Examining PTFE cable dielectric enhancement through nano‑dopants

PTFE Cable Evolution

PTFE (Polytetrafluoroethylene) cables have undergone significant evolution since their inception, driven by the increasing demands for high-performance dielectric materials in various industries. The journey of PTFE cable development can be traced back to the 1930s when PTFE was accidentally discovered by Roy Plunkett at DuPont. Initially, the unique properties of PTFE, such as its excellent electrical insulation and chemical resistance, were not fully recognized in cable applications.

The 1950s marked the beginning of PTFE's use in cable insulation, primarily in military and aerospace applications due to its superior performance in extreme conditions. As the technology progressed, the 1960s and 1970s saw a wider adoption of PTFE cables in industrial and commercial sectors, particularly in high-frequency communication systems and medical equipment.

The 1980s and 1990s witnessed significant advancements in PTFE cable manufacturing techniques, leading to improved consistency and reduced production costs. This period also saw the development of modified PTFE materials, such as expanded PTFE (ePTFE), which offered enhanced mechanical and electrical properties while maintaining the core benefits of standard PTFE.

Entering the 21st century, the focus shifted towards enhancing the dielectric properties of PTFE cables to meet the growing demands of high-speed data transmission and miniaturization in electronics. This led to the exploration of nano-dopants as a means to improve the dielectric constant and loss tangent of PTFE insulation.

The concept of incorporating nano-dopants into PTFE matrices emerged as a promising approach to tailor the material's properties. Various nanoparticles, including metal oxides, ceramics, and carbon-based materials, have been investigated for their potential to enhance the dielectric performance of PTFE cables. These nano-dopants can alter the electronic structure and interfacial properties of the PTFE matrix, resulting in improved dielectric strength, reduced losses, and enhanced thermal stability.

Recent years have seen intensive research into optimizing the dispersion and integration of nano-dopants within PTFE. Techniques such as in-situ polymerization, melt blending, and surface modification of nanoparticles have been developed to achieve uniform distribution and strong interfacial bonding between the dopants and the PTFE matrix. These advancements have led to the creation of PTFE nanocomposites with superior dielectric properties, opening new possibilities for high-performance cable applications.

The evolution of PTFE cables through nano-doping represents a significant leap in material science and cable technology. It addresses the growing need for cables with enhanced electrical performance, particularly in sectors such as telecommunications, aerospace, and high-energy physics experiments. As research in this field continues to progress, we can anticipate further improvements in PTFE cable properties, potentially revolutionizing the capabilities of electrical and communication systems across various industries.

Nano-Doped Dielectrics

Nano-doped dielectrics represent a cutting-edge approach to enhancing the performance of cable insulation materials, particularly in the context of PTFE (Polytetrafluoroethylene) cables. This innovative technology involves the incorporation of nanoscale particles into the dielectric matrix, resulting in significant improvements in electrical, thermal, and mechanical properties.

The primary objective of nano-doping PTFE cables is to address the limitations of traditional dielectric materials, such as low dielectric strength, poor thermal conductivity, and susceptibility to electrical treeing. By introducing carefully selected nanoparticles, researchers aim to create a composite material that combines the excellent insulating properties of PTFE with the unique characteristics of nanomaterials.

Various types of nanoparticles have been explored for this purpose, including metal oxides (e.g., Al2O3, TiO2, SiO2), carbon nanotubes, and graphene derivatives. Each type of nano-dopant offers specific advantages. For instance, metal oxide nanoparticles can enhance dielectric strength and reduce space charge accumulation, while carbon-based nanomaterials can improve thermal conductivity and mechanical strength.

The mechanism behind the enhanced performance of nano-doped dielectrics is multifaceted. Nanoparticles create interfacial regions within the polymer matrix, which can act as charge traps, reducing the mobility of charge carriers and increasing the overall dielectric strength. Additionally, these particles can disrupt the growth of electrical trees, improving the long-term reliability of the insulation.

Thermal management is another critical aspect addressed by nano-doping. The incorporation of thermally conductive nanoparticles can significantly enhance heat dissipation within the cable, allowing for higher current-carrying capacities and improved overall efficiency.

However, the development of nano-doped PTFE cables faces several challenges. Achieving uniform dispersion of nanoparticles within the PTFE matrix is crucial for optimal performance but can be technically challenging due to the non-polar nature of PTFE. Furthermore, the interface between the nanoparticles and the polymer matrix must be carefully engineered to prevent agglomeration and ensure long-term stability.

Research in this field is ongoing, with a focus on optimizing the type, size, and concentration of nanoparticles to achieve the best balance of properties. Advanced characterization techniques, such as electron microscopy and spectroscopy, are employed to understand the nanoscale interactions and their impact on macroscopic properties.

The potential applications of nano-doped PTFE cables are vast, ranging from high-voltage power transmission to aerospace and telecommunications. As the technology matures, it promises to enable the development of more compact, efficient, and reliable electrical systems across various industries.

Technical Hurdles

The enhancement of PTFE cable dielectric properties through nano-dopants faces several significant technical hurdles. One of the primary challenges is achieving uniform dispersion of nanoparticles within the PTFE matrix. The hydrophobic nature of PTFE makes it difficult to incorporate and evenly distribute hydrophilic nanoparticles, leading to potential agglomeration and inconsistent dielectric performance across the cable.

Another major obstacle is maintaining the desirable properties of PTFE, such as its low dielectric loss and excellent thermal stability, while introducing nano-dopants. The addition of nanoparticles can potentially disrupt the crystalline structure of PTFE, affecting its inherent characteristics. Striking the right balance between enhancing dielectric properties and preserving PTFE's unique attributes requires precise control over the type, size, and concentration of nano-dopants.

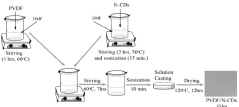

The processing techniques for incorporating nano-dopants into PTFE cables present additional challenges. Traditional melt processing methods may not be suitable due to PTFE's high melting point and viscosity. Alternative techniques like in-situ polymerization or solution blending need to be developed and optimized for large-scale production, ensuring consistent quality and performance of the enhanced dielectric material.

Interfacial adhesion between the nano-dopants and the PTFE matrix is another critical issue. Poor adhesion can lead to the formation of voids or defects at the interfaces, potentially compromising the dielectric strength and long-term reliability of the cable. Developing effective surface modification techniques for nanoparticles to improve their compatibility with PTFE is essential for addressing this challenge.

The long-term stability and aging behavior of nano-doped PTFE cables under various environmental conditions and electrical stresses remain areas of concern. Ensuring that the enhanced dielectric properties are maintained throughout the cable's operational lifetime requires extensive testing and validation. This includes evaluating the impact of temperature fluctuations, humidity, and electrical cycling on the nano-doped PTFE's performance over extended periods.

Lastly, the potential health and environmental implications of using nanomaterials in cable production need to be carefully assessed. Ensuring the safe handling of nanoparticles during manufacturing and addressing any potential risks associated with nanoparticle release during the cable's lifecycle are crucial considerations that must be addressed to meet regulatory requirements and ensure product safety.

Current Solutions

01 PTFE as a dielectric material in cables

PTFE (Polytetrafluoroethylene) is widely used as a dielectric material in cables due to its excellent electrical insulation properties. It has a low dielectric constant and low dissipation factor, making it ideal for high-frequency applications. PTFE's chemical inertness and thermal stability also contribute to its effectiveness as a cable insulator.- PTFE as a dielectric material in cables: PTFE (Polytetrafluoroethylene) is widely used as a dielectric material in cables due to its excellent electrical insulation properties. It has a low dielectric constant and low dielectric loss, making it ideal for high-frequency applications. PTFE's chemical inertness and thermal stability further enhance its suitability for cable insulation.

- Improved dielectric properties through PTFE composites: Researchers have developed PTFE composites with enhanced dielectric properties. By incorporating various fillers or additives into the PTFE matrix, the dielectric constant and loss tangent can be tailored for specific applications. These composites offer improved performance in high-frequency and high-temperature environments.

- PTFE cable design for specific dielectric requirements: Cable manufacturers design PTFE cables with specific dielectric properties to meet various industry needs. This includes adjusting the PTFE thickness, using multi-layer insulation, or incorporating air gaps to achieve desired impedance and capacitance characteristics. Such designs are crucial for applications in telecommunications, aerospace, and medical devices.

- Testing and measurement of PTFE cable dielectric properties: Various methods and equipment are used to test and measure the dielectric properties of PTFE cables. These include impedance analyzers, network analyzers, and specialized test fixtures. Accurate measurement of dielectric constant, dissipation factor, and other parameters is essential for quality control and ensuring cable performance in different applications.

- Environmental effects on PTFE cable dielectric properties: The dielectric properties of PTFE cables can be affected by environmental factors such as temperature, humidity, and mechanical stress. Research has been conducted to understand these effects and develop PTFE cable formulations that maintain stable dielectric properties under various operating conditions. This is particularly important for cables used in extreme environments or critical applications.

02 Dielectric constant and dissipation factor of PTFE cables

PTFE cables exhibit a low dielectric constant, typically around 2.1, which remains stable over a wide range of frequencies. The dissipation factor of PTFE is also very low, usually less than 0.0003 at 1 MHz. These properties make PTFE cables suitable for high-speed data transmission and low-loss RF applications.Expand Specific Solutions03 Temperature and frequency dependence of PTFE dielectric properties

The dielectric properties of PTFE cables remain relatively stable over a wide range of temperatures and frequencies. This stability is crucial for maintaining consistent electrical performance in various operating conditions. However, at extremely high frequencies or temperatures, slight variations in dielectric properties may occur.Expand Specific Solutions04 Modifications to enhance PTFE cable dielectric properties

Various modifications can be made to PTFE to enhance its dielectric properties for specific cable applications. These include the addition of fillers, creation of microporous structures, or blending with other polymers. Such modifications can alter the dielectric constant, improve mechanical properties, or enhance the cable's overall performance in specific environments.Expand Specific Solutions05 Testing and measurement of PTFE cable dielectric properties

Accurate testing and measurement of PTFE cable dielectric properties are essential for quality control and performance verification. Various methods are employed, including impedance analyzers, network analyzers, and specialized dielectric test fixtures. These measurements ensure that the cables meet the required specifications for dielectric constant, dissipation factor, and other electrical parameters.Expand Specific Solutions

Industry Leaders

The market for PTFE cable dielectric enhancement through nano-dopants is in an early growth stage, characterized by increasing research and development activities. The global market size is expanding, driven by demand for high-performance cables in various industries. Technologically, the field is progressing rapidly but still evolving, with companies like Prysmian, Nexans, and 3M Innovative Properties leading innovation. These firms, along with academic institutions such as Tianjin University and Waseda University, are actively developing nano-doped PTFE solutions. The technology's maturity varies, with some commercial applications emerging, but significant potential for further advancements remains, particularly in enhancing dielectric properties and overall cable performance.

Prysmian SpA

Nexans SA

Key Innovations

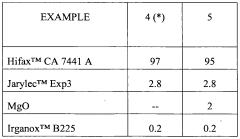

- A thermoplastic composition comprising a heterophasic propylene copolymer intimately admixed with untreated nano-sized fillers, eliminating the need for compatibilizers and enhancing the homogeneity and performance of the insulating layer without compromising mechanical or electrical properties.

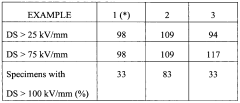

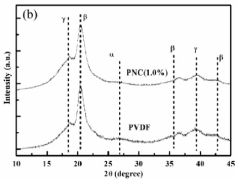

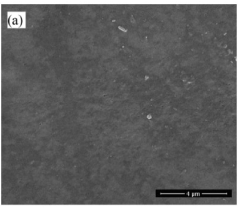

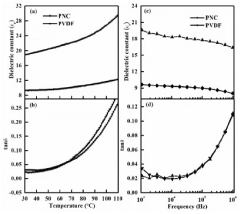

- A polyvinylidene difluoride (PVDF)/Nitrogen-doped carbon dots (N-CDs) nanocomposite film is developed using citric acid and urea synthesis, with a solution cast process and fast-drying silver paste for electric field application, creating a non-toxic, high dielectric constant, and high breakdown strength capacitive energy storage device.

Performance Metrics

Performance metrics play a crucial role in evaluating the effectiveness of PTFE cable dielectric enhancement through nano-dopants. These metrics provide quantitative and qualitative measures to assess the improvements achieved by incorporating nanomaterials into the PTFE matrix.

One of the primary performance metrics is the dielectric constant, which indicates the material's ability to store electrical energy. Nano-doped PTFE cables typically exhibit higher dielectric constants compared to their undoped counterparts, resulting in improved signal transmission and reduced signal loss. The dissipation factor, another essential metric, measures the energy loss within the dielectric material. Lower dissipation factors are desirable, as they indicate reduced energy dissipation and improved overall performance.

Breakdown voltage is a critical parameter that determines the maximum electric field strength a dielectric material can withstand before electrical breakdown occurs. Nano-doped PTFE cables often demonstrate higher breakdown voltages, enhancing their reliability and durability in high-voltage applications. Additionally, the volume resistivity of the material is an important metric, as it reflects the cable's ability to resist current flow through its bulk. Higher volume resistivity values indicate better insulation properties.

The frequency dependence of dielectric properties is another crucial aspect to consider. Nano-doped PTFE cables should maintain stable dielectric properties across a wide range of frequencies, ensuring consistent performance in various applications. Temperature coefficient of capacitance (TCC) is also a significant metric, as it measures the change in capacitance with temperature variations. Lower TCC values indicate better stability of electrical properties under different operating conditions.

Mechanical properties, such as tensile strength and elongation at break, are important performance metrics to evaluate the physical integrity of nano-doped PTFE cables. Enhanced mechanical properties can lead to improved durability and longevity of the cables in demanding environments. Furthermore, the thermal conductivity of the material is a relevant metric, as it affects heat dissipation and overall thermal management of the cable system.

Long-term stability and aging characteristics are crucial performance metrics for assessing the reliability of nano-doped PTFE cables over extended periods. These metrics include resistance to environmental factors, such as moisture, chemicals, and UV radiation, as well as the ability to maintain consistent electrical and mechanical properties over time. Accelerated aging tests and long-term performance studies are often conducted to evaluate these aspects.

In conclusion, a comprehensive evaluation of nano-doped PTFE cable performance requires the consideration of multiple metrics, including electrical, mechanical, and long-term stability parameters. By analyzing these metrics, researchers and engineers can assess the effectiveness of nano-dopants in enhancing PTFE cable dielectric properties and determine their suitability for various applications in the electronics and telecommunications industries.

Environmental Impact

The environmental impact of enhancing PTFE cable dielectrics through nano-dopants is a critical consideration in the development and implementation of this technology. While the primary focus is on improving the electrical performance of cables, it is essential to evaluate the potential environmental consequences throughout the entire lifecycle of these enhanced materials.

Nano-dopants, when incorporated into PTFE cables, can potentially alter the environmental footprint of the product. The production process of nano-doped PTFE cables may require additional energy and resources compared to traditional PTFE cable manufacturing. This increased energy consumption could lead to higher greenhouse gas emissions if not managed properly. However, the improved dielectric properties may result in more efficient power transmission, potentially offsetting some of the environmental costs associated with production.

The use of nanomaterials in PTFE cables raises concerns about their potential release into the environment during the cable's lifetime. While PTFE is known for its chemical stability, the long-term behavior of nano-dopants within the polymer matrix is not fully understood. There is a possibility that these nanoparticles could leach out over time, especially under extreme environmental conditions or during cable degradation. This potential release of nanomaterials into soil or water systems could have unforeseen ecological impacts.

End-of-life management of nano-doped PTFE cables presents another environmental challenge. The presence of nanomaterials may complicate recycling processes, potentially reducing the recyclability of the cables. Proper disposal methods need to be developed to prevent the release of nano-dopants into the environment during cable disposal or incineration. Additionally, the potential for these materials to persist in the environment long after the cable's useful life must be carefully evaluated.

On the positive side, the enhanced dielectric properties of nano-doped PTFE cables could lead to improved energy efficiency in power transmission systems. This increased efficiency may result in reduced energy losses and, consequently, lower overall energy consumption and greenhouse gas emissions associated with power generation and distribution. Furthermore, if the enhanced cables prove to be more durable and have a longer lifespan than traditional PTFE cables, it could reduce the frequency of cable replacement, thereby decreasing the overall material consumption and waste generation in the long term.

To fully assess the environmental impact of this technology, comprehensive life cycle assessments (LCAs) should be conducted. These assessments would compare the environmental footprint of nano-doped PTFE cables with traditional PTFE cables across all stages of their life cycle, from raw material extraction to end-of-life disposal. Such studies would provide valuable insights into the net environmental impact of this technological advancement and guide future development and implementation strategies.