Projecting future PTFE electrolyte applications in organic batteries

PTFE Electrolyte Evolution

The evolution of PTFE (polytetrafluoroethylene) electrolytes in organic batteries has been marked by significant advancements and innovations over the past few decades. Initially, PTFE was primarily used as a binder material in battery electrodes due to its excellent chemical stability and hydrophobic properties. However, researchers soon recognized its potential as an electrolyte component, leading to a series of developments in this field.

In the early stages, PTFE was incorporated into liquid electrolytes as a separator material, enhancing the mechanical strength and thermal stability of battery systems. This application paved the way for further exploration of PTFE's role in electrolyte formulations. As the demand for safer and more efficient batteries grew, scientists began investigating PTFE-based solid and gel electrolytes.

The mid-2000s saw a surge in research focused on PTFE-based composite electrolytes. These composites combined PTFE with other polymers or inorganic materials to create hybrid electrolytes with improved ionic conductivity and mechanical properties. This approach addressed some of the limitations of pure PTFE electrolytes, such as low ionic conductivity at room temperature.

A significant breakthrough came with the development of PTFE-based porous membranes for lithium-ion batteries. These membranes exhibited excellent thermal stability, high porosity, and good wettability with organic electrolytes, leading to enhanced battery performance and safety. The success of these membranes sparked interest in exploring PTFE's potential in other types of organic batteries.

Recent years have witnessed the emergence of novel PTFE-based electrolyte designs, including nanostructured PTFE electrolytes and PTFE-ceramic composites. These advanced materials have shown promise in addressing key challenges in organic battery technology, such as dendrite formation and electrolyte degradation. The incorporation of PTFE nanofibers and nanoparticles has also been explored to enhance the mechanical and electrochemical properties of electrolytes.

Looking ahead, the evolution of PTFE electrolytes in organic batteries is expected to focus on several key areas. One promising direction is the development of ultra-thin PTFE-based solid electrolytes that can enable high-energy-density batteries with improved safety profiles. Additionally, researchers are exploring the potential of PTFE in next-generation battery technologies, such as lithium-sulfur and sodium-ion batteries, where its unique properties could offer significant advantages.

As environmental concerns gain prominence, there is also a growing interest in developing eco-friendly PTFE electrolyte formulations and recycling methods. This trend aligns with the broader push towards sustainable battery technologies and circular economy principles in the energy storage sector.

Organic Battery Market Trends

The organic battery market is experiencing significant growth and transformation, driven by the increasing demand for sustainable energy storage solutions. This trend is particularly evident in the consumer electronics, electric vehicles, and renewable energy sectors. The global organic battery market is projected to expand rapidly over the next decade, with a compound annual growth rate (CAGR) exceeding that of traditional lithium-ion batteries.

One of the key factors propelling this market growth is the rising environmental consciousness among consumers and businesses alike. Organic batteries, which utilize environmentally friendly materials and offer improved recyclability, are becoming increasingly attractive as a green alternative to conventional battery technologies. This shift in consumer preference is encouraging manufacturers to invest more heavily in research and development of organic battery technologies.

The electric vehicle (EV) industry is emerging as a major driver for organic battery adoption. As governments worldwide implement stricter emissions regulations and offer incentives for EV adoption, the demand for high-performance, sustainable batteries is soaring. Organic batteries, with their potential for faster charging times and longer cycle life, are well-positioned to meet this growing demand.

In the consumer electronics sector, the trend towards wearable devices and Internet of Things (IoT) applications is creating new opportunities for organic batteries. These applications often require flexible, lightweight, and safe energy storage solutions – characteristics that organic batteries can potentially offer. As a result, major electronics manufacturers are showing increased interest in incorporating organic battery technologies into their product lines.

The renewable energy sector is another area where organic batteries are gaining traction. As the world transitions towards cleaner energy sources, the need for efficient and sustainable energy storage systems becomes paramount. Organic batteries, with their potential for scalability and environmental friendliness, are being explored for grid-scale energy storage applications.

However, the organic battery market is not without its challenges. Current limitations in energy density and manufacturing scalability are hindering widespread adoption. Nonetheless, ongoing research and development efforts, particularly in the field of PTFE electrolytes, are addressing these issues and showing promising results.

In conclusion, the organic battery market is poised for substantial growth in the coming years. The convergence of environmental concerns, technological advancements, and evolving energy needs across various sectors is creating a favorable landscape for organic battery technologies. As research progresses and manufacturing processes improve, organic batteries, including those utilizing PTFE electrolytes, are expected to play an increasingly significant role in the global energy storage market.

PTFE Electrolyte Challenges

The development of PTFE (polytetrafluoroethylene) electrolytes for organic batteries faces several significant challenges that need to be addressed to realize their full potential. One of the primary obstacles is the inherent non-conductive nature of PTFE, which limits its effectiveness as an electrolyte material. Researchers are grappling with the task of enhancing the ionic conductivity of PTFE-based electrolytes without compromising their excellent chemical stability and mechanical properties.

Another major challenge lies in achieving optimal interfacial compatibility between PTFE electrolytes and electrode materials. The hydrophobic nature of PTFE can lead to poor wetting and inadequate contact with electrodes, potentially resulting in increased interfacial resistance and reduced battery performance. Developing strategies to improve the interfacial interactions while maintaining the desirable properties of PTFE is crucial for advancing this technology.

The processing and fabrication of PTFE electrolytes present additional hurdles. Traditional methods for producing thin, uniform PTFE films are often incompatible with the requirements of battery manufacturing. Researchers are exploring novel techniques such as electrospinning and advanced coating processes to create PTFE electrolyte membranes with the desired thickness, porosity, and mechanical integrity.

Thermal management is another critical challenge in PTFE electrolyte development. While PTFE exhibits excellent thermal stability, its low thermal conductivity can lead to heat accumulation within the battery, potentially affecting performance and safety. Addressing this issue requires innovative approaches to enhance heat dissipation without compromising the electrolyte's other properties.

The long-term stability and cycling performance of PTFE electrolytes in organic batteries remain areas of concern. Although PTFE is known for its chemical inertness, prolonged exposure to organic solvents and electrochemical cycling can potentially lead to degradation or structural changes. Ensuring the longevity and consistent performance of PTFE electrolytes over thousands of charge-discharge cycles is essential for their practical implementation.

Scalability and cost-effectiveness pose significant challenges for the widespread adoption of PTFE electrolytes in organic batteries. Current production methods for high-quality PTFE materials suitable for electrolyte applications are often expensive and difficult to scale up. Developing economically viable manufacturing processes that can produce large quantities of PTFE electrolytes without sacrificing quality is crucial for commercial viability.

Lastly, the environmental impact and recyclability of PTFE electrolytes need to be carefully considered. While PTFE is highly durable and resistant to degradation, this very property makes it challenging to recycle or dispose of at the end of the battery's life cycle. Finding sustainable solutions for the production, use, and end-of-life management of PTFE electrolytes is essential for their long-term success in the battery industry.

Current PTFE Solutions

01 PTFE-based electrolyte membranes

PTFE is used as a base material for electrolyte membranes in various electrochemical applications. These membranes are often modified or combined with other materials to enhance their properties, such as ion conductivity and mechanical strength. The PTFE-based electrolyte membranes are particularly useful in fuel cells, batteries, and other energy storage devices.- PTFE-based electrolyte membranes: PTFE is used as a base material for electrolyte membranes in various electrochemical applications. These membranes offer excellent chemical stability, low electrical resistance, and good mechanical properties. The PTFE matrix can be modified or combined with other materials to enhance its performance as an electrolyte.

- PTFE electrolyte composites: Composite materials incorporating PTFE and other components are developed to improve electrolyte performance. These composites may include inorganic fillers, conductive polymers, or other functional additives to enhance properties such as ionic conductivity, mechanical strength, or thermal stability.

- PTFE electrolyte coatings: PTFE-based coatings are applied to electrodes or other surfaces to create electrolyte layers. These coatings can provide a barrier against corrosion, improve electrode performance, or facilitate ion transport in electrochemical devices such as batteries or fuel cells.

- PTFE electrolyte manufacturing processes: Various manufacturing processes are developed to produce PTFE-based electrolytes with desired properties. These may include extrusion, casting, or electrospinning techniques to create membranes or coatings with specific morphologies and characteristics tailored for electrolyte applications.

- PTFE electrolyte modifications: Chemical or physical modifications of PTFE are employed to enhance its electrolyte properties. These modifications may include surface treatments, grafting of functional groups, or incorporation of additives to improve ionic conductivity, wettability, or other electrochemical properties of the PTFE-based electrolyte.

02 PTFE as a binder in electrolyte compositions

PTFE is utilized as a binder in electrolyte compositions, particularly in solid or gel electrolytes. It helps to improve the mechanical stability and cohesion of the electrolyte material. This application is common in lithium-ion batteries and other energy storage devices, where PTFE contributes to the overall performance and durability of the electrolyte system.Expand Specific Solutions03 PTFE-coated electrodes for electrolyte systems

Electrodes coated with PTFE are used in various electrolyte systems to enhance their performance and longevity. The PTFE coating can improve the electrode's resistance to corrosion, reduce unwanted reactions, and modify the electrode's surface properties. This technology is applied in electrochemical cells, sensors, and electrolysis systems.Expand Specific Solutions04 PTFE-based composite electrolytes

Composite electrolytes incorporating PTFE are developed to combine the advantages of PTFE with other materials. These composites often aim to improve ionic conductivity, mechanical strength, or thermal stability. The resulting materials find applications in advanced battery technologies, fuel cells, and other electrochemical devices requiring high-performance electrolytes.Expand Specific Solutions05 PTFE in electrolyte processing and manufacturing

PTFE plays a role in the processing and manufacturing of electrolytes. It can be used in the production of porous structures, as a processing aid, or in the fabrication of electrolyte components. The unique properties of PTFE, such as its chemical inertness and low surface energy, make it valuable in various stages of electrolyte production and assembly.Expand Specific Solutions

Key PTFE Electrolyte Players

The market for PTFE electrolyte applications in organic batteries is in an early growth stage, with significant potential for expansion. The global market size is projected to increase substantially as demand for high-performance batteries grows across industries. While PTFE electrolyte technology is still evolving, several key players are driving innovation. Companies like DAIKIN INDUSTRIES, Shin-Etsu Chemical, and Sila Nanotechnologies are at the forefront of developing advanced PTFE-based electrolyte solutions. Major automotive manufacturers such as Toyota, GM, and Nissan are also investing in this technology to enhance battery performance and safety in electric vehicles. As research progresses, we can expect rapid advancements in PTFE electrolyte formulations and manufacturing processes, leading to improved battery efficiency and durability.

DAIKIN INDUSTRIES Ltd.

Toyota Motor Corp.

PTFE Electrolyte Innovations

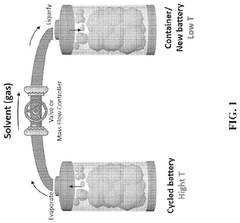

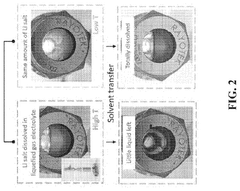

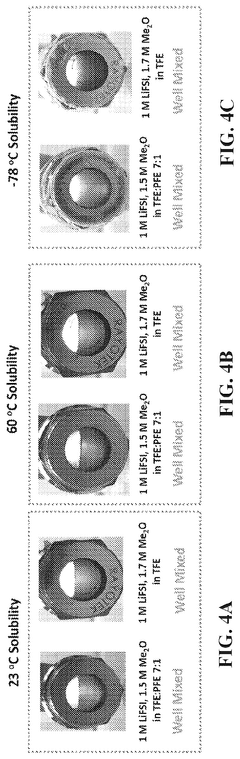

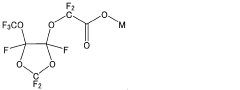

- The use of fire-extinguishing liquefied gas electrolytes based on 1,1,1,2-tetrafluoroethane (TFE) and pentafluoroethane (PFE), which maintain high ionic conductivity from −78 to +80°C and enable stable lithium metal cycling with over 99% Coulombic efficiency, along with a one-step solvent recycling process.

- A polytetrafluoroethylene (PTFE) binder with a specific molecular weight and moisture content is used to form an electrode mixture sheet with excellent strength, eliminating the need for organic solvents and enhancing binding strength with active materials.

Environmental Impact

The environmental impact of PTFE electrolyte applications in organic batteries is a critical consideration as this technology advances. PTFE, or polytetrafluoroethylene, is known for its chemical stability and resistance to degradation, which contributes to its longevity in battery applications. However, this durability also raises concerns about its end-of-life management and potential environmental persistence.

In the production phase, the synthesis of PTFE involves the use of fluoropolymers, which can have significant environmental implications if not properly managed. The manufacturing process may release greenhouse gases and other pollutants, necessitating stringent emission control measures. Additionally, the energy-intensive nature of PTFE production contributes to the overall carbon footprint of organic batteries utilizing this material.

During the operational life of organic batteries with PTFE electrolytes, the environmental impact is generally positive. These batteries often demonstrate improved energy efficiency and longer lifespans compared to conventional alternatives, potentially reducing the frequency of battery replacements and associated waste generation. The stability of PTFE also minimizes the risk of electrolyte leakage, which can be a significant environmental hazard in other battery types.

However, the end-of-life stage presents challenges. While PTFE is recyclable, the process is complex and energy-intensive due to its high melting point and chemical resistance. The recycling infrastructure for PTFE-containing batteries is currently limited, which may lead to improper disposal and potential environmental contamination. Research into more efficient recycling methods and the development of circular economy approaches for PTFE in battery applications is crucial to mitigate these concerns.

The potential for PTFE to persist in the environment if not properly managed is a significant consideration. While it does not biodegrade easily, studies have shown that under certain conditions, such as exposure to high-energy radiation or specific chemical treatments, PTFE can break down into smaller particles. These microplastics and potential byproducts of degradation may have long-term ecological impacts that are not yet fully understood.

To address these environmental challenges, ongoing research is focused on developing more sustainable production methods for PTFE, improving recycling technologies, and exploring bio-based alternatives that maintain the desirable properties of PTFE while reducing environmental persistence. Additionally, life cycle assessments are being conducted to comprehensively evaluate the environmental impact of PTFE electrolytes in organic batteries from cradle to grave, informing policy decisions and guiding future technological developments in this field.

Safety Considerations

Safety considerations are paramount when developing and implementing PTFE electrolyte applications in organic batteries. The inherent chemical stability and inertness of PTFE contribute to its safety profile, but several aspects require careful attention.

Thermal stability is a critical factor in battery safety. PTFE exhibits excellent thermal resistance, maintaining its properties at high temperatures. This characteristic reduces the risk of electrolyte degradation and potential thermal runaway events. However, the interaction between PTFE and other battery components under extreme thermal conditions must be thoroughly evaluated to ensure overall system stability.

Chemical compatibility between PTFE electrolytes and organic solvents used in batteries is another crucial safety aspect. While PTFE is generally chemically inert, long-term exposure to certain organic compounds may lead to subtle changes in its properties. Comprehensive compatibility studies are essential to identify any potential adverse reactions or degradation mechanisms that could compromise battery performance or safety over time.

Mechanical integrity of PTFE-based electrolyte systems is vital for preventing internal short circuits and maintaining battery structural stability. The flexibility and durability of PTFE membranes contribute to their resistance against mechanical stress, but the impact of repeated charge-discharge cycles on the electrolyte's physical properties must be carefully monitored and addressed in battery design.

Electrochemical stability window is a key safety parameter for electrolytes in organic batteries. PTFE's wide electrochemical stability range enhances its suitability for high-voltage applications. However, the boundaries of this stability window must be precisely determined and respected in battery operation to prevent electrolyte decomposition and potential safety hazards.

Gas evolution and pressure build-up within batteries are significant safety concerns. PTFE's low gas permeability can help contain any gases generated during battery operation, but this characteristic also necessitates careful cell design to manage internal pressure effectively. Incorporating appropriate pressure relief mechanisms may be necessary to mitigate risks associated with gas accumulation.

Toxicity and environmental impact of PTFE electrolytes must be considered from a safety perspective. While PTFE is generally considered non-toxic, the potential release of fluorinated compounds during battery manufacturing, use, or disposal requires thorough assessment. Developing safe handling procedures and environmentally responsible disposal methods is essential for the widespread adoption of PTFE-based electrolyte technologies in organic batteries.