A conveyor belt lane change structure

A conveyor belt and drive belt technology, applied in the field of automation, can solve the problems of expensive, easy to damage, complex structure, etc., and achieve the effect of simple structure, low price, and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

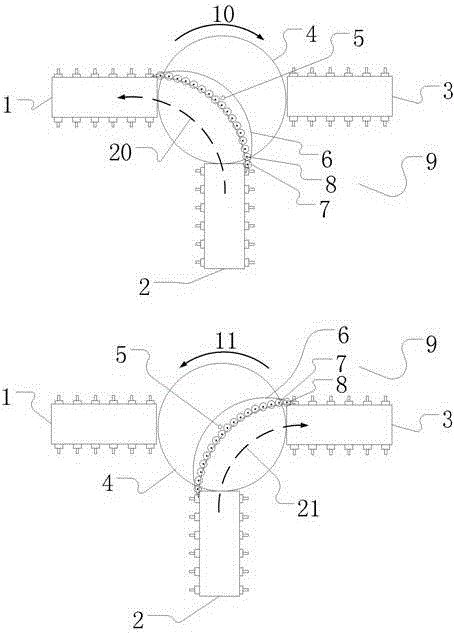

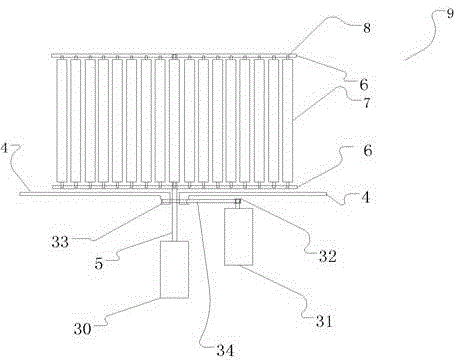

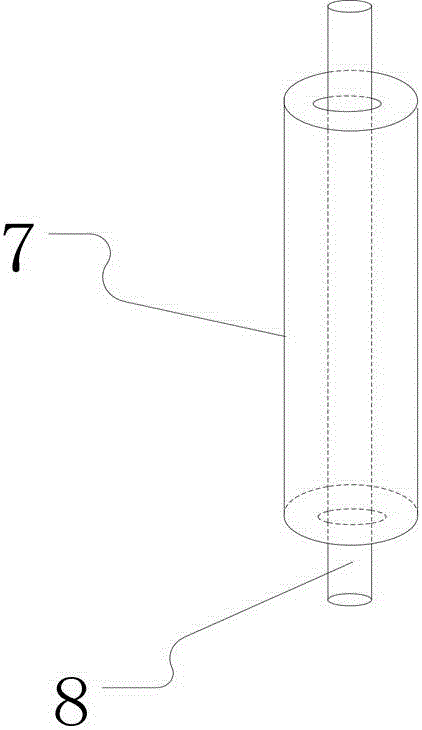

[0017] like Figure 1-3 is a schematic diagram of this embodiment,

[0018] like figure 1 As shown, the process of changing the lane from the transmission channel 20 to the transmission channel 21 is embodied.

[0019] like figure 1 As shown, the lane changing mechanism composed of the disc 4 and the arc baffle 9 is located in the middle of the output conveyor belt 1 , the input conveyor belt 2 and the output conveyor belt 3 .

[0020] like figure 1 As shown, the arc baffle 9 is located above the disc 4 , and the rotation axis 5 of the arc baffle 9 coincides with the central axis of the disc 4 .

[0021] like figure 1 As shown, when an object needs to be transferred from the input conveyor belt 2 to the output conveyor belt 3, the rotating shaft 5 of the arc baffle 9 is rotated so that the inside of the arc baffle 9 connects the input conveyor belt 2 and the outside of the output conveyor belt 3. , and limit the position of the arc baffle 9; at this time, the ...

Embodiment 2

[0029] Based on the implementation example 1, this implementation example is used as a package sorting application. A scanner is set in the middle of the input conveyor belt 2, which can scan the information of the package on the input conveyor belt, and then reroute according to the target area of the package to realize the package sorting. pick.

[0030] From the content of the invention, implementation example 1, appendix figure 1 It can be seen that the main disclosure objects of the present invention are those skilled in the art who have basic knowledge of mechanical principles. In order to highlight the core content of the present invention, that is, the lane changing principle of a conveyor belt lane changing structure of the present invention; this description does not provide some unnecessary foundations. Knowledge points are described, but those skilled in the art with basic knowledge of mechanical principles can figure 1 After understanding the lane-changing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com