Analyzing nanoparticle‑enhanced PTFE gel applications in soft robotics

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanoparticle-PTFE Gel Evolution and Objectives

The evolution of nanoparticle-enhanced PTFE gel technology in soft robotics represents a significant advancement in the field of materials science and robotics. This innovative approach combines the unique properties of polytetrafluoroethylene (PTFE) with the enhanced capabilities offered by nanoparticles, creating a hybrid material with remarkable potential for soft robotic applications.

The development of this technology can be traced back to the early 2000s when researchers began exploring ways to improve the mechanical and functional properties of PTFE. The incorporation of nanoparticles into PTFE gels emerged as a promising avenue for enhancing the material's performance characteristics, including its flexibility, durability, and responsiveness to external stimuli.

Over the past two decades, significant progress has been made in understanding the synergistic effects between nanoparticles and PTFE gel matrices. Various types of nanoparticles, such as carbon nanotubes, graphene, and metal oxide nanoparticles, have been investigated for their ability to impart specific properties to the PTFE gel. These enhancements have led to improved mechanical strength, electrical conductivity, and thermal stability, all of which are crucial for soft robotic applications.

The primary objective of nanoparticle-enhanced PTFE gel research in soft robotics is to develop materials that can mimic the flexibility and adaptability of biological systems while maintaining the robustness required for practical applications. This includes creating actuators that can perform complex movements, sensors that can detect and respond to environmental changes, and structural components that can withstand repeated deformation without failure.

Another key goal is to achieve precise control over the material's properties through the careful selection and distribution of nanoparticles within the PTFE gel matrix. This level of control allows for the creation of soft robotic components with tailored characteristics, such as anisotropic mechanical properties or localized responsiveness to specific stimuli.

Researchers are also focusing on improving the scalability and manufacturability of nanoparticle-enhanced PTFE gels. This involves developing efficient methods for dispersing nanoparticles uniformly throughout the gel, as well as optimizing processing techniques to ensure consistent material properties across different batches and scales of production.

As the field progresses, there is a growing emphasis on exploring the potential of these materials for biomedical applications, such as soft robotic prosthetics and minimally invasive surgical tools. This requires addressing additional challenges related to biocompatibility, sterilization, and long-term stability in physiological environments.

The development of this technology can be traced back to the early 2000s when researchers began exploring ways to improve the mechanical and functional properties of PTFE. The incorporation of nanoparticles into PTFE gels emerged as a promising avenue for enhancing the material's performance characteristics, including its flexibility, durability, and responsiveness to external stimuli.

Over the past two decades, significant progress has been made in understanding the synergistic effects between nanoparticles and PTFE gel matrices. Various types of nanoparticles, such as carbon nanotubes, graphene, and metal oxide nanoparticles, have been investigated for their ability to impart specific properties to the PTFE gel. These enhancements have led to improved mechanical strength, electrical conductivity, and thermal stability, all of which are crucial for soft robotic applications.

The primary objective of nanoparticle-enhanced PTFE gel research in soft robotics is to develop materials that can mimic the flexibility and adaptability of biological systems while maintaining the robustness required for practical applications. This includes creating actuators that can perform complex movements, sensors that can detect and respond to environmental changes, and structural components that can withstand repeated deformation without failure.

Another key goal is to achieve precise control over the material's properties through the careful selection and distribution of nanoparticles within the PTFE gel matrix. This level of control allows for the creation of soft robotic components with tailored characteristics, such as anisotropic mechanical properties or localized responsiveness to specific stimuli.

Researchers are also focusing on improving the scalability and manufacturability of nanoparticle-enhanced PTFE gels. This involves developing efficient methods for dispersing nanoparticles uniformly throughout the gel, as well as optimizing processing techniques to ensure consistent material properties across different batches and scales of production.

As the field progresses, there is a growing emphasis on exploring the potential of these materials for biomedical applications, such as soft robotic prosthetics and minimally invasive surgical tools. This requires addressing additional challenges related to biocompatibility, sterilization, and long-term stability in physiological environments.

Soft Robotics Market Demand Analysis

The soft robotics market is experiencing significant growth, driven by increasing demand across various industries. This emerging field combines principles of robotics, materials science, and biomimicry to create flexible and adaptable robotic systems. The market for soft robotics is expected to expand rapidly in the coming years, with applications spanning healthcare, manufacturing, and consumer electronics.

In the healthcare sector, soft robotics shows immense potential for minimally invasive surgeries, prosthetics, and rehabilitation devices. The ability of soft robots to interact safely with human tissues makes them ideal for medical applications. Hospitals and research institutions are increasingly investing in soft robotic technologies to improve patient care and surgical outcomes.

The manufacturing industry is another key driver of soft robotics market demand. Soft grippers and manipulators are being adopted for handling delicate objects and materials in production lines. These systems offer greater flexibility and adaptability compared to traditional rigid robots, enabling manufacturers to automate complex tasks that were previously challenging to mechanize.

Consumer electronics and wearable technology represent a growing market segment for soft robotics. The integration of soft actuators and sensors in wearable devices allows for more comfortable and responsive user experiences. This trend is particularly evident in the development of advanced haptic feedback systems and adaptive wearables.

The automotive industry is also showing interest in soft robotics for applications such as adaptive interiors and safety systems. Soft robotic components can enhance passenger comfort and safety by providing customizable support and impact absorption.

Environmental monitoring and exploration represent emerging applications for soft robotics. Researchers are developing soft robotic systems for underwater exploration, environmental sampling, and disaster response scenarios where traditional rigid robots may be unsuitable.

Despite the growing market demand, challenges remain in scaling up production and reducing costs of soft robotic systems. The complexity of manufacturing soft materials with embedded sensors and actuators presents technical hurdles that need to be overcome to meet increasing market demands.

The integration of nanoparticle-enhanced PTFE gels in soft robotics is poised to address some of these challenges. These advanced materials offer improved mechanical properties, enhanced responsiveness, and potentially lower production costs. As research in this area progresses, it is likely to further stimulate market demand by enabling new applications and improving the performance of existing soft robotic systems.

In the healthcare sector, soft robotics shows immense potential for minimally invasive surgeries, prosthetics, and rehabilitation devices. The ability of soft robots to interact safely with human tissues makes them ideal for medical applications. Hospitals and research institutions are increasingly investing in soft robotic technologies to improve patient care and surgical outcomes.

The manufacturing industry is another key driver of soft robotics market demand. Soft grippers and manipulators are being adopted for handling delicate objects and materials in production lines. These systems offer greater flexibility and adaptability compared to traditional rigid robots, enabling manufacturers to automate complex tasks that were previously challenging to mechanize.

Consumer electronics and wearable technology represent a growing market segment for soft robotics. The integration of soft actuators and sensors in wearable devices allows for more comfortable and responsive user experiences. This trend is particularly evident in the development of advanced haptic feedback systems and adaptive wearables.

The automotive industry is also showing interest in soft robotics for applications such as adaptive interiors and safety systems. Soft robotic components can enhance passenger comfort and safety by providing customizable support and impact absorption.

Environmental monitoring and exploration represent emerging applications for soft robotics. Researchers are developing soft robotic systems for underwater exploration, environmental sampling, and disaster response scenarios where traditional rigid robots may be unsuitable.

Despite the growing market demand, challenges remain in scaling up production and reducing costs of soft robotic systems. The complexity of manufacturing soft materials with embedded sensors and actuators presents technical hurdles that need to be overcome to meet increasing market demands.

The integration of nanoparticle-enhanced PTFE gels in soft robotics is poised to address some of these challenges. These advanced materials offer improved mechanical properties, enhanced responsiveness, and potentially lower production costs. As research in this area progresses, it is likely to further stimulate market demand by enabling new applications and improving the performance of existing soft robotic systems.

Current Challenges in Nanocomposite Gels

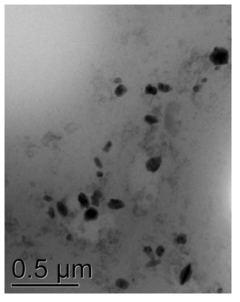

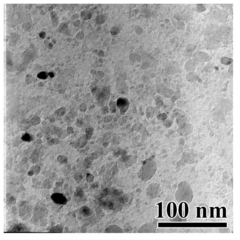

The field of nanocomposite gels, particularly in the context of nanoparticle-enhanced PTFE gel applications for soft robotics, faces several significant challenges that hinder their widespread adoption and optimal performance. One of the primary obstacles is achieving uniform dispersion of nanoparticles within the PTFE gel matrix. The tendency of nanoparticles to agglomerate due to their high surface energy and van der Waals forces can lead to inhomogeneous distribution, compromising the mechanical and functional properties of the composite.

Another critical challenge lies in maintaining the stability of the nanoparticle-enhanced PTFE gel over time and under various environmental conditions. The interface between the nanoparticles and the PTFE matrix is crucial for the overall performance of the composite. Weak interfacial bonding can result in nanoparticle detachment or migration, leading to degradation of the gel's properties and potential failure in soft robotic applications.

The scalability of production processes for nanocomposite gels presents a significant hurdle. While laboratory-scale synthesis may yield promising results, translating these methods to industrial-scale production while maintaining consistent quality and properties remains challenging. This includes issues related to batch-to-batch variability, process control, and cost-effectiveness.

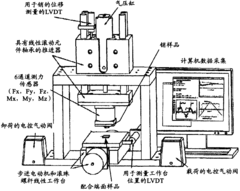

Furthermore, the characterization and testing of nanoparticle-enhanced PTFE gels pose unique challenges. Traditional testing methods may not adequately capture the complex behavior of these materials, especially in the context of soft robotics where dynamic and non-linear responses are critical. Developing standardized testing protocols and predictive models for these nanocomposite gels is essential for their reliable implementation in soft robotic systems.

The long-term durability and fatigue resistance of nanoparticle-enhanced PTFE gels in soft robotic applications are also areas of concern. The repeated deformation and stress cycles experienced in soft robotic actuators can potentially lead to material degradation, nanoparticle dislodgement, or changes in the gel's properties over time. Understanding and mitigating these effects are crucial for ensuring the longevity and reliability of soft robotic devices.

Lastly, the environmental impact and potential toxicity of nanoparticles used in these gels raise concerns about their long-term sustainability and safety. As soft robotics find applications in various fields, including biomedical and environmental monitoring, ensuring the biocompatibility and eco-friendliness of nanoparticle-enhanced PTFE gels becomes increasingly important. Addressing these challenges requires interdisciplinary collaboration and innovative approaches to material design, synthesis, and characterization.

Another critical challenge lies in maintaining the stability of the nanoparticle-enhanced PTFE gel over time and under various environmental conditions. The interface between the nanoparticles and the PTFE matrix is crucial for the overall performance of the composite. Weak interfacial bonding can result in nanoparticle detachment or migration, leading to degradation of the gel's properties and potential failure in soft robotic applications.

The scalability of production processes for nanocomposite gels presents a significant hurdle. While laboratory-scale synthesis may yield promising results, translating these methods to industrial-scale production while maintaining consistent quality and properties remains challenging. This includes issues related to batch-to-batch variability, process control, and cost-effectiveness.

Furthermore, the characterization and testing of nanoparticle-enhanced PTFE gels pose unique challenges. Traditional testing methods may not adequately capture the complex behavior of these materials, especially in the context of soft robotics where dynamic and non-linear responses are critical. Developing standardized testing protocols and predictive models for these nanocomposite gels is essential for their reliable implementation in soft robotic systems.

The long-term durability and fatigue resistance of nanoparticle-enhanced PTFE gels in soft robotic applications are also areas of concern. The repeated deformation and stress cycles experienced in soft robotic actuators can potentially lead to material degradation, nanoparticle dislodgement, or changes in the gel's properties over time. Understanding and mitigating these effects are crucial for ensuring the longevity and reliability of soft robotic devices.

Lastly, the environmental impact and potential toxicity of nanoparticles used in these gels raise concerns about their long-term sustainability and safety. As soft robotics find applications in various fields, including biomedical and environmental monitoring, ensuring the biocompatibility and eco-friendliness of nanoparticle-enhanced PTFE gels becomes increasingly important. Addressing these challenges requires interdisciplinary collaboration and innovative approaches to material design, synthesis, and characterization.

Existing Nanoparticle-PTFE Gel Solutions

01 Nanoparticle-enhanced PTFE gel composition

The incorporation of nanoparticles into PTFE gel formulations enhances the properties of the gel. These nanoparticles can improve the mechanical strength, thermal stability, and chemical resistance of the PTFE gel. The nanoparticles are typically dispersed uniformly throughout the gel matrix, creating a composite material with superior performance characteristics.- Nanoparticle incorporation in PTFE gel: Nanoparticles are integrated into PTFE gel to enhance its properties. This combination can improve the gel's mechanical strength, thermal stability, and chemical resistance. The nanoparticles can be various materials such as metal oxides or carbon-based materials, which interact with the PTFE matrix to create a more robust composite material.

- Surface modification of PTFE with nanoparticles: The surface of PTFE gel is modified using nanoparticles to enhance its characteristics. This process can improve the gel's wettability, adhesion properties, and biocompatibility. The nanoparticles can be functionalized to provide specific surface properties tailored for various applications, such as medical devices or industrial coatings.

- Nanoparticle-enhanced PTFE gel for drug delivery: PTFE gel incorporated with nanoparticles is utilized in drug delivery systems. The nanoparticles can act as carriers for therapeutic agents, while the PTFE gel provides a stable matrix for controlled release. This combination can improve drug efficacy, reduce side effects, and allow for targeted delivery to specific tissues or organs.

- Electrical and thermal properties of nanoparticle-PTFE gel composites: The addition of nanoparticles to PTFE gel can significantly alter its electrical and thermal properties. Depending on the type of nanoparticles used, the composite can exhibit enhanced thermal conductivity, electrical conductivity, or insulation properties. This makes the material suitable for various applications in electronics, energy storage, and thermal management systems.

- Manufacturing processes for nanoparticle-enhanced PTFE gel: Various manufacturing techniques are employed to produce nanoparticle-enhanced PTFE gel. These may include in-situ polymerization, melt blending, or solution mixing methods. The choice of manufacturing process can significantly impact the dispersion of nanoparticles within the PTFE matrix, which in turn affects the final properties of the composite material.

02 Application of nanoparticle-enhanced PTFE gel in coatings

Nanoparticle-enhanced PTFE gels are utilized in various coating applications. These coatings exhibit improved durability, wear resistance, and non-stick properties. The nanoparticles contribute to enhanced adhesion to substrates and can provide additional functionalities such as improved thermal conductivity or electrical insulation.Expand Specific Solutions03 Synthesis methods for nanoparticle-enhanced PTFE gel

Various synthesis methods are employed to produce nanoparticle-enhanced PTFE gels. These methods include in-situ polymerization, sol-gel processes, and mechanical dispersion techniques. The choice of synthesis method affects the distribution and interaction of nanoparticles within the PTFE gel matrix, influencing the final properties of the composite material.Expand Specific Solutions04 Nanoparticle types used in PTFE gel enhancement

Different types of nanoparticles are used to enhance PTFE gels, including metal oxides, carbon nanotubes, and silica nanoparticles. Each type of nanoparticle imparts specific properties to the PTFE gel, such as improved thermal conductivity, increased mechanical strength, or enhanced chemical resistance. The selection of nanoparticle type depends on the desired properties and application of the enhanced PTFE gel.Expand Specific Solutions05 Characterization and testing of nanoparticle-enhanced PTFE gels

Various characterization and testing methods are employed to evaluate the properties of nanoparticle-enhanced PTFE gels. These include microscopy techniques for analyzing nanoparticle distribution, mechanical testing for assessing strength and flexibility, and thermal analysis for determining stability at elevated temperatures. Advanced spectroscopic methods are also used to study the interactions between nanoparticles and the PTFE gel matrix.Expand Specific Solutions

Key Players in Nanocomposite Soft Robotics

The nanoparticle-enhanced PTFE gel applications in soft robotics field is in an early development stage, with significant potential for growth. The market size is relatively small but expanding rapidly as researchers explore novel applications. Technologically, it's still evolving, with key players like University of Florida, Zhejiang University, and W.L. Gore & Associates leading innovation. These institutions are focusing on improving material properties and developing practical applications. While not yet fully mature, the technology shows promise in enhancing soft robotic performance, particularly in flexibility and durability. As research progresses, we can expect increased commercial interest and market expansion in the coming years.

University of Florida

Technical Solution: The University of Florida has developed a novel approach to nanoparticle-enhanced PTFE gel for soft robotics applications. Their research focuses on incorporating various nanoparticles, such as carbon nanotubes and graphene, into PTFE gels to enhance their mechanical and electrical properties[1]. The resulting composite material exhibits improved flexibility, conductivity, and responsiveness to external stimuli, making it ideal for soft robotic actuators[2]. The team has successfully demonstrated a prototype soft robotic gripper using this nanoparticle-enhanced PTFE gel, capable of delicate object manipulation with precise force control[3]. Furthermore, they have explored the use of magnetic nanoparticles to create magnetically responsive PTFE gels, enabling remote actuation and control of soft robotic components[4].

Strengths: Enhanced mechanical and electrical properties, improved flexibility and responsiveness, potential for remote actuation. Weaknesses: Potential challenges in scaling up production, long-term stability of nanoparticle dispersion in the gel matrix.

Zhejiang University

Technical Solution: Zhejiang University has made significant strides in developing nanoparticle-enhanced PTFE gels for soft robotics. Their approach involves the use of surface-modified silica nanoparticles to create a hierarchical structure within the PTFE gel matrix[1]. This results in a material with enhanced mechanical strength and self-healing properties[2]. The research team has also explored the incorporation of thermally responsive nanoparticles, allowing for temperature-controlled actuation of soft robotic components[3]. In a recent breakthrough, they developed a nanoparticle-enhanced PTFE gel with reversible adhesion properties, enabling soft robots to climb vertical surfaces and adhere to various substrates[4]. The university has successfully demonstrated these materials in prototype soft robotic limbs and grippers, showcasing improved dexterity and adaptability compared to conventional soft robotic materials[5].

Strengths: Enhanced mechanical properties, self-healing capabilities, temperature-responsive actuation, and reversible adhesion. Weaknesses: Potential complexity in manufacturing processes, need for further optimization of nanoparticle distribution.

Core Innovations in Nanocomposite Gels

Inert wear resistant fluoropolymer-based solid lubricants, methods of making, and methods of use

PatentInactiveCN102197084A

Innovation

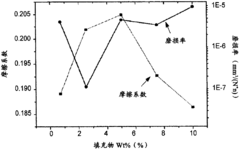

- By mixing a fluoro-reactive compound with PTFE and heating it to form a fluoropolymer-based material with an inert secondary phase, composites with low wear rates and high wear resistance are produced, significantly improving the material's durability with lower filler percentages. Wear resistance.

Composite nano anti-gluing industrial coating and industrial production method and application thereof

PatentActiveCN102977714A

Innovation

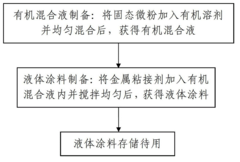

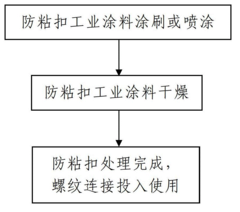

- A composite nano-anti-sticking industrial coating composed of nano-copper powder and nano-polytetrafluoroethylene powder is used. It is uniformly mixed with organic solvents and metal adhesives to form a liquid coating. It is brushed or sprayed on the thread surface and used after drying. Reduce the tightening torque of threaded connections and prevent sticking.

Environmental Impact of Nanoparticle-PTFE Gels

The environmental impact of nanoparticle-enhanced PTFE gels in soft robotics applications is a critical consideration as this technology advances. These materials offer significant performance benefits, but their potential ecological consequences must be carefully evaluated.

Nanoparticles used in PTFE gel formulations may pose risks to aquatic ecosystems if released into the environment. Their small size allows them to penetrate cell membranes and accumulate in organisms, potentially causing toxicity or disrupting food chains. Studies have shown that some nanoparticles can affect the growth and reproduction of aquatic species, even at low concentrations.

The production process of nanoparticle-PTFE gels may involve energy-intensive methods and the use of potentially harmful chemicals. This could contribute to increased carbon emissions and chemical pollution if not properly managed. Additionally, the disposal of soft robotic devices containing these materials at the end of their lifecycle presents challenges for waste management systems.

However, the durability and longevity of nanoparticle-enhanced PTFE gels may lead to reduced material consumption and waste generation over time. Soft robots using these materials could have extended operational lifespans, potentially offsetting some of the environmental impacts associated with their production.

The potential for nanoparticle leaching during the use phase of soft robotic applications is an area of concern. Mechanical stress, wear, and environmental factors could cause the release of nanoparticles into surrounding ecosystems. This risk is particularly relevant in applications where soft robots interact directly with natural environments, such as in marine exploration or agricultural settings.

Efforts to mitigate environmental impacts include developing biodegradable nanoparticles, improving containment strategies, and implementing closed-loop recycling systems for these materials. Research into green synthesis methods for nanoparticles and environmentally friendly PTFE alternatives is ongoing, aiming to reduce the ecological footprint of this technology.

As the field of soft robotics expands, regulatory frameworks and industry standards will need to evolve to address the specific environmental challenges posed by nanoparticle-PTFE gels. Life cycle assessments and long-term environmental monitoring will be crucial in understanding and managing the full ecological impact of these innovative materials in soft robotic applications.

Nanoparticles used in PTFE gel formulations may pose risks to aquatic ecosystems if released into the environment. Their small size allows them to penetrate cell membranes and accumulate in organisms, potentially causing toxicity or disrupting food chains. Studies have shown that some nanoparticles can affect the growth and reproduction of aquatic species, even at low concentrations.

The production process of nanoparticle-PTFE gels may involve energy-intensive methods and the use of potentially harmful chemicals. This could contribute to increased carbon emissions and chemical pollution if not properly managed. Additionally, the disposal of soft robotic devices containing these materials at the end of their lifecycle presents challenges for waste management systems.

However, the durability and longevity of nanoparticle-enhanced PTFE gels may lead to reduced material consumption and waste generation over time. Soft robots using these materials could have extended operational lifespans, potentially offsetting some of the environmental impacts associated with their production.

The potential for nanoparticle leaching during the use phase of soft robotic applications is an area of concern. Mechanical stress, wear, and environmental factors could cause the release of nanoparticles into surrounding ecosystems. This risk is particularly relevant in applications where soft robots interact directly with natural environments, such as in marine exploration or agricultural settings.

Efforts to mitigate environmental impacts include developing biodegradable nanoparticles, improving containment strategies, and implementing closed-loop recycling systems for these materials. Research into green synthesis methods for nanoparticles and environmentally friendly PTFE alternatives is ongoing, aiming to reduce the ecological footprint of this technology.

As the field of soft robotics expands, regulatory frameworks and industry standards will need to evolve to address the specific environmental challenges posed by nanoparticle-PTFE gels. Life cycle assessments and long-term environmental monitoring will be crucial in understanding and managing the full ecological impact of these innovative materials in soft robotic applications.

Scalability and Manufacturing Challenges

The scalability and manufacturing challenges associated with nanoparticle-enhanced PTFE gel applications in soft robotics are significant considerations for the widespread adoption of this technology. One of the primary challenges lies in the consistent production of nanoparticles with uniform size and distribution. The properties of the PTFE gel are heavily influenced by the characteristics of the embedded nanoparticles, making precise control over their synthesis crucial for maintaining product quality at scale.

Another major hurdle is the integration of nanoparticles into the PTFE matrix. Achieving homogeneous dispersion of nanoparticles throughout the gel is essential for optimal performance but becomes increasingly difficult as production volumes increase. Agglomeration of nanoparticles can lead to inconsistent mechanical properties and reduced effectiveness of the enhanced gel in soft robotic applications.

The manufacturing process itself presents challenges in terms of equipment and process optimization. Specialized machinery may be required to handle the unique properties of nanoparticle-enhanced PTFE gels, potentially increasing production costs. Additionally, the process parameters, such as temperature, pressure, and mixing times, need to be carefully controlled and may require adjustment as production scales up.

Quality control and characterization of the final product pose another set of challenges. Ensuring consistent performance across large batches of nanoparticle-enhanced PTFE gels requires sophisticated testing methods and potentially new quality assurance protocols. This may involve the development of novel analytical techniques to assess nanoparticle distribution and gel properties at a nanoscale level.

Environmental and safety considerations also come into play when scaling up production. The handling of nanoparticles in large quantities raises concerns about worker exposure and potential environmental impacts. Implementing robust safety measures and containment systems becomes increasingly important as production volumes grow.

Lastly, the supply chain for raw materials, particularly specialized nanoparticles, may face strain as demand increases. Securing a stable and cost-effective supply of high-quality nanoparticles is crucial for sustainable large-scale manufacturing. This may necessitate the development of new supplier relationships or even in-house production capabilities for key components.

Addressing these scalability and manufacturing challenges will be critical for the successful commercialization of nanoparticle-enhanced PTFE gel applications in soft robotics. Overcoming these hurdles will require collaborative efforts between materials scientists, process engineers, and robotics experts to develop innovative solutions and optimize production processes.

Another major hurdle is the integration of nanoparticles into the PTFE matrix. Achieving homogeneous dispersion of nanoparticles throughout the gel is essential for optimal performance but becomes increasingly difficult as production volumes increase. Agglomeration of nanoparticles can lead to inconsistent mechanical properties and reduced effectiveness of the enhanced gel in soft robotic applications.

The manufacturing process itself presents challenges in terms of equipment and process optimization. Specialized machinery may be required to handle the unique properties of nanoparticle-enhanced PTFE gels, potentially increasing production costs. Additionally, the process parameters, such as temperature, pressure, and mixing times, need to be carefully controlled and may require adjustment as production scales up.

Quality control and characterization of the final product pose another set of challenges. Ensuring consistent performance across large batches of nanoparticle-enhanced PTFE gels requires sophisticated testing methods and potentially new quality assurance protocols. This may involve the development of novel analytical techniques to assess nanoparticle distribution and gel properties at a nanoscale level.

Environmental and safety considerations also come into play when scaling up production. The handling of nanoparticles in large quantities raises concerns about worker exposure and potential environmental impacts. Implementing robust safety measures and containment systems becomes increasingly important as production volumes grow.

Lastly, the supply chain for raw materials, particularly specialized nanoparticles, may face strain as demand increases. Securing a stable and cost-effective supply of high-quality nanoparticles is crucial for sustainable large-scale manufacturing. This may necessitate the development of new supplier relationships or even in-house production capabilities for key components.

Addressing these scalability and manufacturing challenges will be critical for the successful commercialization of nanoparticle-enhanced PTFE gel applications in soft robotics. Overcoming these hurdles will require collaborative efforts between materials scientists, process engineers, and robotics experts to develop innovative solutions and optimize production processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!