Assessing PTFE film transparency improvements for lens overlays

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Film Transparency Goals

Polytetrafluoroethylene (PTFE) film has long been utilized in various optical applications, including lens overlays, due to its unique properties. However, the inherent opacity of PTFE has limited its widespread adoption in high-performance optical systems. The primary goal of improving PTFE film transparency for lens overlays is to enhance light transmission while maintaining the material's other desirable characteristics.

One of the key objectives is to increase the overall light transmittance of PTFE films. Currently, standard PTFE films exhibit relatively low transparency, typically allowing only 40-60% of visible light to pass through. The aim is to achieve a significant improvement, targeting a transmittance of 80% or higher across the visible spectrum. This enhancement would greatly expand the potential applications of PTFE in optical systems, particularly in scenarios where maximum light throughput is critical.

Another important goal is to minimize light scattering within the PTFE film. The microstructure of PTFE tends to cause diffuse scattering of incident light, which can lead to reduced image clarity and contrast when used as a lens overlay. By refining the film's internal structure and surface properties, researchers aim to reduce this scattering effect, thereby improving the overall optical performance of PTFE-based lens systems.

Maintaining the material's excellent chemical resistance and low friction properties while improving transparency is also a crucial objective. PTFE's inertness and non-stick characteristics are valuable in many applications, and preserving these qualities alongside enhanced transparency would significantly broaden its utility in optical systems exposed to harsh environments or frequent cleaning.

Researchers are also focusing on developing PTFE films with consistent optical properties across a wide temperature range. This thermal stability is particularly important for outdoor applications or in environments with significant temperature fluctuations, where maintaining optical performance under varying conditions is essential.

Additionally, there is a push to improve the durability and scratch resistance of transparent PTFE films. While PTFE is known for its toughness, increasing its resistance to surface damage would extend the lifespan of optical components and maintain optical clarity over prolonged periods of use.

Finally, achieving these transparency improvements while keeping manufacturing costs competitive is a critical goal. The development of cost-effective production methods for highly transparent PTFE films would facilitate their widespread adoption in consumer electronics, automotive applications, and other industries where large-scale implementation is necessary.

One of the key objectives is to increase the overall light transmittance of PTFE films. Currently, standard PTFE films exhibit relatively low transparency, typically allowing only 40-60% of visible light to pass through. The aim is to achieve a significant improvement, targeting a transmittance of 80% or higher across the visible spectrum. This enhancement would greatly expand the potential applications of PTFE in optical systems, particularly in scenarios where maximum light throughput is critical.

Another important goal is to minimize light scattering within the PTFE film. The microstructure of PTFE tends to cause diffuse scattering of incident light, which can lead to reduced image clarity and contrast when used as a lens overlay. By refining the film's internal structure and surface properties, researchers aim to reduce this scattering effect, thereby improving the overall optical performance of PTFE-based lens systems.

Maintaining the material's excellent chemical resistance and low friction properties while improving transparency is also a crucial objective. PTFE's inertness and non-stick characteristics are valuable in many applications, and preserving these qualities alongside enhanced transparency would significantly broaden its utility in optical systems exposed to harsh environments or frequent cleaning.

Researchers are also focusing on developing PTFE films with consistent optical properties across a wide temperature range. This thermal stability is particularly important for outdoor applications or in environments with significant temperature fluctuations, where maintaining optical performance under varying conditions is essential.

Additionally, there is a push to improve the durability and scratch resistance of transparent PTFE films. While PTFE is known for its toughness, increasing its resistance to surface damage would extend the lifespan of optical components and maintain optical clarity over prolonged periods of use.

Finally, achieving these transparency improvements while keeping manufacturing costs competitive is a critical goal. The development of cost-effective production methods for highly transparent PTFE films would facilitate their widespread adoption in consumer electronics, automotive applications, and other industries where large-scale implementation is necessary.

Lens Overlay Market Analysis

The lens overlay market has experienced significant growth in recent years, driven by the increasing demand for advanced optical solutions across various industries. This market segment primarily focuses on protective films and coatings applied to lenses to enhance their performance, durability, and functionality. The global lens overlay market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years.

One of the key factors contributing to market growth is the rising adoption of high-performance optical systems in consumer electronics, automotive applications, and industrial equipment. Smartphones, tablets, and wearable devices have become ubiquitous, driving the need for scratch-resistant and anti-reflective lens overlays. Additionally, the automotive industry's shift towards advanced driver assistance systems (ADAS) and autonomous vehicles has created a substantial demand for specialized lens overlays that can withstand harsh environmental conditions while maintaining optical clarity.

The medical and healthcare sectors have also emerged as significant contributors to the lens overlay market. With the increasing use of endoscopes, surgical microscopes, and other optical diagnostic tools, there is a growing need for biocompatible and sterilizable lens overlays that can enhance image quality and protect sensitive optical components.

In terms of material composition, PTFE (polytetrafluoroethylene) films have gained prominence in the lens overlay market due to their excellent chemical resistance, low friction properties, and thermal stability. However, the challenge of improving PTFE film transparency for lens overlays has become a focal point for research and development efforts. Manufacturers are investing in advanced production techniques and material modifications to enhance the optical clarity of PTFE films while maintaining their other desirable properties.

The competitive landscape of the lens overlay market is characterized by a mix of established players and innovative start-ups. Major companies in the optical coatings and materials sector have been expanding their product portfolios to include specialized lens overlays, while new entrants are focusing on niche applications and novel material formulations. This dynamic has led to increased competition and a surge in patent filings related to lens overlay technologies.

Geographically, North America and Europe have traditionally dominated the lens overlay market, owing to their strong presence in high-tech industries and research institutions. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by the expansion of consumer electronics manufacturing and increasing investments in healthcare infrastructure. China, in particular, has seen a significant rise in domestic production and consumption of lens overlays, supported by government initiatives to promote advanced manufacturing capabilities.

One of the key factors contributing to market growth is the rising adoption of high-performance optical systems in consumer electronics, automotive applications, and industrial equipment. Smartphones, tablets, and wearable devices have become ubiquitous, driving the need for scratch-resistant and anti-reflective lens overlays. Additionally, the automotive industry's shift towards advanced driver assistance systems (ADAS) and autonomous vehicles has created a substantial demand for specialized lens overlays that can withstand harsh environmental conditions while maintaining optical clarity.

The medical and healthcare sectors have also emerged as significant contributors to the lens overlay market. With the increasing use of endoscopes, surgical microscopes, and other optical diagnostic tools, there is a growing need for biocompatible and sterilizable lens overlays that can enhance image quality and protect sensitive optical components.

In terms of material composition, PTFE (polytetrafluoroethylene) films have gained prominence in the lens overlay market due to their excellent chemical resistance, low friction properties, and thermal stability. However, the challenge of improving PTFE film transparency for lens overlays has become a focal point for research and development efforts. Manufacturers are investing in advanced production techniques and material modifications to enhance the optical clarity of PTFE films while maintaining their other desirable properties.

The competitive landscape of the lens overlay market is characterized by a mix of established players and innovative start-ups. Major companies in the optical coatings and materials sector have been expanding their product portfolios to include specialized lens overlays, while new entrants are focusing on niche applications and novel material formulations. This dynamic has led to increased competition and a surge in patent filings related to lens overlay technologies.

Geographically, North America and Europe have traditionally dominated the lens overlay market, owing to their strong presence in high-tech industries and research institutions. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by the expansion of consumer electronics manufacturing and increasing investments in healthcare infrastructure. China, in particular, has seen a significant rise in domestic production and consumption of lens overlays, supported by government initiatives to promote advanced manufacturing capabilities.

PTFE Film Transparency Challenges

Polytetrafluoroethylene (PTFE) films have long been utilized in various optical applications, including lens overlays, due to their unique properties such as chemical inertness, low friction, and hydrophobicity. However, the inherent opacity of PTFE has been a significant challenge in achieving high transparency for optical applications. This limitation stems from the semi-crystalline structure of PTFE, which causes light scattering and reduces overall transparency.

One of the primary challenges in improving PTFE film transparency is maintaining its desirable mechanical and chemical properties while enhancing its optical characteristics. Traditional methods of increasing transparency, such as reducing film thickness, often compromise the film's durability and protective capabilities. This trade-off between transparency and functionality has been a persistent issue in the development of PTFE films for lens overlays.

Another significant challenge lies in the processing techniques used to manufacture PTFE films. Conventional methods like skiving or melt extrusion often result in films with inconsistent thickness and surface irregularities, which further contribute to light scattering and reduced transparency. Developing advanced processing techniques that can produce ultra-thin, uniform PTFE films without sacrificing their structural integrity remains a key area of focus for researchers and manufacturers.

The presence of micro-voids and impurities within the PTFE matrix also poses a substantial challenge to achieving high transparency. These defects act as light-scattering centers, diminishing the overall optical clarity of the film. Addressing this issue requires innovative approaches in polymer synthesis and film formation to minimize the occurrence of such defects.

Furthermore, the inherent hydrophobicity of PTFE, while beneficial in many applications, can lead to issues with adhesion and integration in multi-layer optical systems. Improving the compatibility of PTFE films with other materials used in lens overlays, without compromising their transparency or protective properties, presents another significant challenge in this field.

The development of nano-structured or composite PTFE films has emerged as a promising avenue for enhancing transparency. However, controlling the nano-scale architecture of these films while maintaining their macroscopic properties poses considerable technical difficulties. Balancing the introduction of nano-scale features with the preservation of PTFE's bulk characteristics requires precise control over material synthesis and processing parameters.

Lastly, the challenge of achieving consistent and reproducible results in PTFE film transparency improvements across large-scale production remains a significant hurdle. Translating laboratory-scale successes to industrial-scale manufacturing processes while maintaining quality and cost-effectiveness is crucial for the widespread adoption of improved PTFE films in lens overlay applications.

One of the primary challenges in improving PTFE film transparency is maintaining its desirable mechanical and chemical properties while enhancing its optical characteristics. Traditional methods of increasing transparency, such as reducing film thickness, often compromise the film's durability and protective capabilities. This trade-off between transparency and functionality has been a persistent issue in the development of PTFE films for lens overlays.

Another significant challenge lies in the processing techniques used to manufacture PTFE films. Conventional methods like skiving or melt extrusion often result in films with inconsistent thickness and surface irregularities, which further contribute to light scattering and reduced transparency. Developing advanced processing techniques that can produce ultra-thin, uniform PTFE films without sacrificing their structural integrity remains a key area of focus for researchers and manufacturers.

The presence of micro-voids and impurities within the PTFE matrix also poses a substantial challenge to achieving high transparency. These defects act as light-scattering centers, diminishing the overall optical clarity of the film. Addressing this issue requires innovative approaches in polymer synthesis and film formation to minimize the occurrence of such defects.

Furthermore, the inherent hydrophobicity of PTFE, while beneficial in many applications, can lead to issues with adhesion and integration in multi-layer optical systems. Improving the compatibility of PTFE films with other materials used in lens overlays, without compromising their transparency or protective properties, presents another significant challenge in this field.

The development of nano-structured or composite PTFE films has emerged as a promising avenue for enhancing transparency. However, controlling the nano-scale architecture of these films while maintaining their macroscopic properties poses considerable technical difficulties. Balancing the introduction of nano-scale features with the preservation of PTFE's bulk characteristics requires precise control over material synthesis and processing parameters.

Lastly, the challenge of achieving consistent and reproducible results in PTFE film transparency improvements across large-scale production remains a significant hurdle. Translating laboratory-scale successes to industrial-scale manufacturing processes while maintaining quality and cost-effectiveness is crucial for the widespread adoption of improved PTFE films in lens overlay applications.

Current PTFE Transparency Solutions

01 Modification of PTFE film structure

Altering the structure of PTFE films can enhance their transparency. This may involve adjusting the crystallinity, molecular weight, or orientation of the PTFE molecules. Techniques such as stretching, annealing, or incorporating additives can be employed to modify the film structure and improve light transmission.- Modification of PTFE film structure: Altering the structure of PTFE films can enhance their transparency. This may involve adjusting the crystallinity, molecular weight, or orientation of the PTFE molecules. Techniques such as stretching, annealing, or incorporating additives can be employed to modify the film structure and improve light transmission.

- Surface treatment of PTFE films: Applying various surface treatments to PTFE films can increase their transparency. These treatments may include plasma etching, chemical etching, or coating with other materials. Such processes can reduce surface roughness, minimize light scattering, and enhance overall optical clarity of the film.

- Incorporation of transparent fillers: Adding transparent fillers or nanoparticles to PTFE films can improve their optical properties. These additives can help to reduce haze, increase light transmission, and enhance overall transparency while maintaining the desirable properties of PTFE.

- Multilayer PTFE film structures: Creating multilayer structures with PTFE and other transparent materials can enhance overall film transparency. This approach allows for the combination of PTFE's unique properties with the optical characteristics of other materials, resulting in films with improved transparency and performance.

- Optimization of PTFE film thickness: Controlling and optimizing the thickness of PTFE films can significantly impact their transparency. Thinner films generally exhibit higher light transmission, while maintaining the desired mechanical and chemical properties. Advanced manufacturing techniques can be employed to produce ultra-thin PTFE films with enhanced optical clarity.

02 Surface treatment of PTFE films

Applying various surface treatments to PTFE films can increase their transparency. These treatments may include plasma etching, chemical etching, or coating with transparent materials. Such processes can reduce surface roughness and minimize light scattering, resulting in improved optical clarity.Expand Specific Solutions03 Incorporation of nanoparticles or fillers

Adding specific nanoparticles or fillers to PTFE films can enhance their transparency. These additives can modify the refractive index of the film or create a more uniform structure, leading to improved light transmission. Careful selection and dispersion of these particles are crucial for achieving optimal transparency.Expand Specific Solutions04 Multilayer PTFE film structures

Creating multilayer structures with PTFE and other transparent materials can improve overall film transparency. This approach allows for the combination of PTFE's desirable properties with the optical characteristics of other materials. Careful selection of layer materials and thicknesses is essential for optimizing transparency.Expand Specific Solutions05 Optimization of PTFE film production process

Refining the manufacturing process of PTFE films can lead to improved transparency. This may involve adjusting parameters such as extrusion temperature, cooling rate, or drawing ratio. Advanced processing techniques and precise control of production conditions can result in PTFE films with enhanced optical properties.Expand Specific Solutions

Key PTFE Film Manufacturers

The market for PTFE film transparency improvements in lens overlays is in a growth phase, driven by increasing demand for high-performance optical components across various industries. The global market size for advanced optical films is expanding, with projections indicating continued growth. Technologically, PTFE film transparency is advancing, but there's still room for innovation. Key players like W. L. Gore & Associates, 3M Innovative Properties, and DAIKIN INDUSTRIES are leading research efforts, leveraging their expertise in fluoropolymers and optical materials. Companies such as HOYA Corp. and Carl Zeiss SMT are also contributing to advancements in lens technology, potentially incorporating improved PTFE films in their products. The competitive landscape is characterized by a mix of established chemical companies and specialized optical manufacturers, all vying to develop superior solutions for enhanced lens performance.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin has developed advanced PTFE film technologies for lens overlays, focusing on improving transparency while maintaining the material's inherent properties. Their approach involves a proprietary manufacturing process that reduces the crystallinity of PTFE, resulting in enhanced light transmission. This process includes controlled stretching and heat treatment of the PTFE film, which aligns the polymer chains and reduces light scattering[1]. Additionally, Daikin has implemented surface modification techniques to further improve the optical clarity of PTFE films, such as plasma treatment to reduce surface roughness and increase hydrophilicity[3].

Strengths: High transparency achieved while maintaining PTFE's chemical resistance and low friction. Weaknesses: Potentially higher production costs and complexity in maintaining consistent quality across large film areas.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore has pioneered the development of expanded PTFE (ePTFE) films with enhanced transparency for optical applications. Their approach involves a unique expansion process that creates a microporous structure, reducing the overall density of the material while maintaining its chemical and thermal properties. This expanded structure allows for greater light transmission by reducing internal reflections and scattering[2]. Gore has also developed multi-layer film constructions that combine ePTFE with other optically clear materials to achieve optimal transparency and durability for lens overlays[4]. The company has reported achieving transparency levels of up to 95% in the visible spectrum for their advanced ePTFE films[5].

Strengths: High transparency combined with excellent mechanical properties and chemical resistance. Weaknesses: Potential for reduced durability compared to solid PTFE films, and higher production costs.

Innovative PTFE Film Technologies

Highly transmissive PTFE dense film with tunable haze and color

PatentPendingUS20240360286A1

Innovation

- A dense PTFE film is produced through a process involving the stretching of a modified PTFE resin at temperatures above its crystalline melting point, with a specific ethylenically unsaturated monomer, to achieve reduced scattering coefficients and enhanced tensile strength, maintaining low porosity and permeability.

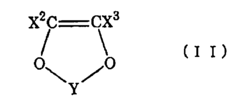

Modified polytetrafluoroethylen fine powder and modified polytetrafluoroethylene molded product

PatentActiveEP1816148A1

Innovation

- A modified PTFE fine powder with a particle core comprising fluoro(alkyl vinyl ether), vinylic heterocyclic compounds, and fluoroolefins, and a particle shell of modified polytetrafluoroethylene, processed through emulsion polymerization, which achieves low cylinder extrusion pressure and high transparency.

Optical Performance Metrics

Optical performance metrics are crucial for evaluating the effectiveness of PTFE film transparency improvements in lens overlays. These metrics provide quantitative measures of how well the film transmits, reflects, and scatters light, which directly impacts the overall performance of the optical system.

Transmittance is a key metric, measuring the percentage of incident light that passes through the PTFE film. Higher transmittance values indicate greater transparency, which is desirable for lens overlays. Improvements in PTFE film manufacturing processes aim to increase transmittance across the visible spectrum, typically ranging from 400 to 700 nanometers.

Haze is another important metric, quantifying the amount of light scattered by the film. Lower haze values result in clearer, more transparent films. For lens overlays, minimizing haze is essential to maintain image clarity and prevent unwanted light diffusion.

Clarity, often measured using the ASTM D1003 standard, assesses the film's ability to transmit an image without distortion. Higher clarity values indicate better optical performance, ensuring that the lens overlay does not compromise the underlying optics' functionality.

Refractive index is a critical parameter that describes how light bends when passing through the PTFE film. Matching the refractive index of the film to that of the lens material can reduce reflections and improve overall optical efficiency.

Spectral transmittance curves provide detailed information about the film's performance across different wavelengths. These curves help identify any wavelength-dependent variations in transparency, which is particularly important for applications requiring consistent performance across the entire visible spectrum.

Reflection measurements, including specular and diffuse reflection, are essential for understanding how much light is lost due to surface reflections. Minimizing reflections through surface treatments or anti-reflective coatings can significantly enhance the overall transparency of the PTFE film.

Durability metrics, such as abrasion resistance and chemical stability, are also considered part of optical performance. These factors ensure that the film maintains its transparency over time, even when exposed to environmental stresses or cleaning processes.

By systematically evaluating and improving these optical performance metrics, researchers and engineers can develop PTFE films with enhanced transparency, making them more suitable for use as lens overlays in various optical applications.

Transmittance is a key metric, measuring the percentage of incident light that passes through the PTFE film. Higher transmittance values indicate greater transparency, which is desirable for lens overlays. Improvements in PTFE film manufacturing processes aim to increase transmittance across the visible spectrum, typically ranging from 400 to 700 nanometers.

Haze is another important metric, quantifying the amount of light scattered by the film. Lower haze values result in clearer, more transparent films. For lens overlays, minimizing haze is essential to maintain image clarity and prevent unwanted light diffusion.

Clarity, often measured using the ASTM D1003 standard, assesses the film's ability to transmit an image without distortion. Higher clarity values indicate better optical performance, ensuring that the lens overlay does not compromise the underlying optics' functionality.

Refractive index is a critical parameter that describes how light bends when passing through the PTFE film. Matching the refractive index of the film to that of the lens material can reduce reflections and improve overall optical efficiency.

Spectral transmittance curves provide detailed information about the film's performance across different wavelengths. These curves help identify any wavelength-dependent variations in transparency, which is particularly important for applications requiring consistent performance across the entire visible spectrum.

Reflection measurements, including specular and diffuse reflection, are essential for understanding how much light is lost due to surface reflections. Minimizing reflections through surface treatments or anti-reflective coatings can significantly enhance the overall transparency of the PTFE film.

Durability metrics, such as abrasion resistance and chemical stability, are also considered part of optical performance. These factors ensure that the film maintains its transparency over time, even when exposed to environmental stresses or cleaning processes.

By systematically evaluating and improving these optical performance metrics, researchers and engineers can develop PTFE films with enhanced transparency, making them more suitable for use as lens overlays in various optical applications.

Environmental Impact Assessment

The environmental impact of improving PTFE film transparency for lens overlays is an important consideration in the development and implementation of this technology. PTFE (polytetrafluoroethylene) is a synthetic fluoropolymer known for its non-reactive properties and resistance to various chemicals. While it offers numerous benefits in optical applications, its production and use can have environmental implications.

The manufacturing process of PTFE films involves the use of fluoropolymers, which can contribute to greenhouse gas emissions. The production of these materials often requires energy-intensive processes and may release perfluorooctanoic acid (PFOA) or other perfluorinated compounds into the environment. These substances are persistent and can accumulate in ecosystems, potentially affecting wildlife and human health.

However, improvements in PTFE film transparency for lens overlays may lead to more efficient optical systems, potentially reducing energy consumption in various applications. Enhanced transparency could result in better light transmission, reducing the need for higher-powered light sources and consequently lowering energy requirements. This indirect environmental benefit should be considered alongside the direct impacts of production.

The durability and longevity of PTFE films also play a role in their environmental impact. Improved transparency may extend the lifespan of lens overlays, reducing the frequency of replacement and minimizing waste generation. Additionally, the chemical inertness of PTFE makes it resistant to degradation, which can be both an advantage and a concern from an environmental perspective.

Recycling and disposal of PTFE films present challenges due to their chemical stability. While this stability prevents leaching of harmful substances into the environment during use, it also makes the material difficult to break down at the end of its life cycle. Developing effective recycling methods for PTFE films used in lens overlays should be a priority to mitigate long-term environmental impacts.

Water usage and potential contamination during the manufacturing process of transparent PTFE films should also be assessed. Implementing closed-loop water systems and advanced filtration technologies can help minimize water consumption and prevent the release of pollutants into aquatic ecosystems.

In conclusion, while improving PTFE film transparency for lens overlays offers potential environmental benefits through increased efficiency and longevity, careful consideration must be given to the entire lifecycle of the material. Balancing the advantages of enhanced optical performance against the environmental costs of production and disposal is crucial for sustainable development in this field.

The manufacturing process of PTFE films involves the use of fluoropolymers, which can contribute to greenhouse gas emissions. The production of these materials often requires energy-intensive processes and may release perfluorooctanoic acid (PFOA) or other perfluorinated compounds into the environment. These substances are persistent and can accumulate in ecosystems, potentially affecting wildlife and human health.

However, improvements in PTFE film transparency for lens overlays may lead to more efficient optical systems, potentially reducing energy consumption in various applications. Enhanced transparency could result in better light transmission, reducing the need for higher-powered light sources and consequently lowering energy requirements. This indirect environmental benefit should be considered alongside the direct impacts of production.

The durability and longevity of PTFE films also play a role in their environmental impact. Improved transparency may extend the lifespan of lens overlays, reducing the frequency of replacement and minimizing waste generation. Additionally, the chemical inertness of PTFE makes it resistant to degradation, which can be both an advantage and a concern from an environmental perspective.

Recycling and disposal of PTFE films present challenges due to their chemical stability. While this stability prevents leaching of harmful substances into the environment during use, it also makes the material difficult to break down at the end of its life cycle. Developing effective recycling methods for PTFE films used in lens overlays should be a priority to mitigate long-term environmental impacts.

Water usage and potential contamination during the manufacturing process of transparent PTFE films should also be assessed. Implementing closed-loop water systems and advanced filtration technologies can help minimize water consumption and prevent the release of pollutants into aquatic ecosystems.

In conclusion, while improving PTFE film transparency for lens overlays offers potential environmental benefits through increased efficiency and longevity, careful consideration must be given to the entire lifecycle of the material. Balancing the advantages of enhanced optical performance against the environmental costs of production and disposal is crucial for sustainable development in this field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!