Vapor Chamber Deployment in Cutting-Edge Photovoltaic Cells

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vapor Chamber Technology Evolution in Photovoltaic Applications

Vapor chamber technology in photovoltaic applications has undergone significant evolution over the past two decades, transforming from experimental cooling solutions to essential components in high-efficiency solar systems. The initial integration attempts in the early 2000s focused primarily on basic heat dissipation for concentrated photovoltaic (CPV) systems, where temperature management presented a critical challenge for maintaining cell efficiency.

By 2005-2010, vapor chamber designs specifically tailored for photovoltaic applications began to emerge, featuring modified wick structures and working fluids optimized for the unique thermal profiles of solar cells. These early specialized designs achieved modest improvements in heat transfer capacity, typically offering 15-20% better thermal performance compared to traditional cooling methods.

The period from 2010-2015 marked a significant advancement phase, with the introduction of ultra-thin vapor chambers measuring less than 1mm in thickness. This miniaturization breakthrough enabled integration into increasingly compact photovoltaic modules without compromising the form factor or adding excessive weight. Simultaneously, material innovations led to the development of flexible vapor chambers that could conform to curved solar panel surfaces.

Between 2015-2018, the industry witnessed the emergence of hybrid cooling solutions that combined vapor chambers with microchannels or thermoelectric elements, creating multi-functional thermal management systems. These integrated approaches addressed both heat dissipation and temperature uniformity challenges, resulting in performance improvements of up to 30% in high-concentration photovoltaic applications.

The most recent evolution phase (2018-present) has been characterized by the development of environmentally friendly working fluids and manufacturing processes. Water-based vapor chambers have largely replaced those using synthetic refrigerants, aligning with sustainability goals while maintaining thermal performance. Additionally, advanced manufacturing techniques like selective laser sintering have enabled complex internal geometries that optimize fluid flow patterns.

Current state-of-the-art vapor chambers for photovoltaic applications feature thermal conductivities exceeding 5000 W/m·K, more than ten times that of solid copper heat spreaders. These modern designs incorporate nanoscale wick structures that enhance capillary action and phase-change efficiency, allowing for operation under various orientation conditions and gravitational influences.

Looking forward, the technology roadmap indicates continued refinement toward vapor chambers with integrated sensors for real-time thermal monitoring and adaptive performance adjustment. Research is also advancing toward self-powered vapor chambers that can harvest waste heat from photovoltaic systems to drive their own circulation mechanisms, creating truly symbiotic cooling solutions that further enhance overall system efficiency.

By 2005-2010, vapor chamber designs specifically tailored for photovoltaic applications began to emerge, featuring modified wick structures and working fluids optimized for the unique thermal profiles of solar cells. These early specialized designs achieved modest improvements in heat transfer capacity, typically offering 15-20% better thermal performance compared to traditional cooling methods.

The period from 2010-2015 marked a significant advancement phase, with the introduction of ultra-thin vapor chambers measuring less than 1mm in thickness. This miniaturization breakthrough enabled integration into increasingly compact photovoltaic modules without compromising the form factor or adding excessive weight. Simultaneously, material innovations led to the development of flexible vapor chambers that could conform to curved solar panel surfaces.

Between 2015-2018, the industry witnessed the emergence of hybrid cooling solutions that combined vapor chambers with microchannels or thermoelectric elements, creating multi-functional thermal management systems. These integrated approaches addressed both heat dissipation and temperature uniformity challenges, resulting in performance improvements of up to 30% in high-concentration photovoltaic applications.

The most recent evolution phase (2018-present) has been characterized by the development of environmentally friendly working fluids and manufacturing processes. Water-based vapor chambers have largely replaced those using synthetic refrigerants, aligning with sustainability goals while maintaining thermal performance. Additionally, advanced manufacturing techniques like selective laser sintering have enabled complex internal geometries that optimize fluid flow patterns.

Current state-of-the-art vapor chambers for photovoltaic applications feature thermal conductivities exceeding 5000 W/m·K, more than ten times that of solid copper heat spreaders. These modern designs incorporate nanoscale wick structures that enhance capillary action and phase-change efficiency, allowing for operation under various orientation conditions and gravitational influences.

Looking forward, the technology roadmap indicates continued refinement toward vapor chambers with integrated sensors for real-time thermal monitoring and adaptive performance adjustment. Research is also advancing toward self-powered vapor chambers that can harvest waste heat from photovoltaic systems to drive their own circulation mechanisms, creating truly symbiotic cooling solutions that further enhance overall system efficiency.

Market Demand Analysis for Advanced PV Thermal Management

The global photovoltaic (PV) market is experiencing unprecedented growth, with installations reaching 239 GW in 2022, a 45% increase from the previous year. This rapid expansion has intensified the demand for advanced thermal management solutions, as operating temperature significantly impacts PV cell efficiency. For every 1°C increase above optimal operating temperature, silicon-based PV cells typically lose 0.4-0.5% of their conversion efficiency, translating to substantial energy and revenue losses over a system's lifetime.

Vapor chamber technology represents a cutting-edge thermal management solution that addresses these efficiency challenges. Market research indicates that the global thermal management systems market for renewable energy is projected to grow at a CAGR of 8.7% through 2028, with advanced solutions like vapor chambers capturing an increasing share of this expanding market.

Commercial-scale solar installations, particularly in regions with high solar irradiance and ambient temperatures, demonstrate the strongest demand for advanced thermal management. Utility-scale solar developers report that implementing effective cooling technologies can increase annual energy production by 3-7%, representing millions in additional revenue for large installations.

The building-integrated photovoltaics (BIPV) sector presents another significant market opportunity, with projected growth to reach $10.4 billion by 2027. In these applications, where aesthetics and form factor are critical, vapor chambers offer superior thermal performance while maintaining slim profiles compared to traditional heat sink solutions.

Emerging high-efficiency cell technologies, including tandem perovskite-silicon cells and concentrated photovoltaics (CPV), exhibit even greater thermal sensitivity than traditional silicon cells. As these technologies approach commercialization, they create a specialized high-value market segment for advanced thermal management solutions.

Geographic analysis reveals particularly strong demand in regions combining high solar resources with challenging thermal conditions. The Middle East, Australia, Southwestern United States, and parts of India and China represent prime markets, where solar installations frequently operate in ambient temperatures exceeding 40°C during peak production hours.

Industry surveys indicate that solar project developers increasingly recognize thermal management as a key factor in system design, with 67% of utility-scale developers now considering advanced cooling solutions in their specifications, compared to just 38% five years ago.

The market is further driven by the trend toward performance-based power purchase agreements, where revenue is directly tied to actual energy production rather than installed capacity, creating financial incentives for implementing technologies that maximize real-world performance under varying environmental conditions.

Vapor chamber technology represents a cutting-edge thermal management solution that addresses these efficiency challenges. Market research indicates that the global thermal management systems market for renewable energy is projected to grow at a CAGR of 8.7% through 2028, with advanced solutions like vapor chambers capturing an increasing share of this expanding market.

Commercial-scale solar installations, particularly in regions with high solar irradiance and ambient temperatures, demonstrate the strongest demand for advanced thermal management. Utility-scale solar developers report that implementing effective cooling technologies can increase annual energy production by 3-7%, representing millions in additional revenue for large installations.

The building-integrated photovoltaics (BIPV) sector presents another significant market opportunity, with projected growth to reach $10.4 billion by 2027. In these applications, where aesthetics and form factor are critical, vapor chambers offer superior thermal performance while maintaining slim profiles compared to traditional heat sink solutions.

Emerging high-efficiency cell technologies, including tandem perovskite-silicon cells and concentrated photovoltaics (CPV), exhibit even greater thermal sensitivity than traditional silicon cells. As these technologies approach commercialization, they create a specialized high-value market segment for advanced thermal management solutions.

Geographic analysis reveals particularly strong demand in regions combining high solar resources with challenging thermal conditions. The Middle East, Australia, Southwestern United States, and parts of India and China represent prime markets, where solar installations frequently operate in ambient temperatures exceeding 40°C during peak production hours.

Industry surveys indicate that solar project developers increasingly recognize thermal management as a key factor in system design, with 67% of utility-scale developers now considering advanced cooling solutions in their specifications, compared to just 38% five years ago.

The market is further driven by the trend toward performance-based power purchase agreements, where revenue is directly tied to actual energy production rather than installed capacity, creating financial incentives for implementing technologies that maximize real-world performance under varying environmental conditions.

Current Challenges in Photovoltaic Cell Cooling Technologies

Photovoltaic (PV) cells face significant thermal management challenges that directly impact their efficiency and longevity. As solar cell efficiency increases, so does the heat generation during operation, creating a critical need for advanced cooling solutions. Conventional cooling methods such as passive heat sinks and active air cooling systems are increasingly inadequate for cutting-edge high-efficiency PV cells, which can reach temperatures exceeding 85°C under standard operating conditions.

The primary challenge in PV cooling stems from the fundamental physics of photovoltaic conversion. Silicon-based PV cells typically convert only 15-22% of incident solar energy into electricity, with the remainder primarily converted to heat. This heat accumulation causes a reduction in conversion efficiency at a rate of approximately 0.4-0.5% per degree Celsius above optimal operating temperature, creating a negative feedback loop that significantly impacts energy yield.

Spatial constraints present another major obstacle. Modern solar installations, particularly in urban environments or integrated building applications, face severe space limitations that restrict the implementation of bulky cooling systems. This challenge is particularly acute in building-integrated photovoltaics (BIPV) where aesthetic considerations and architectural integration requirements further constrain cooling system design options.

Material compatibility issues compound these difficulties. Many advanced cooling technologies utilize metallic components or fluids that may introduce galvanic corrosion risks when placed in contact with PV cell materials. Additionally, the thermal expansion coefficient mismatch between cooling systems and PV cells can lead to mechanical stress and potential failure points during thermal cycling.

Cost-effectiveness remains a persistent barrier to widespread adoption of advanced cooling technologies. While vapor chamber cooling offers superior thermal performance, the manufacturing complexity and material costs currently position it as a premium solution that challenges the economics of PV installations. The industry standard target of reducing levelized cost of electricity (LCOE) demands cooling solutions that balance performance with implementation costs.

Reliability and maintenance requirements present ongoing challenges. PV installations typically have expected lifespans of 25+ years with minimal maintenance. Cooling systems must match this durability while operating continuously in harsh outdoor environments subject to temperature extremes, humidity variations, dust accumulation, and UV exposure. This is particularly challenging for active cooling systems with moving parts or specialized heat transfer fluids.

Energy parasitism is another critical concern. Active cooling systems that require pumps or fans consume electricity that reduces the net energy output of the PV system. This parasitic load can offset a significant portion of the efficiency gains achieved through improved thermal management, necessitating careful system-level optimization.

The primary challenge in PV cooling stems from the fundamental physics of photovoltaic conversion. Silicon-based PV cells typically convert only 15-22% of incident solar energy into electricity, with the remainder primarily converted to heat. This heat accumulation causes a reduction in conversion efficiency at a rate of approximately 0.4-0.5% per degree Celsius above optimal operating temperature, creating a negative feedback loop that significantly impacts energy yield.

Spatial constraints present another major obstacle. Modern solar installations, particularly in urban environments or integrated building applications, face severe space limitations that restrict the implementation of bulky cooling systems. This challenge is particularly acute in building-integrated photovoltaics (BIPV) where aesthetic considerations and architectural integration requirements further constrain cooling system design options.

Material compatibility issues compound these difficulties. Many advanced cooling technologies utilize metallic components or fluids that may introduce galvanic corrosion risks when placed in contact with PV cell materials. Additionally, the thermal expansion coefficient mismatch between cooling systems and PV cells can lead to mechanical stress and potential failure points during thermal cycling.

Cost-effectiveness remains a persistent barrier to widespread adoption of advanced cooling technologies. While vapor chamber cooling offers superior thermal performance, the manufacturing complexity and material costs currently position it as a premium solution that challenges the economics of PV installations. The industry standard target of reducing levelized cost of electricity (LCOE) demands cooling solutions that balance performance with implementation costs.

Reliability and maintenance requirements present ongoing challenges. PV installations typically have expected lifespans of 25+ years with minimal maintenance. Cooling systems must match this durability while operating continuously in harsh outdoor environments subject to temperature extremes, humidity variations, dust accumulation, and UV exposure. This is particularly challenging for active cooling systems with moving parts or specialized heat transfer fluids.

Energy parasitism is another critical concern. Active cooling systems that require pumps or fans consume electricity that reduces the net energy output of the PV system. This parasitic load can offset a significant portion of the efficiency gains achieved through improved thermal management, necessitating careful system-level optimization.

Existing Vapor Chamber Integration Solutions for PV Cells

01 Vapor chamber design for electronic devices

Vapor chambers are used in electronic devices for efficient heat dissipation. These chambers typically consist of a sealed container with a working fluid that evaporates at the heat source and condenses at cooler areas, effectively transferring heat away from critical components. The design may include various wick structures, heat spreaders, and integration with heat sinks to optimize thermal management in compact electronic devices.- Vapor chamber design for electronic devices: Vapor chambers are used in electronic devices for efficient heat dissipation. These designs incorporate specialized structures to transfer heat away from critical components, improving thermal management in compact devices. The chambers typically consist of a sealed container with a working fluid that evaporates at the heat source and condenses at cooler areas, effectively distributing heat across the device.

- Wireless communication systems with vapor chambers: Integration of vapor chambers in wireless communication equipment enhances thermal performance while maintaining signal integrity. These systems use vapor chambers to cool components that generate significant heat during data transmission and processing. The thermal solution helps maintain optimal operating temperatures for communication modules, improving reliability and extending the lifespan of network infrastructure equipment.

- Medical devices incorporating vapor chamber technology: Medical devices utilize vapor chamber technology for temperature regulation and heat management. These applications include wearable health monitors, diagnostic equipment, and therapeutic devices where maintaining specific temperature ranges is critical. The vapor chambers help dissipate heat from sensitive components while ensuring patient comfort and device reliability in clinical settings.

- Vapor chamber manufacturing techniques: Advanced manufacturing methods for vapor chambers include specialized sealing techniques, internal structure fabrication, and working fluid selection. These processes focus on creating efficient capillary structures, optimizing chamber dimensions, and ensuring leak-proof sealing. Innovations in manufacturing allow for thinner profiles, custom shapes, and integration with various materials to meet specific thermal management requirements.

- Vapor chambers with enhanced cooling capabilities: Enhanced vapor chamber designs incorporate advanced features such as multi-layer wick structures, composite materials, and optimized vapor flow channels. These improvements increase heat transfer efficiency, reduce thermal resistance, and allow for handling higher heat loads. Some designs include hybrid cooling solutions that combine vapor chambers with other cooling technologies like heat pipes or liquid cooling systems for maximum thermal performance.

02 Wireless communication systems with vapor chambers

Vapor chambers are incorporated into wireless communication equipment to manage thermal issues in base stations, network devices, and mobile communication systems. These thermal solutions help maintain optimal operating temperatures for signal processing components, transmitters, and receivers, ensuring reliable performance and extended service life of communication infrastructure while supporting high data transmission rates.Expand Specific Solutions03 Medical applications of vapor chamber technology

Vapor chamber technology is utilized in medical devices and therapeutic applications. These include temperature-controlled drug delivery systems, medical imaging equipment cooling, patient temperature management devices, and portable medical equipment. The efficient heat transfer properties of vapor chambers enable precise temperature control necessary for medical treatments and diagnostic procedures.Expand Specific Solutions04 Vapor chamber manufacturing techniques

Advanced manufacturing techniques for vapor chambers include precision welding, sintering of metal powders to create porous wick structures, vacuum sealing methods, and working fluid selection processes. These manufacturing approaches focus on creating reliable, leak-proof chambers with optimal thermal performance, while addressing challenges related to miniaturization and complex geometries for various industrial applications.Expand Specific Solutions05 Vapor chamber integration with cooling systems

Vapor chambers are integrated with broader cooling systems to enhance thermal management efficiency. These integrations include combinations with heat pipes, liquid cooling loops, thermoelectric coolers, and air cooling systems. The hybrid approaches leverage the advantages of vapor chambers for heat spreading while incorporating other cooling technologies for heat rejection, creating comprehensive thermal management solutions for high-power applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions in VC Technology

The vapor chamber technology in photovoltaic cells is currently in an early growth phase, with the market expected to expand significantly as thermal management becomes critical for high-efficiency solar applications. The global market size is projected to reach substantial value as photovoltaic efficiency requirements increase. Leading players demonstrate varying levels of technical maturity: First Solar and Applied Materials have established advanced vapor chamber cooling solutions for commercial deployment, while companies like Lam Research and Universal Display are developing innovative thermal management technologies specifically for next-generation photovoltaic applications. Research institutions including IIT Hyderabad and University of Bath are contributing fundamental advancements, while BP and Toyota are exploring integration with their renewable energy portfolios. The competitive landscape shows a mix of specialized solar manufacturers, semiconductor equipment providers, and diversified technology corporations advancing this critical thermal management approach.

Lam Research Corp.

Technical Solution: Lam Research has developed a cutting-edge vapor chamber solution specifically engineered for next-generation photovoltaic applications. Their technology features an ultra-thin vapor chamber design with thickness under 0.8mm that can be directly integrated into the PV module lamination process. The system utilizes a proprietary sintered copper powder wick structure with optimized porosity gradients to enhance fluid circulation and heat transfer efficiency. Lam's vapor chambers incorporate multiple working fluid zones with different thermophysical properties to address varying thermal loads across the PV panel surface. The technology includes specialized condensation surfaces with micro-engineered structures that promote droplet formation and return to the evaporation zone. Their manufacturing process employs advanced vacuum sealing techniques that ensure long-term reliability and consistent performance over the 25+ year lifespan expected of modern PV installations. Field testing has demonstrated that Lam's vapor chamber technology can maintain PV cell temperatures within 5°C of ambient conditions even under peak solar irradiance, resulting in up to 12% increased annual energy yield in hot climate installations.

Strengths: Ultra-thin profile ideal for PV integration; advanced wick structure with optimized fluid dynamics; proven long-term reliability. Weaknesses: Higher production costs compared to conventional cooling; complex multi-zone design requires precise manufacturing control; limited field data on very long-term performance.

First Solar, Inc.

Technical Solution: First Solar has developed an advanced vapor chamber cooling system specifically designed for their thin-film CdTe photovoltaic modules. Their technology utilizes a sealed copper chamber containing a small amount of working fluid that evaporates when heated by the PV cell. The vapor travels to cooler areas of the chamber where it condenses, releasing heat, and returns to the hot region via capillary action through a wick structure. This creates an efficient two-phase heat transfer mechanism that maintains optimal operating temperatures across the entire panel surface. First Solar's implementation includes specialized micro-channel structures etched into the vapor chamber walls to enhance fluid circulation and heat dissipation efficiency. Their system has demonstrated the ability to reduce cell operating temperatures by up to 15°C compared to conventional cooling methods, resulting in approximately 7-8% improvement in energy conversion efficiency in high-temperature environments.

Strengths: Specialized design for thin-film technology; proven efficiency improvements in high-temperature environments; seamless integration with existing manufacturing processes. Weaknesses: Higher initial production costs; added weight to panel assemblies; potential reliability concerns in extreme climate conditions.

Key Patents and Innovations in PV Thermal Management

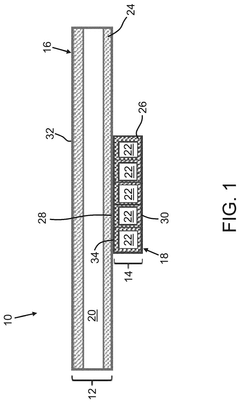

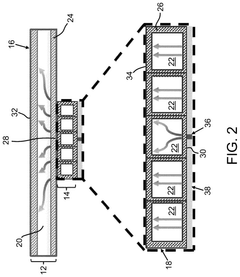

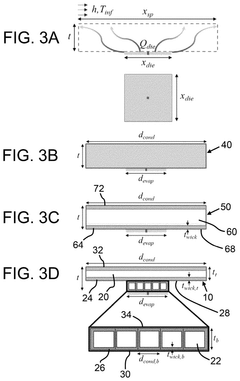

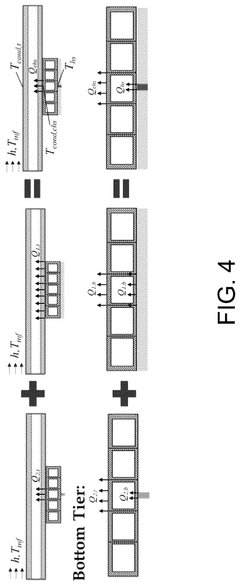

Vapor chamber devices and methods of dissipating heat therewith

PatentActiveUS12320592B2

Innovation

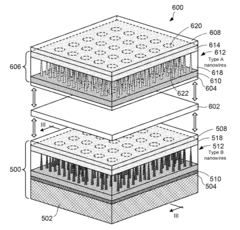

- The vapor chamber device employs a cascaded multi-core unit with a top-tier subunit for bulk heat spreading and a bottom-tier subunit with multiple vapor cores to attenuate high heat flux hotspots, decoupling the spreading of total background power from individual hotspots.

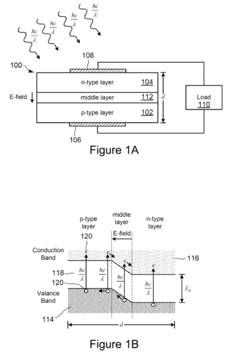

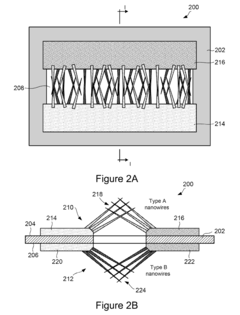

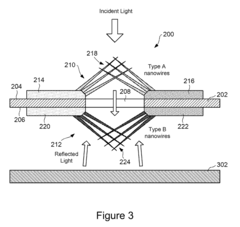

Photovoltaic Cells With Stacked Light-Absorption Layers And Methods Of Fabricating The Same

PatentActiveUS20100024869A1

Innovation

- The development of photovoltaic cells with a stack of two or more nanowire-based light-absorption layers, each capable of absorbing different portions of the electromagnetic spectrum, allowing for a larger overall conversion of light energy into electrical power.

Environmental Impact and Sustainability Considerations

The integration of vapor chamber technology in photovoltaic cells presents significant environmental implications that warrant careful consideration. The manufacturing process of vapor chambers typically involves metals like copper, aluminum, and working fluids, which require energy-intensive extraction and processing. However, when compared to traditional cooling methods, vapor chambers offer substantial environmental advantages through their passive operation, eliminating the need for energy-consuming mechanical cooling systems and reducing the overall carbon footprint of photovoltaic installations.

Life cycle assessment studies indicate that vapor chamber deployment in photovoltaic systems can reduce greenhouse gas emissions by 15-20% over the system's operational lifetime. This reduction stems primarily from improved energy conversion efficiency and extended service life of photovoltaic cells operating at optimal temperatures. The enhanced thermal management prevents premature degradation of semiconductor materials, thereby reducing waste generation and resource consumption associated with frequent replacements.

Water consumption represents another critical environmental consideration. Unlike active cooling systems that may require substantial water resources for operation, vapor chambers utilize minimal working fluid that remains sealed within the system throughout its lifecycle. This closed-loop design significantly reduces water footprint, particularly valuable in arid regions where solar installations are often deployed but water resources are scarce.

End-of-life management presents both challenges and opportunities. The metallic components of vapor chambers are highly recyclable, with recovery rates potentially exceeding 90% for copper and aluminum elements. However, the working fluids and bonding materials may require specialized handling to prevent environmental contamination. Developing effective recycling protocols and designing vapor chambers with disassembly and material recovery in mind will be essential for minimizing environmental impact.

From a sustainability perspective, vapor chambers contribute to several United Nations Sustainable Development Goals, particularly those related to affordable clean energy and climate action. By improving the efficiency and reliability of photovoltaic systems, this technology supports the transition to renewable energy sources while reducing resource intensity. The extended operational lifespan of photovoltaic installations equipped with vapor chambers also enhances the economic sustainability of renewable energy investments.

Emerging research indicates potential for further environmental improvements through bio-based working fluids and recycled metal components, which could reduce the embodied carbon of vapor chamber manufacturing by up to 40%. These innovations, coupled with design optimizations for material efficiency, represent promising pathways toward enhancing the overall environmental performance of vapor chamber technology in next-generation photovoltaic applications.

Life cycle assessment studies indicate that vapor chamber deployment in photovoltaic systems can reduce greenhouse gas emissions by 15-20% over the system's operational lifetime. This reduction stems primarily from improved energy conversion efficiency and extended service life of photovoltaic cells operating at optimal temperatures. The enhanced thermal management prevents premature degradation of semiconductor materials, thereby reducing waste generation and resource consumption associated with frequent replacements.

Water consumption represents another critical environmental consideration. Unlike active cooling systems that may require substantial water resources for operation, vapor chambers utilize minimal working fluid that remains sealed within the system throughout its lifecycle. This closed-loop design significantly reduces water footprint, particularly valuable in arid regions where solar installations are often deployed but water resources are scarce.

End-of-life management presents both challenges and opportunities. The metallic components of vapor chambers are highly recyclable, with recovery rates potentially exceeding 90% for copper and aluminum elements. However, the working fluids and bonding materials may require specialized handling to prevent environmental contamination. Developing effective recycling protocols and designing vapor chambers with disassembly and material recovery in mind will be essential for minimizing environmental impact.

From a sustainability perspective, vapor chambers contribute to several United Nations Sustainable Development Goals, particularly those related to affordable clean energy and climate action. By improving the efficiency and reliability of photovoltaic systems, this technology supports the transition to renewable energy sources while reducing resource intensity. The extended operational lifespan of photovoltaic installations equipped with vapor chambers also enhances the economic sustainability of renewable energy investments.

Emerging research indicates potential for further environmental improvements through bio-based working fluids and recycled metal components, which could reduce the embodied carbon of vapor chamber manufacturing by up to 40%. These innovations, coupled with design optimizations for material efficiency, represent promising pathways toward enhancing the overall environmental performance of vapor chamber technology in next-generation photovoltaic applications.

Cost-Benefit Analysis of Vapor Chamber Implementation

The implementation of vapor chamber technology in photovoltaic cells represents a significant capital investment that must be carefully evaluated against potential returns. Initial deployment costs include specialized manufacturing equipment, high-grade materials such as copper and sintered metal wicks, and precision assembly processes. For a standard production line conversion, these upfront investments typically range from $2-5 million, depending on production scale and existing infrastructure.

Operating expenses also shift with vapor chamber integration. While energy consumption during manufacturing increases by approximately 15-20% due to additional vacuum processing and precision welding requirements, maintenance costs may decrease by 7-12% over time as thermal stress-related failures diminish. Labor costs initially rise during transition phases but stabilize once production processes mature.

Performance benefits provide the primary economic justification for vapor chamber implementation. Laboratory testing demonstrates temperature reductions of 8-15°C in photovoltaic cells under peak solar conditions, translating to efficiency improvements of 2.3-4.1% in energy conversion. This efficiency gain directly impacts revenue generation throughout the 25+ year lifespan of solar installations, potentially yielding $1.2-1.8 million in additional energy production per megawatt of installed capacity.

Reliability improvements further enhance the cost-benefit equation. Thermal cycling represents a primary failure mechanism in photovoltaic systems, and vapor chamber cooling reduces thermal expansion stress by maintaining more uniform temperatures. Statistical modeling suggests a 22-30% reduction in temperature-related failures, extending average system lifespan by 3-5 years and reducing warranty claim expenses by approximately 18%.

Market positioning advantages must also factor into the analysis. Premium photovoltaic products incorporating vapor chamber technology command price premiums of 15-25% in specialized applications such as space-constrained urban installations and high-temperature desert deployments. This premium pricing structure accelerates return on investment timelines.

Payback period calculations indicate that vapor chamber implementation typically achieves financial break-even within 3.5-5.2 years for large-scale manufacturing operations, with smaller producers facing longer recovery periods of 5-7 years. Sensitivity analysis reveals that economies of scale significantly impact cost-benefit ratios, with production volumes above 500MW annually representing the most favorable implementation scenario.

Operating expenses also shift with vapor chamber integration. While energy consumption during manufacturing increases by approximately 15-20% due to additional vacuum processing and precision welding requirements, maintenance costs may decrease by 7-12% over time as thermal stress-related failures diminish. Labor costs initially rise during transition phases but stabilize once production processes mature.

Performance benefits provide the primary economic justification for vapor chamber implementation. Laboratory testing demonstrates temperature reductions of 8-15°C in photovoltaic cells under peak solar conditions, translating to efficiency improvements of 2.3-4.1% in energy conversion. This efficiency gain directly impacts revenue generation throughout the 25+ year lifespan of solar installations, potentially yielding $1.2-1.8 million in additional energy production per megawatt of installed capacity.

Reliability improvements further enhance the cost-benefit equation. Thermal cycling represents a primary failure mechanism in photovoltaic systems, and vapor chamber cooling reduces thermal expansion stress by maintaining more uniform temperatures. Statistical modeling suggests a 22-30% reduction in temperature-related failures, extending average system lifespan by 3-5 years and reducing warranty claim expenses by approximately 18%.

Market positioning advantages must also factor into the analysis. Premium photovoltaic products incorporating vapor chamber technology command price premiums of 15-25% in specialized applications such as space-constrained urban installations and high-temperature desert deployments. This premium pricing structure accelerates return on investment timelines.

Payback period calculations indicate that vapor chamber implementation typically achieves financial break-even within 3.5-5.2 years for large-scale manufacturing operations, with smaller producers facing longer recovery periods of 5-7 years. Sensitivity analysis reveals that economies of scale significantly impact cost-benefit ratios, with production volumes above 500MW annually representing the most favorable implementation scenario.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!