Expansion bolt wrench and method for removing expansion bolts

A technology of expansion bolts and wrenches, applied in the directions of wrenches, connecting components, pins, etc., can solve problems such as unfavorable work safety, waste of time, and inability to completely remove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

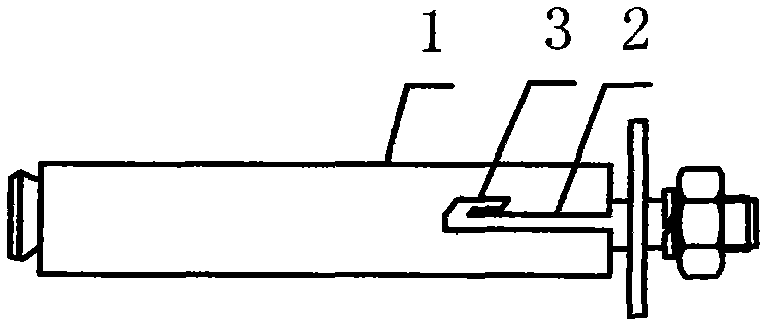

[0016] Such as figure 1 As shown, at least one strip-shaped notch 2 is provided at the front end of the expansion tube 1 , and at least one bayonet groove 3 communicating with the strip-shaped notch 2 is provided on both sides of the strip-shaped notch 2 . The bayonet groove 3 that communicates with the strip gap 2 can be turned back to the front end of the expansion tube 1, and the tail end of the folded bayonet groove 3 is not allowed to communicate with the strip gap 2 or the front end of the expansion tube 1.

example 2

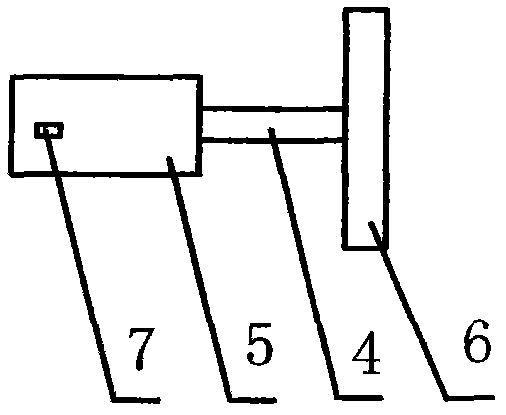

[0018] Such as figure 2 As shown, the expansion bolt wrench is composed of a wrench 5, a wrench 4 and a handle 6 in three parts. The wrench 5 is at the front end of the wrench 4, and the handle 6 is at the tail end of the wrench 4; the wrench 5 is composed of a hollow column and a bayonet key 7, the inner diameter of the hollow column is slightly larger than the diameter of the screw, and the outer diameter is slightly smaller than the expansion tube 1 Internal diameter, the depth from the inner wall of the bayonet key 7 to the bottom of the hollow column is greater than the length from the front end of the screw to the bottom of the bar-shaped gap 2, the bayonet key 7 is fixed on the outer wall of the hollow column, the number and position of the bayonet key 7 and The quantity and position of the bayonet groove 3 match; the bayonet key 7 is preferably located at the front end of the hollow column; the outer mouth of the front end of the hollow column shrinks slightly inward;...

example 3

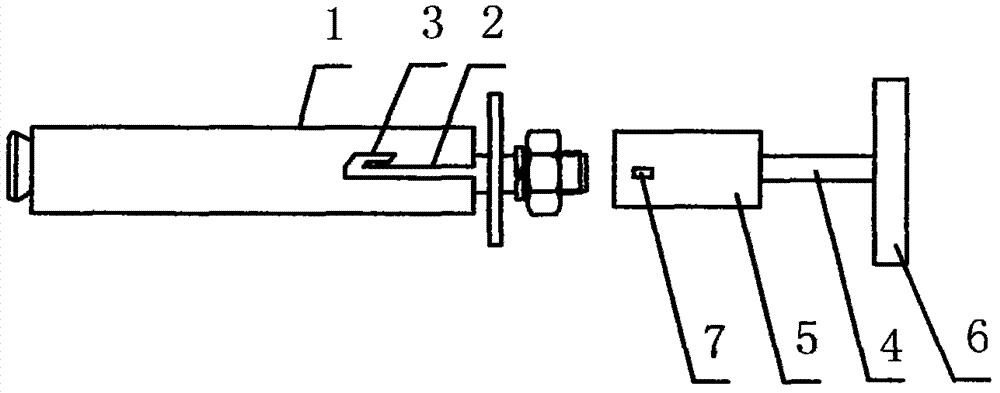

[0020] Such as image 3 As shown, first remove the nut and gasket of the expansion bolt, assemble the expansion bolt wrench, make the bayonet key 7 pass through the bar-shaped gap 2, insert the wrench 5 into the gap between the expansion tube 1 and the screw rod, and then pass the handle 6 Turn the trigger lever 4 to make the bayonet key 7 enter the bayonet groove 3, then hold the handle 6 and pull it outwards or pull it while turning, so that the expansion tube 1 can be taken out first, and finally the screw rod can be taken out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com