Metal ring inputting and outputting device

A technology for taking out devices and metal rings, applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve problems such as low work efficiency, damage to metal rings, and inappropriateness, so as to improve work efficiency, improve work efficiency, shorten The effect of delivery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

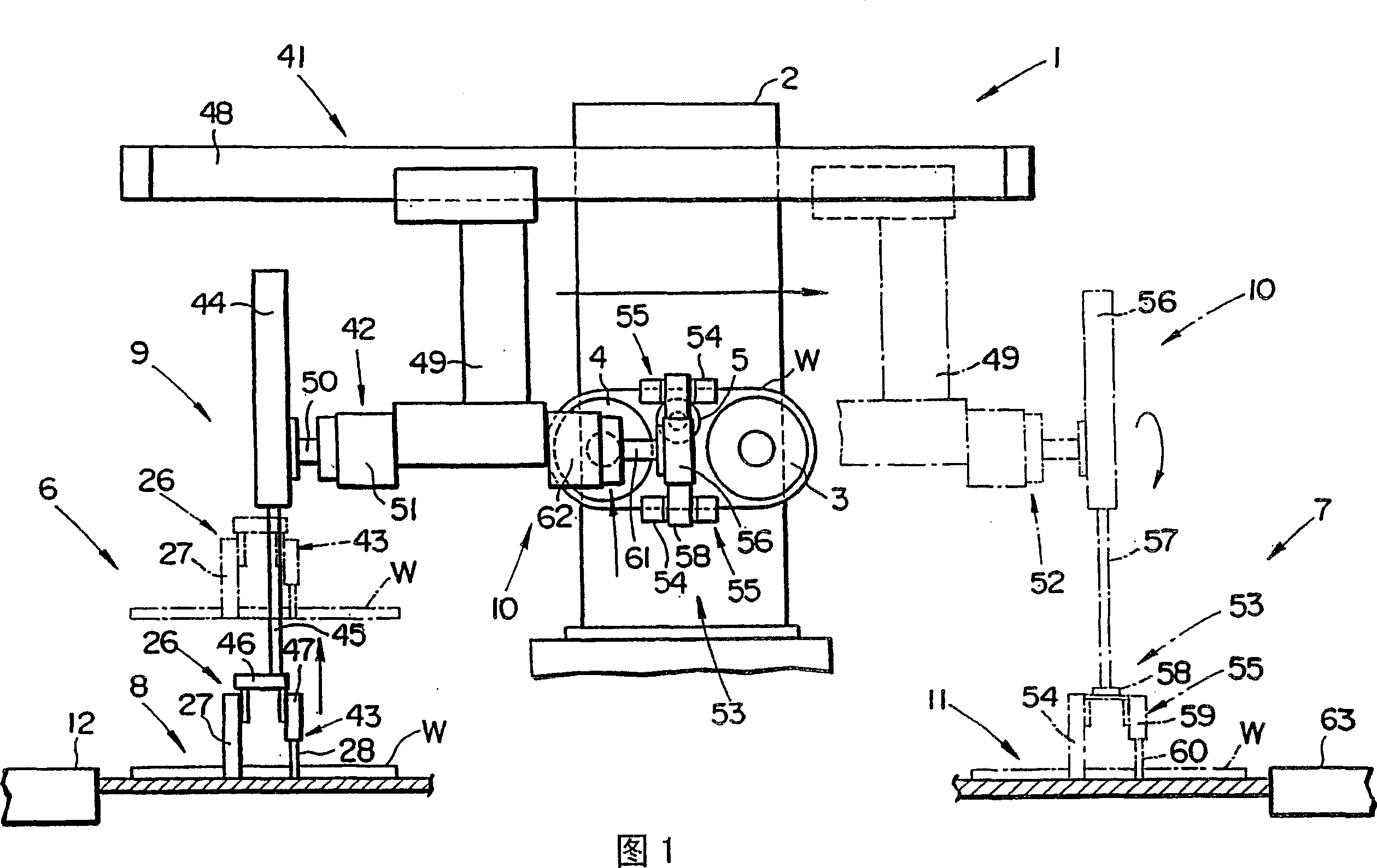

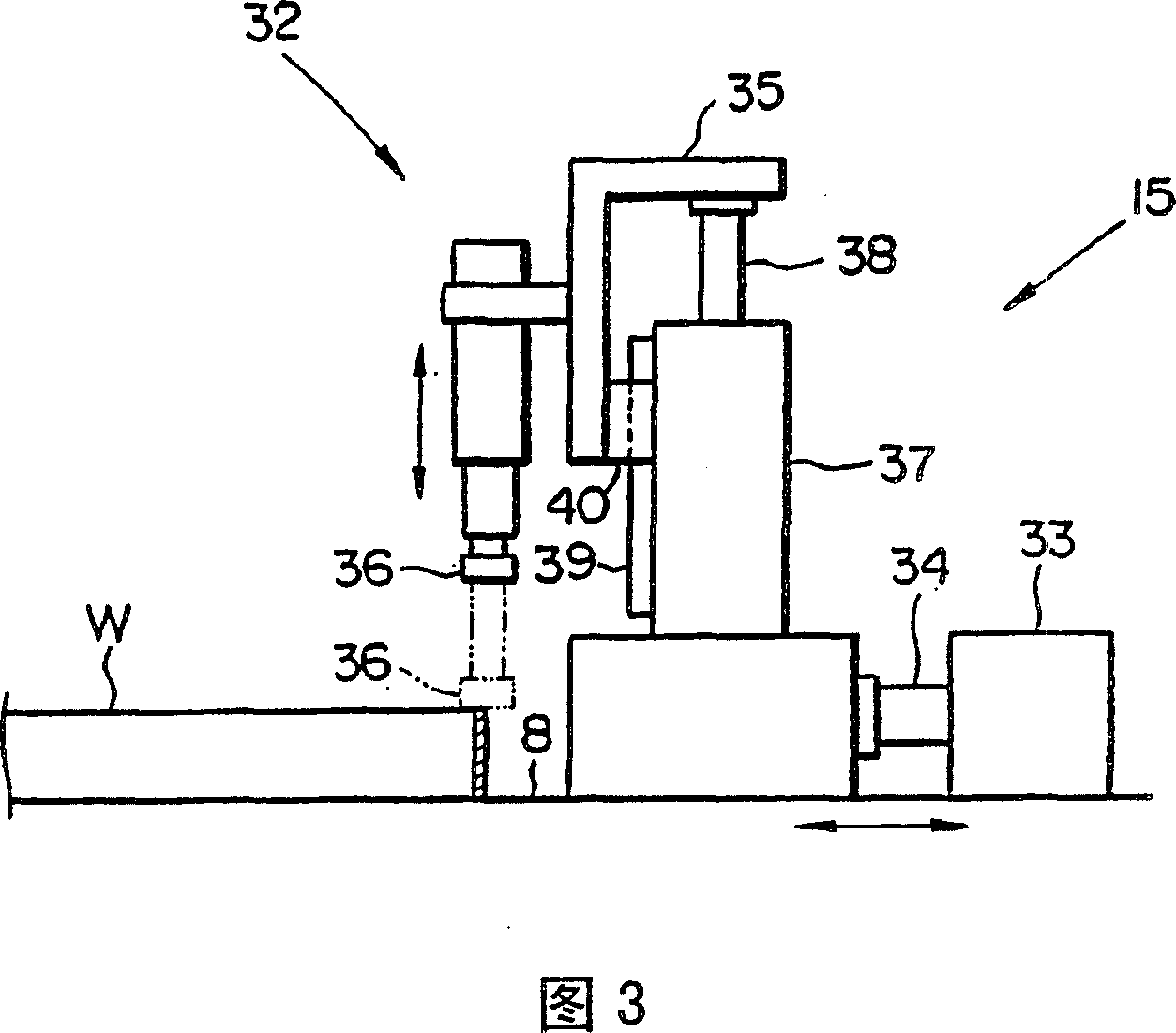

[0034] The loading and unloading device 1 of this embodiment, as shown in FIG. 1 , works while supporting the elastic endless belt-shaped metal ring W on the driving roller 3 and the driven roller 4 of the perimeter straightening machine 2. , the metal ring W supported on the driving roller 3 and the driven roller 4 is taken out. The perimeter straightening machine 2 has a straightening roller 5 that can be raised and lowered between the driving roller 3 and the driven roller 4, and the straightening roller 5 is raised by a lifting mechanism (not shown) to correct the circumference of the metal ring W. In addition, the driven roller 4 is moved in the horizontal direction by a roller moving mechanism (not shown) so as to be separated from the driving roller 3 when the circumference of the metal ring W is corrected, so that tension can be applied to the metal ring W.

[0035] Putting in and taking out device 1 is made of metal ring putting device 6 and metal ring taking out devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com