Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer best known by its trade name, Teflon. Renowned for its exceptional thermal resistance, chemical inertness, and non-stick properties, PTFE is widely applied in demanding environments—from aerospace fasteners to biomedical implants. As industries face growing challenges in safety, longevity, and sustainability, PTFE continues to offer a critical edge in materials innovation.

This article explores PTFE’s composition, key properties, diverse applications, comparative advantages, and future directions—supported by real-time patent insights from the PatSnap Eureka AI Agent.

Material Composition & Key Properties

● Structure Origin: PTFE is synthesized from tetrafluoroethylene (TFE) monomers via free-radical polymerization, resulting in a linear chain of –CF₂– units.

● Processing Techniques: Common methods include suspension polymerization for granular products, or emulsion polymerization for fine powders and coatings.

● Key Properties:

- Extremely high chemical resistance

- Excellent thermal stability (up to 260°C continuous)

- Low coefficient of friction (non-stick)

- Exceptional dielectric strength

- Biocompatible and non-toxic

- Resistant to UV, weathering, and moisture

These traits make PTFE ideal for high-performance applications in harsh, corrosive, or sterile environments.

Application Domains

1. Energy Storage & Conversion

From batteries to thermal systems, modern energy infrastructure demands materials that can withstand extreme conditions, offer strong dielectric properties, and provide chemical durability. PTFE delivers exactly that—acting as a thermal barrier, dielectric membrane, and sealing component in energy conversion devices.

Research Highlights:

- Integration into electrolytes for organic batteries

- High-frequency film capacitors with improved flow-conductivity balance

- Barrier layers in hydrogen and methane storage

Related Reports:

- Projecting future PTFE electrolyte applications in organic batteries

- Evaluating conductivity‑flow trade‑offs in PTFE‑film capacitors

- Exploring PTFE film integration into solar concentrator coatings

- Evaluating hybrid PTFE barrier layers for methane hydrate storage

- Forecasting PTFE use in anti‑icing structural coatings for aircraft

- PTFE in Next‑Gen Energy Storage Solutions

- How to Integrate PTFE for Optimal Energy Solutions?

2. Biomedical & Healthcare Applications

Modern healthcare technologies rely on materials that are inert, sterile, and biocompatible. PTFE fits these needs by offering low friction, non-toxicity, and chemical stability, making it suitable for use in implants, dressings, and diagnostic tools.

Research Highlights:

- PTFE–hydrogel composites for wound treatment

- Fluoropolymer coatings in wearable biosensors

- Low-friction coatings for safer surgical implants

Related Reports:

- PTFE Innovations in Medical Biocompatibility

- PTFE: Leading the Way in Advanced Healthcare Solutions

- Investigating PTFE hydrogel blends for wound dressing

- PTFE for Enhanced Protective Clothing

- Exploring PTFE Applications in Green Technology

- How to Harness PTFE for Enhanced Microfluidic Devices?

- Mapping future pathways for PTFE–bioactive surface development

3. Advanced Electronics & Microengineering

The fast-paced world of electronics demands ultra-low dielectric loss, thermal resilience, and design flexibility. PTFE plays a crucial role in insulating high-frequency components, enabling signal precision in microelectronics and flexible devices.

Research Highlights:

- Atmospheric plasma for nano-patterning

- Enhanced transparency and dielectric control for high-frequency circuits

- Integration in microfluidics and sensors

Related Reports:

- Forecasting PTFE film nanostructure effects on next‑gen sensor technology

- Assessing PTFE nano‑patterning via atmospheric plasma for superhydrophobicity

- Examining PTFE cable dielectric enhancement through nano‑dopants

- PTFE Developments in High‑Frequency Electronics

- PTFE and Its Role in Cutting‑Edge Semiconductor Technology

- PTFE’s Impact on Electronic Component Manufacturing

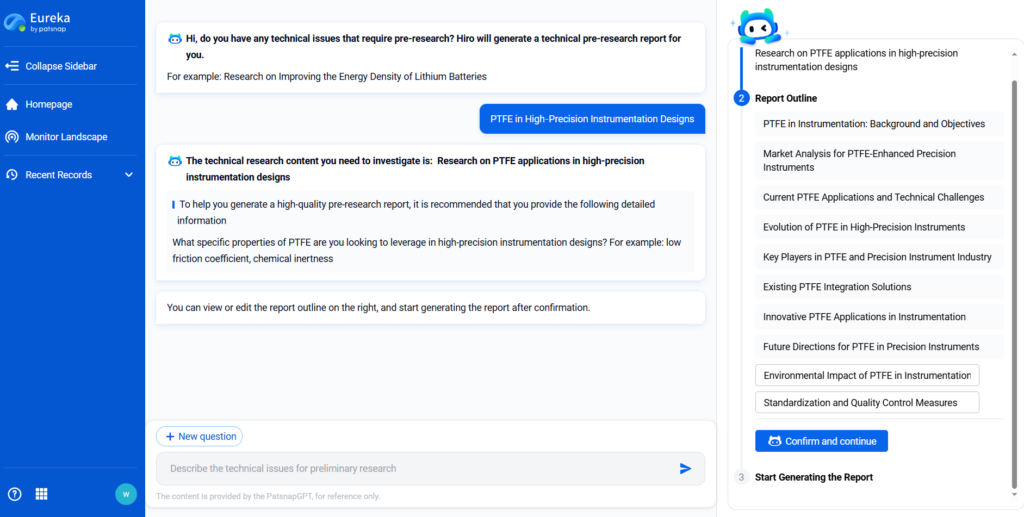

- PTFE in High‑Precision Instrumentation Designs

4. Aerospace, Automotive & Industrial Engineering

Aerospace and industrial applications push materials to their physical and chemical limits. PTFE’s combination of chemical resistance, thermal endurance, and low friction make it an ideal choice for seals, bushings, coatings, and structural parts.

Research Highlights:

- Aerospace-grade thermal barrier coatings

- Enhanced lubrication and anti-stick formulations

- PTFE integration in high-performance sports and industrial gear

Related Reports:

- PTFE in Aerospace Industry: Trends and Innovations

- PTFE’s Role in Lightweight Composite Materials

- PTFE Enhancements in High‑Performance Sports Equipment

- Investigating PTFE thermal barrier coatings for aero‑engine components

- PTFE’s Influence on Modern Lubricant Formulations

- Exploring PTFE–ceramic interfaces for high‑temperature wear protection

- PTFE’s Role in Revolutionizing Surface Engineering

5. Sustainability & Environmental Engineering

Sustainable product design requires materials that resist harsh environments while supporting longer product lifecycles and reducing ecological impact. PTFE meets this challenge with its stability, recyclability potential, and resistance to degradation.

Research Highlights:

- Halogen-free PTFE derivatives

- Biodegradable PTFE composites

- Water and gas filtration in clean energy systems

Related Reports:

- Synthesizing halogen‑free PTFE variants to meet stringent environmental regulations

- Forecasting PTFE biodegradation developments in eco‑designed materials

- PTFE and New‑Age Environmental Solutions

- PTFE in Environmental Plastics: Rethinking Sustainability

- PTFE’s Contribution to Sustainable Manufacturing Practices

- Exploring PTFE’s Influence on Emerging Market Trends

- How to Implement PTFE in Emissions Reduction?

6. Smart Materials, Robotics & Frontier Tech

Smart systems, robotics, and next-gen technologies require materials with multifunctionality, surface precision, and lightweight adaptability. PTFE empowers these innovations with nanoengineered films, lubricious coatings, and low-friction interfaces.

Research Highlights:

- Gel composites in soft robotics

- Surface patterning for droplet manipulation

- High-transparency membranes for optical sensors

Related Reports:

- Assessing PTFE’s role in robotic gripper surface optimization

- Exploring PTFE catalyst use in oxyfluoride synthesis

- Analyzing nanoparticle‑enhanced PTFE gel applications in soft robotics

- Assessing PTFE film transparency improvements for lens overlays

- Forecasting integration of PTFE in foldable antenna substrates

- Exploring the Future of PTFE in 3D Printing Materials

- Exploratory Paths for PTFE in Robotics & AI

Comparative Advantages & Limitations

Advantages:

● Excellent chemical and thermal resistance

● Ultra-low surface energy (non-stick)

● Stable under UV and oxidative conditions

● Biocompatible and FDA-approved for medical uses

● Wide range of processing formats (powder, sheet, dispersion)

Limitations:

● High production costs and energy-intensive synthesis

● Poor adhesion to most substrates without surface treatment

● Limited biodegradability

● Mechanical flexibility is lower than some elastomers

● Environmental regulations on fluorinated compounds tightening

Future Outlook & Research Frontiers

Over the next 5–10 years, PTFE is expected to evolve in tandem with several global megatrends:

● Biodegradable PTFE alternatives for greener materials

● Nano-engineered films with multi-functional surfaces

● Smart PTFE composites for AI-driven robotics

● Integration into hydrogen economy and flexible batteries

● Surface-structured PTFE for biomedical implants

These frontiers will be shaped by ongoing advances in polymer science, manufacturing scalability, and environmental compliance.

Conclusion & Strategic Takeaways

PTFE continues to bridge gaps between performance and durability across sectors. Whether in electric vehicles, surgical tools, or high-speed electronics, its unmatched properties make it a mainstay in advanced materials science.

From industry-grade coatings to flexible electronics, PTFE will remain essential in driving next-generation innovations—particularly as sustainability, reliability, and precision become non-negotiable.

Accelerate Innovation with PatSnap Eureka AI Agent

PTFE’s application landscape is rapidly evolving, driven by global competition and technological convergence. PatSnap Eureka AI Agent empowers researchers and product developers to stay ahead by:

● Mapping innovation trends across 20,000+ PTFE-related patents

● Identifying white-space opportunities and emerging applications

● Benchmarking leading players and technology trajectories

👉 Explore PTFE’s innovation frontier with Eureka. Request a free demo today.