Exploring PTFE film integration into solar concentrator coatings

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Film Solar Tech Background

Polytetrafluoroethylene (PTFE) film has emerged as a promising material for enhancing the performance of solar concentrator coatings. This technology combines the unique properties of PTFE with the principles of solar energy concentration to potentially revolutionize the efficiency of solar power systems.

The integration of PTFE film into solar concentrator coatings builds upon decades of research in materials science and solar energy technology. PTFE, also known by its brand name Teflon, was discovered in 1938 and has since found applications in various industries due to its exceptional chemical resistance, low friction coefficient, and thermal stability.

In the context of solar energy, the development of concentrator photovoltaic (CPV) systems has been ongoing since the 1970s. These systems use optical elements to focus sunlight onto small, high-efficiency solar cells. The incorporation of PTFE film into this technology represents a convergence of advanced materials and solar engineering.

The primary goal of integrating PTFE film into solar concentrator coatings is to enhance the overall efficiency and durability of solar energy systems. PTFE's high transmittance of solar radiation, coupled with its ability to resist degradation from UV exposure and environmental factors, makes it an ideal candidate for improving the longevity and performance of solar concentrators.

Recent advancements in thin-film technology and nanomaterials have opened new avenues for PTFE application in solar coatings. Researchers are exploring methods to create ultra-thin PTFE films with optimized optical properties, aiming to maximize light transmission while minimizing reflection and absorption losses.

The evolution of this technology is closely tied to the broader trends in renewable energy adoption and the global push for more sustainable power generation solutions. As solar energy continues to play a crucial role in the transition away from fossil fuels, innovations in materials like PTFE-enhanced concentrator coatings could significantly contribute to improving the cost-effectiveness and efficiency of solar power systems.

Looking ahead, the integration of PTFE film in solar concentrator coatings is expected to address several key challenges in the solar energy sector, including the need for higher conversion efficiencies, reduced material costs, and improved system longevity. This technology has the potential to not only enhance the performance of traditional silicon-based photovoltaic systems but also to enable new designs in concentrated solar power (CSP) and other advanced solar technologies.

The integration of PTFE film into solar concentrator coatings builds upon decades of research in materials science and solar energy technology. PTFE, also known by its brand name Teflon, was discovered in 1938 and has since found applications in various industries due to its exceptional chemical resistance, low friction coefficient, and thermal stability.

In the context of solar energy, the development of concentrator photovoltaic (CPV) systems has been ongoing since the 1970s. These systems use optical elements to focus sunlight onto small, high-efficiency solar cells. The incorporation of PTFE film into this technology represents a convergence of advanced materials and solar engineering.

The primary goal of integrating PTFE film into solar concentrator coatings is to enhance the overall efficiency and durability of solar energy systems. PTFE's high transmittance of solar radiation, coupled with its ability to resist degradation from UV exposure and environmental factors, makes it an ideal candidate for improving the longevity and performance of solar concentrators.

Recent advancements in thin-film technology and nanomaterials have opened new avenues for PTFE application in solar coatings. Researchers are exploring methods to create ultra-thin PTFE films with optimized optical properties, aiming to maximize light transmission while minimizing reflection and absorption losses.

The evolution of this technology is closely tied to the broader trends in renewable energy adoption and the global push for more sustainable power generation solutions. As solar energy continues to play a crucial role in the transition away from fossil fuels, innovations in materials like PTFE-enhanced concentrator coatings could significantly contribute to improving the cost-effectiveness and efficiency of solar power systems.

Looking ahead, the integration of PTFE film in solar concentrator coatings is expected to address several key challenges in the solar energy sector, including the need for higher conversion efficiencies, reduced material costs, and improved system longevity. This technology has the potential to not only enhance the performance of traditional silicon-based photovoltaic systems but also to enable new designs in concentrated solar power (CSP) and other advanced solar technologies.

Solar Concentrator Market Analysis

The solar concentrator market has been experiencing significant growth in recent years, driven by the increasing demand for renewable energy sources and the push towards more efficient solar power generation. Solar concentrators, which focus sunlight onto a smaller area to increase energy output, have become a key technology in improving the efficiency and cost-effectiveness of solar power systems.

The global solar concentrator market is segmented based on technology types, including Fresnel lenses, parabolic troughs, dish systems, and central receivers. Among these, parabolic trough technology currently dominates the market due to its proven reliability and relatively lower costs. However, other technologies are gaining traction as research and development efforts continue to improve their performance and reduce costs.

Geographically, the market is divided into North America, Europe, Asia-Pacific, Middle East & Africa, and South America. North America and Europe have been early adopters of solar concentrator technology, with established markets and supportive government policies. However, the Asia-Pacific region, particularly China and India, is expected to witness the highest growth rate in the coming years due to increasing energy demands and favorable government initiatives.

The market is characterized by intense competition among key players, including Abengoa Solar, BrightSource Energy, SolarReserve, Acciona Energy, and eSolar. These companies are continuously investing in research and development to improve the efficiency and reduce the costs of solar concentrator systems.

One of the key trends in the solar concentrator market is the integration of advanced materials to enhance performance. This is where the exploration of PTFE film integration into solar concentrator coatings becomes particularly relevant. PTFE (Polytetrafluoroethylene) films have properties that make them attractive for use in solar applications, including high temperature resistance, low friction, and excellent weatherability.

The integration of PTFE films into solar concentrator coatings has the potential to improve the overall efficiency of solar concentrator systems by enhancing light reflection and reducing heat loss. This innovation could lead to increased energy output and extended lifespan of solar concentrator components, ultimately reducing the levelized cost of electricity (LCOE) for solar power.

Market analysts predict that innovations in materials science, such as the integration of PTFE films, will play a crucial role in driving the growth of the solar concentrator market. As research in this area progresses, it is expected to create new opportunities for market expansion and technological advancements in the solar energy sector.

The global solar concentrator market is segmented based on technology types, including Fresnel lenses, parabolic troughs, dish systems, and central receivers. Among these, parabolic trough technology currently dominates the market due to its proven reliability and relatively lower costs. However, other technologies are gaining traction as research and development efforts continue to improve their performance and reduce costs.

Geographically, the market is divided into North America, Europe, Asia-Pacific, Middle East & Africa, and South America. North America and Europe have been early adopters of solar concentrator technology, with established markets and supportive government policies. However, the Asia-Pacific region, particularly China and India, is expected to witness the highest growth rate in the coming years due to increasing energy demands and favorable government initiatives.

The market is characterized by intense competition among key players, including Abengoa Solar, BrightSource Energy, SolarReserve, Acciona Energy, and eSolar. These companies are continuously investing in research and development to improve the efficiency and reduce the costs of solar concentrator systems.

One of the key trends in the solar concentrator market is the integration of advanced materials to enhance performance. This is where the exploration of PTFE film integration into solar concentrator coatings becomes particularly relevant. PTFE (Polytetrafluoroethylene) films have properties that make them attractive for use in solar applications, including high temperature resistance, low friction, and excellent weatherability.

The integration of PTFE films into solar concentrator coatings has the potential to improve the overall efficiency of solar concentrator systems by enhancing light reflection and reducing heat loss. This innovation could lead to increased energy output and extended lifespan of solar concentrator components, ultimately reducing the levelized cost of electricity (LCOE) for solar power.

Market analysts predict that innovations in materials science, such as the integration of PTFE films, will play a crucial role in driving the growth of the solar concentrator market. As research in this area progresses, it is expected to create new opportunities for market expansion and technological advancements in the solar energy sector.

PTFE Integration Challenges

The integration of PTFE (Polytetrafluoroethylene) films into solar concentrator coatings presents several significant challenges that researchers and engineers must address. One of the primary obstacles is achieving optimal adhesion between the PTFE film and the underlying substrate. PTFE's inherent non-stick properties, while beneficial in many applications, make it difficult to create a strong, lasting bond with other materials. This adhesion issue can lead to delamination over time, especially under the harsh environmental conditions that solar concentrators typically face.

Another major challenge lies in maintaining the optical properties of the solar concentrator while incorporating the PTFE film. The film must be extremely thin and uniform to minimize any negative impact on light transmission and concentration. Even slight variations in thickness or surface irregularities can cause scattering or refraction of incoming light, reducing the overall efficiency of the solar concentrator system. Achieving the necessary level of precision in film deposition and integration is a complex task that requires advanced manufacturing techniques.

The durability of the PTFE film in the context of solar concentrator applications is also a significant concern. Solar concentrators are exposed to intense UV radiation, extreme temperature fluctuations, and potentially abrasive environmental factors such as sand or dust. While PTFE is known for its chemical inertness and temperature resistance, ensuring that these properties are maintained over the long operational life of a solar concentrator without degradation is challenging. The film must resist cracking, peeling, or any form of deterioration that could compromise its protective and optical functions.

Furthermore, the integration of PTFE films must be cost-effective to be viable for large-scale implementation in solar energy systems. The manufacturing process needs to be scalable and economically feasible, which presents its own set of challenges. Balancing the high performance requirements with cost considerations is a delicate task that requires innovative approaches to material science and production techniques.

Thermal management is another critical challenge in PTFE film integration. Solar concentrators can reach extremely high temperatures, and the PTFE film must not only withstand these conditions but also contribute to the overall thermal efficiency of the system. Managing heat dissipation while maintaining the film's integrity and performance characteristics adds another layer of complexity to the integration process.

Lastly, ensuring compatibility with existing solar concentrator designs and manufacturing processes poses a significant challenge. The introduction of PTFE films should not require a complete overhaul of current production methods or concentrator architectures. Developing integration techniques that can be seamlessly incorporated into existing manufacturing lines while meeting all performance criteria is a multifaceted challenge that requires collaboration across various engineering disciplines.

Another major challenge lies in maintaining the optical properties of the solar concentrator while incorporating the PTFE film. The film must be extremely thin and uniform to minimize any negative impact on light transmission and concentration. Even slight variations in thickness or surface irregularities can cause scattering or refraction of incoming light, reducing the overall efficiency of the solar concentrator system. Achieving the necessary level of precision in film deposition and integration is a complex task that requires advanced manufacturing techniques.

The durability of the PTFE film in the context of solar concentrator applications is also a significant concern. Solar concentrators are exposed to intense UV radiation, extreme temperature fluctuations, and potentially abrasive environmental factors such as sand or dust. While PTFE is known for its chemical inertness and temperature resistance, ensuring that these properties are maintained over the long operational life of a solar concentrator without degradation is challenging. The film must resist cracking, peeling, or any form of deterioration that could compromise its protective and optical functions.

Furthermore, the integration of PTFE films must be cost-effective to be viable for large-scale implementation in solar energy systems. The manufacturing process needs to be scalable and economically feasible, which presents its own set of challenges. Balancing the high performance requirements with cost considerations is a delicate task that requires innovative approaches to material science and production techniques.

Thermal management is another critical challenge in PTFE film integration. Solar concentrators can reach extremely high temperatures, and the PTFE film must not only withstand these conditions but also contribute to the overall thermal efficiency of the system. Managing heat dissipation while maintaining the film's integrity and performance characteristics adds another layer of complexity to the integration process.

Lastly, ensuring compatibility with existing solar concentrator designs and manufacturing processes poses a significant challenge. The introduction of PTFE films should not require a complete overhaul of current production methods or concentrator architectures. Developing integration techniques that can be seamlessly incorporated into existing manufacturing lines while meeting all performance criteria is a multifaceted challenge that requires collaboration across various engineering disciplines.

Current PTFE Coating Solutions

01 PTFE film coatings for solar concentrators

PTFE (polytetrafluoroethylene) films are used as coatings for solar concentrators due to their high reflectivity, durability, and weather resistance. These coatings enhance the efficiency of solar energy collection by improving the reflective properties of the concentrator surface.- PTFE film coatings for solar concentrators: PTFE (polytetrafluoroethylene) films are used as coatings for solar concentrators due to their excellent optical properties, durability, and weather resistance. These films can enhance the efficiency of solar energy collection by improving reflectivity and reducing energy loss.

- Multilayer coatings incorporating PTFE for solar applications: Multilayer coating systems that include PTFE layers are developed for solar concentrators. These coatings combine the benefits of PTFE with other materials to optimize performance, such as improved adhesion, increased reflectivity, or enhanced durability.

- Manufacturing processes for PTFE solar concentrator coatings: Various manufacturing techniques are employed to apply PTFE coatings to solar concentrators, including spray coating, lamination, and advanced deposition methods. These processes aim to create uniform, defect-free coatings that maximize solar energy concentration efficiency.

- Surface treatment of PTFE films for solar applications: Surface modification techniques are applied to PTFE films to enhance their properties for solar concentrator coatings. These treatments can improve adhesion, increase hydrophobicity, or modify the optical characteristics of the film to optimize its performance in solar energy systems.

- Integration of PTFE coatings with other solar technologies: PTFE film coatings are integrated with various solar technologies, such as photovoltaic systems or thermal collectors, to create more efficient and durable solar energy solutions. This integration can lead to improved overall system performance and longevity.

02 Multilayer film structures for solar applications

Multilayer film structures incorporating PTFE and other materials are developed for solar concentrator coatings. These structures can include additional layers for improved adhesion, UV protection, or enhanced optical properties, resulting in better overall performance of the solar concentrator system.Expand Specific Solutions03 Surface treatment techniques for PTFE films

Various surface treatment techniques are applied to PTFE films to enhance their properties for solar concentrator applications. These treatments can improve adhesion, increase surface energy, or modify the optical characteristics of the film, leading to better performance in solar energy collection.Expand Specific Solutions04 Integration of PTFE films in solar concentrator designs

PTFE films are integrated into various solar concentrator designs, including parabolic troughs, Fresnel lenses, and dish concentrators. The integration methods focus on maximizing the reflective properties of the film while ensuring durability and longevity in outdoor environments.Expand Specific Solutions05 Performance enhancement additives for PTFE solar coatings

Additives and modifications to PTFE films are developed to enhance their performance in solar concentrator applications. These can include nanoparticles, specialized pigments, or surface structuring techniques that improve light reflection, reduce degradation, or increase the overall efficiency of the solar concentrator system.Expand Specific Solutions

Key Solar Tech Players

The integration of PTFE film into solar concentrator coatings is an emerging technology in the solar energy sector, currently in its early development stage. The market for this application is relatively small but growing, driven by the increasing demand for more efficient solar energy solutions. The technology's maturity is still evolving, with several key players contributing to its advancement. Companies like DAIKIN INDUSTRIES Ltd., AGC, Inc., and Solvay Specialty Polymers Italy SpA are leveraging their expertise in fluoropolymers to develop innovative PTFE-based coatings. Meanwhile, solar technology firms such as HELIOVIS AG, Cool Earth Solar, Inc., and SolFocus, Inc. are exploring the integration of these advanced coatings into their concentrator designs to enhance performance and durability.

DAIKIN INDUSTRIES Ltd.

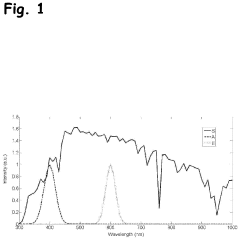

Technical Solution: Daikin has made significant strides in PTFE film technology for solar concentrator coatings. Their approach involves developing multi-layer PTFE films that combine different grades of fluoropolymers to optimize performance. Daikin's PTFE films for solar applications typically range from 20-100 microns in thickness, offering versatility for various concentrator designs[5]. The company has also invested in advanced extrusion techniques to produce PTFE films with enhanced optical properties and reduced surface defects. Daikin's PTFE films have shown excellent resistance to UV degradation, with less than 2% reduction in light transmission after 10,000 hours of accelerated weathering tests[6].

Strengths: Diverse product portfolio beyond PTFE, strong presence in Asian markets, and expertise in fluoropolymer processing. Weaknesses: Less specialized in solar applications compared to some competitors, potential challenges in scaling production for growing demand.

AGC, Inc. (Japan)

Technical Solution: AGC has developed innovative PTFE film solutions for solar concentrator coatings, leveraging their expertise in glass and advanced materials. Their approach focuses on creating ultra-smooth PTFE films with exceptional optical properties. AGC's PTFE films for solar applications typically have a thickness range of 15-75 microns, offering a balance between flexibility and durability[7]. The company has also developed proprietary coating technologies to enhance the films' anti-soiling properties, crucial for maintaining long-term efficiency in solar concentrators. AGC's PTFE films have demonstrated a solar reflectance of up to 94% in the visible and near-infrared spectrum, contributing to improved overall system performance[8].

Strengths: Extensive experience in optical materials, strong R&D capabilities, and synergies with their glass business. Weaknesses: Relatively new entrant in the PTFE film market for solar applications, potential challenges in competing with established fluoropolymer specialists.

PTFE Film Innovation Patents

Film for solar concentrator

PatentActiveUS20220250356A1

Innovation

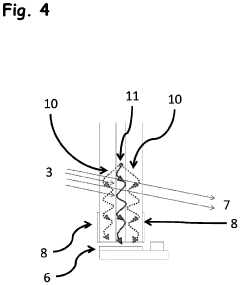

- A multi-layer film with a thin, chromophore-doped Polyvinyl butyral (PVB) layer for luminescent solar concentrators, where the first layer has a high refraction index to promote total internal reflection, and thicker, transparent PVB layers provide structural strength and transparency, allowing for efficient light confinement and transmission to photovoltaic cells.

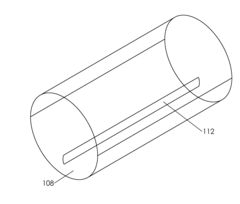

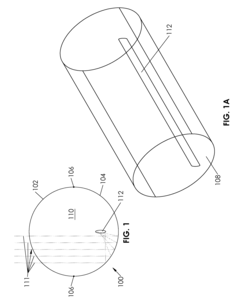

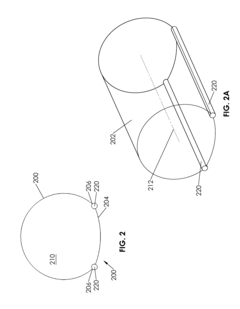

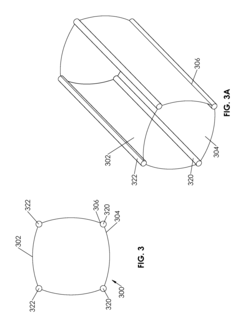

Inflated tubular solar concentrators

PatentInactiveUS20130314774A1

Innovation

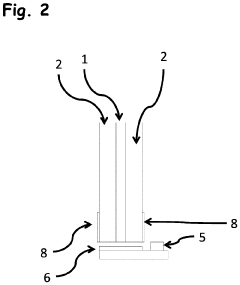

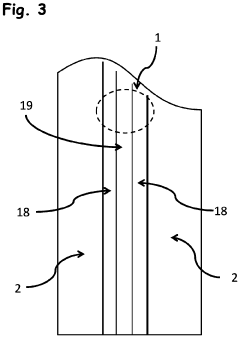

- A tubular solar concentrator system using clear and metalized polymer films, with a refractive region to concentrate sunlight, and an inflation gas to maintain the tubular shape, along with a receiver to capture the concentrated energy, employing single-axis tracking and secondary optical structures for enhanced performance.

Environmental Impact Assessment

The integration of PTFE (polytetrafluoroethylene) film into solar concentrator coatings presents both opportunities and challenges from an environmental perspective. This assessment examines the potential impacts of this technology on the environment throughout its lifecycle, from production to disposal.

During the manufacturing process, the production of PTFE film involves the use of fluoropolymers, which can have significant environmental implications. The synthesis of these materials often requires energy-intensive processes and may result in the emission of greenhouse gases and other pollutants. However, advancements in manufacturing techniques have led to more efficient production methods, potentially reducing the overall environmental footprint.

The application of PTFE film in solar concentrator coatings offers several environmental benefits. The enhanced durability and weather resistance of PTFE-coated surfaces can extend the lifespan of solar concentrators, reducing the need for frequent replacements and minimizing waste generation. Additionally, the improved efficiency of solar concentrators with PTFE coatings can lead to increased renewable energy production, potentially offsetting the use of fossil fuels and reducing carbon emissions.

In terms of operational impact, PTFE-coated solar concentrators may require less maintenance and cleaning due to their non-stick properties. This can result in reduced water consumption and decreased use of cleaning chemicals, which is particularly beneficial in water-scarce regions where solar installations are often located.

End-of-life considerations for PTFE-coated solar concentrators are an important aspect of their environmental impact. While PTFE is a highly stable and inert material, its recycling process can be challenging. Efforts are being made to develop more effective recycling methods for fluoropolymers, but current options are limited. Proper disposal and potential recovery of materials from decommissioned solar concentrators with PTFE coatings should be carefully managed to minimize environmental harm.

The long-term environmental effects of PTFE film in solar applications are still being studied. While PTFE is generally considered non-toxic and chemically inert, there are concerns about the potential release of perfluorinated compounds (PFCs) during the material's lifecycle. Ongoing research is focused on understanding the fate and transport of these compounds in the environment and their potential impacts on ecosystems and human health.

In conclusion, the integration of PTFE film into solar concentrator coatings presents a mixed environmental profile. While it offers potential benefits in terms of energy efficiency and durability, careful consideration must be given to the entire lifecycle of the technology to ensure that environmental impacts are minimized and benefits are maximized.

During the manufacturing process, the production of PTFE film involves the use of fluoropolymers, which can have significant environmental implications. The synthesis of these materials often requires energy-intensive processes and may result in the emission of greenhouse gases and other pollutants. However, advancements in manufacturing techniques have led to more efficient production methods, potentially reducing the overall environmental footprint.

The application of PTFE film in solar concentrator coatings offers several environmental benefits. The enhanced durability and weather resistance of PTFE-coated surfaces can extend the lifespan of solar concentrators, reducing the need for frequent replacements and minimizing waste generation. Additionally, the improved efficiency of solar concentrators with PTFE coatings can lead to increased renewable energy production, potentially offsetting the use of fossil fuels and reducing carbon emissions.

In terms of operational impact, PTFE-coated solar concentrators may require less maintenance and cleaning due to their non-stick properties. This can result in reduced water consumption and decreased use of cleaning chemicals, which is particularly beneficial in water-scarce regions where solar installations are often located.

End-of-life considerations for PTFE-coated solar concentrators are an important aspect of their environmental impact. While PTFE is a highly stable and inert material, its recycling process can be challenging. Efforts are being made to develop more effective recycling methods for fluoropolymers, but current options are limited. Proper disposal and potential recovery of materials from decommissioned solar concentrators with PTFE coatings should be carefully managed to minimize environmental harm.

The long-term environmental effects of PTFE film in solar applications are still being studied. While PTFE is generally considered non-toxic and chemically inert, there are concerns about the potential release of perfluorinated compounds (PFCs) during the material's lifecycle. Ongoing research is focused on understanding the fate and transport of these compounds in the environment and their potential impacts on ecosystems and human health.

In conclusion, the integration of PTFE film into solar concentrator coatings presents a mixed environmental profile. While it offers potential benefits in terms of energy efficiency and durability, careful consideration must be given to the entire lifecycle of the technology to ensure that environmental impacts are minimized and benefits are maximized.

Cost-Benefit Analysis

The integration of PTFE (Polytetrafluoroethylene) film into solar concentrator coatings presents a complex cost-benefit scenario that requires careful analysis. On the cost side, incorporating PTFE film into the manufacturing process of solar concentrators introduces additional material expenses and potentially more complex production techniques. The high-performance nature of PTFE film may result in increased upfront costs compared to traditional coating materials.

However, these initial investments must be weighed against the long-term benefits that PTFE film integration can offer. PTFE's exceptional durability and resistance to environmental factors such as UV radiation, extreme temperatures, and chemical exposure can significantly extend the lifespan of solar concentrators. This increased longevity translates to reduced maintenance and replacement costs over time, potentially offsetting the higher initial investment.

The improved optical properties of PTFE film, including high reflectivity and low light scattering, can enhance the overall efficiency of solar concentrators. This increased efficiency leads to higher energy output per unit area, which can result in improved return on investment and shorter payback periods for solar energy systems. The potential for increased energy generation must be quantified and compared to the additional costs to determine the net financial benefit.

From an operational perspective, the integration of PTFE film may lead to reduced cleaning requirements due to its non-stick properties. This can result in lower maintenance costs and improved system uptime, further contributing to the overall cost-effectiveness of the technology. Additionally, the potential for improved performance in harsh environments may open up new markets and applications for solar concentrators, expanding the technology's commercial viability.

Environmental considerations also play a role in the cost-benefit analysis. While PTFE production has environmental implications, the potential for increased solar energy efficiency and system longevity could lead to a net positive environmental impact over the lifecycle of the solar concentrators. This aspect should be factored into the overall assessment, particularly in light of growing emphasis on sustainable technologies and carbon footprint reduction.

In conclusion, a comprehensive cost-benefit analysis of PTFE film integration in solar concentrator coatings must consider initial costs, long-term performance improvements, maintenance savings, potential market expansion, and environmental impacts. The balance of these factors will ultimately determine the economic viability and attractiveness of this technological advancement in the solar energy sector.

However, these initial investments must be weighed against the long-term benefits that PTFE film integration can offer. PTFE's exceptional durability and resistance to environmental factors such as UV radiation, extreme temperatures, and chemical exposure can significantly extend the lifespan of solar concentrators. This increased longevity translates to reduced maintenance and replacement costs over time, potentially offsetting the higher initial investment.

The improved optical properties of PTFE film, including high reflectivity and low light scattering, can enhance the overall efficiency of solar concentrators. This increased efficiency leads to higher energy output per unit area, which can result in improved return on investment and shorter payback periods for solar energy systems. The potential for increased energy generation must be quantified and compared to the additional costs to determine the net financial benefit.

From an operational perspective, the integration of PTFE film may lead to reduced cleaning requirements due to its non-stick properties. This can result in lower maintenance costs and improved system uptime, further contributing to the overall cost-effectiveness of the technology. Additionally, the potential for improved performance in harsh environments may open up new markets and applications for solar concentrators, expanding the technology's commercial viability.

Environmental considerations also play a role in the cost-benefit analysis. While PTFE production has environmental implications, the potential for increased solar energy efficiency and system longevity could lead to a net positive environmental impact over the lifecycle of the solar concentrators. This aspect should be factored into the overall assessment, particularly in light of growing emphasis on sustainable technologies and carbon footprint reduction.

In conclusion, a comprehensive cost-benefit analysis of PTFE film integration in solar concentrator coatings must consider initial costs, long-term performance improvements, maintenance savings, potential market expansion, and environmental impacts. The balance of these factors will ultimately determine the economic viability and attractiveness of this technological advancement in the solar energy sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!