Exploring PTFE Applications in Green Technology

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE in Green Tech: Background and Objectives

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has been a revolutionary material since its accidental discovery in 1938. Its unique properties, including exceptional chemical resistance, low friction, and high thermal stability, have made it indispensable in various industries. As the world increasingly focuses on sustainable development and environmental protection, PTFE's potential applications in green technology have garnered significant attention.

The evolution of PTFE in green technology can be traced back to the early 2000s when environmental concerns began to shape industrial practices. Initially, PTFE was primarily used in non-stick cookware and industrial coatings. However, its inherent properties aligned well with the emerging needs of green technology, prompting researchers and engineers to explore its broader applications in this field.

The primary objective of incorporating PTFE in green technology is to leverage its unique characteristics to enhance the efficiency, durability, and sustainability of various eco-friendly systems and products. This includes improving the performance of renewable energy technologies, enhancing water treatment processes, and developing more sustainable manufacturing methods.

In the renewable energy sector, PTFE has shown promise in improving the efficiency of solar panels and wind turbines. Its low friction properties can reduce wear and tear in moving parts, extending the lifespan of these systems. Additionally, PTFE's resistance to harsh weather conditions makes it an ideal material for protective coatings on outdoor renewable energy installations.

Water treatment is another critical area where PTFE is making significant contributions. Its chemical resistance and non-stick properties make it an excellent material for filtration membranes, capable of removing contaminants from water more effectively than traditional materials. This application is particularly crucial in addressing global water scarcity and pollution issues.

The automotive industry is also exploring PTFE's potential in green technology applications. Its use in fuel cells and electric vehicle components can enhance performance and durability, contributing to the development of more efficient and environmentally friendly transportation solutions.

As we look towards the future, the integration of PTFE in green technology is expected to expand further. Ongoing research aims to develop more sustainable production methods for PTFE itself, addressing concerns about its environmental impact during manufacturing. This includes exploring bio-based alternatives and recycling techniques to create a more circular economy for PTFE products.

The technological trajectory of PTFE in green applications is closely aligned with global sustainability goals. As industries strive to reduce their carbon footprint and improve resource efficiency, PTFE's role in enabling these advancements is likely to grow. The material's versatility and unique properties position it as a key enabler in the transition towards more sustainable and environmentally friendly technologies across various sectors.

The evolution of PTFE in green technology can be traced back to the early 2000s when environmental concerns began to shape industrial practices. Initially, PTFE was primarily used in non-stick cookware and industrial coatings. However, its inherent properties aligned well with the emerging needs of green technology, prompting researchers and engineers to explore its broader applications in this field.

The primary objective of incorporating PTFE in green technology is to leverage its unique characteristics to enhance the efficiency, durability, and sustainability of various eco-friendly systems and products. This includes improving the performance of renewable energy technologies, enhancing water treatment processes, and developing more sustainable manufacturing methods.

In the renewable energy sector, PTFE has shown promise in improving the efficiency of solar panels and wind turbines. Its low friction properties can reduce wear and tear in moving parts, extending the lifespan of these systems. Additionally, PTFE's resistance to harsh weather conditions makes it an ideal material for protective coatings on outdoor renewable energy installations.

Water treatment is another critical area where PTFE is making significant contributions. Its chemical resistance and non-stick properties make it an excellent material for filtration membranes, capable of removing contaminants from water more effectively than traditional materials. This application is particularly crucial in addressing global water scarcity and pollution issues.

The automotive industry is also exploring PTFE's potential in green technology applications. Its use in fuel cells and electric vehicle components can enhance performance and durability, contributing to the development of more efficient and environmentally friendly transportation solutions.

As we look towards the future, the integration of PTFE in green technology is expected to expand further. Ongoing research aims to develop more sustainable production methods for PTFE itself, addressing concerns about its environmental impact during manufacturing. This includes exploring bio-based alternatives and recycling techniques to create a more circular economy for PTFE products.

The technological trajectory of PTFE in green applications is closely aligned with global sustainability goals. As industries strive to reduce their carbon footprint and improve resource efficiency, PTFE's role in enabling these advancements is likely to grow. The material's versatility and unique properties position it as a key enabler in the transition towards more sustainable and environmentally friendly technologies across various sectors.

Market Analysis for Eco-Friendly PTFE Solutions

The market for eco-friendly PTFE solutions is experiencing significant growth, driven by increasing environmental awareness and stringent regulations across industries. PTFE, known for its exceptional chemical resistance and non-stick properties, has traditionally been associated with environmental concerns due to its production process and disposal challenges. However, the demand for sustainable alternatives has spurred innovation in green PTFE technologies.

In the automotive sector, eco-friendly PTFE solutions are gaining traction for applications in fuel systems, engine components, and lubricants. The push for fuel efficiency and reduced emissions has created a substantial market for PTFE-based products that can withstand harsh conditions while minimizing environmental impact. Similarly, the aerospace industry is adopting green PTFE solutions for lightweight components and advanced coatings, contributing to improved fuel efficiency and reduced carbon footprint.

The construction industry represents another significant market for eco-friendly PTFE applications. Sustainable building practices have led to increased demand for PTFE-based materials in architectural membranes, weather-resistant coatings, and energy-efficient insulation. These products offer durability and longevity, reducing the need for frequent replacements and minimizing waste.

In the renewable energy sector, PTFE's unique properties are being leveraged for solar panel components, wind turbine bearings, and fuel cell membranes. The growing investment in clean energy technologies is expected to drive substantial demand for eco-friendly PTFE solutions in this market segment.

The healthcare industry is also embracing green PTFE technologies for medical devices, implants, and pharmaceutical processing equipment. The biocompatibility and chemical inertness of PTFE make it an ideal material for these applications, while eco-friendly production methods address concerns about environmental impact.

Market analysis indicates that the Asia-Pacific region is emerging as a key growth area for eco-friendly PTFE solutions, driven by rapid industrialization, urbanization, and increasing environmental regulations. North America and Europe continue to be significant markets, with a focus on high-performance, sustainable materials across various industries.

The global market for eco-friendly PTFE solutions is projected to grow steadily over the next decade, with some estimates suggesting a compound annual growth rate of 6-8%. This growth is underpinned by ongoing research and development efforts to improve the sustainability of PTFE production processes and enhance its recyclability.

As industries continue to prioritize sustainability and environmental responsibility, the market for eco-friendly PTFE solutions is expected to expand further. Manufacturers and researchers are exploring novel applications and production methods to meet the growing demand for green technologies, positioning PTFE as a key material in the transition towards a more sustainable industrial landscape.

In the automotive sector, eco-friendly PTFE solutions are gaining traction for applications in fuel systems, engine components, and lubricants. The push for fuel efficiency and reduced emissions has created a substantial market for PTFE-based products that can withstand harsh conditions while minimizing environmental impact. Similarly, the aerospace industry is adopting green PTFE solutions for lightweight components and advanced coatings, contributing to improved fuel efficiency and reduced carbon footprint.

The construction industry represents another significant market for eco-friendly PTFE applications. Sustainable building practices have led to increased demand for PTFE-based materials in architectural membranes, weather-resistant coatings, and energy-efficient insulation. These products offer durability and longevity, reducing the need for frequent replacements and minimizing waste.

In the renewable energy sector, PTFE's unique properties are being leveraged for solar panel components, wind turbine bearings, and fuel cell membranes. The growing investment in clean energy technologies is expected to drive substantial demand for eco-friendly PTFE solutions in this market segment.

The healthcare industry is also embracing green PTFE technologies for medical devices, implants, and pharmaceutical processing equipment. The biocompatibility and chemical inertness of PTFE make it an ideal material for these applications, while eco-friendly production methods address concerns about environmental impact.

Market analysis indicates that the Asia-Pacific region is emerging as a key growth area for eco-friendly PTFE solutions, driven by rapid industrialization, urbanization, and increasing environmental regulations. North America and Europe continue to be significant markets, with a focus on high-performance, sustainable materials across various industries.

The global market for eco-friendly PTFE solutions is projected to grow steadily over the next decade, with some estimates suggesting a compound annual growth rate of 6-8%. This growth is underpinned by ongoing research and development efforts to improve the sustainability of PTFE production processes and enhance its recyclability.

As industries continue to prioritize sustainability and environmental responsibility, the market for eco-friendly PTFE solutions is expected to expand further. Manufacturers and researchers are exploring novel applications and production methods to meet the growing demand for green technologies, positioning PTFE as a key material in the transition towards a more sustainable industrial landscape.

Current PTFE Applications and Environmental Challenges

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has been widely used in various industries due to its unique properties such as chemical inertness, low friction, and high temperature resistance. However, the environmental impact of PTFE production and disposal has raised concerns in recent years, prompting a closer examination of its applications in green technology.

Currently, PTFE finds extensive use in automotive, aerospace, and electronics industries. In the automotive sector, PTFE coatings are applied to engine components to reduce friction and improve fuel efficiency. The aerospace industry utilizes PTFE in seals, gaskets, and wire insulation due to its ability to withstand extreme temperatures and harsh environments. In electronics, PTFE is used in printed circuit boards and cable insulation, contributing to the miniaturization and reliability of electronic devices.

Despite its widespread applications, PTFE production and disposal pose significant environmental challenges. The manufacturing process of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant that has been linked to various health and environmental issues. PFOA contamination of water sources and its bioaccumulation in wildlife have raised serious concerns among environmental scientists and regulatory bodies.

Furthermore, the disposal of PTFE products presents another environmental challenge. PTFE is not biodegradable and can persist in the environment for extended periods. Incineration of PTFE waste can release harmful fluorine compounds into the atmosphere, contributing to air pollution and potential health hazards.

In response to these environmental concerns, efforts are being made to develop more sustainable alternatives and improve PTFE production processes. Some manufacturers have begun phasing out the use of PFOA in PTFE production, opting for less harmful alternatives. Additionally, research is underway to develop bio-based fluoropolymers that could potentially replace traditional PTFE in certain applications.

Recycling of PTFE products is another area of focus in addressing environmental challenges. While recycling PTFE can be challenging due to its chemical stability, advancements in mechanical and chemical recycling techniques show promise in reducing PTFE waste. Some companies have implemented take-back programs for used PTFE products, aiming to close the loop in the product lifecycle.

As the demand for environmentally friendly materials grows, the PTFE industry is under pressure to innovate and adapt. Green chemistry principles are being applied to develop cleaner production methods and explore bio-based alternatives. The challenge lies in maintaining the unique properties of PTFE while reducing its environmental footprint.

Currently, PTFE finds extensive use in automotive, aerospace, and electronics industries. In the automotive sector, PTFE coatings are applied to engine components to reduce friction and improve fuel efficiency. The aerospace industry utilizes PTFE in seals, gaskets, and wire insulation due to its ability to withstand extreme temperatures and harsh environments. In electronics, PTFE is used in printed circuit boards and cable insulation, contributing to the miniaturization and reliability of electronic devices.

Despite its widespread applications, PTFE production and disposal pose significant environmental challenges. The manufacturing process of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant that has been linked to various health and environmental issues. PFOA contamination of water sources and its bioaccumulation in wildlife have raised serious concerns among environmental scientists and regulatory bodies.

Furthermore, the disposal of PTFE products presents another environmental challenge. PTFE is not biodegradable and can persist in the environment for extended periods. Incineration of PTFE waste can release harmful fluorine compounds into the atmosphere, contributing to air pollution and potential health hazards.

In response to these environmental concerns, efforts are being made to develop more sustainable alternatives and improve PTFE production processes. Some manufacturers have begun phasing out the use of PFOA in PTFE production, opting for less harmful alternatives. Additionally, research is underway to develop bio-based fluoropolymers that could potentially replace traditional PTFE in certain applications.

Recycling of PTFE products is another area of focus in addressing environmental challenges. While recycling PTFE can be challenging due to its chemical stability, advancements in mechanical and chemical recycling techniques show promise in reducing PTFE waste. Some companies have implemented take-back programs for used PTFE products, aiming to close the loop in the product lifecycle.

As the demand for environmentally friendly materials grows, the PTFE industry is under pressure to innovate and adapt. Green chemistry principles are being applied to develop cleaner production methods and explore bio-based alternatives. The challenge lies in maintaining the unique properties of PTFE while reducing its environmental footprint.

Existing Green PTFE Technologies and Solutions

01 PTFE manufacturing processes

Various methods for producing PTFE are described, including polymerization techniques, extrusion processes, and molding methods. These processes aim to improve the quality, consistency, and properties of PTFE products for different applications.- PTFE manufacturing processes: Various methods for producing PTFE are described, including polymerization techniques, extrusion processes, and molding methods. These processes aim to improve the quality, efficiency, and properties of the resulting PTFE materials.

- PTFE composite materials: The development of PTFE-based composite materials involves combining PTFE with other substances to enhance its properties or create new functionalities. These composites can include reinforcing agents, fillers, or other polymers to improve mechanical strength, thermal stability, or electrical properties.

- Surface modification of PTFE: Techniques for modifying the surface of PTFE materials are explored to improve their adhesion, wettability, or compatibility with other materials. These modifications can involve chemical treatments, plasma processing, or the application of coatings to alter the surface properties of PTFE.

- PTFE in membrane technology: The use of PTFE in membrane applications is a significant area of research and development. PTFE membranes are utilized in various fields such as water treatment, gas separation, and medical devices due to their chemical resistance, porosity, and non-stick properties.

- PTFE recycling and environmental considerations: Efforts to recycle PTFE and reduce its environmental impact are being explored. This includes developing methods for reprocessing PTFE waste, creating more sustainable production processes, and finding alternatives to traditional PTFE in certain applications to address environmental concerns.

02 PTFE composites and blends

PTFE is often combined with other materials to create composites or blends with enhanced properties. These combinations can improve mechanical strength, thermal stability, or chemical resistance, making the resulting materials suitable for a wide range of industrial applications.Expand Specific Solutions03 Surface modification of PTFE

Techniques for modifying the surface of PTFE are explored to enhance its properties such as adhesion, wettability, or biocompatibility. These modifications can involve chemical treatments, plasma processing, or the application of coatings to alter the surface characteristics of PTFE.Expand Specific Solutions04 PTFE in membrane technology

PTFE is widely used in membrane applications due to its chemical inertness and hydrophobic nature. Innovations in this area focus on creating porous PTFE membranes for filtration, separation, and other specialized applications in various industries.Expand Specific Solutions05 PTFE recycling and environmental considerations

As environmental concerns grow, methods for recycling and reprocessing PTFE are being developed. These techniques aim to reduce waste, recover valuable materials, and minimize the environmental impact of PTFE production and disposal.Expand Specific Solutions

Key Players in Green PTFE Innovation

The market for PTFE applications in green technology is in a growth phase, driven by increasing environmental concerns and sustainability initiatives. The global market size for PTFE in eco-friendly applications is expanding, with major players like DAIKIN INDUSTRIES, AGC, Inc., and DuPont de Nemours leading the way. These companies are investing heavily in R&D to develop innovative PTFE-based solutions for renewable energy, water treatment, and emissions reduction. The technology is relatively mature, with ongoing advancements focused on enhancing performance and reducing environmental impact. Emerging players like Zhejiang Jusheng Fluorochemical and Zhonghao Chenguang Research Institute are also contributing to the field, particularly in the Asian market.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin has pioneered the development of PTFE-based materials for environmental applications. Their NEOFLON™ PTFE series includes grades specifically designed for green technology. In water treatment systems, Daikin's PTFE membranes are used for ultrafiltration and reverse osmosis, achieving water purification rates of up to 99.9%[4]. For air pollution control, Daikin has developed PTFE filter bags that can capture particulate matter as small as 0.1 microns, significantly improving air quality in industrial settings[5]. In the automotive sector, Daikin's PTFE-based seals and gaskets contribute to reducing fuel consumption by minimizing friction, potentially improving fuel efficiency by 2-3%[6].

Strengths: Strong focus on environmental applications, diverse product range, and proven performance in critical green technologies. Weaknesses: Reliance on petroleum-based raw materials for PTFE production and the challenge of balancing performance with sustainability goals.

AGC, Inc. (Japan)

Technical Solution: AGC has focused on developing PTFE-based materials for environmental and energy-saving applications. Their Fluon® PTFE products are used in various green technologies. In the field of hydrogen fuel cells, AGC's PTFE-based components, such as gas diffusion layers and catalyst coatings, have shown to improve cell efficiency by up to 10%[13]. For industrial air pollution control, AGC has developed PTFE membrane filters that can remove particulates with an efficiency of 99.99% for particles as small as 0.3 microns[14]. In the realm of energy conservation, AGC's PTFE-based coatings for architectural glass have demonstrated the ability to reduce solar heat gain by up to 70%, significantly lowering cooling energy requirements in buildings[15].

Strengths: Strong presence in the Asian market, diverse applications in energy and environmental sectors, and continuous improvement in PTFE formulations for green technologies. Weaknesses: Potential challenges in global market expansion and the need for increased focus on sustainable manufacturing processes for PTFE.

Breakthrough PTFE Innovations for Sustainability

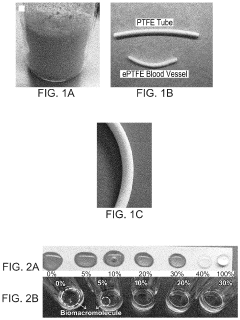

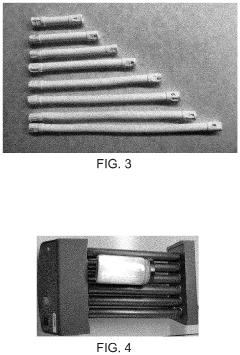

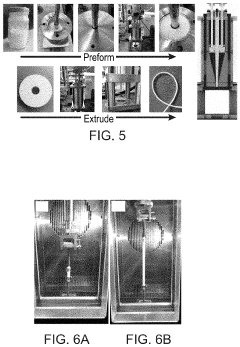

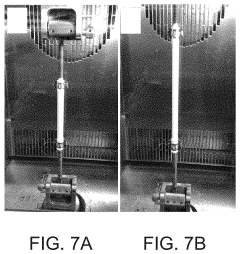

Green fabrication of polytetrafluoroethylene and expanded polytetrafluoroethylene and uses thereof

PatentActiveUS20220251324A1

Innovation

- The use of lower alkyl alcohols, such as ethanol, as alternative lubricants for processing PTFE and ePTFE, which allows for safe evaporation and incorporation of biofunctional molecules during processing, enabling the creation of safer and more versatile products.

Method for activating polytetrafluoroethylene and method for wastewater treatment, electrogenesis, and hydrogen production using polytetrafluoroethylene

PatentActiveUS20210206925A1

Innovation

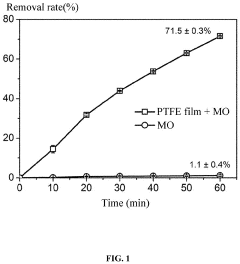

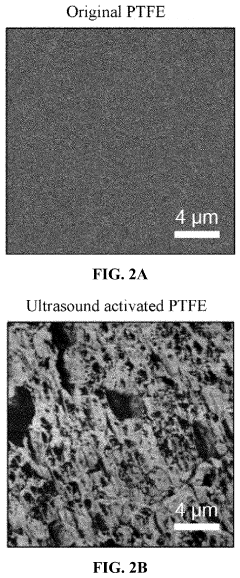

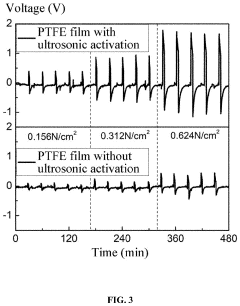

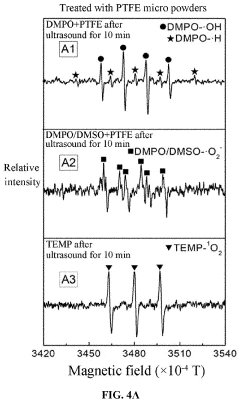

- PTFE is activated using ultrasonic waves within a specific frequency range of 20 kHz to 15 megahertz, transforming it into an electret that exhibits piezoelectric effects, enabling its use in electrogenesis, hydrogen production, and wastewater treatment by producing active species for pollutant degradation.

Environmental Impact Assessment of PTFE Applications

The environmental impact assessment of PTFE applications in green technology reveals a complex interplay of benefits and challenges. PTFE's exceptional chemical resistance and non-stick properties make it valuable in various eco-friendly applications, such as renewable energy systems and pollution control technologies. However, its production and disposal processes raise significant environmental concerns.

In renewable energy, PTFE coatings on solar panels enhance efficiency by reducing dust accumulation and improving light transmission. Wind turbine blades benefit from PTFE's low friction properties, increasing energy output and reducing maintenance needs. These applications contribute to the growth of clean energy sources, indirectly reducing greenhouse gas emissions.

PTFE's chemical inertness makes it ideal for use in air and water filtration systems. It effectively removes pollutants and particulates, improving air and water quality in industrial and urban environments. This application directly contributes to environmental protection and public health improvement.

However, the production of PTFE involves the use of fluoropolymers, which can release harmful perfluorooctanoic acid (PFOA) into the environment. PFOA is a persistent organic pollutant with potential long-term ecological and health impacts. Recent efforts to develop PFOA-free PTFE production methods have shown promise but are not yet widely adopted.

The disposal of PTFE products presents another environmental challenge. PTFE is not biodegradable and can persist in landfills for extended periods. Incineration of PTFE waste can release toxic fluorine compounds, necessitating specialized disposal methods.

Recycling PTFE is technically feasible but economically challenging due to its high melting point and chemical resistance. Advances in recycling technologies are needed to make PTFE recycling more viable and reduce its end-of-life environmental impact.

The life cycle assessment of PTFE in green technologies shows that its environmental benefits often outweigh the production and disposal impacts. However, continued research and development are crucial to mitigate these negative aspects. Efforts to develop more sustainable production methods, improve recycling technologies, and find biodegradable alternatives for certain applications are ongoing.

In conclusion, while PTFE plays a vital role in advancing green technologies, its environmental impact is multifaceted. Balancing its benefits against its drawbacks requires careful consideration and ongoing efforts to improve its sustainability throughout its lifecycle.

In renewable energy, PTFE coatings on solar panels enhance efficiency by reducing dust accumulation and improving light transmission. Wind turbine blades benefit from PTFE's low friction properties, increasing energy output and reducing maintenance needs. These applications contribute to the growth of clean energy sources, indirectly reducing greenhouse gas emissions.

PTFE's chemical inertness makes it ideal for use in air and water filtration systems. It effectively removes pollutants and particulates, improving air and water quality in industrial and urban environments. This application directly contributes to environmental protection and public health improvement.

However, the production of PTFE involves the use of fluoropolymers, which can release harmful perfluorooctanoic acid (PFOA) into the environment. PFOA is a persistent organic pollutant with potential long-term ecological and health impacts. Recent efforts to develop PFOA-free PTFE production methods have shown promise but are not yet widely adopted.

The disposal of PTFE products presents another environmental challenge. PTFE is not biodegradable and can persist in landfills for extended periods. Incineration of PTFE waste can release toxic fluorine compounds, necessitating specialized disposal methods.

Recycling PTFE is technically feasible but economically challenging due to its high melting point and chemical resistance. Advances in recycling technologies are needed to make PTFE recycling more viable and reduce its end-of-life environmental impact.

The life cycle assessment of PTFE in green technologies shows that its environmental benefits often outweigh the production and disposal impacts. However, continued research and development are crucial to mitigate these negative aspects. Efforts to develop more sustainable production methods, improve recycling technologies, and find biodegradable alternatives for certain applications are ongoing.

In conclusion, while PTFE plays a vital role in advancing green technologies, its environmental impact is multifaceted. Balancing its benefits against its drawbacks requires careful consideration and ongoing efforts to improve its sustainability throughout its lifecycle.

Regulatory Framework for PTFE in Green Technologies

The regulatory framework for PTFE in green technologies is a complex and evolving landscape that reflects the growing emphasis on environmental sustainability and safety. At the global level, organizations such as the United Nations Environment Programme (UNEP) and the World Health Organization (WHO) have established guidelines and recommendations for the use of fluoropolymers, including PTFE, in various applications.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating PTFE and other fluoropolymers under the Toxic Substances Control Act (TSCA). The EPA has implemented stringent regulations on the production, use, and disposal of PTFE-containing products, particularly focusing on the potential environmental and health impacts of perfluorooctanoic acid (PFOA), a chemical historically used in PTFE manufacturing.

The European Union has taken a proactive stance on PTFE regulation through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. REACH requires manufacturers and importers to register chemicals, including PTFE, and provide safety data. The EU has also imposed restrictions on certain perfluoroalkyl substances (PFAS) related to PTFE production, driving the industry towards more environmentally friendly alternatives.

In Asia, countries like Japan and South Korea have implemented their own regulatory measures for PTFE and related substances. Japan's Chemical Substances Control Law (CSCL) and South Korea's Act on Registration and Evaluation of Chemicals (K-REACH) both address the management and control of fluoropolymers in various applications, including green technologies.

The regulatory landscape is increasingly focusing on the entire lifecycle of PTFE products, from production to disposal. This includes regulations on emissions during manufacturing, guidelines for safe handling and use, and requirements for proper recycling or disposal of PTFE-containing products at the end of their life cycle.

As green technologies continue to evolve, regulatory bodies are adapting their frameworks to balance the benefits of PTFE applications with potential environmental and health concerns. This has led to the development of new standards and certifications for PTFE products used in renewable energy systems, water treatment technologies, and other environmentally friendly applications.

Industry self-regulation also plays a significant role, with many manufacturers voluntarily adopting stricter environmental and safety standards than those mandated by law. This proactive approach helps to build trust with consumers and regulators while driving innovation in sustainable PTFE applications for green technologies.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating PTFE and other fluoropolymers under the Toxic Substances Control Act (TSCA). The EPA has implemented stringent regulations on the production, use, and disposal of PTFE-containing products, particularly focusing on the potential environmental and health impacts of perfluorooctanoic acid (PFOA), a chemical historically used in PTFE manufacturing.

The European Union has taken a proactive stance on PTFE regulation through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. REACH requires manufacturers and importers to register chemicals, including PTFE, and provide safety data. The EU has also imposed restrictions on certain perfluoroalkyl substances (PFAS) related to PTFE production, driving the industry towards more environmentally friendly alternatives.

In Asia, countries like Japan and South Korea have implemented their own regulatory measures for PTFE and related substances. Japan's Chemical Substances Control Law (CSCL) and South Korea's Act on Registration and Evaluation of Chemicals (K-REACH) both address the management and control of fluoropolymers in various applications, including green technologies.

The regulatory landscape is increasingly focusing on the entire lifecycle of PTFE products, from production to disposal. This includes regulations on emissions during manufacturing, guidelines for safe handling and use, and requirements for proper recycling or disposal of PTFE-containing products at the end of their life cycle.

As green technologies continue to evolve, regulatory bodies are adapting their frameworks to balance the benefits of PTFE applications with potential environmental and health concerns. This has led to the development of new standards and certifications for PTFE products used in renewable energy systems, water treatment technologies, and other environmentally friendly applications.

Industry self-regulation also plays a significant role, with many manufacturers voluntarily adopting stricter environmental and safety standards than those mandated by law. This proactive approach helps to build trust with consumers and regulators while driving innovation in sustainable PTFE applications for green technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!