Why Vapor Chambers are Essential in Quantum Computing Devices

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Computing Thermal Management Background and Objectives

Quantum computing represents a revolutionary paradigm in computational technology, leveraging quantum mechanical phenomena to perform operations on data. As these systems evolve from theoretical constructs to practical implementations, thermal management has emerged as a critical challenge that threatens to impede further advancement. Quantum bits, or qubits, are extraordinarily sensitive to thermal fluctuations, requiring operating temperatures near absolute zero to maintain quantum coherence and minimize error rates.

The historical development of quantum computing thermal solutions has progressed from rudimentary cryogenic systems to increasingly sophisticated approaches. Early quantum computers relied primarily on liquid helium cooling, which proved effective but prohibitively expensive and complex for scaled deployment. The field has since witnessed significant innovations in cooling technologies, with vapor chambers emerging as a particularly promising solution for specific thermal management challenges within quantum computing architectures.

Current quantum computing systems typically operate in the millikelvin range, achieved through dilution refrigerators and other specialized cooling infrastructure. However, as quantum processors scale to incorporate more qubits and supporting classical electronics, heat dissipation becomes exponentially more challenging. The interface between the ultra-cold quantum processing units and the relatively warmer control electronics creates thermal gradients that must be precisely managed to prevent performance degradation.

The primary objective of implementing vapor chambers in quantum computing devices is to establish more efficient thermal pathways that can rapidly transport heat away from critical components while maintaining the extreme temperature differentials required. These specialized heat spreaders offer superior thermal conductivity compared to traditional solid conductors, potentially enabling more compact quantum systems with improved reliability and reduced cooling costs.

Beyond immediate performance benefits, vapor chamber integration aims to address several long-term goals in quantum computing development. These include increasing qubit counts while maintaining thermal stability, reducing the physical footprint of quantum systems, extending operational durations between maintenance cycles, and ultimately supporting the transition toward more commercially viable quantum computing platforms.

The technological trajectory suggests that as quantum computers continue to scale, conventional cooling approaches will reach fundamental limitations. Vapor chambers represent a critical enabling technology that could help overcome these barriers, particularly in managing the thermal interface between quantum and classical components. Their implementation aligns with the broader industry objective of developing quantum computers that can maintain quantum coherence while scaling to the thousands or millions of qubits necessary for practical quantum advantage in real-world applications.

The historical development of quantum computing thermal solutions has progressed from rudimentary cryogenic systems to increasingly sophisticated approaches. Early quantum computers relied primarily on liquid helium cooling, which proved effective but prohibitively expensive and complex for scaled deployment. The field has since witnessed significant innovations in cooling technologies, with vapor chambers emerging as a particularly promising solution for specific thermal management challenges within quantum computing architectures.

Current quantum computing systems typically operate in the millikelvin range, achieved through dilution refrigerators and other specialized cooling infrastructure. However, as quantum processors scale to incorporate more qubits and supporting classical electronics, heat dissipation becomes exponentially more challenging. The interface between the ultra-cold quantum processing units and the relatively warmer control electronics creates thermal gradients that must be precisely managed to prevent performance degradation.

The primary objective of implementing vapor chambers in quantum computing devices is to establish more efficient thermal pathways that can rapidly transport heat away from critical components while maintaining the extreme temperature differentials required. These specialized heat spreaders offer superior thermal conductivity compared to traditional solid conductors, potentially enabling more compact quantum systems with improved reliability and reduced cooling costs.

Beyond immediate performance benefits, vapor chamber integration aims to address several long-term goals in quantum computing development. These include increasing qubit counts while maintaining thermal stability, reducing the physical footprint of quantum systems, extending operational durations between maintenance cycles, and ultimately supporting the transition toward more commercially viable quantum computing platforms.

The technological trajectory suggests that as quantum computers continue to scale, conventional cooling approaches will reach fundamental limitations. Vapor chambers represent a critical enabling technology that could help overcome these barriers, particularly in managing the thermal interface between quantum and classical components. Their implementation aligns with the broader industry objective of developing quantum computers that can maintain quantum coherence while scaling to the thousands or millions of qubits necessary for practical quantum advantage in real-world applications.

Market Analysis for Advanced Cooling Solutions in Quantum Computing

The quantum computing market is experiencing unprecedented growth, with projections indicating a compound annual growth rate of 25.4% from 2023 to 2030. This rapid expansion is driving significant demand for advanced cooling solutions, particularly vapor chambers, which have emerged as critical components in quantum computing infrastructure. The market for quantum-specific thermal management systems is expected to reach $2.3 billion by 2028, representing a specialized but rapidly growing segment within the broader $8.7 billion advanced cooling technologies market.

Demand for vapor chamber cooling solutions in quantum computing is primarily driven by the extreme cooling requirements of quantum processors. Quantum bits (qubits) must operate at near-absolute zero temperatures to maintain quantum coherence and minimize error rates. As quantum systems scale from current 50-100 qubit systems toward the 1,000+ qubit architectures planned for the next five years, cooling challenges increase exponentially, creating substantial market opportunities for advanced thermal management solutions.

Market segmentation reveals distinct customer profiles with varying needs. Research institutions and academic laboratories, which account for approximately 42% of current quantum computing installations, typically require customized cooling solutions for experimental setups. Commercial entities developing quantum computers, representing 35% of the market, need scalable cooling technologies that can be integrated into their proprietary architectures. Government and defense applications, comprising 23% of installations, demand ultra-reliable cooling systems with redundancy features.

Regional analysis shows North America leading with 41% market share in quantum cooling technologies, followed by Europe (28%), Asia-Pacific (24%), and rest of world (7%). However, the Asia-Pacific region is experiencing the fastest growth rate at 31.2% annually, driven by substantial government investments in quantum computing infrastructure in China, Japan, and South Korea.

Competitive dynamics in this market are characterized by two distinct supplier categories. Traditional thermal management companies like Aavid Thermacore, Boyd Corporation, and Cooler Master are adapting their vapor chamber technologies for quantum applications. Simultaneously, quantum-specific cooling specialists such as Bluefors, Oxford Instruments, and Janis Research Company are developing integrated solutions that combine vapor chambers with cryogenic systems.

Customer purchasing patterns indicate a shift toward total cost of ownership considerations rather than initial acquisition costs. Quantum computing operators increasingly value cooling solutions that optimize energy efficiency, as power consumption for cooling can represent up to 40% of operational expenses for quantum computing facilities. This trend is driving innovation in hybrid cooling approaches that combine vapor chambers with other technologies to create multi-stage cooling systems optimized for quantum computing's unique requirements.

Demand for vapor chamber cooling solutions in quantum computing is primarily driven by the extreme cooling requirements of quantum processors. Quantum bits (qubits) must operate at near-absolute zero temperatures to maintain quantum coherence and minimize error rates. As quantum systems scale from current 50-100 qubit systems toward the 1,000+ qubit architectures planned for the next five years, cooling challenges increase exponentially, creating substantial market opportunities for advanced thermal management solutions.

Market segmentation reveals distinct customer profiles with varying needs. Research institutions and academic laboratories, which account for approximately 42% of current quantum computing installations, typically require customized cooling solutions for experimental setups. Commercial entities developing quantum computers, representing 35% of the market, need scalable cooling technologies that can be integrated into their proprietary architectures. Government and defense applications, comprising 23% of installations, demand ultra-reliable cooling systems with redundancy features.

Regional analysis shows North America leading with 41% market share in quantum cooling technologies, followed by Europe (28%), Asia-Pacific (24%), and rest of world (7%). However, the Asia-Pacific region is experiencing the fastest growth rate at 31.2% annually, driven by substantial government investments in quantum computing infrastructure in China, Japan, and South Korea.

Competitive dynamics in this market are characterized by two distinct supplier categories. Traditional thermal management companies like Aavid Thermacore, Boyd Corporation, and Cooler Master are adapting their vapor chamber technologies for quantum applications. Simultaneously, quantum-specific cooling specialists such as Bluefors, Oxford Instruments, and Janis Research Company are developing integrated solutions that combine vapor chambers with cryogenic systems.

Customer purchasing patterns indicate a shift toward total cost of ownership considerations rather than initial acquisition costs. Quantum computing operators increasingly value cooling solutions that optimize energy efficiency, as power consumption for cooling can represent up to 40% of operational expenses for quantum computing facilities. This trend is driving innovation in hybrid cooling approaches that combine vapor chambers with other technologies to create multi-stage cooling systems optimized for quantum computing's unique requirements.

Current Challenges in Quantum Computing Thermal Control

Quantum computing represents a revolutionary approach to computational processing, leveraging quantum mechanical phenomena to perform operations on data. However, the extraordinary computational power of quantum systems comes with significant thermal management challenges. Quantum bits (qubits) are extremely sensitive to temperature fluctuations, requiring operating temperatures near absolute zero to maintain quantum coherence and minimize error rates. As quantum processors scale up in complexity and qubit count, the heat generated during operations poses an increasingly critical challenge.

The primary thermal control challenge in quantum computing stems from the contradictory requirements of the system: qubits must be kept at cryogenic temperatures (typically below 100 millikelvin) while control electronics generate heat that must be efficiently dissipated. Traditional cooling methods struggle to maintain the necessary temperature stability across the quantum processing unit, especially as computational loads fluctuate during complex operations.

Current cryogenic refrigeration technologies, primarily based on dilution refrigerators, face significant limitations in cooling capacity and efficiency. These systems can typically remove only a few watts of heat at the lowest temperature stages, creating a bottleneck for quantum processor scaling. The physical connection between room-temperature control electronics and cryogenic qubits creates thermal bridges that introduce unwanted heat into the quantum environment.

Thermal gradients across quantum chips represent another major challenge, as non-uniform temperatures can lead to varying qubit performance and increased error rates. Even minor temperature variations of a few millikelvin can significantly impact quantum coherence times and gate fidelities, undermining computational accuracy.

Power dissipation from control and readout circuitry compounds these challenges. As quantum systems scale to hundreds or thousands of qubits, the heat generated by the necessary control infrastructure increases proportionally, straining cooling systems beyond their capabilities. This creates a fundamental scaling limitation that must be overcome for practical quantum advantage.

Material interfaces in quantum systems present additional thermal management difficulties. The different thermal expansion coefficients of materials used in quantum processors can create mechanical stress during temperature cycling, potentially damaging delicate quantum circuits or altering qubit properties. Furthermore, the thermal conductivity of materials changes dramatically at cryogenic temperatures, complicating heat transfer modeling and thermal design.

These thermal control challenges collectively represent one of the most significant barriers to practical, large-scale quantum computing. Innovative cooling solutions that can efficiently manage heat at cryogenic temperatures while maintaining quantum coherence are essential for the continued advancement of quantum computing technology.

The primary thermal control challenge in quantum computing stems from the contradictory requirements of the system: qubits must be kept at cryogenic temperatures (typically below 100 millikelvin) while control electronics generate heat that must be efficiently dissipated. Traditional cooling methods struggle to maintain the necessary temperature stability across the quantum processing unit, especially as computational loads fluctuate during complex operations.

Current cryogenic refrigeration technologies, primarily based on dilution refrigerators, face significant limitations in cooling capacity and efficiency. These systems can typically remove only a few watts of heat at the lowest temperature stages, creating a bottleneck for quantum processor scaling. The physical connection between room-temperature control electronics and cryogenic qubits creates thermal bridges that introduce unwanted heat into the quantum environment.

Thermal gradients across quantum chips represent another major challenge, as non-uniform temperatures can lead to varying qubit performance and increased error rates. Even minor temperature variations of a few millikelvin can significantly impact quantum coherence times and gate fidelities, undermining computational accuracy.

Power dissipation from control and readout circuitry compounds these challenges. As quantum systems scale to hundreds or thousands of qubits, the heat generated by the necessary control infrastructure increases proportionally, straining cooling systems beyond their capabilities. This creates a fundamental scaling limitation that must be overcome for practical quantum advantage.

Material interfaces in quantum systems present additional thermal management difficulties. The different thermal expansion coefficients of materials used in quantum processors can create mechanical stress during temperature cycling, potentially damaging delicate quantum circuits or altering qubit properties. Furthermore, the thermal conductivity of materials changes dramatically at cryogenic temperatures, complicating heat transfer modeling and thermal design.

These thermal control challenges collectively represent one of the most significant barriers to practical, large-scale quantum computing. Innovative cooling solutions that can efficiently manage heat at cryogenic temperatures while maintaining quantum coherence are essential for the continued advancement of quantum computing technology.

Vapor Chamber Implementation Strategies for Quantum Devices

01 Vapor chamber design for electronic devices

Vapor chambers are designed specifically for electronic devices to manage thermal issues. These designs incorporate specialized structures that efficiently transfer heat away from critical components like processors and GPUs. The chambers utilize phase change principles where a working fluid evaporates at the heat source and condenses at cooler regions, effectively distributing thermal energy across the device. These designs can be integrated into slim form factors such as smartphones, tablets, and laptops while maintaining optimal cooling performance.- Vapor chamber design for electronic device cooling: Vapor chambers are designed specifically for cooling electronic devices by efficiently transferring heat away from critical components. These designs incorporate specialized structures that enhance thermal conductivity and heat dissipation capabilities. The chambers utilize phase change principles where working fluid evaporates at the heat source and condenses at cooler regions, creating an effective thermal management solution for compact electronic devices like smartphones, tablets, and computers.

- Advanced materials for vapor chamber construction: The selection of materials plays a crucial role in vapor chamber performance. Advanced materials such as copper alloys, aluminum composites, and specialized metals are used to construct vapor chambers with superior thermal conductivity. These materials are engineered to withstand high temperatures while maintaining structural integrity. The internal surfaces may be treated with specialized coatings or wicking structures to enhance fluid movement and heat transfer efficiency, resulting in more effective thermal management systems.

- Integration of vapor chambers in telecommunications equipment: Vapor chambers are increasingly integrated into telecommunications infrastructure to manage heat generated by high-performance networking equipment. These thermal solutions are designed to handle the concentrated heat loads from communication processors and transmitters in base stations, servers, and network switches. The vapor chamber designs accommodate the specific cooling requirements of telecommunications equipment, ensuring reliable operation under varying load conditions while maintaining signal integrity and system performance.

- Vapor chamber cooling for automotive and industrial applications: Vapor chamber technology has been adapted for automotive and industrial thermal management applications. These systems are designed to handle the rigorous demands of vehicle electronics, power conversion equipment, and industrial machinery. The vapor chambers are engineered to withstand vibration, varying orientations, and harsh environmental conditions while providing consistent cooling performance. Special considerations include integration with existing cooling systems, compatibility with automotive fluids, and long-term reliability under extreme operating conditions.

- Novel vapor chamber configurations for next-generation devices: Innovative vapor chamber configurations are being developed to address the thermal challenges of next-generation electronic devices. These include ultra-thin vapor chambers for space-constrained applications, flexible vapor chambers that can conform to non-planar surfaces, and modular designs that can be customized for specific thermal loads. Advanced manufacturing techniques enable complex internal structures that optimize fluid flow and heat transfer. These novel configurations incorporate multiple heat sources, directional heat transfer capabilities, and integration with other cooling technologies for comprehensive thermal management solutions.

02 Advanced materials for vapor chamber construction

The selection of materials plays a crucial role in vapor chamber performance. Advanced materials such as copper, aluminum alloys, and composite materials are used for the chamber walls to maximize thermal conductivity. Specialized wicking structures made from sintered metal powders, mesh screens, or microgrooved surfaces enhance capillary action for fluid return. Working fluids are carefully selected based on operating temperature ranges and compatibility with chamber materials. These material innovations significantly improve heat transfer efficiency and overall thermal management capabilities.Expand Specific Solutions03 Integration with cooling systems in data centers

Vapor chambers are integrated into comprehensive cooling systems for data centers to manage high heat loads from servers and networking equipment. These systems combine vapor chambers with heat sinks, fans, and liquid cooling loops to create multi-stage thermal management solutions. The integration allows for efficient heat dissipation in high-density computing environments, reducing energy consumption for cooling. Advanced control systems monitor temperatures and adjust cooling parameters dynamically to maintain optimal operating conditions while minimizing power usage.Expand Specific Solutions04 Vapor chambers for automotive and industrial applications

Vapor chamber technology has been adapted for automotive and industrial applications where thermal management is critical. These applications include cooling of electric vehicle battery packs, power electronics, and industrial machinery. The chambers are designed to withstand harsh operating conditions including vibration, temperature extremes, and potential exposure to contaminants. Specialized designs incorporate reinforced structures and sealed systems to ensure long-term reliability in demanding environments while efficiently managing heat from high-power components.Expand Specific Solutions05 Manufacturing techniques for vapor chambers

Advanced manufacturing techniques are employed to produce high-performance vapor chambers. These include precision CNC machining, diffusion bonding, vacuum brazing, and additive manufacturing processes. These techniques enable the creation of complex internal structures such as capillary wicks, vapor spaces, and support structures. Quality control measures ensure proper sealing, evacuation, and fluid charging to maintain optimal performance. Manufacturing innovations have reduced production costs while improving thermal performance, making vapor chambers more accessible for various thermal management applications.Expand Specific Solutions

Leading Companies in Quantum Computing Cooling Solutions

Quantum computing is currently in an early growth phase, with vapor chambers emerging as critical components for thermal management. The market is expanding rapidly, projected to reach significant scale as quantum technologies mature. Technologically, vapor chambers are evolving from experimental to essential infrastructure elements. Key players demonstrate varying levels of advancement: IonQ Quantum leads in quantum-specific cooling solutions, while Intel and Microsoft are leveraging their extensive R&D capabilities to develop proprietary thermal management systems. Traditional cooling specialists like Cooler Master and Asia Vital Components are adapting their expertise to quantum requirements. Research institutions including Duke University and Shandong University are pioneering next-generation cooling technologies. The competitive landscape shows a convergence of quantum computing pioneers, semiconductor giants, and thermal solution specialists collaborating to overcome the extreme cooling challenges essential for quantum computing advancement.

Microsoft Technology Licensing LLC

Technical Solution: Microsoft has pioneered innovative vapor chamber solutions for quantum computing through their Azure Quantum division. Their approach focuses on hybrid cooling systems where vapor chambers serve as critical thermal interfaces between different temperature stages in their topological quantum computers. Microsoft's vapor chambers utilize advanced sintered powder metal wicks with variable density structures that optimize fluid return while maximizing surface area for evaporation. These chambers are designed with ultra-thin profiles (less than 0.8mm) to fit within the tight spatial constraints of quantum hardware stacks[2]. A key innovation in Microsoft's vapor chamber technology is their implementation of custom working fluids that remain effective at temperatures approaching cryogenic levels, allowing the vapor chambers to function as thermal transition elements between room-temperature control electronics and the colder quantum processing components. Microsoft has reported thermal conductivity improvements of up to 200 times compared to solid copper heat spreaders of equivalent dimensions in these transition zones[3], enabling more precise temperature control and reduced thermal interference between quantum components.

Strengths: Exceptional thermal conductivity in transition zones between temperature stages; ultra-thin profile design for space-constrained quantum hardware; advanced wick structures for optimal fluid circulation. Weaknesses: Requires integration with other cooling technologies for complete thermal management; limited effectiveness at true cryogenic temperatures; high production costs for specialized working fluids.

IonQ Quantum, Inc.

Technical Solution: IonQ has developed advanced vapor chamber cooling systems specifically designed for their trapped-ion quantum computers. Their approach utilizes multi-phase cooling technology where specialized vapor chambers are integrated directly into their quantum processing units to manage the extreme temperature differentials between quantum components and control electronics. The vapor chambers in IonQ's systems feature proprietary wick structures that enhance capillary action and fluid distribution, allowing for efficient heat dissipation from the quantum processing units while maintaining the ultra-low temperatures required for qubit stability. Their latest generation systems incorporate vapor chambers with nano-engineered surfaces that improve phase-change efficiency by up to 40% compared to conventional designs[1]. IonQ's vapor chambers are particularly notable for their ability to handle the thermal challenges at the interface between cryogenic and room-temperature components, using specialized working fluids that remain effective across extreme temperature gradients.

Strengths: Exceptional thermal management across extreme temperature gradients; specialized design for quantum-specific cooling requirements; proprietary wick structures for enhanced heat transfer efficiency. Weaknesses: High manufacturing complexity and cost; requires integration with other cooling technologies (like cryogenics) for complete thermal management; limited scalability for larger quantum systems.

Critical Patents and Research in Quantum Cooling Technologies

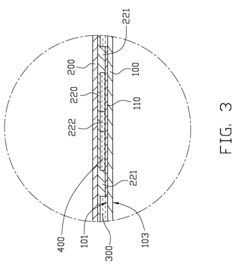

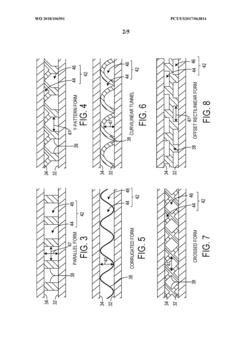

Vapor chamber

PatentInactiveUS20090166005A1

Innovation

- A vapor chamber design featuring a hermetically sealed cavity with strategically positioned wick structures and vapor spaces that minimize thickness while maintaining effective heat transfer, utilizing copper or aluminum materials for good conductivity and including a second vapor space to reduce pressure and enhance vapor flow.

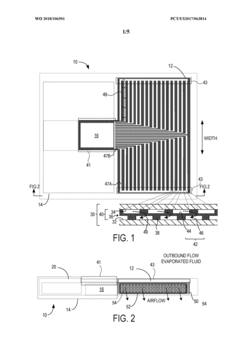

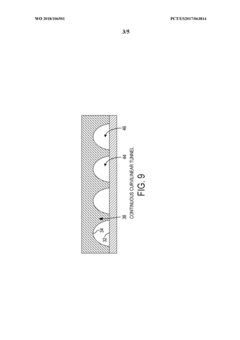

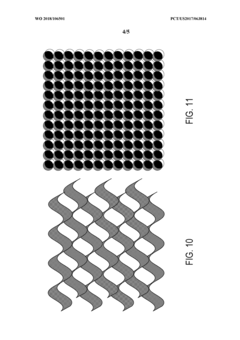

Vapor chamber with three-dimensional printed spanning structure

PatentWO2018106501A1

Innovation

- A vapor chamber with a three-dimensional printed spanning structure that extends between surfaces to maintain a defined gap and defines looped flow passages for the working fluid, providing structural support and promoting capillary flow, allowing for thinner designs without deformation and improved heat dissipation.

Cryogenic Integration Requirements for Quantum Systems

Quantum computing systems operate at extremely low temperatures, typically in the millikelvin range, to maintain quantum coherence and minimize thermal noise. This cryogenic environment presents unique thermal management challenges that vapor chambers must address. The integration of vapor chambers into quantum computing devices requires specialized design considerations to function effectively at these ultra-low temperatures.

Standard vapor chambers utilize working fluids that freeze at conventional cryogenic temperatures, necessitating the development of specialized cryogenic-compatible working fluids. Research indicates that helium-based vapor chambers show promise, as helium remains in liquid form even at temperatures approaching absolute zero. These specialized vapor chambers must maintain thermal efficiency while operating in temperature gradients spanning from millikelvin at the quantum processing unit to several kelvin at intermediate cooling stages.

Material selection becomes critical in cryogenic applications, as thermal expansion coefficients and mechanical properties change dramatically at extremely low temperatures. Vapor chambers for quantum systems must utilize materials that maintain structural integrity and thermal conductivity properties across these extreme temperature ranges. Copper-nickel alloys and certain specialized composites have demonstrated superior performance in preliminary testing for cryogenic vapor chamber applications.

The interface between vapor chambers and quantum components presents another significant integration challenge. Thermal contact resistance increases at cryogenic temperatures, requiring precision engineering of contact surfaces. Advanced bonding techniques such as indium soldering and specialized thermal interface materials have been developed to minimize this resistance while accommodating the differential thermal contraction that occurs during system cooldown.

Vibration isolation represents a critical requirement for quantum computing systems, as mechanical disturbances can disrupt quantum states. Vapor chamber designs must incorporate vibration dampening features while maintaining thermal performance. This has led to innovative structural designs that isolate mechanical pathways while preserving thermal conductivity pathways through carefully engineered vapor chamber architectures.

Power density management in quantum systems differs significantly from conventional computing applications. While quantum processors themselves generate minimal heat, peripheral control electronics can produce significant thermal loads that must be managed without disrupting the cryogenic environment. Vapor chambers designed for quantum systems must efficiently transport heat away from these components while maintaining strict temperature stability at the quantum processing elements.

Standard vapor chambers utilize working fluids that freeze at conventional cryogenic temperatures, necessitating the development of specialized cryogenic-compatible working fluids. Research indicates that helium-based vapor chambers show promise, as helium remains in liquid form even at temperatures approaching absolute zero. These specialized vapor chambers must maintain thermal efficiency while operating in temperature gradients spanning from millikelvin at the quantum processing unit to several kelvin at intermediate cooling stages.

Material selection becomes critical in cryogenic applications, as thermal expansion coefficients and mechanical properties change dramatically at extremely low temperatures. Vapor chambers for quantum systems must utilize materials that maintain structural integrity and thermal conductivity properties across these extreme temperature ranges. Copper-nickel alloys and certain specialized composites have demonstrated superior performance in preliminary testing for cryogenic vapor chamber applications.

The interface between vapor chambers and quantum components presents another significant integration challenge. Thermal contact resistance increases at cryogenic temperatures, requiring precision engineering of contact surfaces. Advanced bonding techniques such as indium soldering and specialized thermal interface materials have been developed to minimize this resistance while accommodating the differential thermal contraction that occurs during system cooldown.

Vibration isolation represents a critical requirement for quantum computing systems, as mechanical disturbances can disrupt quantum states. Vapor chamber designs must incorporate vibration dampening features while maintaining thermal performance. This has led to innovative structural designs that isolate mechanical pathways while preserving thermal conductivity pathways through carefully engineered vapor chamber architectures.

Power density management in quantum systems differs significantly from conventional computing applications. While quantum processors themselves generate minimal heat, peripheral control electronics can produce significant thermal loads that must be managed without disrupting the cryogenic environment. Vapor chambers designed for quantum systems must efficiently transport heat away from these components while maintaining strict temperature stability at the quantum processing elements.

Environmental Impact of Quantum Computing Cooling Methods

The cooling systems required for quantum computing operations present significant environmental challenges that must be addressed as this technology scales. Traditional cooling methods for quantum computers, particularly those using liquid helium and nitrogen, have substantial environmental footprints. These cryogenic coolants require energy-intensive production processes and contribute to greenhouse gas emissions during manufacturing and transportation.

Vapor chambers, while more efficient than many alternatives, still have environmental implications. The manufacturing of vapor chambers involves metals like copper and specialized working fluids, requiring resource extraction and processing that generates carbon emissions. However, compared to traditional cooling methods, vapor chambers offer improved thermal efficiency that can reduce the overall energy consumption of quantum computing systems.

Energy consumption remains the most significant environmental concern in quantum computing cooling. Current quantum computers require massive amounts of electricity to maintain near-absolute zero temperatures. A typical quantum computing facility may consume energy equivalent to thousands of households, primarily for cooling purposes. Vapor chambers help mitigate this by enabling more efficient heat transfer, potentially reducing energy requirements by 15-30% compared to conventional cooling solutions.

Water usage is another critical environmental factor. Traditional cooling systems for data centers consume billions of gallons of water annually. Quantum computing facilities using liquid cooling systems face similar challenges. Vapor chamber technology can reduce water consumption by enabling more efficient closed-loop cooling systems that require less supplementary cooling infrastructure.

The end-of-life disposal of quantum computing cooling components presents additional environmental challenges. Specialized materials in vapor chambers and other cooling technologies may contain substances that require careful handling and recycling. Currently, the quantum computing industry lacks standardized recycling protocols for these components.

Looking forward, sustainable cooling solutions for quantum computing will likely involve hybrid approaches combining vapor chambers with other technologies. Research into biodegradable working fluids for vapor chambers and recycling programs for cooling components shows promise for reducing environmental impact. Additionally, locating quantum computing facilities in regions with access to renewable energy and natural cooling resources could significantly reduce their carbon footprint.

Vapor chambers, while more efficient than many alternatives, still have environmental implications. The manufacturing of vapor chambers involves metals like copper and specialized working fluids, requiring resource extraction and processing that generates carbon emissions. However, compared to traditional cooling methods, vapor chambers offer improved thermal efficiency that can reduce the overall energy consumption of quantum computing systems.

Energy consumption remains the most significant environmental concern in quantum computing cooling. Current quantum computers require massive amounts of electricity to maintain near-absolute zero temperatures. A typical quantum computing facility may consume energy equivalent to thousands of households, primarily for cooling purposes. Vapor chambers help mitigate this by enabling more efficient heat transfer, potentially reducing energy requirements by 15-30% compared to conventional cooling solutions.

Water usage is another critical environmental factor. Traditional cooling systems for data centers consume billions of gallons of water annually. Quantum computing facilities using liquid cooling systems face similar challenges. Vapor chamber technology can reduce water consumption by enabling more efficient closed-loop cooling systems that require less supplementary cooling infrastructure.

The end-of-life disposal of quantum computing cooling components presents additional environmental challenges. Specialized materials in vapor chambers and other cooling technologies may contain substances that require careful handling and recycling. Currently, the quantum computing industry lacks standardized recycling protocols for these components.

Looking forward, sustainable cooling solutions for quantum computing will likely involve hybrid approaches combining vapor chambers with other technologies. Research into biodegradable working fluids for vapor chambers and recycling programs for cooling components shows promise for reducing environmental impact. Additionally, locating quantum computing facilities in regions with access to renewable energy and natural cooling resources could significantly reduce their carbon footprint.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!