PTFE Enhancements in High‑Performance Sports Equipment

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE in Sports Equipment: Evolution and Objectives

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has revolutionized the sports equipment industry since its accidental discovery in 1938. This synthetic fluoropolymer's unique properties, including low friction, hydrophobicity, and chemical inertness, have made it an invaluable material in high-performance sports gear. The evolution of PTFE in sports equipment has been driven by the constant pursuit of enhanced performance, durability, and athlete comfort.

Initially, PTFE found its way into sports equipment through simple applications such as lubricants for moving parts in bicycles and ski bindings. As manufacturing techniques advanced, PTFE coatings began to be applied to a wider range of sports equipment, including skis, snowboards, and fishing lines. The 1980s and 1990s saw a significant expansion in PTFE use, with the material being incorporated into fabrics for waterproof and breathable sportswear.

The turn of the millennium marked a new era for PTFE in sports, with nanotechnology enabling the development of more sophisticated PTFE-based materials. These advancements led to the creation of ultra-thin, highly durable coatings that could be applied to a variety of surfaces, further expanding PTFE's applications in sports equipment. From reducing drag in competitive swimming suits to enhancing the aerodynamics of cycling gear, PTFE continued to push the boundaries of sports performance.

Today, the objectives for PTFE enhancements in high-performance sports equipment are multifaceted. Researchers and manufacturers are focusing on developing PTFE composites that offer even lower friction coefficients while maintaining or improving durability. There is also a growing emphasis on creating environmentally friendly PTFE alternatives that retain the material's beneficial properties without the associated environmental concerns.

Another key objective is the integration of PTFE with smart materials and sensors, aiming to create adaptive sports equipment that can respond to changing environmental conditions or athlete performance in real-time. This fusion of PTFE with cutting-edge technologies promises to open new frontiers in sports equipment design and functionality.

As we look to the future, the evolution of PTFE in sports equipment is likely to continue along several trajectories. These include the development of bio-based PTFE alternatives, the exploration of PTFE's potential in 3D-printed sports equipment, and the creation of hybrid materials that combine PTFE with other high-performance substances to achieve unprecedented levels of performance and durability.

Initially, PTFE found its way into sports equipment through simple applications such as lubricants for moving parts in bicycles and ski bindings. As manufacturing techniques advanced, PTFE coatings began to be applied to a wider range of sports equipment, including skis, snowboards, and fishing lines. The 1980s and 1990s saw a significant expansion in PTFE use, with the material being incorporated into fabrics for waterproof and breathable sportswear.

The turn of the millennium marked a new era for PTFE in sports, with nanotechnology enabling the development of more sophisticated PTFE-based materials. These advancements led to the creation of ultra-thin, highly durable coatings that could be applied to a variety of surfaces, further expanding PTFE's applications in sports equipment. From reducing drag in competitive swimming suits to enhancing the aerodynamics of cycling gear, PTFE continued to push the boundaries of sports performance.

Today, the objectives for PTFE enhancements in high-performance sports equipment are multifaceted. Researchers and manufacturers are focusing on developing PTFE composites that offer even lower friction coefficients while maintaining or improving durability. There is also a growing emphasis on creating environmentally friendly PTFE alternatives that retain the material's beneficial properties without the associated environmental concerns.

Another key objective is the integration of PTFE with smart materials and sensors, aiming to create adaptive sports equipment that can respond to changing environmental conditions or athlete performance in real-time. This fusion of PTFE with cutting-edge technologies promises to open new frontiers in sports equipment design and functionality.

As we look to the future, the evolution of PTFE in sports equipment is likely to continue along several trajectories. These include the development of bio-based PTFE alternatives, the exploration of PTFE's potential in 3D-printed sports equipment, and the creation of hybrid materials that combine PTFE with other high-performance substances to achieve unprecedented levels of performance and durability.

Market Analysis for PTFE-Enhanced Sports Gear

The market for PTFE-enhanced sports equipment has experienced significant growth in recent years, driven by increasing demand for high-performance gear across various sports disciplines. PTFE (Polytetrafluoroethylene) coatings and materials have found widespread application in sports equipment due to their unique properties, including low friction, chemical resistance, and durability.

In the global sports equipment market, PTFE-enhanced products have carved out a substantial niche, particularly in high-end and professional segments. The market size for PTFE-enhanced sports gear is estimated to be a significant portion of the overall sports equipment market, with steady growth projected over the next five years.

Key market segments for PTFE-enhanced sports equipment include winter sports gear, such as skis and snowboards, where PTFE-based waxes and coatings improve glide and performance. In water sports, PTFE coatings on surfboards and kayaks reduce drag and enhance speed. The cycling industry has also embraced PTFE technology in chain lubricants and bearing components, improving efficiency and durability.

The market demand for PTFE-enhanced sports equipment is driven by several factors. Professional athletes and serious enthusiasts seek cutting-edge technology to gain competitive advantages, fueling innovation in PTFE applications. The growing trend of outdoor and adventure sports has expanded the consumer base for high-performance gear. Additionally, increasing awareness of the benefits of PTFE in sports equipment among recreational users has broadened the market.

Market trends indicate a shift towards more sustainable and environmentally friendly PTFE formulations, addressing concerns about the environmental impact of traditional PTFE production. This trend is likely to open new market opportunities and drive further innovation in the sector.

Geographically, North America and Europe lead in the adoption of PTFE-enhanced sports equipment, with Asia-Pacific showing rapid growth potential. The market is characterized by a mix of established sporting goods manufacturers incorporating PTFE technology and specialized companies focusing exclusively on PTFE-enhanced products.

Looking ahead, the market for PTFE-enhanced sports equipment is expected to continue its growth trajectory. Factors such as ongoing technological advancements, increasing sports participation rates, and the premiumization of sports gear are likely to sustain market expansion. The integration of PTFE with other advanced materials and smart technologies presents opportunities for product differentiation and market growth in the coming years.

In the global sports equipment market, PTFE-enhanced products have carved out a substantial niche, particularly in high-end and professional segments. The market size for PTFE-enhanced sports gear is estimated to be a significant portion of the overall sports equipment market, with steady growth projected over the next five years.

Key market segments for PTFE-enhanced sports equipment include winter sports gear, such as skis and snowboards, where PTFE-based waxes and coatings improve glide and performance. In water sports, PTFE coatings on surfboards and kayaks reduce drag and enhance speed. The cycling industry has also embraced PTFE technology in chain lubricants and bearing components, improving efficiency and durability.

The market demand for PTFE-enhanced sports equipment is driven by several factors. Professional athletes and serious enthusiasts seek cutting-edge technology to gain competitive advantages, fueling innovation in PTFE applications. The growing trend of outdoor and adventure sports has expanded the consumer base for high-performance gear. Additionally, increasing awareness of the benefits of PTFE in sports equipment among recreational users has broadened the market.

Market trends indicate a shift towards more sustainable and environmentally friendly PTFE formulations, addressing concerns about the environmental impact of traditional PTFE production. This trend is likely to open new market opportunities and drive further innovation in the sector.

Geographically, North America and Europe lead in the adoption of PTFE-enhanced sports equipment, with Asia-Pacific showing rapid growth potential. The market is characterized by a mix of established sporting goods manufacturers incorporating PTFE technology and specialized companies focusing exclusively on PTFE-enhanced products.

Looking ahead, the market for PTFE-enhanced sports equipment is expected to continue its growth trajectory. Factors such as ongoing technological advancements, increasing sports participation rates, and the premiumization of sports gear are likely to sustain market expansion. The integration of PTFE with other advanced materials and smart technologies presents opportunities for product differentiation and market growth in the coming years.

Current PTFE Applications and Challenges in Sports

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has found widespread applications in high-performance sports equipment due to its unique properties. In the realm of sports, PTFE is primarily utilized for its low friction coefficient, hydrophobicity, and durability. These characteristics make it an ideal material for enhancing the performance of various sports gear and equipment.

One of the most prominent applications of PTFE in sports is in the manufacturing of ski and snowboard bases. The low friction properties of PTFE allow for increased glide and speed on snow, giving athletes a competitive edge. PTFE coatings are also applied to the surfaces of boats and racing shells to reduce drag and improve performance in water sports. In cycling, PTFE-based lubricants are used to reduce friction in bike chains and other moving parts, enhancing overall efficiency and longevity of the components.

The material's hydrophobic nature makes it valuable in the production of water-repellent sportswear and outdoor gear. PTFE membranes, such as those used in Gore-Tex fabrics, provide waterproof and breathable properties to jackets, shoes, and other apparel, keeping athletes dry and comfortable in challenging weather conditions. In tennis and other racquet sports, PTFE-based strings offer improved durability and consistent performance over time.

Despite its widespread use, PTFE applications in sports face several challenges. One significant issue is the environmental impact of PTFE production and disposal. The manufacturing process involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant with potential health risks. This has led to increased scrutiny and calls for more sustainable alternatives.

Another challenge is the limited ability to modify PTFE's surface properties without compromising its beneficial characteristics. While PTFE's low surface energy is advantageous in many applications, it can also make it difficult to bond with other materials or incorporate additional functionalities. This limitation restricts the potential for further enhancements in certain sports equipment designs.

The wear resistance of PTFE, while generally good, can be a limiting factor in high-stress applications. In some sports equipment, such as ski bases, the PTFE layer may wear down over time, requiring frequent maintenance or replacement. Improving the wear resistance of PTFE without sacrificing its low friction properties remains an ongoing challenge for materials scientists and engineers in the sports industry.

Lastly, the high cost of PTFE compared to alternative materials can be a barrier to its widespread adoption in some segments of the sports equipment market. Balancing the performance benefits with cost considerations is an ongoing challenge for manufacturers, particularly in mass-market products where price sensitivity is a significant factor.

One of the most prominent applications of PTFE in sports is in the manufacturing of ski and snowboard bases. The low friction properties of PTFE allow for increased glide and speed on snow, giving athletes a competitive edge. PTFE coatings are also applied to the surfaces of boats and racing shells to reduce drag and improve performance in water sports. In cycling, PTFE-based lubricants are used to reduce friction in bike chains and other moving parts, enhancing overall efficiency and longevity of the components.

The material's hydrophobic nature makes it valuable in the production of water-repellent sportswear and outdoor gear. PTFE membranes, such as those used in Gore-Tex fabrics, provide waterproof and breathable properties to jackets, shoes, and other apparel, keeping athletes dry and comfortable in challenging weather conditions. In tennis and other racquet sports, PTFE-based strings offer improved durability and consistent performance over time.

Despite its widespread use, PTFE applications in sports face several challenges. One significant issue is the environmental impact of PTFE production and disposal. The manufacturing process involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant with potential health risks. This has led to increased scrutiny and calls for more sustainable alternatives.

Another challenge is the limited ability to modify PTFE's surface properties without compromising its beneficial characteristics. While PTFE's low surface energy is advantageous in many applications, it can also make it difficult to bond with other materials or incorporate additional functionalities. This limitation restricts the potential for further enhancements in certain sports equipment designs.

The wear resistance of PTFE, while generally good, can be a limiting factor in high-stress applications. In some sports equipment, such as ski bases, the PTFE layer may wear down over time, requiring frequent maintenance or replacement. Improving the wear resistance of PTFE without sacrificing its low friction properties remains an ongoing challenge for materials scientists and engineers in the sports industry.

Lastly, the high cost of PTFE compared to alternative materials can be a barrier to its widespread adoption in some segments of the sports equipment market. Balancing the performance benefits with cost considerations is an ongoing challenge for manufacturers, particularly in mass-market products where price sensitivity is a significant factor.

Existing PTFE Enhancement Techniques for Sports Gear

01 Enhanced thermal and chemical resistance

PTFE exhibits exceptional thermal stability and chemical resistance, making it suitable for high-temperature applications and environments with aggressive chemicals. Its performance in these conditions contributes to its widespread use in various industries, including automotive, aerospace, and chemical processing.- Enhanced mechanical properties of PTFE: PTFE can be modified to improve its mechanical properties such as tensile strength, wear resistance, and durability. This can be achieved through various methods including the addition of fillers, nanoparticles, or by altering the molecular structure of PTFE. These enhancements make PTFE suitable for a wider range of applications, particularly in high-stress environments.

- Improved thermal and chemical resistance: PTFE exhibits excellent thermal stability and chemical resistance, which can be further enhanced through specific formulations or processing techniques. This allows PTFE to maintain its properties in extreme temperatures and harsh chemical environments, making it ideal for use in industrial applications, chemical processing, and high-temperature settings.

- Enhanced non-stick and low friction properties: PTFE is renowned for its non-stick and low friction characteristics, which can be optimized through surface treatments or the incorporation of additives. These improvements result in better release properties and reduced friction coefficients, making PTFE valuable in applications such as cookware, bearings, and seals.

- Improved electrical insulation properties: PTFE's excellent dielectric properties can be further enhanced to improve its performance as an electrical insulator. This can involve modifying the material's structure or incorporating specific additives to increase its dielectric strength and reduce electrical losses, making it suitable for high-frequency and high-voltage applications.

- Enhanced processability and fabrication techniques: Advancements in PTFE processing and fabrication techniques have led to improved manufacturability and expanded application possibilities. These include novel sintering methods, extrusion techniques, and the development of PTFE composites that combine the material's unique properties with those of other materials, resulting in enhanced overall performance and easier integration into various products.

02 Improved mechanical properties

Techniques have been developed to enhance the mechanical properties of PTFE, such as tensile strength, wear resistance, and dimensional stability. These improvements are achieved through various methods, including the addition of fillers, modification of the polymer structure, and specialized processing techniques.Expand Specific Solutions03 Advanced surface modifications

Surface modification techniques have been applied to PTFE to enhance its performance in specific applications. These modifications can improve properties such as adhesion, wettability, and biocompatibility, expanding the range of potential uses for PTFE in fields like medical devices and coatings.Expand Specific Solutions04 Nanocomposite formulations

The incorporation of nanoparticles or nanostructures into PTFE has led to the development of nanocomposites with enhanced performance characteristics. These formulations can improve properties such as thermal conductivity, electrical conductivity, and tribological performance while maintaining PTFE's inherent benefits.Expand Specific Solutions05 Specialized processing techniques

Advanced processing techniques have been developed to optimize PTFE performance for specific applications. These include methods for creating porous PTFE structures, thin films, and specialized molding processes that enhance the material's properties and expand its range of applications in industries such as filtration, electronics, and energy storage.Expand Specific Solutions

Key Manufacturers and Suppliers in PTFE Sports Tech

The PTFE enhancements in high-performance sports equipment market is in a growth phase, driven by increasing demand for advanced materials in sports gear. The global market size is estimated to be in the hundreds of millions of dollars, with steady expansion expected. Technologically, PTFE applications are mature but still evolving, with ongoing innovations in formulations and manufacturing processes. Key players like W. L. Gore & Associates, The Chemours Co., and Daikin Industries are leading development efforts, leveraging their expertise in fluoropolymers to create specialized PTFE-based materials for sports applications. Universities and research institutions are also contributing to advancements, indicating a dynamic competitive landscape with opportunities for further innovation and market growth.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has developed advanced PTFE-based materials for high-performance sports equipment. Their GORE-TEX technology incorporates expanded PTFE (ePTFE) membranes into fabrics, providing waterproof and breathable properties for outdoor sports apparel[1]. For sports footwear, they've created GORE-TEX INVISIBLE FIT technology, which integrates the ePTFE membrane directly into the shoe upper, reducing weight and improving fit[2]. In cycling, Gore's SHAKEDRY fabric technology utilizes a thin PTFE membrane as the outer layer, offering exceptional water repellency and breathability while minimizing weight[3]. For winter sports, Gore has developed GORE-TEX INFINIUM™ THERMIUM™ insulation, which uses PTFE to create micro-chambers that trap warm air, providing superior warmth without bulk in ski and snowboard gear[4].

Strengths: Unparalleled waterproofing and breathability, lightweight solutions, and innovative integration of PTFE into various sports equipment. Weaknesses: Potentially higher cost compared to traditional materials, and some products may require special care or cleaning methods.

The Chemours Co.

Technical Solution: The Chemours Company has made significant strides in PTFE enhancements for high-performance sports equipment through their Teflon™ fluoropolymer technology. They have developed Teflon EcoElite™, a renewably sourced, plant-based, non-fluorinated water repellent finish for outdoor apparel and gear[5]. This technology provides durable water repellency (DWR) performance comparable to traditional fluorinated treatments while being more environmentally friendly. For winter sports, Chemours has created Teflon™ PTFE-based ski wax additives that significantly reduce friction and improve glide performance on snow[6]. In tennis racket manufacturing, their Teflon™ fiber technologies are used to enhance string durability and reduce friction, leading to improved power and control[7]. Additionally, Chemours has developed PTFE-based coatings for sports equipment like golf clubs and bicycle chains, reducing friction and improving overall performance[8].

Strengths: Eco-friendly innovations, wide range of applications across various sports, and proven performance enhancements. Weaknesses: Potential regulatory challenges due to environmental concerns surrounding some fluoropolymers, and the need for continuous innovation to stay ahead in a competitive market.

Innovative PTFE Formulations for Sports Applications

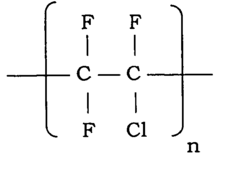

Sliding material for sport devices

PatentInactiveEP1626073A1

Innovation

- Polychlorotrifluoroethylene (PCTFE) polymers with specific molecular weights and pour points are used as lubricants, which are miscible with paraffin and fluorinated waxes, allowing for universal application and improved sliding properties without the need for heating, and can be applied in various forms including liquid, aerosol, or powder, enhancing adhesion and abrasion resistance.

Lubricant for sport device

PatentInactiveJP2006083374A

Innovation

- Polychlorotrifluoroethylene (PCTFE) is used as a lubricant, which can be in liquid or solid form, applied directly or mixed with conventional waxes, providing improved gliding properties and adhesion across various weather conditions without requiring heating, and is cost-effective.

Environmental Impact of PTFE in Sports Products

The use of PTFE (Polytetrafluoroethylene) in high-performance sports equipment has raised concerns about its environmental impact. While PTFE offers exceptional performance benefits, its production, use, and disposal can have significant ecological consequences.

PTFE manufacturing processes involve the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant. Although many manufacturers have phased out PFOA, alternative chemicals used may still pose environmental risks. The production of PTFE also requires substantial energy inputs, contributing to greenhouse gas emissions and climate change.

During the use phase, PTFE-enhanced sports equipment can release microplastics into the environment. This is particularly problematic in water sports, where PTFE particles can enter aquatic ecosystems. These microplastics can be ingested by marine life, potentially entering the food chain and affecting biodiversity.

The durability of PTFE presents challenges at the end of a product's life cycle. PTFE is not biodegradable and can persist in the environment for extended periods. Recycling PTFE is technically possible but often not economically viable, leading to most PTFE-containing products ending up in landfills or incineration facilities.

Incineration of PTFE can release harmful substances, including fluorinated compounds and greenhouse gases. These emissions can contribute to air pollution and ozone depletion. Landfill disposal, while avoiding these emissions, leads to long-term soil contamination as PTFE slowly breaks down.

The sports industry is increasingly aware of these environmental concerns and is exploring alternatives. Bio-based and recyclable materials are being developed as potential substitutes for PTFE in some applications. Additionally, improved manufacturing processes and end-of-life management strategies are being implemented to reduce the environmental footprint of PTFE-enhanced sports equipment.

Efforts are also being made to extend the lifespan of PTFE-containing products, thereby reducing waste generation. This includes designing for durability, repairability, and upgradability. Some manufacturers are implementing take-back programs to ensure proper disposal or recycling of used equipment.

In conclusion, while PTFE offers significant performance advantages in sports equipment, its environmental impact throughout the product lifecycle is considerable. Balancing performance requirements with environmental sustainability remains a key challenge for the sports industry. Future developments in materials science and circular economy practices may provide more environmentally friendly alternatives without compromising the high performance demanded by athletes.

PTFE manufacturing processes involve the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant. Although many manufacturers have phased out PFOA, alternative chemicals used may still pose environmental risks. The production of PTFE also requires substantial energy inputs, contributing to greenhouse gas emissions and climate change.

During the use phase, PTFE-enhanced sports equipment can release microplastics into the environment. This is particularly problematic in water sports, where PTFE particles can enter aquatic ecosystems. These microplastics can be ingested by marine life, potentially entering the food chain and affecting biodiversity.

The durability of PTFE presents challenges at the end of a product's life cycle. PTFE is not biodegradable and can persist in the environment for extended periods. Recycling PTFE is technically possible but often not economically viable, leading to most PTFE-containing products ending up in landfills or incineration facilities.

Incineration of PTFE can release harmful substances, including fluorinated compounds and greenhouse gases. These emissions can contribute to air pollution and ozone depletion. Landfill disposal, while avoiding these emissions, leads to long-term soil contamination as PTFE slowly breaks down.

The sports industry is increasingly aware of these environmental concerns and is exploring alternatives. Bio-based and recyclable materials are being developed as potential substitutes for PTFE in some applications. Additionally, improved manufacturing processes and end-of-life management strategies are being implemented to reduce the environmental footprint of PTFE-enhanced sports equipment.

Efforts are also being made to extend the lifespan of PTFE-containing products, thereby reducing waste generation. This includes designing for durability, repairability, and upgradability. Some manufacturers are implementing take-back programs to ensure proper disposal or recycling of used equipment.

In conclusion, while PTFE offers significant performance advantages in sports equipment, its environmental impact throughout the product lifecycle is considerable. Balancing performance requirements with environmental sustainability remains a key challenge for the sports industry. Future developments in materials science and circular economy practices may provide more environmentally friendly alternatives without compromising the high performance demanded by athletes.

Performance Testing Standards for PTFE Sports Equipment

Performance testing standards for PTFE sports equipment play a crucial role in ensuring the quality, safety, and effectiveness of high-performance sports gear. These standards provide a framework for evaluating the performance characteristics of PTFE-enhanced equipment across various sports disciplines.

The International Organization for Standardization (ISO) has developed several standards specifically for sports equipment testing. For PTFE-enhanced products, ISO 10328 is particularly relevant, as it outlines the testing procedures for structural strength of lower-limb prostheses. This standard can be adapted to assess the durability and load-bearing capacity of PTFE-coated components in sports equipment.

ASTM International also provides a range of standards applicable to PTFE sports equipment testing. ASTM D4894 and D4895 focus on the standard specification for PTFE granular molding and ram extrusion materials, which are often used in the manufacturing of sports equipment components. These standards ensure the consistency and quality of PTFE materials used in production.

For specific sports applications, such as skiing and snowboarding, the ISO 11088 standard sets guidelines for the assembly, adjustment, and inspection of a ski/binding/boot system. This standard can be extended to include testing protocols for PTFE-enhanced ski bases and other snow sports equipment.

In the realm of water sports, the European Standard EN ISO 12215 provides guidelines for small craft construction and scantlings. This standard can be adapted to test PTFE-coated surfaces on watercraft and water sports equipment, evaluating their performance in terms of hydrodynamics and durability.

The American Society for Testing and Materials (ASTM) has developed the F1976 standard, which specifies test methods for shock-attenuating properties of playing surface systems. This standard can be applied to assess the impact resistance and energy absorption capabilities of PTFE-enhanced sports flooring and protective gear.

For cycling equipment, the EN 14781 standard for racing bicycles outlines safety requirements and test methods. This standard can be expanded to include specific tests for PTFE-coated bicycle components, such as chains and bearings, to evaluate their friction-reducing properties and wear resistance.

In the field of tennis, the International Tennis Federation (ITF) has established comprehensive testing procedures for rackets, strings, and court surfaces. These procedures can be adapted to include specific tests for PTFE-enhanced tennis equipment, focusing on factors such as spin generation, durability, and performance consistency.

As PTFE technology continues to evolve in sports equipment, it is essential for testing standards to keep pace. Industry stakeholders, including manufacturers, sports governing bodies, and testing laboratories, must collaborate to develop and refine standards that accurately assess the unique properties and benefits of PTFE-enhanced sports gear. This ongoing process ensures that performance claims are substantiated and that athletes can rely on the equipment to deliver consistent, high-level performance.

The International Organization for Standardization (ISO) has developed several standards specifically for sports equipment testing. For PTFE-enhanced products, ISO 10328 is particularly relevant, as it outlines the testing procedures for structural strength of lower-limb prostheses. This standard can be adapted to assess the durability and load-bearing capacity of PTFE-coated components in sports equipment.

ASTM International also provides a range of standards applicable to PTFE sports equipment testing. ASTM D4894 and D4895 focus on the standard specification for PTFE granular molding and ram extrusion materials, which are often used in the manufacturing of sports equipment components. These standards ensure the consistency and quality of PTFE materials used in production.

For specific sports applications, such as skiing and snowboarding, the ISO 11088 standard sets guidelines for the assembly, adjustment, and inspection of a ski/binding/boot system. This standard can be extended to include testing protocols for PTFE-enhanced ski bases and other snow sports equipment.

In the realm of water sports, the European Standard EN ISO 12215 provides guidelines for small craft construction and scantlings. This standard can be adapted to test PTFE-coated surfaces on watercraft and water sports equipment, evaluating their performance in terms of hydrodynamics and durability.

The American Society for Testing and Materials (ASTM) has developed the F1976 standard, which specifies test methods for shock-attenuating properties of playing surface systems. This standard can be applied to assess the impact resistance and energy absorption capabilities of PTFE-enhanced sports flooring and protective gear.

For cycling equipment, the EN 14781 standard for racing bicycles outlines safety requirements and test methods. This standard can be expanded to include specific tests for PTFE-coated bicycle components, such as chains and bearings, to evaluate their friction-reducing properties and wear resistance.

In the field of tennis, the International Tennis Federation (ITF) has established comprehensive testing procedures for rackets, strings, and court surfaces. These procedures can be adapted to include specific tests for PTFE-enhanced tennis equipment, focusing on factors such as spin generation, durability, and performance consistency.

As PTFE technology continues to evolve in sports equipment, it is essential for testing standards to keep pace. Industry stakeholders, including manufacturers, sports governing bodies, and testing laboratories, must collaborate to develop and refine standards that accurately assess the unique properties and benefits of PTFE-enhanced sports gear. This ongoing process ensures that performance claims are substantiated and that athletes can rely on the equipment to deliver consistent, high-level performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!