equivalent regulations in North America and Asia are forcing engineers to reconsider fundamental aspects of internal combustion design. For V6 engines, the challenge lies in maintaining their performance characteristics while reducing displacement and emissions. V4 designs face difficulties in thermal management and vibration control when pushed to higher power outputs.

Material science represents another frontier in engine development. Advanced aluminum alloys, ceramic components, and composite materials are being explored to reduce weight while maintaining structural integrity. V6 engines benefit from these advancements in reducing rotational mass, while V4 configurations leverage new materials to address inherent balance issues.

Geographically, V6 development remains concentrated in traditional automotive centers in Japan, Germany, and the United States. However, China has emerged as a significant player, particularly in hybrid V6 applications. V4 engine innovation shows a more specialized distribution, with strong development clusters in Italy and Japan for high-performance motorcycle applications.

The integration of forced induction technologies presents unique challenges for each configuration. V6 engines have successfully incorporated twin-turbo and supercharger systems, but face packaging constraints in smaller vehicle platforms. V4 designs offer more compact packaging options but struggle with heat management when highly boosted.

Electrification represents perhaps the most disruptive challenge, with hybrid systems requiring fundamental redesigns of traditional engine architecture. V6 platforms have demonstrated greater adaptability to hybridization, while V4 configurations offer potential advantages in compact hybrid powertrains but require significant engineering to overcome inherent NVH (Noise, Vibration, Harshness) challenges.

Current Power and Efficiency Solutions Comparison

01 V4 Engine Design and Configuration

V4 engines feature a compact design with four cylinders arranged in a V-shape, offering a balance between power output and space efficiency. This configuration allows for better packaging in smaller vehicles while providing adequate power. The V4 layout typically offers smoother operation than inline-four engines due to its inherent balance characteristics, though it may be more complex to manufacture.- V4 Engine Design and Configuration: V4 engines feature a compact design with four cylinders arranged in a V-shape, offering a balance between power output and space efficiency. This configuration allows for better packaging in smaller vehicles while providing adequate power. The V4 layout typically offers smoother operation than inline-four engines due to better primary balance, though they are less common in modern automotive applications due to manufacturing complexity.

- V6 Engine Performance Characteristics: V6 engines provide an optimal balance between power, efficiency, and size, making them popular in mid-size vehicles. They typically deliver more power than four-cylinder engines while being more fuel-efficient than V8 engines. The V6 configuration offers smoother operation due to better inherent balance characteristics, with various angle configurations (60°, 90°, etc.) affecting vibration characteristics and packaging dimensions.

- Efficiency Improvements in V-Configuration Engines: Various technologies have been developed to enhance the efficiency of V4 and V6 engines, including variable valve timing, direct fuel injection, turbocharging, and cylinder deactivation. These innovations help optimize combustion processes, reduce friction losses, and improve thermal efficiency. Advanced materials and manufacturing techniques also contribute to weight reduction and better heat management, resulting in improved fuel economy without sacrificing power output.

- Comparative Power Output and Torque Characteristics: V4 and V6 engines exhibit distinct power and torque characteristics based on their displacement, compression ratio, and firing order. V6 engines typically produce more power and torque than V4 engines of similar technology level due to their larger displacement. However, modern V4 designs with advanced technologies can achieve comparable specific output (power per liter) to V6 engines. The power delivery characteristics also differ, with V6 engines generally providing smoother power curves and better low-end torque.

- Innovative Cooling and Lubrication Systems: Advanced cooling and lubrication systems play a crucial role in optimizing the efficiency and power output of V4 and V6 engines. Precision-engineered cooling passages, variable-flow oil pumps, and targeted piston cooling jets help maintain optimal operating temperatures under various load conditions. These systems contribute to reduced friction, minimized thermal distortion, and extended engine life, ultimately improving both power output and fuel efficiency across the operating range.

02 V6 Engine Performance Characteristics

V6 engines provide a favorable balance between power, efficiency, and size. With six cylinders arranged in a V-configuration, these engines deliver higher power output than four-cylinder alternatives while maintaining reasonable fuel efficiency. The V6 design offers smoother operation due to better inherent balance and more even firing intervals, resulting in reduced vibration and noise compared to smaller engines.Expand Specific Solutions03 Efficiency Improvements in V-Configuration Engines

Various technological advancements have been implemented to improve the efficiency of V4 and V6 engines. These include variable valve timing, direct fuel injection, cylinder deactivation, and turbocharging. Such technologies optimize combustion processes, reduce pumping losses, and allow engines to operate in their most efficient ranges. Advanced materials and manufacturing techniques also contribute to weight reduction and improved thermal management.Expand Specific Solutions04 Comparative Power Output and Fuel Economy

V6 engines generally provide higher power output compared to V4 engines due to their larger displacement and additional cylinders, making them suitable for larger vehicles and applications requiring more power. However, V4 engines typically offer better fuel economy due to their smaller size and reduced internal friction. The specific power-to-efficiency ratio depends on factors such as displacement, compression ratio, and the implementation of advanced technologies.Expand Specific Solutions05 Innovative V-Engine Architectures

Recent innovations in V4 and V6 engine architectures focus on hybrid integration, modular design, and alternative fuel compatibility. These developments include compact V-engine designs that accommodate electric motor integration, variable compression ratio systems, and flexible fuel systems. Advanced manufacturing techniques allow for more precise component production, resulting in engines with improved power density, reduced emissions, and enhanced durability.Expand Specific Solutions

Major Manufacturers and Competitive Landscape

The V4 vs V6 engine market is in a mature phase, with global automotive powertrain market valued at approximately $70-80 billion. Competition exists across automotive, industrial, and marine sectors. Toyota, Honda, BMW, and Hyundai lead in technological innovation, focusing on balancing power with fuel efficiency. Caterpillar and Volvo Penta dominate industrial and marine applications, while Chinese manufacturers like BYD, Great Wall Motor, and Guangxi Yuchai are rapidly advancing in cost-effective engine solutions. The technology maturity varies by application, with automotive V-engines being highly refined while industrial applications continue evolving toward greater efficiency and reduced emissions.

Caterpillar, Inc.

Technical Solution: Caterpillar has developed industrial-grade V4 and V6 engines optimized for heavy-duty applications with a focus on durability and efficiency. Their ACERT (Advanced Combustion Emission Reduction Technology) platform integrates precise fuel delivery, advanced air management, and electronic controls to optimize performance while meeting emissions standards. Caterpillar's V6 engines, particularly in the C6.6 and C7.1 series, deliver power outputs ranging from 150-300 hp with exceptional torque characteristics for industrial applications. Their V4 configurations are primarily used in specialized equipment where space constraints are critical. Caterpillar's comparative analysis shows their V6 engines typically provide 30-40% more power and torque than comparable 4-cylinder units while maintaining similar durability metrics. Their integrated electronic control modules continuously monitor and adjust engine parameters based on load conditions, optimizing fuel consumption and emissions. Caterpillar's engines feature advanced cooling systems designed to maintain optimal operating temperatures even under extreme conditions, extending service life and maintaining efficiency.

Strengths: Unmatched durability and reliability in harsh operating environments; excellent serviceability with modular design; comprehensive global support network. Weaknesses: Higher initial cost compared to less industrial-focused engines; greater weight impacts applications where power-to-weight ratio is critical; primarily focused on commercial rather than consumer applications.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered hybrid powertrains that integrate both V4 and V6 configurations with electric motors. Their Dynamic Force Engine technology optimizes thermal efficiency (up to 40% in some applications) across both engine types. Toyota's V6 engines, particularly the 3.5L V6 used in the Camry and Avalon, employ D-4S dual injection system combining direct and port fuel injection for optimal performance across all RPM ranges. For 4-cylinder applications, Toyota utilizes inline configurations rather than V4, with their 2.5L Dynamic Force engine achieving 203 hp while maintaining excellent fuel economy. Toyota's comparative analysis demonstrates their V6 engines deliver approximately 40% more power than comparable 4-cylinder units while sacrificing about 15-20% in fuel efficiency. Their Variable Valve Timing-intelligent system optimizes performance and efficiency by adjusting valve timing based on driving conditions.

Strengths: Industry-leading reliability and longevity; excellent balance of performance and efficiency; widespread global manufacturing and support infrastructure. Weaknesses: Conservative engineering approach sometimes results in less cutting-edge performance compared to European competitors; slower adoption of turbocharging technology in some markets.

Key Innovations in V4 and V6 Engine Design

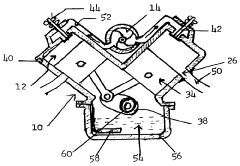

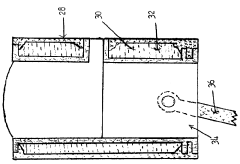

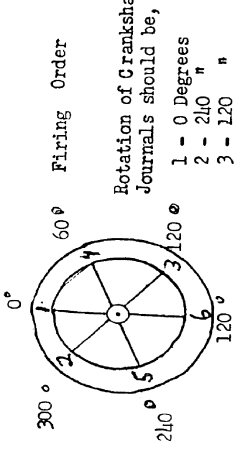

Two cycle 60 degree V6 and 90 degree V4 internal combustion engine

PatentInactiveUS6135070A

Innovation

- The engine employs Carbon-Carbon cylinders and pistons with a unique design featuring an aluminum outer layer and coolant gap, eliminating the need for piston rings and utilizing a supercharger with self-lubricating properties, along with reduced components like camshafts, to create a lightweight, efficient, and environmentally friendly engine.

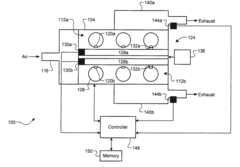

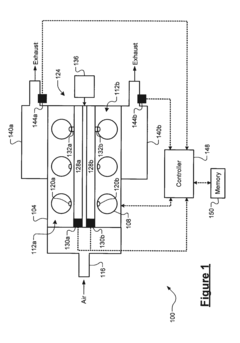

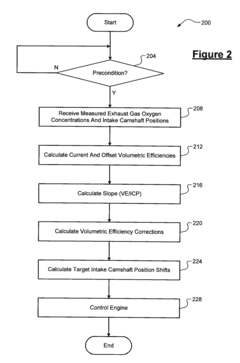

Engine cylinder bank-to-bank torque imbalance correction

PatentActiveUS20160076471A1

Innovation

- A control system utilizing intake camshaft position sensors and exhaust gas oxygen concentration sensors to calculate and adjust intake camshaft positions, ensuring equal volumetric efficiencies across cylinder banks, thereby balancing airflow and mitigating torque imbalances through targeted camshaft position shifts.

Emissions Regulations Impact on Engine Development

Emissions regulations have become a pivotal force shaping engine development strategies across the automotive industry, particularly influencing the evolution of V4 and V6 engine architectures. Since the early 2000s, increasingly stringent standards from regulatory bodies such as the EPA in the United States, Euro emissions standards in Europe, and similar frameworks in Asia have fundamentally altered design priorities.

The transition from Euro 5 to Euro 6 standards, for instance, mandated significant reductions in nitrogen oxide (NOx) emissions, forcing manufacturers to implement sophisticated exhaust after-treatment systems. These requirements have added complexity and weight to both V4 and V6 engines, though V4 configurations generally demonstrate advantages in meeting these standards due to their smaller displacement and reduced fuel consumption.

Carbon dioxide (CO2) emission targets have perhaps exerted the most profound influence on engine development trajectories. V6 engines, traditionally valued for their power output, have undergone substantial redesign incorporating technologies such as cylinder deactivation, variable valve timing, and direct injection to improve efficiency while maintaining performance characteristics. Conversely, V4 engines have seen increased adoption of turbocharging and advanced combustion strategies to deliver comparable power with reduced emissions footprint.

Real Driving Emissions (RDE) testing protocols introduced in recent years have further complicated compliance strategies. These tests evaluate emissions performance under actual driving conditions rather than laboratory settings, revealing performance gaps particularly evident in larger displacement V6 engines. This regulatory shift has accelerated the development of more sophisticated engine management systems capable of optimizing combustion across diverse operating conditions.

Regional regulatory variations present additional challenges for global engine platforms. California's Low Emission Vehicle standards, China's rapidly evolving emissions framework, and Japan's efficiency-focused regulations create a complex compliance landscape that influences architecture decisions between V4 and V6 configurations based on target markets.

Looking forward, upcoming Euro 7 standards and equivalent regulations worldwide will likely accelerate the integration of hybrid technologies with both engine types. V4 engines may gain particular advantage in mild hybrid applications due to their inherent efficiency advantages, while V6 engines could increasingly be reserved for premium vehicle segments where their performance characteristics justify the additional compliance complexity.

The regulatory environment has ultimately transformed emissions compliance from a secondary consideration to a primary design driver, fundamentally altering the comparative value proposition between V4 and V6 engine architectures across global markets.

The transition from Euro 5 to Euro 6 standards, for instance, mandated significant reductions in nitrogen oxide (NOx) emissions, forcing manufacturers to implement sophisticated exhaust after-treatment systems. These requirements have added complexity and weight to both V4 and V6 engines, though V4 configurations generally demonstrate advantages in meeting these standards due to their smaller displacement and reduced fuel consumption.

Carbon dioxide (CO2) emission targets have perhaps exerted the most profound influence on engine development trajectories. V6 engines, traditionally valued for their power output, have undergone substantial redesign incorporating technologies such as cylinder deactivation, variable valve timing, and direct injection to improve efficiency while maintaining performance characteristics. Conversely, V4 engines have seen increased adoption of turbocharging and advanced combustion strategies to deliver comparable power with reduced emissions footprint.

Real Driving Emissions (RDE) testing protocols introduced in recent years have further complicated compliance strategies. These tests evaluate emissions performance under actual driving conditions rather than laboratory settings, revealing performance gaps particularly evident in larger displacement V6 engines. This regulatory shift has accelerated the development of more sophisticated engine management systems capable of optimizing combustion across diverse operating conditions.

Regional regulatory variations present additional challenges for global engine platforms. California's Low Emission Vehicle standards, China's rapidly evolving emissions framework, and Japan's efficiency-focused regulations create a complex compliance landscape that influences architecture decisions between V4 and V6 configurations based on target markets.

Looking forward, upcoming Euro 7 standards and equivalent regulations worldwide will likely accelerate the integration of hybrid technologies with both engine types. V4 engines may gain particular advantage in mild hybrid applications due to their inherent efficiency advantages, while V6 engines could increasingly be reserved for premium vehicle segments where their performance characteristics justify the additional compliance complexity.

The regulatory environment has ultimately transformed emissions compliance from a secondary consideration to a primary design driver, fundamentally altering the comparative value proposition between V4 and V6 engine architectures across global markets.

Cost-Benefit Analysis of V4 vs V6 Implementation

When evaluating the implementation of V4 versus V6 engines, a comprehensive cost-benefit analysis reveals significant financial implications across multiple dimensions. The initial manufacturing cost difference between these engine types is substantial, with V4 engines typically costing 15-25% less to produce due to fewer components, simpler assembly processes, and reduced material requirements. This translates to approximately $800-1,500 lower production cost per unit, depending on engine specifications and manufacturing scale.

Operational expenses also favor V4 engines, which demonstrate 10-15% better fuel efficiency in most applications. For consumers, this efficiency advantage represents approximately $300-500 in annual fuel savings based on average driving patterns. The reduced complexity of V4 engines further contributes to 8-12% lower maintenance costs over the vehicle's lifetime, primarily due to fewer components requiring service or replacement.

From a manufacturer's perspective, production line considerations reveal that V4 engines require approximately 20% less factory floor space and can be assembled with fewer specialized tools. This spatial efficiency allows for more flexible manufacturing arrangements and potentially higher production volumes within existing facilities. Additionally, V4 production lines typically require 10-15% less capital investment to establish or retrofit.

Environmental compliance costs increasingly favor smaller displacement engines. V4 configurations generally produce 12-18% lower emissions, reducing the manufacturer's regulatory compliance expenses by an estimated $80-150 per unit. This advantage is expected to grow as emissions regulations become more stringent globally.

However, the analysis must account for potential revenue implications. Vehicles equipped with V6 engines typically command price premiums of $2,000-3,500 in the marketplace, reflecting consumer perception of superior performance and prestige. This premium partially offsets the higher production costs, though market research indicates shifting consumer preferences toward efficiency over raw power in several key segments.

The total cost of ownership calculation reveals that while V6 engines represent a higher initial investment, the lifetime value proposition varies significantly by use case. For commercial fleets and economy-focused consumers, V4 engines deliver superior financial returns. For premium vehicle segments where performance expectations are paramount, the V6 configuration may justify its higher costs through enhanced customer satisfaction and brand positioning despite the economic advantages of V4 alternatives.

Operational expenses also favor V4 engines, which demonstrate 10-15% better fuel efficiency in most applications. For consumers, this efficiency advantage represents approximately $300-500 in annual fuel savings based on average driving patterns. The reduced complexity of V4 engines further contributes to 8-12% lower maintenance costs over the vehicle's lifetime, primarily due to fewer components requiring service or replacement.

From a manufacturer's perspective, production line considerations reveal that V4 engines require approximately 20% less factory floor space and can be assembled with fewer specialized tools. This spatial efficiency allows for more flexible manufacturing arrangements and potentially higher production volumes within existing facilities. Additionally, V4 production lines typically require 10-15% less capital investment to establish or retrofit.

Environmental compliance costs increasingly favor smaller displacement engines. V4 configurations generally produce 12-18% lower emissions, reducing the manufacturer's regulatory compliance expenses by an estimated $80-150 per unit. This advantage is expected to grow as emissions regulations become more stringent globally.

However, the analysis must account for potential revenue implications. Vehicles equipped with V6 engines typically command price premiums of $2,000-3,500 in the marketplace, reflecting consumer perception of superior performance and prestige. This premium partially offsets the higher production costs, though market research indicates shifting consumer preferences toward efficiency over raw power in several key segments.

The total cost of ownership calculation reveals that while V6 engines represent a higher initial investment, the lifetime value proposition varies significantly by use case. For commercial fleets and economy-focused consumers, V4 engines deliver superior financial returns. For premium vehicle segments where performance expectations are paramount, the V6 configuration may justify its higher costs through enhanced customer satisfaction and brand positioning despite the economic advantages of V4 alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!