PTFE in Next‑Gen Energy Storage Solutions

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE in Energy Storage: Background and Objectives

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has emerged as a crucial material in the development of next-generation energy storage solutions. This synthetic fluoropolymer, discovered in 1938 by Roy Plunkett at DuPont, has found widespread applications across various industries due to its unique properties. In the context of energy storage, PTFE's exceptional chemical resistance, thermal stability, and low friction coefficient make it an ideal candidate for enhancing the performance and longevity of advanced battery systems.

The evolution of PTFE in energy storage applications can be traced back to the early 2000s when researchers began exploring its potential in lithium-ion batteries. Initially, PTFE was primarily used as a binder material in electrode formulations. However, as the demand for more efficient and durable energy storage solutions grew, scientists and engineers started investigating PTFE's role in addressing key challenges faced by conventional battery technologies.

One of the primary objectives of incorporating PTFE in next-generation energy storage solutions is to improve the overall stability and safety of battery systems. PTFE's inherent resistance to chemical degradation and its ability to withstand high temperatures make it an excellent choice for creating protective coatings and separators in advanced batteries. These properties help mitigate issues such as electrolyte decomposition and thermal runaway, which are critical concerns in high-performance energy storage devices.

Another significant goal is to enhance the energy density and cycle life of batteries by leveraging PTFE's unique characteristics. Researchers are exploring novel electrode designs that utilize PTFE-based nanostructures to increase the active surface area and improve ion transport within the battery. This approach has shown promise in boosting both the capacity and longevity of energy storage devices, potentially revolutionizing applications ranging from portable electronics to electric vehicles and grid-scale storage systems.

The integration of PTFE in energy storage solutions also aims to address environmental concerns associated with traditional battery technologies. As a chemically inert and non-toxic material, PTFE offers the potential for developing more sustainable and environmentally friendly energy storage systems. This aligns with the growing global emphasis on green technologies and circular economy principles in the energy sector.

As we look towards the future, the role of PTFE in next-generation energy storage solutions is expected to expand further. Ongoing research is focused on developing advanced PTFE-based composites and hybrid materials that can synergistically enhance the performance of various battery components. These innovations are driven by the need for more efficient, reliable, and sustainable energy storage technologies to support the transition towards renewable energy sources and electrification of transportation.

The evolution of PTFE in energy storage applications can be traced back to the early 2000s when researchers began exploring its potential in lithium-ion batteries. Initially, PTFE was primarily used as a binder material in electrode formulations. However, as the demand for more efficient and durable energy storage solutions grew, scientists and engineers started investigating PTFE's role in addressing key challenges faced by conventional battery technologies.

One of the primary objectives of incorporating PTFE in next-generation energy storage solutions is to improve the overall stability and safety of battery systems. PTFE's inherent resistance to chemical degradation and its ability to withstand high temperatures make it an excellent choice for creating protective coatings and separators in advanced batteries. These properties help mitigate issues such as electrolyte decomposition and thermal runaway, which are critical concerns in high-performance energy storage devices.

Another significant goal is to enhance the energy density and cycle life of batteries by leveraging PTFE's unique characteristics. Researchers are exploring novel electrode designs that utilize PTFE-based nanostructures to increase the active surface area and improve ion transport within the battery. This approach has shown promise in boosting both the capacity and longevity of energy storage devices, potentially revolutionizing applications ranging from portable electronics to electric vehicles and grid-scale storage systems.

The integration of PTFE in energy storage solutions also aims to address environmental concerns associated with traditional battery technologies. As a chemically inert and non-toxic material, PTFE offers the potential for developing more sustainable and environmentally friendly energy storage systems. This aligns with the growing global emphasis on green technologies and circular economy principles in the energy sector.

As we look towards the future, the role of PTFE in next-generation energy storage solutions is expected to expand further. Ongoing research is focused on developing advanced PTFE-based composites and hybrid materials that can synergistically enhance the performance of various battery components. These innovations are driven by the need for more efficient, reliable, and sustainable energy storage technologies to support the transition towards renewable energy sources and electrification of transportation.

Market Analysis for PTFE-Enhanced Energy Storage

The global market for PTFE-enhanced energy storage solutions is experiencing significant growth, driven by the increasing demand for high-performance and long-lasting energy storage systems. PTFE, or polytetrafluoroethylene, is a versatile material that offers unique properties such as chemical resistance, thermal stability, and low friction, making it an attractive component in next-generation energy storage technologies.

In the battery sector, PTFE is gaining traction as a crucial ingredient in electrode binders and separators. The material's hydrophobic nature and excellent chemical stability contribute to improved battery life and performance, particularly in lithium-ion batteries. This application is expected to see substantial growth as electric vehicle adoption accelerates worldwide, with the automotive industry being a major driver for PTFE-enhanced energy storage solutions.

The renewable energy sector is another key market for PTFE-enhanced energy storage. As wind and solar power generation continue to expand, the need for efficient and reliable energy storage systems grows in parallel. PTFE components in flow batteries and other large-scale storage solutions are becoming increasingly popular due to their ability to withstand harsh chemical environments and maintain performance over extended periods.

The aerospace and defense industries are also significant consumers of PTFE-enhanced energy storage technologies. These sectors require high-performance, lightweight, and durable energy storage solutions for various applications, from satellites to military equipment. PTFE's unique properties make it an ideal material for these demanding environments.

Market analysts project that the PTFE-enhanced energy storage market will continue to grow at a compound annual growth rate (CAGR) of over 8% in the coming years. This growth is attributed to the increasing adoption of electric vehicles, the expansion of renewable energy infrastructure, and the ongoing development of advanced energy storage technologies.

Geographically, Asia-Pacific is expected to dominate the market, with China and South Korea leading in both production and consumption of PTFE-enhanced energy storage solutions. North America and Europe are also significant markets, driven by stringent environmental regulations and investments in clean energy technologies.

As the energy storage landscape evolves, PTFE is poised to play an increasingly important role in enhancing the performance, durability, and efficiency of various storage technologies. The material's unique properties align well with the industry's demands for improved energy density, longer cycle life, and enhanced safety features in next-generation energy storage solutions.

In the battery sector, PTFE is gaining traction as a crucial ingredient in electrode binders and separators. The material's hydrophobic nature and excellent chemical stability contribute to improved battery life and performance, particularly in lithium-ion batteries. This application is expected to see substantial growth as electric vehicle adoption accelerates worldwide, with the automotive industry being a major driver for PTFE-enhanced energy storage solutions.

The renewable energy sector is another key market for PTFE-enhanced energy storage. As wind and solar power generation continue to expand, the need for efficient and reliable energy storage systems grows in parallel. PTFE components in flow batteries and other large-scale storage solutions are becoming increasingly popular due to their ability to withstand harsh chemical environments and maintain performance over extended periods.

The aerospace and defense industries are also significant consumers of PTFE-enhanced energy storage technologies. These sectors require high-performance, lightweight, and durable energy storage solutions for various applications, from satellites to military equipment. PTFE's unique properties make it an ideal material for these demanding environments.

Market analysts project that the PTFE-enhanced energy storage market will continue to grow at a compound annual growth rate (CAGR) of over 8% in the coming years. This growth is attributed to the increasing adoption of electric vehicles, the expansion of renewable energy infrastructure, and the ongoing development of advanced energy storage technologies.

Geographically, Asia-Pacific is expected to dominate the market, with China and South Korea leading in both production and consumption of PTFE-enhanced energy storage solutions. North America and Europe are also significant markets, driven by stringent environmental regulations and investments in clean energy technologies.

As the energy storage landscape evolves, PTFE is poised to play an increasingly important role in enhancing the performance, durability, and efficiency of various storage technologies. The material's unique properties align well with the industry's demands for improved energy density, longer cycle life, and enhanced safety features in next-generation energy storage solutions.

Current Challenges in PTFE Energy Storage Applications

PTFE (Polytetrafluoroethylene) has been widely recognized for its potential in next-generation energy storage solutions due to its unique properties. However, several challenges persist in its application, hindering its full integration into advanced energy storage systems.

One of the primary challenges is the inherent non-conductive nature of PTFE. While its excellent chemical resistance and thermal stability make it an attractive option for energy storage applications, its electrical insulation properties pose significant obstacles. This limitation restricts PTFE's direct use in electrodes or other components that require electrical conductivity, necessitating complex modifications or composite formulations to enhance its conductivity.

The hydrophobicity of PTFE presents another hurdle in energy storage applications. Many energy storage systems, particularly those involving aqueous electrolytes, require materials with good wettability. PTFE's water-repellent nature can lead to poor electrolyte penetration and reduced active surface area, potentially limiting the overall performance and efficiency of the energy storage device.

Adhesion issues also plague PTFE in energy storage applications. Its low surface energy makes it difficult for PTFE to bond effectively with other materials, which is crucial for creating stable and durable composite structures in energy storage devices. This challenge often necessitates additional surface treatments or the use of specialized adhesives, adding complexity and cost to manufacturing processes.

The high cost of high-quality PTFE remains a significant barrier to its widespread adoption in energy storage solutions. While PTFE offers superior performance in many aspects, its production process is complex and energy-intensive, resulting in higher material costs compared to alternative options. This economic factor often forces manufacturers to seek less expensive alternatives, potentially compromising on performance.

Furthermore, the processing and shaping of PTFE for specific energy storage applications present technical difficulties. PTFE's high melting point and viscosity in its molten state make it challenging to process using conventional polymer processing techniques. This limitation restricts the design flexibility and scalability of PTFE-based components in energy storage systems.

Lastly, the environmental persistence of PTFE raises concerns about its long-term sustainability in energy storage applications. While PTFE is chemically inert and non-toxic, its non-biodegradability and potential to form microplastics pose environmental challenges. As the energy storage industry increasingly focuses on sustainability and circular economy principles, finding ways to recycle or safely dispose of PTFE-containing components becomes a critical challenge.

One of the primary challenges is the inherent non-conductive nature of PTFE. While its excellent chemical resistance and thermal stability make it an attractive option for energy storage applications, its electrical insulation properties pose significant obstacles. This limitation restricts PTFE's direct use in electrodes or other components that require electrical conductivity, necessitating complex modifications or composite formulations to enhance its conductivity.

The hydrophobicity of PTFE presents another hurdle in energy storage applications. Many energy storage systems, particularly those involving aqueous electrolytes, require materials with good wettability. PTFE's water-repellent nature can lead to poor electrolyte penetration and reduced active surface area, potentially limiting the overall performance and efficiency of the energy storage device.

Adhesion issues also plague PTFE in energy storage applications. Its low surface energy makes it difficult for PTFE to bond effectively with other materials, which is crucial for creating stable and durable composite structures in energy storage devices. This challenge often necessitates additional surface treatments or the use of specialized adhesives, adding complexity and cost to manufacturing processes.

The high cost of high-quality PTFE remains a significant barrier to its widespread adoption in energy storage solutions. While PTFE offers superior performance in many aspects, its production process is complex and energy-intensive, resulting in higher material costs compared to alternative options. This economic factor often forces manufacturers to seek less expensive alternatives, potentially compromising on performance.

Furthermore, the processing and shaping of PTFE for specific energy storage applications present technical difficulties. PTFE's high melting point and viscosity in its molten state make it challenging to process using conventional polymer processing techniques. This limitation restricts the design flexibility and scalability of PTFE-based components in energy storage systems.

Lastly, the environmental persistence of PTFE raises concerns about its long-term sustainability in energy storage applications. While PTFE is chemically inert and non-toxic, its non-biodegradability and potential to form microplastics pose environmental challenges. As the energy storage industry increasingly focuses on sustainability and circular economy principles, finding ways to recycle or safely dispose of PTFE-containing components becomes a critical challenge.

Existing PTFE Solutions for Energy Storage

01 PTFE manufacturing processes

Various methods for producing PTFE are described, including polymerization techniques and processing methods to create different forms of PTFE such as powders, dispersions, and films. These processes aim to improve the properties and performance of PTFE for specific applications.- PTFE manufacturing processes: Various methods for producing PTFE are described, including polymerization techniques, extrusion processes, and molding methods. These processes aim to improve the quality, efficiency, and properties of the resulting PTFE materials.

- PTFE composite materials: The development of PTFE-based composite materials is explored, combining PTFE with other substances to enhance its properties or create new functionalities. These composites may include fillers, reinforcing agents, or other polymers to improve mechanical strength, thermal conductivity, or other characteristics.

- Surface modification of PTFE: Techniques for modifying the surface properties of PTFE are discussed, including chemical treatments, plasma treatments, and coating methods. These modifications aim to improve adhesion, wettability, or other surface characteristics of PTFE for specific applications.

- PTFE in membrane technology: The use of PTFE in membrane applications is explored, including the development of porous PTFE membranes for filtration, separation, and other processes. These membranes leverage PTFE's unique properties such as chemical resistance and hydrophobicity.

- PTFE in coating applications: The application of PTFE as a coating material is discussed, including its use in non-stick surfaces, protective coatings, and lubrication. Various methods for applying PTFE coatings and improving their durability and performance are explored.

02 PTFE composites and blends

PTFE is often combined with other materials to create composites or blends with enhanced properties. These combinations can improve characteristics such as wear resistance, thermal conductivity, or mechanical strength, making the resulting materials suitable for a wide range of applications.Expand Specific Solutions03 Surface modification of PTFE

Techniques for modifying the surface of PTFE are explored to enhance its properties such as adhesion, wettability, or biocompatibility. These modifications can involve chemical treatments, plasma processing, or the application of coatings to alter the surface characteristics of PTFE.Expand Specific Solutions04 PTFE in membrane technology

PTFE is widely used in membrane applications due to its chemical resistance and non-stick properties. Innovations in this area focus on creating porous PTFE membranes with controlled pore sizes and structures for filtration, separation, and other membrane-based processes.Expand Specific Solutions05 PTFE in coating applications

PTFE is utilized in various coating applications to impart non-stick, low friction, and chemical resistance properties to surfaces. Research in this area focuses on developing improved PTFE coating formulations, application methods, and enhancing the durability and performance of PTFE coatings.Expand Specific Solutions

Key Players in PTFE and Energy Storage Industries

The PTFE in Next-Gen Energy Storage Solutions market is in a growth phase, driven by increasing demand for advanced energy storage technologies. The market size is expanding rapidly, with significant potential in various applications. Technologically, PTFE solutions are advancing, but maturity levels vary among key players. Companies like DAIKIN INDUSTRIES Ltd., AGC, Inc., and Nitto Denko Corp. are leading in PTFE innovation, while Tesla, Inc. and GM Global Technology Operations LLC are integrating these materials into energy storage systems. Research institutions such as Xi'an Jiaotong University and North China Electric Power University are contributing to technological advancements, indicating a collaborative ecosystem of industry and academia pushing the boundaries of PTFE applications in energy storage.

DAIKIN INDUSTRIES Ltd.

Technical Solution: DAIKIN INDUSTRIES Ltd. has focused on developing advanced PTFE materials for energy storage applications, particularly in the realm of lithium-ion batteries and fuel cells. Their approach involves creating specialized PTFE grades with tailored properties for specific energy storage components. One of their key innovations is a microporous PTFE membrane for battery separators, which offers improved thermal stability and enhanced safety features[2]. DAIKIN has also developed PTFE-based electrode binders that demonstrate superior adhesion and electrochemical stability, leading to improved cycle life in lithium-ion batteries[4]. For fuel cell applications, the company has created PTFE-based gas diffusion layers that optimize water management and gas permeability, resulting in enhanced overall cell performance[6].

Strengths: High thermal stability, excellent chemical resistance, improved safety features in battery applications. Weaknesses: Potential cost implications for high-performance PTFE grades, challenges in processing for certain applications.

AGC, Inc. (Japan)

Technical Solution: AGC, Inc. has developed innovative PTFE-based solutions for next-generation energy storage systems, focusing on improving the performance and durability of various components. Their approach involves creating advanced PTFE composites and modified PTFE materials tailored for specific energy storage applications. One of their key innovations is a PTFE-based separator for lithium-ion batteries that offers enhanced thermal stability and improved safety characteristics[1]. AGC has also developed PTFE-based coatings for battery current collectors, which provide superior corrosion resistance and contribute to extended battery life[3]. In the field of fuel cells, the company has created PTFE-based membranes with improved proton conductivity and mechanical strength, leading to enhanced overall cell efficiency[5]. Additionally, AGC has explored the use of PTFE in solid-state electrolytes, leveraging its excellent dielectric properties and chemical stability[7].

Strengths: High chemical and thermal resistance, improved safety features, enhanced component longevity. Weaknesses: Potentially higher material costs, challenges in achieving optimal adhesion in some applications.

Innovative PTFE Applications in Energy Storage

High Electric Energy Density Polymer Capacitors With Fast Discharge Speed and High Efficiency Based On Unique Poly (Vinylidene Fluoride) Copolymers and Terpolymers as Dielectric Materials

PatentInactiveUS20090030152A1

Innovation

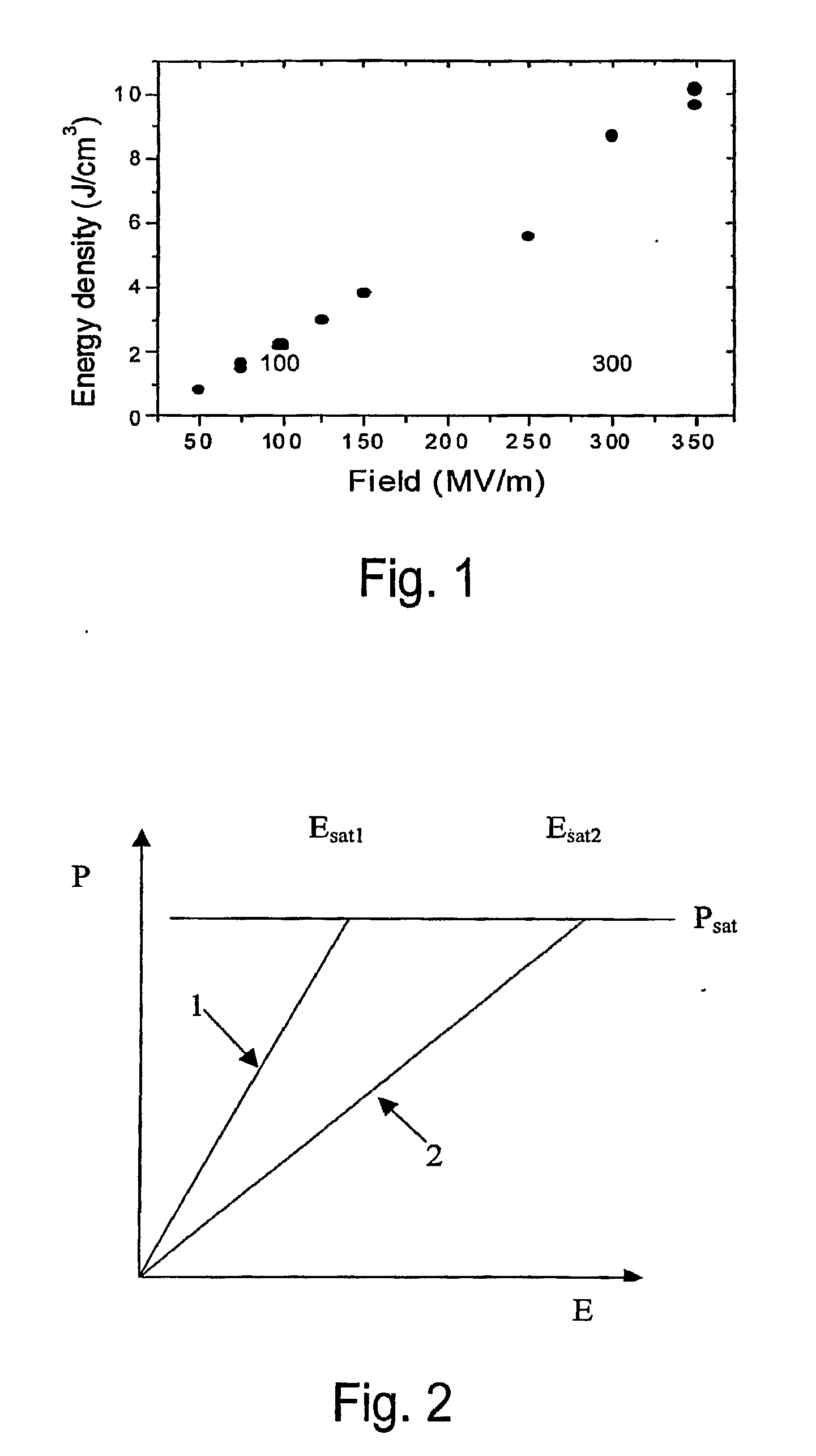

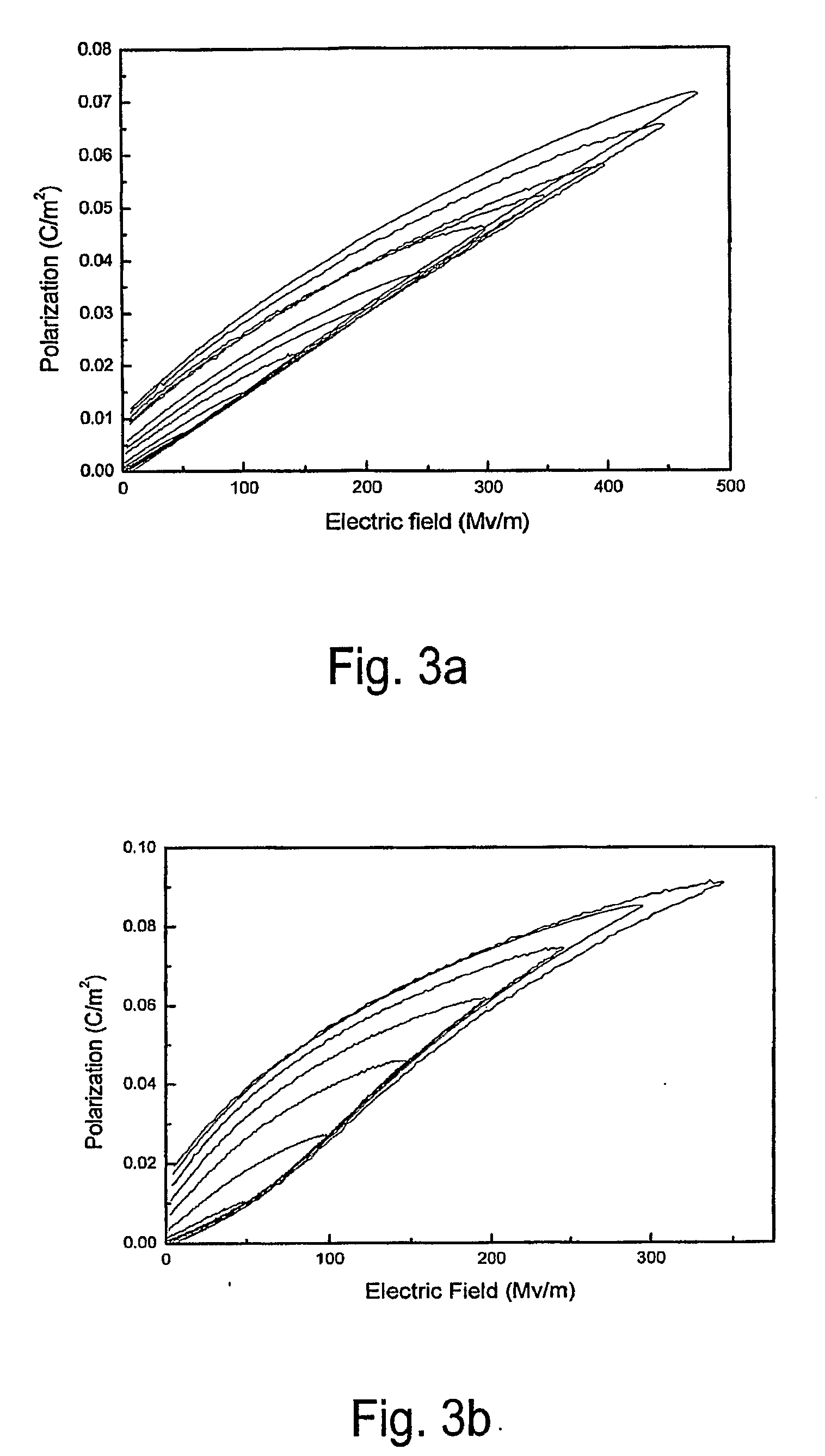

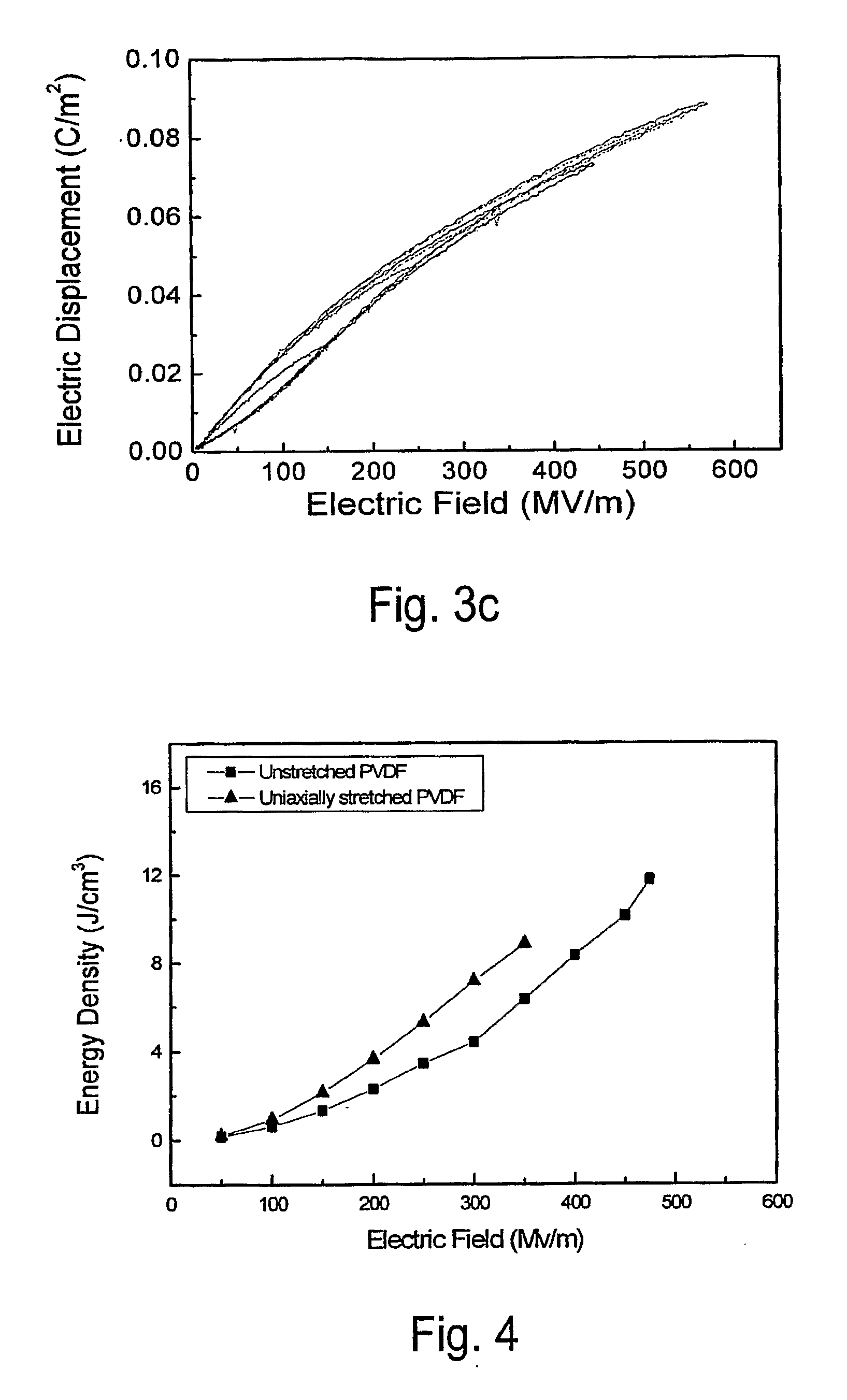

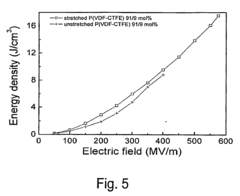

- Development of modified PVDF-based copolymers and terpolymers with specific molecular structures, such as P(VDF-CTFE), P(VDF-CFE), and P(VDF-HFP, that combine high breakdown fields with improved dielectric constants and phase stability, enabling energy densities above 10 J/cm3 and discharge efficiencies exceeding 85% in less than 0.001 seconds.

High electric energy density polymer capacitors with fast discharge speed and high efficiency based on unique poly(vinylidene fluoride) copolymers and terpolymers as dielectric materials

PatentInactiveEP1966810A2

Innovation

- The development of unique PVDF-based copolymers and terpolymers, such as P(VDF-CTFE), P(VDF-CFE), and P(VDF-HFP, which combine high breakdown fields with improved dielectric constants and phase stability, enabling energy densities of at least 10 J/cm³ and fast discharge times of less than 0.001 seconds with high efficiency.

Environmental Impact of PTFE in Energy Storage

The environmental impact of PTFE in energy storage solutions is a critical consideration as the demand for advanced energy storage technologies continues to grow. PTFE, or polytetrafluoroethylene, is widely used in various components of energy storage systems due to its excellent chemical resistance, thermal stability, and low friction properties. However, its environmental implications throughout the lifecycle of energy storage devices warrant careful examination.

During the production phase of PTFE, the primary environmental concern is the emission of perfluorooctanoic acid (PFOA) and other perfluorinated compounds. These substances are persistent in the environment and have been linked to various health and ecological issues. While many manufacturers have phased out PFOA use, alternative production methods may still have environmental impacts that require ongoing assessment and mitigation efforts.

In the operational phase of energy storage systems, PTFE contributes to improved efficiency and longevity of components, potentially reducing the overall environmental footprint of these technologies. Its resistance to chemical degradation and thermal stress helps extend the lifespan of energy storage devices, thereby reducing the frequency of replacements and associated resource consumption.

However, the end-of-life management of PTFE-containing energy storage components presents significant challenges. PTFE is not biodegradable and can persist in the environment for extended periods. Recycling PTFE is technically feasible but often economically challenging, leading to concerns about its accumulation in landfills or potential incineration, which can release harmful fluorinated compounds.

The use of PTFE in next-generation energy storage solutions also raises questions about resource efficiency and circular economy principles. As global demand for energy storage technologies increases, the sustainable sourcing and management of fluoropolymers like PTFE become increasingly important considerations for manufacturers and policymakers.

Efforts to address the environmental impact of PTFE in energy storage are ongoing. Research into bio-based alternatives, improved recycling technologies, and more environmentally friendly production methods are areas of active development. Additionally, lifecycle assessment studies are being conducted to quantify the net environmental impact of PTFE use in energy storage, considering both its benefits in terms of device performance and longevity, and its potential negative impacts throughout its lifecycle.

As the energy storage sector evolves, balancing the technical advantages of PTFE with its environmental implications will be crucial. This may involve developing strategies for closed-loop recycling systems, exploring alternative materials with similar properties but lower environmental impacts, and implementing stricter regulations on the production and disposal of PTFE-containing components in energy storage applications.

During the production phase of PTFE, the primary environmental concern is the emission of perfluorooctanoic acid (PFOA) and other perfluorinated compounds. These substances are persistent in the environment and have been linked to various health and ecological issues. While many manufacturers have phased out PFOA use, alternative production methods may still have environmental impacts that require ongoing assessment and mitigation efforts.

In the operational phase of energy storage systems, PTFE contributes to improved efficiency and longevity of components, potentially reducing the overall environmental footprint of these technologies. Its resistance to chemical degradation and thermal stress helps extend the lifespan of energy storage devices, thereby reducing the frequency of replacements and associated resource consumption.

However, the end-of-life management of PTFE-containing energy storage components presents significant challenges. PTFE is not biodegradable and can persist in the environment for extended periods. Recycling PTFE is technically feasible but often economically challenging, leading to concerns about its accumulation in landfills or potential incineration, which can release harmful fluorinated compounds.

The use of PTFE in next-generation energy storage solutions also raises questions about resource efficiency and circular economy principles. As global demand for energy storage technologies increases, the sustainable sourcing and management of fluoropolymers like PTFE become increasingly important considerations for manufacturers and policymakers.

Efforts to address the environmental impact of PTFE in energy storage are ongoing. Research into bio-based alternatives, improved recycling technologies, and more environmentally friendly production methods are areas of active development. Additionally, lifecycle assessment studies are being conducted to quantify the net environmental impact of PTFE use in energy storage, considering both its benefits in terms of device performance and longevity, and its potential negative impacts throughout its lifecycle.

As the energy storage sector evolves, balancing the technical advantages of PTFE with its environmental implications will be crucial. This may involve developing strategies for closed-loop recycling systems, exploring alternative materials with similar properties but lower environmental impacts, and implementing stricter regulations on the production and disposal of PTFE-containing components in energy storage applications.

Regulatory Framework for PTFE in Energy Storage

The regulatory framework for PTFE in energy storage is a complex and evolving landscape that plays a crucial role in shaping the development and adoption of next-generation energy storage solutions. As PTFE (Polytetrafluoroethylene) finds increasing applications in advanced energy storage technologies, regulatory bodies worldwide are adapting their guidelines to ensure safety, environmental protection, and performance standards are met.

In the United States, the Environmental Protection Agency (EPA) has established regulations under the Toxic Substances Control Act (TSCA) that govern the manufacturing, processing, and use of PTFE in various applications, including energy storage. These regulations focus on minimizing potential environmental and health risks associated with PTFE production and disposal. Additionally, the Department of Energy (DOE) has set forth guidelines for energy storage systems that incorporate PTFE components, emphasizing safety and performance criteria.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which applies to PTFE used in energy storage applications. This comprehensive framework requires manufacturers and importers to register PTFE and provide detailed information on its properties, potential risks, and safe handling procedures. The EU's Battery Directive also impacts PTFE use in energy storage, setting standards for battery composition, recycling, and disposal.

In Asia, countries like China and Japan have established their own regulatory frameworks for PTFE in energy storage. China's Ministry of Environmental Protection has issued guidelines on the production and use of fluoropolymers, including PTFE, in various industries. Japan's Chemical Substances Control Law (CSCL) regulates the manufacture, import, and use of PTFE in energy storage applications, focusing on environmental and health protection.

International standards organizations, such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE), have developed specific standards for energy storage systems that incorporate PTFE components. These standards address issues such as thermal management, electrical insulation, and long-term reliability, ensuring that PTFE-based energy storage solutions meet global quality and safety benchmarks.

As the energy storage industry continues to evolve, regulatory frameworks are expected to adapt to new technological developments. Future regulations may focus on enhancing the recyclability of PTFE-containing energy storage components, promoting sustainable manufacturing practices, and addressing potential long-term environmental impacts. The ongoing dialogue between industry stakeholders, regulatory bodies, and research institutions will be crucial in shaping a balanced regulatory landscape that fosters innovation while ensuring public safety and environmental protection.

In the United States, the Environmental Protection Agency (EPA) has established regulations under the Toxic Substances Control Act (TSCA) that govern the manufacturing, processing, and use of PTFE in various applications, including energy storage. These regulations focus on minimizing potential environmental and health risks associated with PTFE production and disposal. Additionally, the Department of Energy (DOE) has set forth guidelines for energy storage systems that incorporate PTFE components, emphasizing safety and performance criteria.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which applies to PTFE used in energy storage applications. This comprehensive framework requires manufacturers and importers to register PTFE and provide detailed information on its properties, potential risks, and safe handling procedures. The EU's Battery Directive also impacts PTFE use in energy storage, setting standards for battery composition, recycling, and disposal.

In Asia, countries like China and Japan have established their own regulatory frameworks for PTFE in energy storage. China's Ministry of Environmental Protection has issued guidelines on the production and use of fluoropolymers, including PTFE, in various industries. Japan's Chemical Substances Control Law (CSCL) regulates the manufacture, import, and use of PTFE in energy storage applications, focusing on environmental and health protection.

International standards organizations, such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE), have developed specific standards for energy storage systems that incorporate PTFE components. These standards address issues such as thermal management, electrical insulation, and long-term reliability, ensuring that PTFE-based energy storage solutions meet global quality and safety benchmarks.

As the energy storage industry continues to evolve, regulatory frameworks are expected to adapt to new technological developments. Future regulations may focus on enhancing the recyclability of PTFE-containing energy storage components, promoting sustainable manufacturing practices, and addressing potential long-term environmental impacts. The ongoing dialogue between industry stakeholders, regulatory bodies, and research institutions will be crucial in shaping a balanced regulatory landscape that fosters innovation while ensuring public safety and environmental protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!