PTFE in Environmental Plastics: Rethinking Sustainability

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Evolution and Goals

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has been a revolutionary material since its accidental discovery in 1938. Initially prized for its non-stick properties and chemical resistance, PTFE has evolved to become a ubiquitous component in various industries, from cookware to aerospace. However, its environmental impact has increasingly come under scrutiny, necessitating a reevaluation of its role in sustainable plastics.

The evolution of PTFE has been marked by significant milestones. In the 1950s and 1960s, its applications expanded rapidly, finding use in everything from space suits to industrial machinery. The 1970s and 1980s saw further refinements in PTFE production techniques, leading to improved performance and wider adoption. By the 1990s, concerns about the environmental persistence of perfluorooctanoic acid (PFOA), used in PTFE manufacturing, began to emerge.

Recent years have witnessed a shift towards more sustainable PTFE production methods. The industry has largely phased out PFOA, replacing it with alternative processing aids. This transition represents a critical juncture in PTFE's evolution, balancing its valuable properties with environmental considerations. The development of PTFE recycling technologies and the exploration of bio-based alternatives are also gaining traction, reflecting the growing emphasis on circular economy principles.

Looking forward, the goals for PTFE in environmental plastics are multifaceted. Primarily, there is a push to further reduce the environmental footprint of PTFE production and use. This includes developing more efficient manufacturing processes that minimize waste and energy consumption. Additionally, improving end-of-life management for PTFE products is crucial, with increased focus on recyclability and biodegradability.

Another key objective is to enhance PTFE's compatibility with other materials, potentially leading to new composite materials that combine PTFE's unique properties with improved environmental profiles. Research into PTFE alternatives that maintain its beneficial characteristics while offering better sustainability is also a priority. This includes exploring fluoropolymers with shorter carbon chains or investigating entirely new classes of materials that could serve as eco-friendly substitutes.

The ultimate aim is to position PTFE and its derivatives as materials that can contribute positively to sustainability efforts. This involves not only addressing the environmental concerns associated with PTFE but also leveraging its durability and performance to create long-lasting, resource-efficient products. By rethinking PTFE's role in environmental plastics, the industry seeks to align this versatile material with the broader goals of sustainable development and circular economy principles.

The evolution of PTFE has been marked by significant milestones. In the 1950s and 1960s, its applications expanded rapidly, finding use in everything from space suits to industrial machinery. The 1970s and 1980s saw further refinements in PTFE production techniques, leading to improved performance and wider adoption. By the 1990s, concerns about the environmental persistence of perfluorooctanoic acid (PFOA), used in PTFE manufacturing, began to emerge.

Recent years have witnessed a shift towards more sustainable PTFE production methods. The industry has largely phased out PFOA, replacing it with alternative processing aids. This transition represents a critical juncture in PTFE's evolution, balancing its valuable properties with environmental considerations. The development of PTFE recycling technologies and the exploration of bio-based alternatives are also gaining traction, reflecting the growing emphasis on circular economy principles.

Looking forward, the goals for PTFE in environmental plastics are multifaceted. Primarily, there is a push to further reduce the environmental footprint of PTFE production and use. This includes developing more efficient manufacturing processes that minimize waste and energy consumption. Additionally, improving end-of-life management for PTFE products is crucial, with increased focus on recyclability and biodegradability.

Another key objective is to enhance PTFE's compatibility with other materials, potentially leading to new composite materials that combine PTFE's unique properties with improved environmental profiles. Research into PTFE alternatives that maintain its beneficial characteristics while offering better sustainability is also a priority. This includes exploring fluoropolymers with shorter carbon chains or investigating entirely new classes of materials that could serve as eco-friendly substitutes.

The ultimate aim is to position PTFE and its derivatives as materials that can contribute positively to sustainability efforts. This involves not only addressing the environmental concerns associated with PTFE but also leveraging its durability and performance to create long-lasting, resource-efficient products. By rethinking PTFE's role in environmental plastics, the industry seeks to align this versatile material with the broader goals of sustainable development and circular economy principles.

Market Demand Analysis

The market demand for PTFE (Polytetrafluoroethylene) in environmental plastics has been experiencing significant growth due to its unique properties and versatile applications. As industries and consumers increasingly prioritize sustainability, there is a growing need to reevaluate the use of PTFE in environmental plastics and explore more eco-friendly alternatives.

PTFE's exceptional chemical resistance, low friction coefficient, and high thermal stability have made it a popular choice in various industries, including automotive, electronics, and construction. However, the environmental impact of PTFE production and disposal has raised concerns among environmentally conscious consumers and regulatory bodies.

The global market for PTFE in environmental plastics is driven by the increasing demand for high-performance materials in water treatment, air filtration, and waste management systems. The water treatment sector, in particular, has shown substantial growth potential due to the rising need for clean water solutions in both developed and developing countries.

Despite its benefits, the non-biodegradable nature of PTFE has led to a shift in market demand towards more sustainable alternatives. This trend is particularly evident in the packaging industry, where biodegradable and compostable materials are gaining traction. Manufacturers are now exploring bio-based fluoropolymers and other environmentally friendly substitutes to meet this evolving market demand.

The automotive industry represents another significant market for PTFE in environmental applications, particularly in fuel systems and emissions control components. As vehicle emission standards become more stringent worldwide, the demand for high-performance, environmentally compatible materials like PTFE is expected to grow.

In the electronics sector, the miniaturization trend and the need for heat-resistant, chemically inert materials continue to drive the demand for PTFE. However, the industry is also exploring alternatives that offer similar performance characteristics with improved environmental profiles.

The construction industry's focus on energy-efficient buildings and sustainable infrastructure has created new opportunities for PTFE in environmental plastics. Applications such as weatherproof membranes and low-friction bearings in green building designs contribute to the market growth.

As environmental regulations become more stringent globally, the market is witnessing a shift towards PTFE recycling and upcycling initiatives. This trend is expected to create new market segments and business opportunities in the environmental plastics sector.

In conclusion, while the market demand for PTFE in environmental plastics remains strong, there is a clear trend towards more sustainable solutions. This shift presents both challenges and opportunities for manufacturers and researchers to innovate and develop environmentally friendly alternatives that maintain the performance benefits of PTFE.

PTFE's exceptional chemical resistance, low friction coefficient, and high thermal stability have made it a popular choice in various industries, including automotive, electronics, and construction. However, the environmental impact of PTFE production and disposal has raised concerns among environmentally conscious consumers and regulatory bodies.

The global market for PTFE in environmental plastics is driven by the increasing demand for high-performance materials in water treatment, air filtration, and waste management systems. The water treatment sector, in particular, has shown substantial growth potential due to the rising need for clean water solutions in both developed and developing countries.

Despite its benefits, the non-biodegradable nature of PTFE has led to a shift in market demand towards more sustainable alternatives. This trend is particularly evident in the packaging industry, where biodegradable and compostable materials are gaining traction. Manufacturers are now exploring bio-based fluoropolymers and other environmentally friendly substitutes to meet this evolving market demand.

The automotive industry represents another significant market for PTFE in environmental applications, particularly in fuel systems and emissions control components. As vehicle emission standards become more stringent worldwide, the demand for high-performance, environmentally compatible materials like PTFE is expected to grow.

In the electronics sector, the miniaturization trend and the need for heat-resistant, chemically inert materials continue to drive the demand for PTFE. However, the industry is also exploring alternatives that offer similar performance characteristics with improved environmental profiles.

The construction industry's focus on energy-efficient buildings and sustainable infrastructure has created new opportunities for PTFE in environmental plastics. Applications such as weatherproof membranes and low-friction bearings in green building designs contribute to the market growth.

As environmental regulations become more stringent globally, the market is witnessing a shift towards PTFE recycling and upcycling initiatives. This trend is expected to create new market segments and business opportunities in the environmental plastics sector.

In conclusion, while the market demand for PTFE in environmental plastics remains strong, there is a clear trend towards more sustainable solutions. This shift presents both challenges and opportunities for manufacturers and researchers to innovate and develop environmentally friendly alternatives that maintain the performance benefits of PTFE.

PTFE Challenges

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has long been celebrated for its unique properties, including chemical inertness, low friction, and high heat resistance. However, its widespread use in environmental plastics has raised significant concerns regarding sustainability and environmental impact.

One of the primary challenges associated with PTFE in environmental plastics is its persistence in the environment. PTFE is a fluoropolymer that does not biodegrade naturally, leading to long-term accumulation in ecosystems. This persistence poses a threat to wildlife and marine life, as PTFE particles can be ingested by animals, potentially causing harm to their digestive systems and overall health.

The production process of PTFE also presents environmental challenges. The manufacturing of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant that has been linked to various health issues in humans and animals. Although many manufacturers have phased out PFOA, alternative production methods may still have environmental implications that require further investigation and mitigation.

Recycling PTFE-containing products poses another significant challenge. The high melting point and chemical resistance of PTFE make it difficult to separate from other materials in mixed waste streams. This complicates recycling efforts and often results in PTFE-containing products being sent to landfills or incineration facilities, further contributing to environmental pollution.

The release of microplastics containing PTFE into the environment is an emerging concern. As PTFE-coated products wear down over time, they can release microscopic particles that find their way into water systems and soil. These microplastics can potentially enter the food chain, raising questions about their long-term impact on ecosystems and human health.

Furthermore, the durability of PTFE, while advantageous in many applications, contributes to the overall problem of plastic waste accumulation. Products containing PTFE often have extended lifespans, which can lead to a false sense of sustainability. In reality, this longevity means that PTFE-containing items will persist in the environment long after their useful life has ended.

Addressing these challenges requires a multifaceted approach. Research into biodegradable alternatives that can match PTFE's performance characteristics is crucial. Additionally, developing more efficient recycling technologies specifically designed for fluoropolymers could help mitigate the end-of-life issues associated with PTFE products. Implementing stricter regulations on PTFE production and use, particularly in consumer goods, may also be necessary to reduce its environmental footprint.

One of the primary challenges associated with PTFE in environmental plastics is its persistence in the environment. PTFE is a fluoropolymer that does not biodegrade naturally, leading to long-term accumulation in ecosystems. This persistence poses a threat to wildlife and marine life, as PTFE particles can be ingested by animals, potentially causing harm to their digestive systems and overall health.

The production process of PTFE also presents environmental challenges. The manufacturing of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant that has been linked to various health issues in humans and animals. Although many manufacturers have phased out PFOA, alternative production methods may still have environmental implications that require further investigation and mitigation.

Recycling PTFE-containing products poses another significant challenge. The high melting point and chemical resistance of PTFE make it difficult to separate from other materials in mixed waste streams. This complicates recycling efforts and often results in PTFE-containing products being sent to landfills or incineration facilities, further contributing to environmental pollution.

The release of microplastics containing PTFE into the environment is an emerging concern. As PTFE-coated products wear down over time, they can release microscopic particles that find their way into water systems and soil. These microplastics can potentially enter the food chain, raising questions about their long-term impact on ecosystems and human health.

Furthermore, the durability of PTFE, while advantageous in many applications, contributes to the overall problem of plastic waste accumulation. Products containing PTFE often have extended lifespans, which can lead to a false sense of sustainability. In reality, this longevity means that PTFE-containing items will persist in the environment long after their useful life has ended.

Addressing these challenges requires a multifaceted approach. Research into biodegradable alternatives that can match PTFE's performance characteristics is crucial. Additionally, developing more efficient recycling technologies specifically designed for fluoropolymers could help mitigate the end-of-life issues associated with PTFE products. Implementing stricter regulations on PTFE production and use, particularly in consumer goods, may also be necessary to reduce its environmental footprint.

Current PTFE Solutions

01 Recycling and reuse of PTFE materials

Developing methods for recycling and reusing PTFE materials to reduce waste and improve sustainability. This includes techniques for processing scrap PTFE, recovering valuable components, and reintegrating recycled PTFE into new products.- Recycling and reuse of PTFE materials: Sustainable practices for PTFE involve recycling and reusing materials to reduce waste and environmental impact. This includes developing methods for processing scrap PTFE, recovering valuable components, and reintegrating recycled PTFE into new products. These approaches help to extend the lifecycle of PTFE materials and promote a circular economy.

- Eco-friendly production methods for PTFE: Innovations in PTFE production focus on reducing environmental impact through improved manufacturing processes. This includes developing solvent-free methods, using renewable resources, and implementing energy-efficient techniques. These advancements aim to minimize the carbon footprint and resource consumption associated with PTFE production.

- PTFE alternatives and composites for sustainability: Research into sustainable alternatives to traditional PTFE involves developing new materials or composites that offer similar properties with reduced environmental impact. This includes exploring bio-based polymers, creating PTFE-hybrid materials, and formulating composites that incorporate recycled content while maintaining desired performance characteristics.

- PTFE surface modifications for enhanced durability: Enhancing the durability and longevity of PTFE products contributes to sustainability by reducing the need for frequent replacements. This involves developing surface modification techniques, such as plasma treatments or nanocoatings, to improve wear resistance, chemical resistance, and overall performance of PTFE materials in various applications.

- PTFE waste management and environmental remediation: Addressing the environmental concerns associated with PTFE waste involves developing effective waste management strategies and remediation techniques. This includes methods for safely disposing of PTFE-containing products, techniques for breaking down PTFE in the environment, and approaches to mitigate the potential long-term impacts of PTFE pollution.

02 Eco-friendly production processes

Implementing more environmentally friendly production processes for PTFE, focusing on reducing energy consumption, minimizing harmful emissions, and using sustainable raw materials. This includes optimizing manufacturing techniques and exploring alternative production methods.Expand Specific Solutions03 Development of biodegradable alternatives

Research and development of biodegradable alternatives to PTFE that maintain similar performance characteristics while reducing environmental impact. This involves exploring new materials and composites that can replace PTFE in various applications.Expand Specific Solutions04 Improving PTFE durability and longevity

Enhancing the durability and longevity of PTFE products to reduce the need for frequent replacements, thereby decreasing overall material consumption and waste. This includes developing new formulations and surface treatments to extend product lifespan.Expand Specific Solutions05 PTFE waste management and disposal

Developing effective waste management and disposal strategies for PTFE products at the end of their lifecycle. This includes creating systems for proper collection, sorting, and environmentally responsible disposal or repurposing of PTFE waste.Expand Specific Solutions

Key Industry Players

The environmental plastics industry, focusing on PTFE alternatives, is in a transitional phase as companies strive to balance performance with sustainability. The market is expanding rapidly, driven by increasing environmental concerns and regulatory pressures. While the technology is still evolving, several key players are making significant strides. Companies like BioLogiQ and Braskem are pioneering bio-based alternatives, while established firms such as W. L. Gore & Associates and Momentive Performance Materials are leveraging their expertise in PTFE to develop more sustainable options. Research institutions, including Tsinghua University and Washington State University, are contributing to technological advancements. The competitive landscape is diverse, with a mix of chemical giants, specialized materials companies, and innovative startups vying for market share in this growing sector.

Braskem SA

Technical Solution: Braskem has developed a bio-based alternative to PTFE called I'm green™ Polyethylene. This material is derived from sugarcane ethanol, offering a renewable source for plastic production. The company's approach focuses on reducing carbon footprint while maintaining the performance characteristics required for various applications. Braskem's I'm green™ Polyethylene captures and fixes CO2 from the atmosphere during its production process, contributing to a negative carbon footprint[4]. The company has also invested in chemical recycling technologies to address end-of-life issues for plastic products, including those traditionally made with PTFE[5]. Braskem's commitment to sustainability extends to their circular economy program, which aims to eliminate plastic waste through innovative recycling solutions and partnerships across the value chain[6].

Strengths: Bio-based alternative to traditional plastics, carbon-negative production process, and investment in chemical recycling. Weaknesses: May not fully replicate all PTFE properties, potentially limiting applications in some high-performance sectors.

Shandong Dongyue Polymer Material Co. Ltd.

Technical Solution: Shandong Dongyue has focused on developing eco-friendly alternatives to traditional PTFE. Their research includes the creation of PTFE micropowders with improved dispersibility and reduced environmental impact. The company has invested in green manufacturing processes that aim to reduce emissions and energy consumption in PTFE production[7]. They have also explored the use of recycled PTFE in various applications, contributing to a more circular economy approach. Shandong Dongyue's efforts extend to the development of water-based PTFE dispersions, which reduce the use of harmful solvents in coating applications[8]. Additionally, the company has been working on improving the degradability of PTFE products to address end-of-life environmental concerns[9].

Strengths: Green manufacturing processes, development of eco-friendly PTFE alternatives, and focus on recycling. Weaknesses: Still primarily focused on PTFE-based solutions, which may face long-term sustainability challenges.

PTFE Innovations

A high-strength polytetrafluoroethylene recycled powder composite material and its preparation process

PatentActiveCN118459910B

Innovation

- By mixing the polytetrafluoroethylene dispersion and polytetrafluoroethylene regenerated powder, polytetrafluoroethylene fibers are produced in the powder gaps of the regenerated powder to improve the strength of the product. An organic solvent is used to form a stable suspension, which is washed and crushed. Obtain uniform high-strength recycled powder composite.

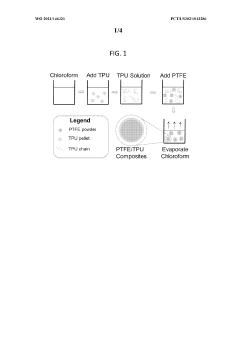

Methods of making polytetrafluoroethylene/polymer composites and uses thereof

PatentWO2021146321A1

Innovation

- A method involving dissolving a polymer in a solvent, immersing PTFE into the solution, and extruding the blend to form composite products, which allows for the incorporation of biodegradable polymers and bio-functional materials, enabling improved biocompatibility, bioactivity, and controlled drug release.

Environmental Impact

The environmental impact of PTFE (Polytetrafluoroethylene) in plastics is a complex issue that requires careful consideration. PTFE, commonly known as Teflon, has been widely used in various applications due to its unique properties, such as chemical resistance, low friction, and thermal stability. However, its persistence in the environment and potential health risks have raised concerns about its sustainability.

PTFE's environmental impact begins with its production process, which involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant. Although many manufacturers have phased out PFOA, alternative production methods may still have environmental implications. The release of fluoropolymer particles during manufacturing and product use contributes to environmental contamination, particularly in water bodies and soil.

One of the most significant environmental concerns associated with PTFE is its extreme persistence. As a fluoropolymer, PTFE does not biodegrade naturally, leading to long-term accumulation in the environment. This persistence raises questions about its impact on ecosystems and wildlife. Studies have shown that PTFE particles can be ingested by marine organisms, potentially entering the food chain and affecting biodiversity.

The disposal of PTFE-containing products presents another environmental challenge. Incineration of PTFE can release harmful substances, including hydrogen fluoride and other toxic gases. Landfilling is not an ideal solution either, as PTFE remains intact for extended periods, contributing to long-term environmental pollution.

Furthermore, the production and use of PTFE contribute to greenhouse gas emissions. The manufacturing process of PTFE and its precursors involves energy-intensive steps, leading to a significant carbon footprint. Additionally, the release of fluorinated gases during production and disposal can have a potent global warming effect.

However, it is important to note that PTFE's durability and unique properties can also contribute to environmental benefits in certain applications. For instance, its use in renewable energy technologies, such as solar panels and fuel cells, can enhance efficiency and longevity, potentially offsetting some of its negative environmental impacts.

As the environmental impact of PTFE becomes increasingly apparent, there is a growing need for sustainable alternatives and improved lifecycle management. Research into bio-based and biodegradable fluoropolymers is ongoing, aiming to address the persistence issue while maintaining the desirable properties of PTFE. Additionally, efforts to improve recycling technologies for PTFE-containing products are crucial for reducing environmental impact and promoting a circular economy approach.

PTFE's environmental impact begins with its production process, which involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant. Although many manufacturers have phased out PFOA, alternative production methods may still have environmental implications. The release of fluoropolymer particles during manufacturing and product use contributes to environmental contamination, particularly in water bodies and soil.

One of the most significant environmental concerns associated with PTFE is its extreme persistence. As a fluoropolymer, PTFE does not biodegrade naturally, leading to long-term accumulation in the environment. This persistence raises questions about its impact on ecosystems and wildlife. Studies have shown that PTFE particles can be ingested by marine organisms, potentially entering the food chain and affecting biodiversity.

The disposal of PTFE-containing products presents another environmental challenge. Incineration of PTFE can release harmful substances, including hydrogen fluoride and other toxic gases. Landfilling is not an ideal solution either, as PTFE remains intact for extended periods, contributing to long-term environmental pollution.

Furthermore, the production and use of PTFE contribute to greenhouse gas emissions. The manufacturing process of PTFE and its precursors involves energy-intensive steps, leading to a significant carbon footprint. Additionally, the release of fluorinated gases during production and disposal can have a potent global warming effect.

However, it is important to note that PTFE's durability and unique properties can also contribute to environmental benefits in certain applications. For instance, its use in renewable energy technologies, such as solar panels and fuel cells, can enhance efficiency and longevity, potentially offsetting some of its negative environmental impacts.

As the environmental impact of PTFE becomes increasingly apparent, there is a growing need for sustainable alternatives and improved lifecycle management. Research into bio-based and biodegradable fluoropolymers is ongoing, aiming to address the persistence issue while maintaining the desirable properties of PTFE. Additionally, efforts to improve recycling technologies for PTFE-containing products are crucial for reducing environmental impact and promoting a circular economy approach.

Regulatory Framework

The regulatory framework surrounding PTFE in environmental plastics is complex and evolving, reflecting growing concerns about the environmental impact of these materials. At the international level, the Stockholm Convention on Persistent Organic Pollutants has been instrumental in regulating long-chain perfluoroalkyl substances (PFASs), which include some PTFE precursors. This treaty, ratified by over 180 countries, aims to eliminate or restrict the production and use of persistent organic pollutants.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation plays a crucial role in managing the risks associated with PTFE and related substances. REACH requires manufacturers and importers to register chemicals and provide safety information, with specific provisions for substances of very high concern (SVHCs). Several PFAS compounds have been identified as SVHCs under REACH, leading to restrictions on their use and production.

The United States has also taken significant steps in regulating PTFE and related compounds. The Environmental Protection Agency (EPA) has implemented the PFOA Stewardship Program, which led to the phase-out of long-chain PFASs by major manufacturers. Additionally, the EPA has established health advisories for certain PFAS compounds in drinking water and is considering further regulatory actions under the Toxic Substances Control Act (TSCA).

At the state level in the US, several jurisdictions have enacted more stringent regulations. For example, California's Proposition 65 requires businesses to provide warnings about significant exposures to chemicals that cause cancer, birth defects, or other reproductive harm, which includes certain PFAS compounds used in PTFE production.

In Asia, countries like Japan and South Korea have implemented their own chemical management systems, which include provisions for PTFE and related substances. Japan's Chemical Substances Control Law and South Korea's Act on Registration and Evaluation of Chemicals (K-REACH) both aim to assess and manage the risks associated with these materials.

The regulatory landscape is continuously evolving, with a trend towards stricter controls and increased transparency. Many jurisdictions are moving towards a more precautionary approach, considering not only the direct impacts of PTFE but also its entire lifecycle and potential degradation products. This shift is driving innovation in alternative materials and production processes, as industries seek to adapt to the changing regulatory environment and meet growing demands for more sustainable solutions.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation plays a crucial role in managing the risks associated with PTFE and related substances. REACH requires manufacturers and importers to register chemicals and provide safety information, with specific provisions for substances of very high concern (SVHCs). Several PFAS compounds have been identified as SVHCs under REACH, leading to restrictions on their use and production.

The United States has also taken significant steps in regulating PTFE and related compounds. The Environmental Protection Agency (EPA) has implemented the PFOA Stewardship Program, which led to the phase-out of long-chain PFASs by major manufacturers. Additionally, the EPA has established health advisories for certain PFAS compounds in drinking water and is considering further regulatory actions under the Toxic Substances Control Act (TSCA).

At the state level in the US, several jurisdictions have enacted more stringent regulations. For example, California's Proposition 65 requires businesses to provide warnings about significant exposures to chemicals that cause cancer, birth defects, or other reproductive harm, which includes certain PFAS compounds used in PTFE production.

In Asia, countries like Japan and South Korea have implemented their own chemical management systems, which include provisions for PTFE and related substances. Japan's Chemical Substances Control Law and South Korea's Act on Registration and Evaluation of Chemicals (K-REACH) both aim to assess and manage the risks associated with these materials.

The regulatory landscape is continuously evolving, with a trend towards stricter controls and increased transparency. Many jurisdictions are moving towards a more precautionary approach, considering not only the direct impacts of PTFE but also its entire lifecycle and potential degradation products. This shift is driving innovation in alternative materials and production processes, as industries seek to adapt to the changing regulatory environment and meet growing demands for more sustainable solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!