Vorticity compression pump

A scroll compressor, compression chamber technology, applied in the direction of rotary piston machinery, rotary piston pump, mechanical equipment, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

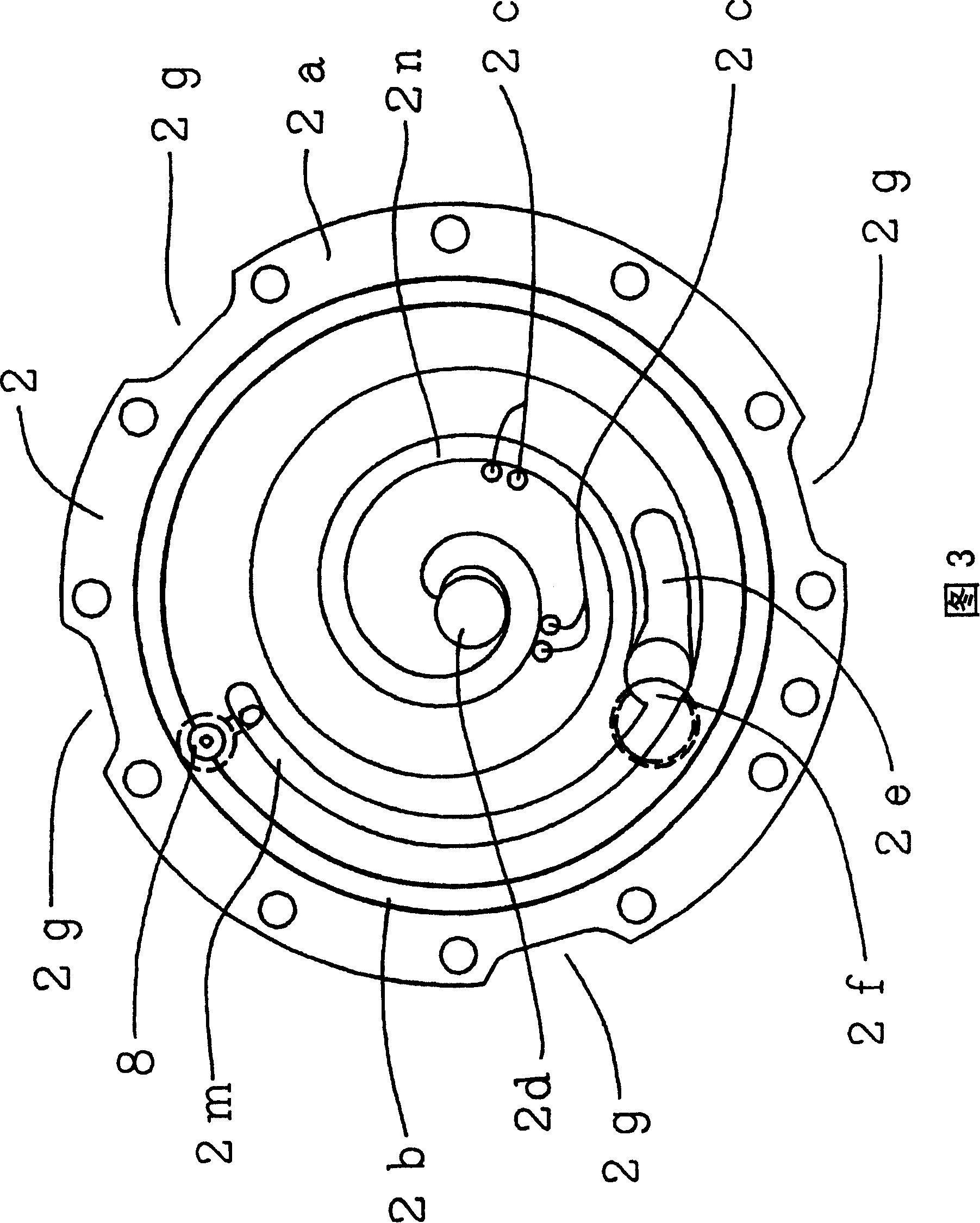

[0026] Hereinafter, referring to the drawings, the use of a carbon dioxide-adapted heat pump water heater will be described as a first embodiment of the present invention. First, the structure will be described. The scroll compressor shown in FIG. 1 is composed of a fixed scroll 2 , a movable scroll 1 , a motor 12 , an airtight container 22 , and a frame 9 . Wherein, the movable scroll 1 is combined with the fixed scroll 2 to form a compression chamber 3 and performs an eccentric rotary motion relative to the fixed scroll 2; the motor 12 drives the movable scroll 1 to perform an eccentric rotary motion; The airtight container 22 accommodates the fixed scroll 2, the movable scroll 1 and the motor 12; the frame 9 is fixed on the wall of the airtight container 22, and the movable scroll 1 is sandwiched in the middle in a rotatable manner. , as a fixed scroll fixing mechanism that supports and fixes the fixed scroll 2; the scroll compressor compresses the working fluid sucked int...

no. 2 Embodiment

[0060] Referring to Fig. 10 below, Figure 11 A second embodiment of the present invention will be described. The difference between this embodiment and the above-mentioned first embodiment is that an oil supply pump 25 driven by the rotating shaft 11 is provided inside the countershaft housing 15; A sealing ring 26 is installed on the surface of the bearing holder 1d, and an oil bag 1g that can travel between the thrust storage chamber 9i and the intermediate pressure chamber 23 is formed on the axial end surface of the bearing holding portion 1d. Since the other configurations are the same, they are given the same symbols and descriptions thereof are omitted here. Components with the same symbols as in the first embodiment are the same components and have the same functions.

[0061] In this embodiment, as shown in FIG. 10 , an oil supply pump 25 driven by the rotary shaft 11 is provided inside the countershaft housing 15 mounted on the sub-bearing support plate 14 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com