Assessing PTFE nano‑patterning via atmospheric plasma for superhydrophobicity

PTFE Nano-patterning Background and Objectives

Polytetrafluoroethylene (PTFE) nano-patterning has emerged as a cutting-edge technology in the field of surface engineering, particularly for achieving superhydrophobic properties. This technique combines the inherent hydrophobic nature of PTFE with advanced nano-scale surface structuring to create surfaces with exceptional water-repellent characteristics. The development of this technology has been driven by the increasing demand for self-cleaning, anti-fouling, and water-resistant surfaces across various industries.

The evolution of PTFE nano-patterning can be traced back to the discovery of the lotus effect in nature, where the micro and nano-scale structures on lotus leaves contribute to their remarkable water-repellent properties. Researchers and engineers have since sought to replicate this phenomenon using synthetic materials and advanced manufacturing techniques. PTFE, known for its low surface energy and chemical inertness, has become a material of choice for such applications.

The primary objective of PTFE nano-patterning via atmospheric plasma is to create highly controlled and reproducible nano-scale surface structures that enhance the material's inherent hydrophobicity. This process aims to achieve contact angles exceeding 150 degrees, which is the threshold for superhydrophobicity. The use of atmospheric plasma offers several advantages over traditional vacuum-based plasma treatments, including lower costs, higher throughput, and the ability to treat larger surface areas.

Recent technological advancements have focused on optimizing the plasma treatment parameters to achieve precise control over the nano-pattern formation. This includes tailoring the plasma composition, power, and exposure time to create specific surface morphologies. The goal is to develop a robust and scalable process that can be applied to various PTFE-based products and components.

The potential applications of superhydrophobic PTFE surfaces span across multiple sectors, including aerospace, automotive, textiles, and biomedical industries. In aerospace, these surfaces can reduce ice formation on aircraft components. In automotive applications, they can improve windshield visibility during rainy conditions. The textile industry benefits from water-resistant and self-cleaning fabrics, while the biomedical field explores their use in preventing bacterial adhesion on medical devices.

As research in this area progresses, there is a growing emphasis on understanding the fundamental mechanisms of nano-pattern formation during atmospheric plasma treatment. This knowledge is crucial for developing predictive models and design tools that can accelerate the optimization of treatment processes for specific applications. Additionally, efforts are being made to enhance the durability and longevity of these nano-patterned surfaces, ensuring their effectiveness under various environmental conditions and mechanical stresses.

The future trajectory of PTFE nano-patterning technology is expected to focus on expanding its applicability to more complex geometries and larger surface areas. There is also a push towards developing environmentally friendly and energy-efficient plasma treatment processes, aligning with global sustainability goals. As the technology matures, it is anticipated to play a significant role in advancing surface engineering capabilities and enabling the development of next-generation materials with superior water-repellent properties.

Market Analysis for Superhydrophobic Surfaces

The market for superhydrophobic surfaces has been experiencing significant growth in recent years, driven by increasing demand across various industries. These surfaces, characterized by their extreme water-repellent properties, offer a wide range of applications in sectors such as automotive, aerospace, construction, electronics, and textiles.

In the automotive industry, superhydrophobic coatings are being utilized to create self-cleaning surfaces, improve visibility in adverse weather conditions, and enhance overall vehicle aesthetics. The aerospace sector is adopting these materials to reduce ice formation on aircraft surfaces, potentially leading to improved safety and fuel efficiency.

The construction industry is exploring superhydrophobic coatings for building exteriors to prevent water damage, reduce maintenance costs, and improve energy efficiency. In electronics, these surfaces are being developed to protect sensitive components from moisture and extend the lifespan of devices.

The textile industry is incorporating superhydrophobic treatments into fabrics to create water-resistant and stain-resistant clothing and upholstery. This technology is also finding applications in outdoor gear and protective equipment.

The global market for superhydrophobic coatings is projected to grow substantially in the coming years. Factors contributing to this growth include increasing awareness of the benefits of these materials, advancements in nanotechnology, and the rising demand for durable and low-maintenance surfaces across various industries.

Key market players are investing heavily in research and development to improve the durability, cost-effectiveness, and scalability of superhydrophobic coatings. The development of environmentally friendly and sustainable superhydrophobic materials is also a growing trend, driven by increasing environmental regulations and consumer preferences.

Challenges in the market include the high cost of production for some superhydrophobic materials and the need for improved durability in certain applications. However, ongoing research and development efforts, such as the PTFE nano-patterning via atmospheric plasma technique, are addressing these challenges and opening up new possibilities for superhydrophobic surface applications.

As the technology continues to mature and production costs decrease, the market for superhydrophobic surfaces is expected to expand into new industries and applications. This growth is likely to be particularly strong in regions with high industrial activity and stringent environmental regulations, such as North America, Europe, and parts of Asia.

Current Challenges in Atmospheric Plasma PTFE Patterning

The atmospheric plasma PTFE patterning process for achieving superhydrophobicity faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is the precise control of plasma parameters during the treatment process. The atmospheric plasma's inherent instability and sensitivity to environmental factors make it difficult to maintain consistent plasma characteristics, which directly impacts the quality and uniformity of the PTFE nano-patterns.

Another major challenge lies in the scalability of the process. While atmospheric plasma treatment offers advantages in terms of cost-effectiveness and simplicity compared to vacuum-based methods, scaling up the process for large-scale industrial applications remains problematic. The need to maintain uniform plasma distribution over larger surface areas without compromising the nano-patterning quality poses significant engineering challenges.

The durability and longevity of the created superhydrophobic surfaces present another critical issue. PTFE nano-patterns produced by atmospheric plasma treatment can be susceptible to mechanical wear and degradation over time, potentially losing their superhydrophobic properties. Enhancing the robustness of these surfaces without sacrificing their water-repellent characteristics is a key area of ongoing research and development.

Furthermore, the optimization of surface chemistry and topography simultaneously is a complex task. The interplay between the plasma-induced chemical modifications of the PTFE surface and the physical nano-patterning effects is not fully understood. This knowledge gap hampers the ability to fine-tune the process for achieving optimal superhydrophobic properties consistently.

The environmental impact and safety considerations of the atmospheric plasma PTFE patterning process also pose challenges. The use of fluorine-containing compounds and the potential generation of harmful byproducts during the plasma treatment raise concerns about the eco-friendliness and worker safety of the process. Developing greener alternatives and implementing effective containment and filtration systems are crucial for addressing these issues.

Lastly, the integration of atmospheric plasma PTFE patterning into existing manufacturing processes presents logistical and technical hurdles. Adapting the technology to fit within current production lines while maintaining efficiency and cost-effectiveness requires careful consideration of factors such as processing speed, equipment compatibility, and quality control measures.

Existing Atmospheric Plasma PTFE Patterning Methods

01 PTFE nano-patterning techniques

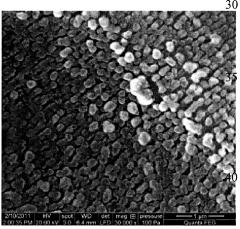

Various methods are used to create nano-patterns on PTFE surfaces, including lithography, etching, and templating. These techniques allow for precise control over surface structures at the nanoscale, which is crucial for achieving superhydrophobic properties. The nano-patterns increase surface roughness and create air pockets, enhancing water repellency.- PTFE nano-patterning techniques: Various methods are used to create nano-patterns on PTFE surfaces, including lithography, etching, and templating. These techniques allow for precise control over surface structures at the nanoscale, which is crucial for achieving superhydrophobic properties. The resulting nano-patterns can significantly enhance the water-repellent characteristics of PTFE surfaces.

- Surface modification of PTFE for superhydrophobicity: Chemical and physical treatments are applied to modify PTFE surfaces, enhancing their superhydrophobic properties. These modifications can include plasma treatment, chemical vapor deposition, and the application of nanoparticles or other materials to create hierarchical structures on the PTFE surface, further improving its water-repellent capabilities.

- Fabrication of PTFE-based composite materials: PTFE is combined with other materials to create composite structures with enhanced superhydrophobic properties. These composites often incorporate nanoparticles, fibers, or other reinforcing agents to create multi-scale surface roughness and improve the overall performance of the superhydrophobic coating or material.

- Application of PTFE superhydrophobic coatings: Superhydrophobic PTFE coatings are applied to various substrates for practical applications. These coatings can be used on textiles, glass, metals, and other materials to impart water-repellent, self-cleaning, and anti-fouling properties. The application methods and formulations are optimized for different substrate materials and end-use requirements.

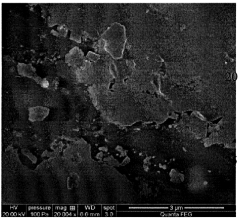

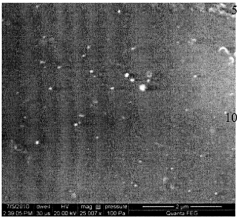

- Characterization and testing of PTFE superhydrophobic surfaces: Various techniques are employed to characterize and test the superhydrophobic properties of PTFE nano-patterned surfaces. These include contact angle measurements, surface roughness analysis, and durability tests. Advanced imaging techniques such as scanning electron microscopy (SEM) and atomic force microscopy (AFM) are used to analyze the surface morphology and nano-structures responsible for the superhydrophobic behavior.

02 Surface modification of PTFE

Chemical and physical treatments are applied to modify PTFE surfaces, enhancing their superhydrophobic characteristics. These modifications can include plasma treatment, chemical etching, or the application of nanoparticles. Such processes alter the surface energy and topography of PTFE, significantly improving its water-repellent properties.Expand Specific Solutions03 Composite materials with PTFE

Incorporating PTFE into composite materials or coating it with other substances can enhance superhydrophobicity. These composites often combine the low surface energy of PTFE with additional nano-structured materials to create hierarchical surfaces with excellent water-repellent properties.Expand Specific Solutions04 Fabrication of PTFE-based superhydrophobic coatings

Specialized coating techniques are developed to apply PTFE-based superhydrophobic layers to various substrates. These coatings often involve the dispersion of PTFE particles in a suitable matrix, followed by application methods such as spray coating, dip coating, or electrospinning to achieve uniform and durable superhydrophobic surfaces.Expand Specific Solutions05 Characterization and testing of superhydrophobic PTFE surfaces

Advanced methods are employed to characterize and test the superhydrophobic properties of PTFE nano-patterned surfaces. These include contact angle measurements, sliding angle tests, and durability assessments. Such evaluations are crucial for understanding the performance and longevity of superhydrophobic PTFE surfaces in various applications.Expand Specific Solutions

Key Players in Superhydrophobic Coatings Industry

The field of PTFE nano-patterning via atmospheric plasma for superhydrophobicity is in its early development stage, with significant potential for growth. The market size is expanding as industries recognize the value of superhydrophobic surfaces in various applications. While the technology is still evolving, several key players are driving innovation. Zhejiang University and Beijing University of Technology are leading academic research, while companies like Medtronic and Hyundai Motor Co. are exploring industrial applications. The technology's maturity varies, with some institutions like KIST Corp. and Imec focusing on advanced research, while others like Beneq Group Oy are developing practical applications. Overall, the competitive landscape is diverse, with a mix of academic, industrial, and research organizations contributing to the field's advancement.

Zhejiang University

KIST Corp. (South Korea)

Core Innovations in PTFE Nano-patterning

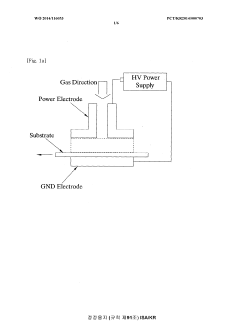

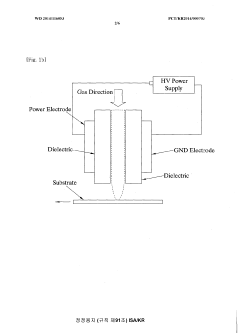

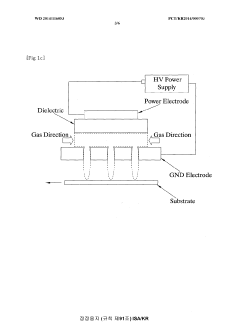

- A method involving plasma treatment with a mixed gas of hydrocarbon-based acetylene and carbon dioxide under atmospheric pressure, where the amount of carbon dioxide exceeds acetylene, effectively modifying the PTFE surface to enhance hydrophilicity without discoloration, using a DBD type plasma generator.

- Two-step plasma treatment process: initial non-polymerizing plasma exposure followed by plasma polymerization.

- Flexibility in process parameters: stationary or flow conditions, adjustable pressure range (1-150 Pa).

- Application of the method to textile materials for creating superhydrophobic surfaces.

Environmental Impact of PTFE Nano-patterning Processes

The environmental impact of PTFE nano-patterning processes via atmospheric plasma for superhydrophobicity is a critical consideration in the development and application of this technology. While the potential benefits of superhydrophobic surfaces are significant, it is essential to evaluate the ecological footprint of their production methods.

Atmospheric plasma treatment for PTFE nano-patterning offers several environmental advantages compared to traditional chemical etching processes. This method reduces the use of hazardous chemicals and minimizes waste generation, aligning with green chemistry principles. The process typically operates at ambient temperatures and pressures, resulting in lower energy consumption and reduced greenhouse gas emissions.

However, the environmental impact is not entirely negligible. The production of PTFE itself involves the use of fluoropolymers, which can persist in the environment and potentially contribute to long-term ecological concerns. The nano-scale modifications may also lead to the release of small PTFE particles during the manufacturing process or throughout the product lifecycle, raising questions about potential environmental accumulation and effects on ecosystems.

The durability of superhydrophobic PTFE surfaces created through atmospheric plasma treatment can have both positive and negative environmental implications. On one hand, increased durability can extend product lifespans, reducing waste and the need for frequent replacements. On the other hand, the enhanced resistance to degradation may prolong the environmental presence of these materials after disposal.

Energy consumption during the atmospheric plasma treatment process, while lower than some alternatives, still contributes to the overall environmental footprint. The specific impact depends on the energy source and efficiency of the plasma generation equipment. Advancements in plasma technology and the use of renewable energy sources could further mitigate this aspect of the environmental impact.

The potential for resource conservation through the application of superhydrophobic PTFE surfaces should also be considered. These surfaces can reduce the need for chemical cleaning agents and water consumption in various applications, potentially offsetting some of the environmental costs associated with their production.

As research in this field progresses, it is crucial to conduct comprehensive life cycle assessments to fully understand and quantify the environmental impact of PTFE nano-patterning via atmospheric plasma. This will enable informed decision-making regarding the adoption and scaling of this technology, ensuring that the pursuit of superhydrophobicity does not come at an unacceptable environmental cost.

Scalability and Industrial Application Potential

The scalability and industrial application potential of PTFE nano-patterning via atmospheric plasma for superhydrophobicity are significant factors in determining the technology's widespread adoption and commercial viability. This process offers several advantages that make it attractive for large-scale manufacturing and diverse industrial applications.

One of the key strengths of this technology is its compatibility with existing production lines. Atmospheric plasma treatment can be easily integrated into continuous roll-to-roll processes, allowing for high-throughput manufacturing of nano-patterned PTFE surfaces. This adaptability to current industrial setups significantly reduces the barriers to implementation and capital investment requirements for companies looking to adopt this technology.

The process's scalability is further enhanced by its relatively low energy consumption and operational costs compared to other nano-patterning techniques. Atmospheric plasma treatment does not require vacuum conditions, which eliminates the need for expensive and energy-intensive vacuum chambers. This aspect not only improves the economic feasibility of large-scale production but also aligns with growing industrial trends towards more sustainable and energy-efficient manufacturing processes.

In terms of industrial applications, the superhydrophobic PTFE surfaces created through this method have potential uses across a wide range of sectors. In the automotive industry, these surfaces could be applied to windshields and side mirrors to improve visibility in rainy conditions. The aerospace sector could benefit from reduced ice formation on aircraft surfaces, enhancing safety and fuel efficiency. Marine applications include anti-fouling coatings for ship hulls, which could lead to significant fuel savings and reduced maintenance costs.

The textile industry represents another promising area for industrial application. Superhydrophobic PTFE coatings on fabrics could create highly water-resistant and self-cleaning clothing, outdoor gear, and industrial protective wear. This technology could also revolutionize the packaging industry by producing water-repellent and easy-to-clean food containers and beverage packaging.

However, challenges remain in scaling up this technology for certain applications. Ensuring uniform nano-patterning over large surface areas and maintaining the durability of the superhydrophobic properties under various environmental conditions are areas that require further research and development. Additionally, the cost-effectiveness of the process for different types of products and production volumes needs to be carefully evaluated to determine its economic viability in various industrial contexts.