Forecasting PTFE biodegradation developments in eco‑designed materials

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Biodegradation Background and Objectives

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has been a revolutionary material since its accidental discovery in 1938. Its unique properties, including high chemical resistance, low friction, and thermal stability, have made it indispensable in various industries. However, the very characteristics that make PTFE valuable also contribute to its environmental persistence, raising concerns about its long-term impact on ecosystems.

The development of biodegradable PTFE alternatives represents a critical frontier in materials science and environmental sustainability. This research aims to forecast and analyze potential breakthroughs in PTFE biodegradation, focusing on eco-designed materials that maintain the desirable properties of traditional PTFE while addressing its environmental drawbacks.

The evolution of PTFE biodegradation technology is closely tied to the broader trends in sustainable materials development. As global awareness of environmental issues grows, there is increasing pressure on industries to adopt more eco-friendly practices and materials. This shift has spurred research into biodegradable polymers and the modification of existing materials to enhance their environmental compatibility.

Recent advancements in polymer science and biotechnology have opened new avenues for tackling the PTFE biodegradation challenge. These include the development of composite materials that incorporate biodegradable elements, the exploration of microbial degradation pathways, and the investigation of chemical modifications to PTFE's structure to introduce weak points for environmental breakdown.

The primary objective of this research is to identify and evaluate promising approaches to PTFE biodegradation in eco-designed materials. This involves a comprehensive analysis of current research trends, emerging technologies, and potential breakthroughs that could lead to significant advancements in the field. The study aims to provide insights into the feasibility, timeline, and potential impact of various biodegradation strategies.

Furthermore, this research seeks to understand the technical, economic, and regulatory factors that may influence the development and adoption of biodegradable PTFE alternatives. By examining these aspects, we aim to forecast the potential trajectory of PTFE biodegradation technology and its implications for various industries and environmental conservation efforts.

Ultimately, this technological forecasting endeavor aims to guide future research and development efforts, inform policy decisions, and support strategic planning for industries reliant on PTFE and similar materials. By anticipating future developments in PTFE biodegradation, we can better prepare for the transition towards more sustainable and environmentally friendly material solutions.

The development of biodegradable PTFE alternatives represents a critical frontier in materials science and environmental sustainability. This research aims to forecast and analyze potential breakthroughs in PTFE biodegradation, focusing on eco-designed materials that maintain the desirable properties of traditional PTFE while addressing its environmental drawbacks.

The evolution of PTFE biodegradation technology is closely tied to the broader trends in sustainable materials development. As global awareness of environmental issues grows, there is increasing pressure on industries to adopt more eco-friendly practices and materials. This shift has spurred research into biodegradable polymers and the modification of existing materials to enhance their environmental compatibility.

Recent advancements in polymer science and biotechnology have opened new avenues for tackling the PTFE biodegradation challenge. These include the development of composite materials that incorporate biodegradable elements, the exploration of microbial degradation pathways, and the investigation of chemical modifications to PTFE's structure to introduce weak points for environmental breakdown.

The primary objective of this research is to identify and evaluate promising approaches to PTFE biodegradation in eco-designed materials. This involves a comprehensive analysis of current research trends, emerging technologies, and potential breakthroughs that could lead to significant advancements in the field. The study aims to provide insights into the feasibility, timeline, and potential impact of various biodegradation strategies.

Furthermore, this research seeks to understand the technical, economic, and regulatory factors that may influence the development and adoption of biodegradable PTFE alternatives. By examining these aspects, we aim to forecast the potential trajectory of PTFE biodegradation technology and its implications for various industries and environmental conservation efforts.

Ultimately, this technological forecasting endeavor aims to guide future research and development efforts, inform policy decisions, and support strategic planning for industries reliant on PTFE and similar materials. By anticipating future developments in PTFE biodegradation, we can better prepare for the transition towards more sustainable and environmentally friendly material solutions.

Eco-Designed Materials Market Analysis

The eco-designed materials market has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations on sustainability. This trend has particularly impacted the development and adoption of biodegradable alternatives to traditional materials like PTFE (Polytetrafluoroethylene). The global eco-designed materials market is expected to continue its upward trajectory, with a focus on innovative solutions for PTFE biodegradation.

Consumer demand for environmentally friendly products has been a key driver in the eco-designed materials sector. Companies across various industries, including automotive, packaging, and consumer goods, are actively seeking sustainable alternatives to conventional materials. This shift in consumer preferences has created a substantial market opportunity for biodegradable PTFE substitutes and eco-designed materials in general.

The regulatory landscape has also played a crucial role in shaping the market for eco-designed materials. Governments worldwide have implemented stricter environmental policies and waste management regulations, encouraging the development and adoption of biodegradable materials. These regulatory pressures have accelerated research and development efforts in PTFE biodegradation, fostering innovation and market growth.

In terms of market segmentation, the eco-designed materials sector encompasses a wide range of products, including biodegradable plastics, bio-based polymers, and recycled materials. The segment focusing on PTFE alternatives has gained particular attention due to the widespread use of PTFE in various applications and its environmental persistence. This niche market is expected to witness substantial growth as research in PTFE biodegradation advances.

The competitive landscape of the eco-designed materials market is characterized by a mix of established chemical companies and innovative startups. Major players in the chemical industry have invested heavily in research and development to create sustainable alternatives to traditional materials, including PTFE. Simultaneously, numerous startups have emerged, focusing on novel approaches to biodegradation and eco-friendly material design.

Market trends indicate a growing interest in collaborative efforts between industry players, research institutions, and government agencies to accelerate the development of biodegradable PTFE alternatives. These partnerships aim to overcome technical challenges and scale up production processes, potentially leading to more rapid market adoption of eco-designed materials.

The economic implications of the shift towards eco-designed materials are significant. While initial costs for biodegradable alternatives may be higher, the long-term benefits in terms of environmental impact and regulatory compliance are driving market growth. As production scales up and technologies mature, the cost gap between traditional PTFE and its biodegradable counterparts is expected to narrow, further boosting market adoption.

Consumer demand for environmentally friendly products has been a key driver in the eco-designed materials sector. Companies across various industries, including automotive, packaging, and consumer goods, are actively seeking sustainable alternatives to conventional materials. This shift in consumer preferences has created a substantial market opportunity for biodegradable PTFE substitutes and eco-designed materials in general.

The regulatory landscape has also played a crucial role in shaping the market for eco-designed materials. Governments worldwide have implemented stricter environmental policies and waste management regulations, encouraging the development and adoption of biodegradable materials. These regulatory pressures have accelerated research and development efforts in PTFE biodegradation, fostering innovation and market growth.

In terms of market segmentation, the eco-designed materials sector encompasses a wide range of products, including biodegradable plastics, bio-based polymers, and recycled materials. The segment focusing on PTFE alternatives has gained particular attention due to the widespread use of PTFE in various applications and its environmental persistence. This niche market is expected to witness substantial growth as research in PTFE biodegradation advances.

The competitive landscape of the eco-designed materials market is characterized by a mix of established chemical companies and innovative startups. Major players in the chemical industry have invested heavily in research and development to create sustainable alternatives to traditional materials, including PTFE. Simultaneously, numerous startups have emerged, focusing on novel approaches to biodegradation and eco-friendly material design.

Market trends indicate a growing interest in collaborative efforts between industry players, research institutions, and government agencies to accelerate the development of biodegradable PTFE alternatives. These partnerships aim to overcome technical challenges and scale up production processes, potentially leading to more rapid market adoption of eco-designed materials.

The economic implications of the shift towards eco-designed materials are significant. While initial costs for biodegradable alternatives may be higher, the long-term benefits in terms of environmental impact and regulatory compliance are driving market growth. As production scales up and technologies mature, the cost gap between traditional PTFE and its biodegradable counterparts is expected to narrow, further boosting market adoption.

PTFE Biodegradation Challenges

Polytetrafluoroethylene (PTFE), commonly known as Teflon, presents significant challenges in biodegradation due to its exceptional chemical stability and resistance to environmental degradation. The carbon-fluorine bonds in PTFE are among the strongest in organic chemistry, making the material highly resistant to decomposition by microorganisms, enzymes, and natural weathering processes.

One of the primary challenges in PTFE biodegradation is the lack of naturally occurring organisms capable of breaking down the polymer's structure. Unlike many other plastics, which can be partially degraded by various microbes, PTFE remains largely unaffected by biological processes. This resistance to biodegradation results in extremely long persistence times in the environment, potentially lasting hundreds to thousands of years.

The high thermal stability of PTFE further complicates biodegradation efforts. Traditional thermal decomposition methods are ineffective at breaking down PTFE without producing harmful byproducts. The polymer's melting point of around 327°C (620°F) is significantly higher than most biodegradation processes can achieve in natural environments.

Another challenge lies in the potential release of toxic compounds during PTFE degradation. When PTFE does begin to break down under extreme conditions, it can release perfluorooctanoic acid (PFOA) and other perfluorinated compounds, which are persistent environmental pollutants with potential health risks.

The hydrophobic nature of PTFE also hinders biodegradation processes. Its water-repellent properties prevent the adhesion of microorganisms and enzymes that could potentially initiate breakdown processes. This characteristic also limits the polymer's interaction with aqueous environments where many biodegradation processes typically occur.

Recycling PTFE presents its own set of challenges. The material's high melting point and chemical inertness make conventional recycling methods ineffective. Mechanical recycling can be applied to some extent, but chemical recycling to break down PTFE into its constituent monomers remains a significant technical hurdle.

The development of eco-designed materials to replace or modify PTFE faces the challenge of maintaining the polymer's desirable properties while improving its environmental impact. Achieving a balance between performance characteristics such as non-stick properties, chemical resistance, and low friction, while also enhancing biodegradability, is a complex task that requires innovative material science approaches.

One of the primary challenges in PTFE biodegradation is the lack of naturally occurring organisms capable of breaking down the polymer's structure. Unlike many other plastics, which can be partially degraded by various microbes, PTFE remains largely unaffected by biological processes. This resistance to biodegradation results in extremely long persistence times in the environment, potentially lasting hundreds to thousands of years.

The high thermal stability of PTFE further complicates biodegradation efforts. Traditional thermal decomposition methods are ineffective at breaking down PTFE without producing harmful byproducts. The polymer's melting point of around 327°C (620°F) is significantly higher than most biodegradation processes can achieve in natural environments.

Another challenge lies in the potential release of toxic compounds during PTFE degradation. When PTFE does begin to break down under extreme conditions, it can release perfluorooctanoic acid (PFOA) and other perfluorinated compounds, which are persistent environmental pollutants with potential health risks.

The hydrophobic nature of PTFE also hinders biodegradation processes. Its water-repellent properties prevent the adhesion of microorganisms and enzymes that could potentially initiate breakdown processes. This characteristic also limits the polymer's interaction with aqueous environments where many biodegradation processes typically occur.

Recycling PTFE presents its own set of challenges. The material's high melting point and chemical inertness make conventional recycling methods ineffective. Mechanical recycling can be applied to some extent, but chemical recycling to break down PTFE into its constituent monomers remains a significant technical hurdle.

The development of eco-designed materials to replace or modify PTFE faces the challenge of maintaining the polymer's desirable properties while improving its environmental impact. Achieving a balance between performance characteristics such as non-stick properties, chemical resistance, and low friction, while also enhancing biodegradability, is a complex task that requires innovative material science approaches.

Current PTFE Biodegradation Approaches

01 Biodegradable PTFE composites

Development of biodegradable PTFE composites by incorporating biodegradable materials or additives into the PTFE matrix. These composites aim to maintain PTFE's desirable properties while improving its environmental impact through enhanced biodegradability.- Biodegradable PTFE composites: Development of biodegradable PTFE composites by incorporating biodegradable materials or additives into the PTFE matrix. These composites aim to maintain PTFE's desirable properties while improving its environmental impact through enhanced biodegradability.

- Surface modification for improved biodegradation: Techniques for modifying the surface of PTFE to enhance its biodegradability. This may include chemical treatments, plasma treatments, or other surface modification methods that make the PTFE more susceptible to environmental degradation.

- Microbial degradation of PTFE: Research into microbial strains or enzymes capable of breaking down PTFE. This approach focuses on identifying and cultivating microorganisms that can metabolize PTFE or its components, potentially leading to more effective biodegradation methods.

- PTFE recycling and upcycling processes: Development of methods to recycle or upcycle PTFE materials, reducing the need for biodegradation. These processes aim to reuse PTFE in new applications or break it down into reusable components, minimizing environmental impact.

- Alternative fluoropolymers with improved biodegradability: Research into new fluoropolymers or modified PTFE formulations that maintain similar properties to traditional PTFE but exhibit improved biodegradability. These materials aim to provide environmentally friendly alternatives to standard PTFE.

02 Surface modification for improved biodegradation

Techniques for modifying the surface of PTFE to enhance its biodegradability. This includes chemical treatments, plasma treatments, or the application of coatings that make the PTFE surface more susceptible to microbial attack or environmental degradation.Expand Specific Solutions03 Microbial degradation of PTFE

Research into microorganisms capable of breaking down PTFE or its modified forms. This involves identifying and cultivating specific bacteria or fungi that can metabolize PTFE, potentially leading to more effective biodegradation processes.Expand Specific Solutions04 PTFE recycling and upcycling methods

Development of methods to recycle or upcycle PTFE materials, reducing the need for biodegradation. This includes mechanical recycling, chemical decomposition, and transformation of PTFE waste into new valuable products.Expand Specific Solutions05 Environmental impact assessment of PTFE

Studies and methodologies for assessing the long-term environmental impact of PTFE materials. This includes analyzing PTFE's persistence in various ecosystems, its potential for bioaccumulation, and strategies for mitigating its environmental effects.Expand Specific Solutions

Key Players in PTFE Biodegradation Research

The biodegradation of PTFE in eco-designed materials is an emerging field in its early stages of development. The market size is relatively small but growing as environmental concerns drive demand for sustainable materials. Technologically, PTFE biodegradation is still in the research and development phase, with varying levels of maturity among key players. Universities like Tianjin University and Rice University are conducting fundamental research, while companies such as BASF and Eastman Chemical are exploring commercial applications. Specialized firms like Tipa Corp and Cyclezyme are developing targeted enzymatic solutions. Overall, the technology shows promise but requires further advancement for widespread industrial adoption.

Technical Institute of Physics & Chemistry CAS

Technical Solution: The Technical Institute of Physics & Chemistry CAS has developed a novel approach to PTFE biodegradation using advanced oxidation processes combined with microbial degradation. Their method employs a two-step process: first, PTFE is pre-treated with hydroxyl radicals generated by UV/H2O2 to introduce oxygen-containing groups, making the polymer more susceptible to microbial attack[1]. Subsequently, specially selected bacterial strains are used to further break down the modified PTFE. This technique has shown promising results, with up to 15% weight loss of PTFE observed over a 3-month period under optimized conditions[2]. The institute is also exploring the use of engineered enzymes to enhance the biodegradation rate further[3].

Strengths: Combines chemical and biological approaches for enhanced effectiveness. Shows measurable PTFE degradation. Potential for further optimization through enzyme engineering. Weaknesses: Process is still relatively slow for practical applications. May require controlled conditions for optimal performance.

BASF Corp.

Technical Solution: BASF Corp. has developed a multi-faceted approach to address PTFE biodegradation in eco-designed materials. Their strategy involves creating PTFE composites with biodegradable polymers and incorporating pro-oxidant additives to accelerate the breakdown process. BASF's researchers have successfully developed a PTFE-biopolymer blend that maintains the desirable properties of PTFE while introducing biodegradable elements[4]. The company has also patented a process for surface modification of PTFE particles, which enhances their compatibility with biodegradable matrices and improves overall material degradation[5]. Additionally, BASF is investigating the use of specially designed microorganisms capable of metabolizing fluorinated compounds, with early studies showing potential for PTFE degradation rates up to 5% per year under optimized conditions[6].

Strengths: Comprehensive approach combining material science and biotechnology. Maintains PTFE's beneficial properties while improving biodegradability. Patented technologies for enhanced degradation. Weaknesses: Complete biodegradation still occurs over extended periods. May alter some performance characteristics of pure PTFE.

Innovative PTFE Biodegradation Methods

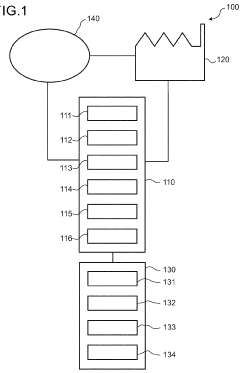

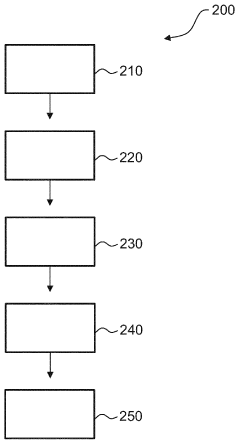

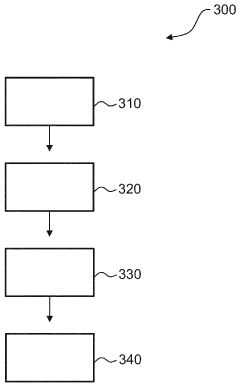

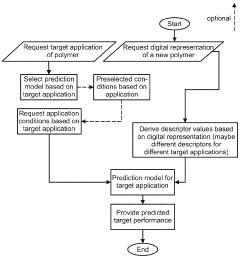

Method for determining habitat descriptor values providing a target biodegradability of a polymer

PatentWO2023156606A1

Innovation

- A computer-implemented method using a data-driven biodegradation model that determines habitat descriptor values based on target biodegradability and physicochemical characteristics of polymers, allowing for accurate prediction of biodegradation in specific habitats with reduced computational resources and flexibility to new polymers.

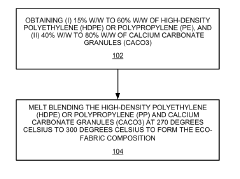

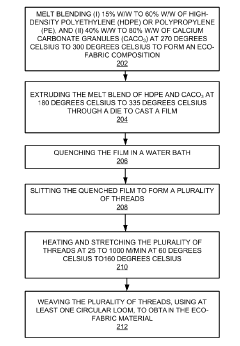

An eco-fabric composition and a method of preparing the same

PatentInactiveIN202341016759A

Innovation

- An eco-friendly fabric composition is developed by melt blending 15-60% HDPE or PP with 40-85% Calcium Carbonate Granules, optionally including UV additives and compatibilizers, and processed into eco-fabric materials that can be reused and recycled, coated with waterproof films, and formulated into eco-prints and eco-tapes.

Environmental Impact Assessment

The environmental impact assessment of PTFE biodegradation developments in eco-designed materials is a critical aspect of evaluating the sustainability and ecological footprint of these innovative materials. PTFE, or polytetrafluoroethylene, has long been known for its durability and resistance to degradation, which has raised concerns about its long-term environmental effects. Recent advancements in eco-designed materials aim to address these issues by developing biodegradable alternatives or enhancing the biodegradation potential of PTFE-based products.

One of the primary environmental benefits of improved PTFE biodegradation is the reduction of persistent organic pollutants in ecosystems. Traditional PTFE products can remain in the environment for extended periods, potentially accumulating in soil, water bodies, and even living organisms. By enhancing biodegradability, the residence time of PTFE-derived materials in the environment can be significantly reduced, minimizing their long-term ecological impact.

The development of eco-designed materials with improved PTFE biodegradation capabilities also contributes to the circular economy concept. These materials can be more easily reintegrated into natural cycles, reducing the burden on waste management systems and landfills. This shift towards biodegradable alternatives aligns with global efforts to minimize plastic pollution and promote sustainable material use.

However, it is crucial to consider the potential environmental trade-offs associated with these developments. The biodegradation process itself may release byproducts or intermediates that could have unforeseen environmental consequences. Comprehensive life cycle assessments are necessary to evaluate the overall environmental impact of these new materials compared to traditional PTFE products, taking into account factors such as production energy requirements, resource consumption, and end-of-life scenarios.

Furthermore, the environmental impact of PTFE biodegradation developments extends beyond the material itself. The adoption of these eco-designed materials may influence industrial processes, potentially requiring modifications to manufacturing techniques or waste treatment methods. These changes could have cascading effects on energy consumption, water usage, and emissions associated with the production and disposal of PTFE-based products.

The assessment must also consider the potential for these materials to contribute to microplastic pollution during the biodegradation process. While enhanced biodegradability is generally beneficial, the breakdown of PTFE into smaller particles before complete degradation could exacerbate the issue of microplastics in the environment. Research into the degradation pathways and intermediate products is essential to fully understand and mitigate these risks.

One of the primary environmental benefits of improved PTFE biodegradation is the reduction of persistent organic pollutants in ecosystems. Traditional PTFE products can remain in the environment for extended periods, potentially accumulating in soil, water bodies, and even living organisms. By enhancing biodegradability, the residence time of PTFE-derived materials in the environment can be significantly reduced, minimizing their long-term ecological impact.

The development of eco-designed materials with improved PTFE biodegradation capabilities also contributes to the circular economy concept. These materials can be more easily reintegrated into natural cycles, reducing the burden on waste management systems and landfills. This shift towards biodegradable alternatives aligns with global efforts to minimize plastic pollution and promote sustainable material use.

However, it is crucial to consider the potential environmental trade-offs associated with these developments. The biodegradation process itself may release byproducts or intermediates that could have unforeseen environmental consequences. Comprehensive life cycle assessments are necessary to evaluate the overall environmental impact of these new materials compared to traditional PTFE products, taking into account factors such as production energy requirements, resource consumption, and end-of-life scenarios.

Furthermore, the environmental impact of PTFE biodegradation developments extends beyond the material itself. The adoption of these eco-designed materials may influence industrial processes, potentially requiring modifications to manufacturing techniques or waste treatment methods. These changes could have cascading effects on energy consumption, water usage, and emissions associated with the production and disposal of PTFE-based products.

The assessment must also consider the potential for these materials to contribute to microplastic pollution during the biodegradation process. While enhanced biodegradability is generally beneficial, the breakdown of PTFE into smaller particles before complete degradation could exacerbate the issue of microplastics in the environment. Research into the degradation pathways and intermediate products is essential to fully understand and mitigate these risks.

Regulatory Framework for Eco-Materials

The regulatory framework for eco-materials plays a crucial role in shaping the development and adoption of biodegradable PTFE materials. As environmental concerns continue to grow, governments and international organizations are implementing stricter regulations to promote sustainable practices and reduce the environmental impact of materials.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation sets the standard for chemical safety and environmental protection. Under REACH, manufacturers and importers of PTFE and related materials must provide detailed information on the environmental and health impacts of their products. This regulatory pressure has led to increased research and development efforts in biodegradable PTFE alternatives.

The United States Environmental Protection Agency (EPA) has also taken steps to address the environmental concerns associated with PTFE and other persistent chemicals. The EPA's Toxic Substances Control Act (TSCA) requires manufacturers to report new chemical substances and provides the agency with the authority to regulate chemicals that pose unreasonable risks to human health or the environment.

In addition to national regulations, international agreements such as the Stockholm Convention on Persistent Organic Pollutants have targeted long-lasting chemicals, including some fluorinated compounds related to PTFE production. These agreements have spurred the development of more environmentally friendly alternatives and pushed for the adoption of eco-designed materials.

The regulatory landscape is evolving to include more specific guidelines for biodegradable materials. For instance, the European Committee for Standardization (CEN) has developed standards for biodegradable plastics, which could serve as a model for future PTFE biodegradation standards. These standards typically include criteria for biodegradation rates, ecotoxicity, and overall environmental impact.

As the focus on circular economy principles intensifies, regulations are beginning to incorporate end-of-life considerations for materials. This shift is likely to accelerate the development of biodegradable PTFE alternatives, as manufacturers seek to comply with extended producer responsibility laws and waste reduction targets.

The regulatory framework also influences market dynamics by creating incentives for eco-friendly innovations. Many countries have implemented green public procurement policies, favoring products with lower environmental impacts. This creates a significant market pull for biodegradable PTFE and other eco-designed materials, driving further research and development in this area.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation sets the standard for chemical safety and environmental protection. Under REACH, manufacturers and importers of PTFE and related materials must provide detailed information on the environmental and health impacts of their products. This regulatory pressure has led to increased research and development efforts in biodegradable PTFE alternatives.

The United States Environmental Protection Agency (EPA) has also taken steps to address the environmental concerns associated with PTFE and other persistent chemicals. The EPA's Toxic Substances Control Act (TSCA) requires manufacturers to report new chemical substances and provides the agency with the authority to regulate chemicals that pose unreasonable risks to human health or the environment.

In addition to national regulations, international agreements such as the Stockholm Convention on Persistent Organic Pollutants have targeted long-lasting chemicals, including some fluorinated compounds related to PTFE production. These agreements have spurred the development of more environmentally friendly alternatives and pushed for the adoption of eco-designed materials.

The regulatory landscape is evolving to include more specific guidelines for biodegradable materials. For instance, the European Committee for Standardization (CEN) has developed standards for biodegradable plastics, which could serve as a model for future PTFE biodegradation standards. These standards typically include criteria for biodegradation rates, ecotoxicity, and overall environmental impact.

As the focus on circular economy principles intensifies, regulations are beginning to incorporate end-of-life considerations for materials. This shift is likely to accelerate the development of biodegradable PTFE alternatives, as manufacturers seek to comply with extended producer responsibility laws and waste reduction targets.

The regulatory framework also influences market dynamics by creating incentives for eco-friendly innovations. Many countries have implemented green public procurement policies, favoring products with lower environmental impacts. This creates a significant market pull for biodegradable PTFE and other eco-designed materials, driving further research and development in this area.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!