Zero-emissions transportation with fully electric PMSM systems

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Evolution and Goals

Permanent Magnet Synchronous Motors (PMSMs) have emerged as a cornerstone technology in the pursuit of zero-emissions transportation. The evolution of PMSMs can be traced back to the early 20th century, with significant advancements occurring in the latter half of the century. Initially developed for industrial applications, PMSMs have since found their way into various sectors, with transportation being a key focus area in recent decades.

The primary goal driving PMSM development in the context of zero-emissions transportation is to achieve high efficiency, power density, and reliability while minimizing environmental impact. This aligns with the broader objective of creating sustainable and eco-friendly transportation solutions. As global concerns about climate change and air pollution intensify, the automotive industry has been compelled to shift towards electrification, with PMSMs playing a crucial role in this transition.

In the evolution of PMSMs, several key milestones have shaped their current state. The introduction of rare-earth permanent magnets in the 1980s significantly boosted motor performance, enabling higher torque and power output. Subsequent advancements in power electronics and control systems further enhanced PMSM efficiency and controllability, making them increasingly suitable for electric vehicle applications.

The goals for PMSM technology in zero-emissions transportation are multifaceted. One primary objective is to improve energy efficiency, reducing energy losses and extending the range of electric vehicles. This involves optimizing motor design, enhancing magnetic materials, and refining control algorithms. Another crucial goal is to increase power density, allowing for more compact and lightweight motor designs that can deliver higher performance without compromising vehicle design or payload capacity.

Durability and reliability remain critical objectives in PMSM development. As electric vehicles become more prevalent, ensuring long-term performance and minimizing maintenance requirements are essential for widespread adoption. This includes addressing challenges such as thermal management, vibration resistance, and protection against environmental factors.

Cost reduction is another significant goal in PMSM evolution. As the technology matures, efforts are being made to optimize manufacturing processes, explore alternative materials, and increase production scalability. These initiatives aim to make electric vehicles more affordable and accessible to a broader consumer base, accelerating the transition to zero-emissions transportation.

Looking ahead, the future goals for PMSMs in zero-emissions transportation include further advancements in materials science, such as the development of high-performance magnets with reduced reliance on rare-earth elements. Additionally, there is a focus on integrating PMSMs with advanced power electronics and intelligent control systems to create more efficient and responsive drivetrain solutions. The ultimate aim is to establish PMSMs as the dominant propulsion technology in electric vehicles, supporting the global shift towards sustainable transportation and contributing to the reduction of greenhouse gas emissions.

The primary goal driving PMSM development in the context of zero-emissions transportation is to achieve high efficiency, power density, and reliability while minimizing environmental impact. This aligns with the broader objective of creating sustainable and eco-friendly transportation solutions. As global concerns about climate change and air pollution intensify, the automotive industry has been compelled to shift towards electrification, with PMSMs playing a crucial role in this transition.

In the evolution of PMSMs, several key milestones have shaped their current state. The introduction of rare-earth permanent magnets in the 1980s significantly boosted motor performance, enabling higher torque and power output. Subsequent advancements in power electronics and control systems further enhanced PMSM efficiency and controllability, making them increasingly suitable for electric vehicle applications.

The goals for PMSM technology in zero-emissions transportation are multifaceted. One primary objective is to improve energy efficiency, reducing energy losses and extending the range of electric vehicles. This involves optimizing motor design, enhancing magnetic materials, and refining control algorithms. Another crucial goal is to increase power density, allowing for more compact and lightweight motor designs that can deliver higher performance without compromising vehicle design or payload capacity.

Durability and reliability remain critical objectives in PMSM development. As electric vehicles become more prevalent, ensuring long-term performance and minimizing maintenance requirements are essential for widespread adoption. This includes addressing challenges such as thermal management, vibration resistance, and protection against environmental factors.

Cost reduction is another significant goal in PMSM evolution. As the technology matures, efforts are being made to optimize manufacturing processes, explore alternative materials, and increase production scalability. These initiatives aim to make electric vehicles more affordable and accessible to a broader consumer base, accelerating the transition to zero-emissions transportation.

Looking ahead, the future goals for PMSMs in zero-emissions transportation include further advancements in materials science, such as the development of high-performance magnets with reduced reliance on rare-earth elements. Additionally, there is a focus on integrating PMSMs with advanced power electronics and intelligent control systems to create more efficient and responsive drivetrain solutions. The ultimate aim is to establish PMSMs as the dominant propulsion technology in electric vehicles, supporting the global shift towards sustainable transportation and contributing to the reduction of greenhouse gas emissions.

EV Market Demand Analysis

The global electric vehicle (EV) market has experienced unprecedented growth in recent years, driven by increasing environmental concerns, government regulations, and technological advancements. This surge in demand for zero-emissions transportation solutions has created a significant market opportunity for fully electric Permanent Magnet Synchronous Motor (PMSM) systems.

Consumer awareness and preference for environmentally friendly transportation options have risen dramatically. A growing number of consumers are prioritizing sustainability in their purchasing decisions, leading to a shift towards electric vehicles. This trend is particularly evident in urban areas where air quality concerns are more pronounced and charging infrastructure is more readily available.

Government policies and incentives have played a crucial role in stimulating EV market demand. Many countries have implemented stringent emissions regulations and set ambitious targets for phasing out internal combustion engine vehicles. These policies, coupled with financial incentives such as tax credits and subsidies, have made EVs more attractive to consumers and accelerated market adoption.

The automotive industry has responded to this growing demand by investing heavily in electric vehicle technology. Major automakers have announced plans to electrify their vehicle lineups, with some committing to phase out internal combustion engine vehicles entirely within the next decade. This industry-wide shift has further fueled consumer interest and confidence in EV technology.

Advancements in battery technology have addressed many of the early concerns about electric vehicles, such as range anxiety and charging times. Improved energy density, faster charging capabilities, and declining battery costs have made EVs more practical and cost-competitive with traditional vehicles. These technological improvements have expanded the potential market for EVs beyond early adopters to mainstream consumers.

The commercial sector has also shown increasing interest in electric vehicles, particularly for fleet operations. Companies are recognizing the potential for lower operating costs and improved sustainability metrics by transitioning to electric fleets. This trend is especially prominent in delivery services, public transportation, and corporate fleets.

Market analysis indicates that the global EV market is poised for continued growth. Factors such as improving charging infrastructure, decreasing battery costs, and expanding vehicle options are expected to drive further adoption. The market for electric PMSM systems, which are critical components in many EV powertrains, is projected to grow in tandem with the overall EV market.

However, challenges remain in meeting the growing demand for EVs. Supply chain constraints, particularly in battery production and rare earth materials for PMSM systems, could potentially limit growth in the short term. Additionally, the need for widespread charging infrastructure development remains a key factor in supporting mass EV adoption.

Consumer awareness and preference for environmentally friendly transportation options have risen dramatically. A growing number of consumers are prioritizing sustainability in their purchasing decisions, leading to a shift towards electric vehicles. This trend is particularly evident in urban areas where air quality concerns are more pronounced and charging infrastructure is more readily available.

Government policies and incentives have played a crucial role in stimulating EV market demand. Many countries have implemented stringent emissions regulations and set ambitious targets for phasing out internal combustion engine vehicles. These policies, coupled with financial incentives such as tax credits and subsidies, have made EVs more attractive to consumers and accelerated market adoption.

The automotive industry has responded to this growing demand by investing heavily in electric vehicle technology. Major automakers have announced plans to electrify their vehicle lineups, with some committing to phase out internal combustion engine vehicles entirely within the next decade. This industry-wide shift has further fueled consumer interest and confidence in EV technology.

Advancements in battery technology have addressed many of the early concerns about electric vehicles, such as range anxiety and charging times. Improved energy density, faster charging capabilities, and declining battery costs have made EVs more practical and cost-competitive with traditional vehicles. These technological improvements have expanded the potential market for EVs beyond early adopters to mainstream consumers.

The commercial sector has also shown increasing interest in electric vehicles, particularly for fleet operations. Companies are recognizing the potential for lower operating costs and improved sustainability metrics by transitioning to electric fleets. This trend is especially prominent in delivery services, public transportation, and corporate fleets.

Market analysis indicates that the global EV market is poised for continued growth. Factors such as improving charging infrastructure, decreasing battery costs, and expanding vehicle options are expected to drive further adoption. The market for electric PMSM systems, which are critical components in many EV powertrains, is projected to grow in tandem with the overall EV market.

However, challenges remain in meeting the growing demand for EVs. Supply chain constraints, particularly in battery production and rare earth materials for PMSM systems, could potentially limit growth in the short term. Additionally, the need for widespread charging infrastructure development remains a key factor in supporting mass EV adoption.

PMSM Tech Challenges

Permanent Magnet Synchronous Motors (PMSMs) have emerged as a promising technology for zero-emissions transportation systems. However, their widespread adoption faces several technical challenges that need to be addressed to fully realize their potential in electric vehicle applications.

One of the primary challenges is the optimization of motor efficiency across a wide range of operating conditions. PMSMs exhibit high efficiency at their nominal operating point, but maintaining this efficiency throughout various driving scenarios, including low-speed urban driving and high-speed highway cruising, remains a significant hurdle. This challenge is compounded by the need to balance performance with energy conservation, as the motor's efficiency directly impacts the vehicle's range.

Thermal management presents another critical challenge in PMSM systems. As electric vehicles demand higher power densities, the heat generated by the motor increases substantially. Effective cooling solutions are essential to prevent performance degradation and ensure the longevity of the motor components, particularly the permanent magnets which are sensitive to high temperatures. Innovative cooling techniques, such as oil-spray cooling or advanced liquid cooling systems, are being explored but require further development for optimal integration into vehicle designs.

The control complexity of PMSM systems poses a significant technical challenge. Advanced control algorithms are necessary to maximize torque production, minimize losses, and ensure smooth operation across various driving conditions. Implementing robust sensorless control techniques, which eliminate the need for position sensors, can enhance reliability and reduce system costs but requires sophisticated estimation algorithms and processing power.

Material limitations also present obstacles in PMSM development. The reliance on rare-earth materials for high-performance permanent magnets raises concerns about supply chain stability and environmental impact. Research into alternative magnet materials or motor designs that reduce or eliminate rare-earth content is ongoing but has yet to match the performance of traditional neodymium-based magnets.

Manufacturing and assembly processes for PMSMs require high precision to maintain tight tolerances, particularly in the air gap between the rotor and stator. Achieving consistent quality in mass production while keeping costs competitive is a significant challenge that impacts the scalability of PMSM technology in the automotive industry.

Lastly, the integration of PMSMs with power electronics and battery systems presents system-level challenges. Optimizing the entire powertrain for efficiency, performance, and cost-effectiveness requires a holistic approach, considering factors such as voltage levels, inverter design, and battery characteristics. Achieving seamless integration while meeting stringent automotive reliability and safety standards remains an ongoing challenge for engineers and researchers in the field.

One of the primary challenges is the optimization of motor efficiency across a wide range of operating conditions. PMSMs exhibit high efficiency at their nominal operating point, but maintaining this efficiency throughout various driving scenarios, including low-speed urban driving and high-speed highway cruising, remains a significant hurdle. This challenge is compounded by the need to balance performance with energy conservation, as the motor's efficiency directly impacts the vehicle's range.

Thermal management presents another critical challenge in PMSM systems. As electric vehicles demand higher power densities, the heat generated by the motor increases substantially. Effective cooling solutions are essential to prevent performance degradation and ensure the longevity of the motor components, particularly the permanent magnets which are sensitive to high temperatures. Innovative cooling techniques, such as oil-spray cooling or advanced liquid cooling systems, are being explored but require further development for optimal integration into vehicle designs.

The control complexity of PMSM systems poses a significant technical challenge. Advanced control algorithms are necessary to maximize torque production, minimize losses, and ensure smooth operation across various driving conditions. Implementing robust sensorless control techniques, which eliminate the need for position sensors, can enhance reliability and reduce system costs but requires sophisticated estimation algorithms and processing power.

Material limitations also present obstacles in PMSM development. The reliance on rare-earth materials for high-performance permanent magnets raises concerns about supply chain stability and environmental impact. Research into alternative magnet materials or motor designs that reduce or eliminate rare-earth content is ongoing but has yet to match the performance of traditional neodymium-based magnets.

Manufacturing and assembly processes for PMSMs require high precision to maintain tight tolerances, particularly in the air gap between the rotor and stator. Achieving consistent quality in mass production while keeping costs competitive is a significant challenge that impacts the scalability of PMSM technology in the automotive industry.

Lastly, the integration of PMSMs with power electronics and battery systems presents system-level challenges. Optimizing the entire powertrain for efficiency, performance, and cost-effectiveness requires a holistic approach, considering factors such as voltage levels, inverter design, and battery characteristics. Achieving seamless integration while meeting stringent automotive reliability and safety standards remains an ongoing challenge for engineers and researchers in the field.

Current PMSM Solutions

01 Emission reduction in PMSM systems

Various techniques are employed to reduce emissions in Permanent Magnet Synchronous Motor (PMSM) systems. These may include optimizing motor design, improving control strategies, and implementing advanced materials to enhance efficiency and reduce electromagnetic emissions.- Emission reduction in PMSM systems: Various techniques are employed to reduce emissions in Permanent Magnet Synchronous Motor (PMSM) systems. These may include optimizing motor design, improving control strategies, and implementing advanced materials to enhance efficiency and reduce electromagnetic emissions.

- Electromagnetic compatibility in PMSM systems: Addressing electromagnetic compatibility (EMC) issues in PMSM systems is crucial for reducing emissions. This involves implementing shielding techniques, filtering methods, and optimizing circuit layouts to minimize electromagnetic interference and ensure compliance with EMC standards.

- Thermal management for emission control: Effective thermal management in PMSM systems plays a significant role in controlling emissions. This includes innovative cooling solutions, heat dissipation techniques, and temperature monitoring systems to maintain optimal operating conditions and reduce thermal-related emissions.

- Advanced control algorithms for emission reduction: Implementing sophisticated control algorithms in PMSM systems can significantly reduce emissions. These algorithms may include adaptive control techniques, model predictive control, and intelligent control strategies to optimize motor performance and minimize unwanted emissions across various operating conditions.

- Innovative PMSM designs for low emissions: Novel PMSM designs are being developed to inherently reduce emissions. These may include advancements in rotor and stator configurations, innovative magnet arrangements, and the use of advanced materials to create more efficient and lower-emission motor systems.

02 Electromagnetic compatibility in PMSM

Addressing electromagnetic compatibility (EMC) issues in PMSM systems is crucial for reducing emissions. This involves designing motors and control systems to minimize electromagnetic interference and ensure compliance with EMC standards.Expand Specific Solutions03 Thermal management for emission control

Effective thermal management in PMSM systems can contribute to reduced emissions. This includes innovative cooling techniques and temperature control strategies to maintain optimal operating conditions and minimize thermal-related emissions.Expand Specific Solutions04 Advanced control algorithms for PMSM

Implementing sophisticated control algorithms in PMSM systems can lead to improved performance and reduced emissions. These algorithms may focus on optimizing motor operation, minimizing losses, and enhancing overall system efficiency.Expand Specific Solutions05 Innovative PMSM designs for low emissions

Novel PMSM designs are being developed to inherently reduce emissions. These may include new rotor and stator configurations, advanced magnet arrangements, or the use of innovative materials to minimize electromagnetic and acoustic emissions.Expand Specific Solutions

EV Industry Players

The zero-emissions transportation market with fully electric PMSM systems is in a growth phase, driven by increasing environmental concerns and government regulations. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing quickly but still evolving. Companies like BYD, Hyundai Motor, and CRRC are at the forefront, developing innovative PMSM systems for electric vehicles and trains. Academic institutions such as Zhejiang University and IIT Delhi are contributing to research and development. While established players dominate, new entrants like Beijing Chehejia Automobile Technology are also emerging, indicating a dynamic and competitive landscape.

GM Global Technology Operations LLC

Technical Solution: GM has developed a state-of-the-art PMSM system for their Ultium electric vehicle platform. Their design features a modular approach, allowing for scalability across different vehicle types. GM's PMSM utilizes a patented stator winding configuration that reduces copper losses and improves thermal management[7]. The system incorporates advanced silicon carbide (SiC) power electronics, which enable higher switching frequencies and reduced switching losses, contributing to overall system efficiency[8]. GM has also implemented a sophisticated control strategy that optimizes torque production and minimizes energy consumption across various driving conditions. The Ultium platform's PMSM system achieves a peak efficiency of 98% and maintains high efficiency over a wide operating range[9].

Strengths: Modular design, advanced power electronics, and high system efficiency. Weaknesses: Higher initial costs due to SiC components, potential supply chain challenges for specialized materials.

CRRC Zhuzhou Institute Co., Ltd.

Technical Solution: CRRC Zhuzhou Institute has developed an advanced PMSM system for electric locomotives and urban rail transit vehicles. Their system features a high-power density design with a focus on reliability and efficiency in heavy-duty applications. CRRC's PMSM utilizes a novel rotor construction with optimized magnet arrangements to enhance flux distribution and reduce torque ripple[13]. The company has implemented an advanced control strategy that incorporates real-time adaptive algorithms to optimize performance under varying load conditions. CRRC's electric traction system achieves a power output of up to 1,200 kW per motor and maintains high efficiency across a wide speed range[14]. The system also incorporates regenerative braking capabilities, recovering up to 40% of the vehicle's kinetic energy during deceleration[15].

Strengths: High power output, optimized for heavy-duty applications, and advanced control strategies. Weaknesses: Potentially higher costs due to specialized design for rail applications, limited applicability to smaller electric vehicles.

Key PMSM Innovations

System for controlling a motor of vehicle

PatentActiveUS20120139458A1

Innovation

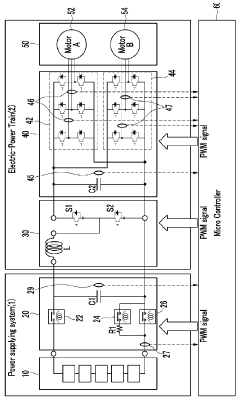

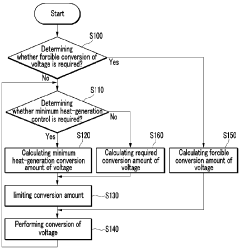

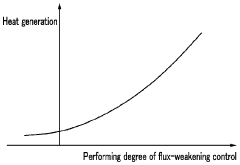

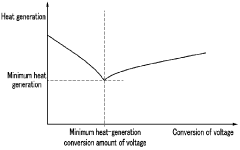

- A motor control system that includes a power source, converter, relay module, inverter module, and controller, which performs minimum heat-generation control by calculating and applying inverter input voltage to minimize heat generated through flux-weakening control and its suppression, using characteristic values related to currents and voltage-converting characteristics.

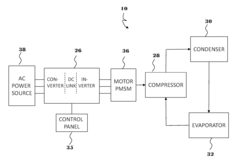

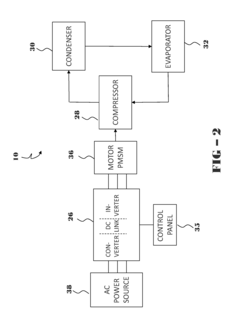

Variable speed drive with pulse-width modulated speed control

PatentActiveUS8336323B2

Innovation

- A variable speed drive system utilizing a converter, DC link, and inverter with a controller applying randomized Pulse-Width Modulation (PWM) to vary the switching frequency of transistors, enabling output AC power with variable voltage and frequency, and powering a PMSM motor.

EV Policy and Regulations

The global shift towards zero-emissions transportation has led to a surge in electric vehicle (EV) adoption, with fully electric Permanent Magnet Synchronous Motor (PMSM) systems playing a crucial role. This transition is heavily influenced by evolving EV policies and regulations worldwide, which are shaping the automotive industry's future.

Governments across the globe are implementing stringent emissions standards and offering incentives to accelerate EV adoption. The European Union, for instance, has set ambitious targets to reduce CO2 emissions from new cars by 37.5% by 2030, compared to 2021 levels. This has prompted automakers to invest heavily in electric powertrain technologies, including PMSM systems.

In the United States, federal tax credits of up to $7,500 for eligible EVs have been extended under the Inflation Reduction Act, with additional state-level incentives further boosting EV sales. China, the world's largest EV market, has implemented a dual-credit policy that rewards automakers for producing low-emission vehicles while penalizing those who fail to meet targets.

Regulatory frameworks are also evolving to address charging infrastructure development. The EU's Alternative Fuels Infrastructure Regulation mandates the installation of charging stations along major highways, while many countries are offering grants and subsidies for home and public charging point installations.

Safety regulations for EVs are becoming increasingly stringent, with a focus on battery safety, electromagnetic compatibility, and cybersecurity. The UN Global Technical Regulation No. 20 on Electric Vehicle Safety sets international standards for battery safety and electrical safety, which manufacturers must adhere to when developing PMSM-based EV systems.

Environmental regulations are extending beyond vehicle emissions to encompass the entire lifecycle of EVs. The EU's proposed Battery Regulation aims to ensure sustainable and ethical sourcing of raw materials, promote circular economy principles in battery production, and establish end-of-life recycling requirements.

As PMSM systems become more prevalent in EVs, policymakers are also addressing the challenges associated with rare earth elements used in these motors. Initiatives to diversify supply chains and promote research into alternative motor technologies are gaining traction, driven by concerns over resource scarcity and geopolitical tensions.

The regulatory landscape for autonomous electric vehicles is rapidly evolving, with countries developing frameworks to enable testing and deployment of self-driving EVs. This intersection of electrification and automation presents new challenges for policymakers in areas such as liability, data privacy, and infrastructure readiness.

Governments across the globe are implementing stringent emissions standards and offering incentives to accelerate EV adoption. The European Union, for instance, has set ambitious targets to reduce CO2 emissions from new cars by 37.5% by 2030, compared to 2021 levels. This has prompted automakers to invest heavily in electric powertrain technologies, including PMSM systems.

In the United States, federal tax credits of up to $7,500 for eligible EVs have been extended under the Inflation Reduction Act, with additional state-level incentives further boosting EV sales. China, the world's largest EV market, has implemented a dual-credit policy that rewards automakers for producing low-emission vehicles while penalizing those who fail to meet targets.

Regulatory frameworks are also evolving to address charging infrastructure development. The EU's Alternative Fuels Infrastructure Regulation mandates the installation of charging stations along major highways, while many countries are offering grants and subsidies for home and public charging point installations.

Safety regulations for EVs are becoming increasingly stringent, with a focus on battery safety, electromagnetic compatibility, and cybersecurity. The UN Global Technical Regulation No. 20 on Electric Vehicle Safety sets international standards for battery safety and electrical safety, which manufacturers must adhere to when developing PMSM-based EV systems.

Environmental regulations are extending beyond vehicle emissions to encompass the entire lifecycle of EVs. The EU's proposed Battery Regulation aims to ensure sustainable and ethical sourcing of raw materials, promote circular economy principles in battery production, and establish end-of-life recycling requirements.

As PMSM systems become more prevalent in EVs, policymakers are also addressing the challenges associated with rare earth elements used in these motors. Initiatives to diversify supply chains and promote research into alternative motor technologies are gaining traction, driven by concerns over resource scarcity and geopolitical tensions.

The regulatory landscape for autonomous electric vehicles is rapidly evolving, with countries developing frameworks to enable testing and deployment of self-driving EVs. This intersection of electrification and automation presents new challenges for policymakers in areas such as liability, data privacy, and infrastructure readiness.

PMSM Efficiency Metrics

Efficiency metrics for Permanent Magnet Synchronous Motors (PMSM) are crucial in evaluating and optimizing the performance of zero-emissions transportation systems. These metrics provide quantitative measures of how effectively the motor converts electrical energy into mechanical energy, and vice versa. The primary efficiency metric for PMSMs is the overall efficiency, typically expressed as a percentage, which represents the ratio of output mechanical power to input electrical power.

Power density is another key metric, measuring the amount of power output per unit volume or weight of the motor. This is particularly important in electric vehicle applications where space and weight constraints are significant. PMSMs generally excel in this aspect, offering high power density compared to other motor types.

Torque density, closely related to power density, measures the torque output per unit volume or weight. This metric is crucial for applications requiring high starting torque or rapid acceleration, such as in electric vehicles. PMSMs are known for their high torque density, contributing to their popularity in automotive applications.

The speed-torque characteristic is an essential efficiency metric that describes the motor's performance across its operating range. It illustrates how torque output varies with motor speed, providing insights into the motor's capabilities at different operating points. This characteristic is particularly important for optimizing motor control strategies and matching the motor to specific application requirements.

Thermal efficiency is another critical metric, indicating how well the motor manages heat generation and dissipation. Efficient thermal management is crucial for maintaining motor performance and longevity, especially in high-power applications like electric vehicles.

The power factor, which measures the ratio of real power to apparent power, is an important efficiency metric for PMSMs. A higher power factor indicates more efficient use of the supplied electrical power, reducing losses in the power electronics and supply system.

Harmonic distortion is a metric that quantifies the deviation of the motor's current and voltage waveforms from ideal sinusoidal shapes. Lower harmonic distortion contributes to improved efficiency and reduced electromagnetic interference.

Finally, the motor constant, which relates torque to the square root of power loss, serves as a useful metric for comparing motor designs. A higher motor constant indicates better overall motor performance and efficiency.

These efficiency metrics collectively provide a comprehensive evaluation of PMSM performance, guiding design optimization and selection for zero-emissions transportation applications. They enable engineers to balance various performance aspects and make informed decisions in developing fully electric PMSM systems for sustainable transportation solutions.

Power density is another key metric, measuring the amount of power output per unit volume or weight of the motor. This is particularly important in electric vehicle applications where space and weight constraints are significant. PMSMs generally excel in this aspect, offering high power density compared to other motor types.

Torque density, closely related to power density, measures the torque output per unit volume or weight. This metric is crucial for applications requiring high starting torque or rapid acceleration, such as in electric vehicles. PMSMs are known for their high torque density, contributing to their popularity in automotive applications.

The speed-torque characteristic is an essential efficiency metric that describes the motor's performance across its operating range. It illustrates how torque output varies with motor speed, providing insights into the motor's capabilities at different operating points. This characteristic is particularly important for optimizing motor control strategies and matching the motor to specific application requirements.

Thermal efficiency is another critical metric, indicating how well the motor manages heat generation and dissipation. Efficient thermal management is crucial for maintaining motor performance and longevity, especially in high-power applications like electric vehicles.

The power factor, which measures the ratio of real power to apparent power, is an important efficiency metric for PMSMs. A higher power factor indicates more efficient use of the supplied electrical power, reducing losses in the power electronics and supply system.

Harmonic distortion is a metric that quantifies the deviation of the motor's current and voltage waveforms from ideal sinusoidal shapes. Lower harmonic distortion contributes to improved efficiency and reduced electromagnetic interference.

Finally, the motor constant, which relates torque to the square root of power loss, serves as a useful metric for comparing motor designs. A higher motor constant indicates better overall motor performance and efficiency.

These efficiency metrics collectively provide a comprehensive evaluation of PMSM performance, guiding design optimization and selection for zero-emissions transportation applications. They enable engineers to balance various performance aspects and make informed decisions in developing fully electric PMSM systems for sustainable transportation solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!