Achieving Consistent Ultrafiltration Output through Process Control

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafiltration Process Control Background and Objectives

Ultrafiltration (UF) technology has evolved significantly since its inception in the mid-20th century, transitioning from laboratory-scale applications to widespread industrial implementation. Initially developed for water purification, UF has expanded into diverse sectors including pharmaceuticals, food processing, and wastewater treatment. The evolution of membrane materials—from cellulose acetate to advanced polymeric and ceramic compositions—has dramatically enhanced separation efficiency and operational durability.

Recent technological advancements have focused on improving membrane fouling resistance, reducing energy consumption, and extending operational lifespan. Despite these improvements, achieving consistent ultrafiltration output remains a persistent challenge across industries, primarily due to membrane fouling, pressure fluctuations, and feed composition variability.

The primary objective of process control in ultrafiltration systems is to maintain consistent permeate quality and flux rates regardless of variations in feed characteristics or environmental conditions. This requires sophisticated monitoring and adjustment mechanisms that can respond in real-time to system changes. Secondary objectives include minimizing energy consumption, reducing chemical cleaning frequency, and extending membrane life—all while maintaining output consistency.

Current industry trends indicate a shift toward intelligent process control systems that incorporate machine learning algorithms to predict fouling events and optimize operational parameters proactively rather than reactively. These systems aim to balance the competing demands of throughput, quality, and operational efficiency.

The technological trajectory suggests increasing integration of sensor technologies for real-time monitoring of critical parameters such as transmembrane pressure, permeate turbidity, and specific contaminant concentrations. These advancements enable more precise control interventions and facilitate predictive maintenance strategies.

Regulatory frameworks worldwide are simultaneously evolving to require higher standards for process consistency, particularly in applications related to potable water and pharmaceutical manufacturing. This regulatory pressure serves as an additional driver for innovation in ultrafiltration process control methodologies.

The convergence of these technological developments and market demands creates an environment where achieving consistent ultrafiltration output through advanced process control represents not merely an operational improvement but a competitive necessity. Future research directions will likely focus on developing integrated control systems that combine traditional PID (Proportional-Integral-Derivative) control with artificial intelligence to create self-optimizing ultrafiltration processes capable of maintaining consistency across a wider range of operating conditions.

Recent technological advancements have focused on improving membrane fouling resistance, reducing energy consumption, and extending operational lifespan. Despite these improvements, achieving consistent ultrafiltration output remains a persistent challenge across industries, primarily due to membrane fouling, pressure fluctuations, and feed composition variability.

The primary objective of process control in ultrafiltration systems is to maintain consistent permeate quality and flux rates regardless of variations in feed characteristics or environmental conditions. This requires sophisticated monitoring and adjustment mechanisms that can respond in real-time to system changes. Secondary objectives include minimizing energy consumption, reducing chemical cleaning frequency, and extending membrane life—all while maintaining output consistency.

Current industry trends indicate a shift toward intelligent process control systems that incorporate machine learning algorithms to predict fouling events and optimize operational parameters proactively rather than reactively. These systems aim to balance the competing demands of throughput, quality, and operational efficiency.

The technological trajectory suggests increasing integration of sensor technologies for real-time monitoring of critical parameters such as transmembrane pressure, permeate turbidity, and specific contaminant concentrations. These advancements enable more precise control interventions and facilitate predictive maintenance strategies.

Regulatory frameworks worldwide are simultaneously evolving to require higher standards for process consistency, particularly in applications related to potable water and pharmaceutical manufacturing. This regulatory pressure serves as an additional driver for innovation in ultrafiltration process control methodologies.

The convergence of these technological developments and market demands creates an environment where achieving consistent ultrafiltration output through advanced process control represents not merely an operational improvement but a competitive necessity. Future research directions will likely focus on developing integrated control systems that combine traditional PID (Proportional-Integral-Derivative) control with artificial intelligence to create self-optimizing ultrafiltration processes capable of maintaining consistency across a wider range of operating conditions.

Market Demand Analysis for Consistent Ultrafiltration Systems

The global market for ultrafiltration systems has been experiencing robust growth, driven by increasing water scarcity concerns and stringent regulations regarding water quality across various industries. The demand for consistent ultrafiltration output is particularly pronounced in pharmaceutical manufacturing, food and beverage processing, biotechnology applications, and municipal water treatment facilities where precision and reliability are paramount.

Recent market research indicates that the industrial ultrafiltration market is projected to grow at a compound annual growth rate of 7.2% through 2028, with the segment focused on process control and consistency showing even stronger growth potential. This acceleration is primarily attributed to end-users' increasing recognition of the direct correlation between filtration consistency and operational efficiency, product quality, and regulatory compliance.

In the pharmaceutical sector, the implementation of Quality by Design (QbD) principles has significantly elevated the importance of consistent ultrafiltration processes. Manufacturers are increasingly seeking systems that can deliver predictable performance with minimal variability, as inconsistencies in filtration can lead to batch rejections, costly production delays, and potential compliance issues with regulatory bodies such as the FDA and EMA.

The food and beverage industry represents another substantial market segment, where consistent ultrafiltration is essential for maintaining product quality, extending shelf life, and ensuring consumer safety. Major players in this sector are willing to invest in advanced process control technologies that can guarantee uniform filtration performance across production cycles, reducing waste and optimizing resource utilization.

Municipal water treatment facilities are also driving demand for consistent ultrafiltration systems as they face increasing pressure to maintain water quality standards while managing operational costs. The ability to achieve consistent output regardless of fluctuations in source water quality has become a critical factor in technology selection decisions.

Geographically, North America and Europe currently lead the market for advanced ultrafiltration systems with sophisticated process controls, while the Asia-Pacific region is emerging as the fastest-growing market due to rapid industrialization, urbanization, and increasing regulatory focus on water quality and environmental protection.

Customer surveys reveal that end-users are willing to pay a premium of up to 25% for ultrafiltration systems that can demonstrate consistent performance metrics and reduced variability in output quality. This price sensitivity is lower in highly regulated industries where the cost of inconsistency far outweighs the initial investment in superior process control capabilities.

The market is also witnessing a shift toward service-based business models, with customers increasingly valuing predictive maintenance capabilities, remote monitoring, and performance guarantees that ensure consistent ultrafiltration output over the entire system lifecycle.

Recent market research indicates that the industrial ultrafiltration market is projected to grow at a compound annual growth rate of 7.2% through 2028, with the segment focused on process control and consistency showing even stronger growth potential. This acceleration is primarily attributed to end-users' increasing recognition of the direct correlation between filtration consistency and operational efficiency, product quality, and regulatory compliance.

In the pharmaceutical sector, the implementation of Quality by Design (QbD) principles has significantly elevated the importance of consistent ultrafiltration processes. Manufacturers are increasingly seeking systems that can deliver predictable performance with minimal variability, as inconsistencies in filtration can lead to batch rejections, costly production delays, and potential compliance issues with regulatory bodies such as the FDA and EMA.

The food and beverage industry represents another substantial market segment, where consistent ultrafiltration is essential for maintaining product quality, extending shelf life, and ensuring consumer safety. Major players in this sector are willing to invest in advanced process control technologies that can guarantee uniform filtration performance across production cycles, reducing waste and optimizing resource utilization.

Municipal water treatment facilities are also driving demand for consistent ultrafiltration systems as they face increasing pressure to maintain water quality standards while managing operational costs. The ability to achieve consistent output regardless of fluctuations in source water quality has become a critical factor in technology selection decisions.

Geographically, North America and Europe currently lead the market for advanced ultrafiltration systems with sophisticated process controls, while the Asia-Pacific region is emerging as the fastest-growing market due to rapid industrialization, urbanization, and increasing regulatory focus on water quality and environmental protection.

Customer surveys reveal that end-users are willing to pay a premium of up to 25% for ultrafiltration systems that can demonstrate consistent performance metrics and reduced variability in output quality. This price sensitivity is lower in highly regulated industries where the cost of inconsistency far outweighs the initial investment in superior process control capabilities.

The market is also witnessing a shift toward service-based business models, with customers increasingly valuing predictive maintenance capabilities, remote monitoring, and performance guarantees that ensure consistent ultrafiltration output over the entire system lifecycle.

Current Ultrafiltration Technology Challenges and Limitations

Ultrafiltration technology, while widely adopted across various industries, faces several significant challenges that impede consistent output performance. Membrane fouling remains the primary limitation, occurring when particles, colloids, and macromolecules accumulate on membrane surfaces or within pores. This phenomenon progressively reduces permeate flux, increases transmembrane pressure requirements, and ultimately compromises separation efficiency. The fouling mechanisms vary considerably depending on feed composition, operating conditions, and membrane properties, making universal prevention strategies elusive.

Concentration polarization presents another substantial challenge, manifesting when rejected solutes accumulate near the membrane surface, creating a concentration gradient that opposes the filtration driving force. This boundary layer phenomenon reduces effective transmembrane pressure and increases osmotic pressure, directly impacting process efficiency. Current control methods often involve increasing cross-flow velocity or implementing pulsatile flow, but these approaches increase energy consumption and system complexity.

Temperature and pH fluctuations in industrial settings significantly impact ultrafiltration performance. Even minor variations can alter solution viscosity, solute solubility, and membrane-solute interactions. Most existing process control systems struggle to compensate for these variations in real-time, resulting in inconsistent output quality and quantity. The challenge is particularly acute in applications requiring precise separation characteristics, such as pharmaceutical manufacturing and food processing.

Membrane material limitations further constrain ultrafiltration capabilities. Current polymeric membranes exhibit trade-offs between selectivity, permeability, and chemical/mechanical stability. While ceramic membranes offer superior durability, their higher cost and lower packing density limit widespread adoption. The development of membranes with consistent pore size distribution and resistance to chemical degradation remains an ongoing challenge.

Process control systems for ultrafiltration typically rely on simplified models that inadequately capture the complex, non-linear dynamics of membrane processes. Most industrial implementations utilize basic PID controllers with fixed setpoints, which cannot adapt to changing feed characteristics or membrane conditions. Advanced control strategies like model predictive control (MPC) or artificial intelligence-based approaches show promise but face implementation barriers including computational complexity and lack of robust sensing technologies.

Monitoring and sensing limitations further complicate process control efforts. Real-time measurement of critical parameters such as local flux distribution, membrane fouling state, and permeate quality remains challenging. Existing sensors often provide only indirect measurements with significant lag times, hampering timely control interventions. Non-invasive monitoring techniques like ultrasonic or optical methods show potential but require further development for industrial reliability.

Concentration polarization presents another substantial challenge, manifesting when rejected solutes accumulate near the membrane surface, creating a concentration gradient that opposes the filtration driving force. This boundary layer phenomenon reduces effective transmembrane pressure and increases osmotic pressure, directly impacting process efficiency. Current control methods often involve increasing cross-flow velocity or implementing pulsatile flow, but these approaches increase energy consumption and system complexity.

Temperature and pH fluctuations in industrial settings significantly impact ultrafiltration performance. Even minor variations can alter solution viscosity, solute solubility, and membrane-solute interactions. Most existing process control systems struggle to compensate for these variations in real-time, resulting in inconsistent output quality and quantity. The challenge is particularly acute in applications requiring precise separation characteristics, such as pharmaceutical manufacturing and food processing.

Membrane material limitations further constrain ultrafiltration capabilities. Current polymeric membranes exhibit trade-offs between selectivity, permeability, and chemical/mechanical stability. While ceramic membranes offer superior durability, their higher cost and lower packing density limit widespread adoption. The development of membranes with consistent pore size distribution and resistance to chemical degradation remains an ongoing challenge.

Process control systems for ultrafiltration typically rely on simplified models that inadequately capture the complex, non-linear dynamics of membrane processes. Most industrial implementations utilize basic PID controllers with fixed setpoints, which cannot adapt to changing feed characteristics or membrane conditions. Advanced control strategies like model predictive control (MPC) or artificial intelligence-based approaches show promise but face implementation barriers including computational complexity and lack of robust sensing technologies.

Monitoring and sensing limitations further complicate process control efforts. Real-time measurement of critical parameters such as local flux distribution, membrane fouling state, and permeate quality remains challenging. Existing sensors often provide only indirect measurements with significant lag times, hampering timely control interventions. Non-invasive monitoring techniques like ultrasonic or optical methods show potential but require further development for industrial reliability.

Current Process Control Solutions for Ultrafiltration Consistency

01 Membrane filtration systems for consistent ultrafiltration output

Advanced membrane filtration systems are designed to maintain consistent ultrafiltration output by optimizing membrane configuration and operational parameters. These systems incorporate specialized membrane materials and structures that enhance filtration efficiency while minimizing fouling. The designs often include automated pressure control mechanisms and flow distribution systems to ensure uniform filtration across the membrane surface, resulting in more reliable and consistent output quality.- Membrane filtration systems for consistent ultrafiltration output: Advanced membrane filtration systems are designed to maintain consistent ultrafiltration output by optimizing membrane configuration and operational parameters. These systems incorporate specialized membrane materials and structures that enhance filtration efficiency while minimizing fouling. The designs often include automated pressure control mechanisms and flow distribution systems to ensure uniform filtration across the membrane surface, resulting in more reliable and consistent output quality.

- Process control systems for ultrafiltration consistency: Sophisticated process control systems are implemented to monitor and adjust ultrafiltration parameters in real-time, ensuring consistent output quality. These systems utilize sensors and analyzers to continuously measure critical parameters such as pressure, flow rate, temperature, and permeate quality. Advanced algorithms process this data to make automatic adjustments to operating conditions, maintaining optimal filtration performance despite variations in feed composition or environmental conditions.

- Data analytics and machine learning for ultrafiltration optimization: Data analytics and machine learning techniques are applied to ultrafiltration processes to predict performance and optimize operations for consistent output. These approaches analyze historical operational data to identify patterns and correlations between process variables and filtration outcomes. Machine learning models can predict membrane fouling, recommend maintenance schedules, and suggest optimal operating parameters to maintain consistent filtration performance over time.

- Cleaning and maintenance protocols for consistent ultrafiltration: Specialized cleaning and maintenance protocols are developed to preserve membrane integrity and ensure consistent ultrafiltration output over extended operational periods. These protocols include chemical cleaning regimens, backwashing techniques, and physical maintenance procedures designed to remove foulants and restore membrane performance. Automated cleaning systems can be programmed to initiate cleaning cycles based on performance indicators, preventing significant declines in filtration consistency.

- Hybrid ultrafiltration systems for enhanced consistency: Hybrid ultrafiltration systems combine multiple filtration technologies or pretreatment methods to achieve more consistent output quality. These systems may integrate ultrafiltration with other separation techniques such as microfiltration, nanofiltration, or adsorption processes. By addressing different contaminants through complementary mechanisms, hybrid systems can maintain consistent permeate quality despite variations in feed water characteristics, extending membrane life and improving overall system reliability.

02 Process control systems for ultrafiltration consistency

Sophisticated process control systems are implemented to monitor and adjust ultrafiltration parameters in real-time, ensuring consistent output quality. These systems utilize sensors and analytical instruments to continuously measure key performance indicators such as pressure differential, flow rate, and permeate quality. Advanced algorithms process this data to make automatic adjustments to operating conditions, maintaining optimal filtration performance despite variations in feed composition or environmental conditions.Expand Specific Solutions03 Data management and analytics for ultrafiltration optimization

Data management and analytics platforms are employed to analyze historical and real-time ultrafiltration performance data, identifying patterns and optimizing operations for consistent output. These systems collect comprehensive operational data and apply machine learning algorithms to predict potential issues before they affect filtration consistency. By analyzing trends in membrane performance, feed characteristics, and output quality, these platforms enable proactive maintenance and process adjustments that maintain consistent ultrafiltration results.Expand Specific Solutions04 Cleaning and maintenance protocols for sustained ultrafiltration performance

Specialized cleaning and maintenance protocols are developed to prevent membrane fouling and degradation, ensuring long-term consistency in ultrafiltration output. These protocols include optimized chemical cleaning regimens, backwashing procedures, and physical maintenance techniques that effectively remove foulants without damaging membrane integrity. Implementing these protocols at strategic intervals based on operational data helps maintain consistent permeability and selectivity of the membranes over extended operational periods.Expand Specific Solutions05 Innovative ultrafiltration module designs for output consistency

Novel ultrafiltration module designs incorporate features specifically aimed at maintaining consistent output quality and quantity. These designs include improved flow distribution channels, enhanced membrane support structures, and innovative housing configurations that minimize dead zones and concentration polarization. Some modules feature self-cleaning mechanisms or integrated monitoring systems that detect and address inconsistencies in real-time, ensuring reliable filtration performance across varying operational conditions.Expand Specific Solutions

Key Industry Players in Ultrafiltration Technology

The ultrafiltration process control market is currently in a growth phase, with increasing demand for consistent output solutions across pharmaceutical, water treatment, and healthcare sectors. The global market size is estimated to exceed $2 billion, driven by stringent regulatory requirements and growing applications in biopharmaceuticals. Technologically, the field shows varying maturity levels, with companies like Fresenius Medical Care and Gambro Lundia leading in medical applications, while Kurita Water Industries and Organo Corp. dominate industrial water treatment solutions. Merck Patent GmbH and EMD Millipore offer advanced filtration technologies for pharmaceutical applications, while Sartorius Stedim Biotech is pioneering process automation integration. Emerging players like Aseptium and Nomura Micro Science are introducing innovative control mechanisms to address consistency challenges in ultrafiltration processes.

Gambro Lundia AB

Technical Solution: Gambro (now part of Baxter International) has developed the AK 98 hemodialysis system with advanced ultrafiltration control technology specifically designed for clinical applications. Their system utilizes volumetric balancing chambers with precision flow control to achieve consistent ultrafiltration rates during dialysis treatments. The technology incorporates a dual-pump architecture where one pump controls blood flow while a separate dedicated pump manages ultrafiltration, allowing for independent optimization of both parameters. Their UltraControl system continuously monitors transmembrane pressure and automatically adjusts pump speeds to maintain target ultrafiltration rates despite changes in patient hemodynamics or filter performance. The platform features an adaptive algorithm that learns from historical treatment data to optimize ultrafiltration profiles for individual patients, reducing intradialytic complications while achieving target fluid removal. Gambro's system also incorporates safety features that automatically detect and respond to pressure anomalies, preventing excessive ultrafiltration rates that could compromise patient safety.

Strengths: Exceptional reliability in clinical settings with documented uptime exceeding 99%; intuitive user interface requiring minimal training; comprehensive safety features protecting against operator error. Weaknesses: Limited flexibility for non-standard applications; higher unit cost compared to basic systems; proprietary consumables increase operational expenses.

Kurita Water Industries Ltd.

Technical Solution: Kurita Water Industries has developed an integrated ultrafiltration process control system for industrial water treatment applications that focuses on achieving consistent output quality while maximizing operational efficiency. Their technology employs a multi-stage monitoring approach with distributed sensor networks that track differential pressure, flow rates, and permeate quality parameters in real-time. The system utilizes adaptive backwash scheduling algorithms that analyze membrane performance trends to optimize cleaning cycles, preventing fouling while minimizing downtime and water consumption. Their proprietary S.sensing™ technology continuously monitors key water quality parameters and automatically adjusts chemical dosing and filtration parameters to maintain consistent output quality despite variations in feed water characteristics. The platform incorporates predictive maintenance capabilities that identify early signs of membrane degradation or system inefficiencies, allowing for planned interventions before performance deterioration affects output consistency. Kurita's system also features energy optimization algorithms that adjust pump speeds and pressure settings to maintain target filtration rates while minimizing power consumption.

Strengths: Exceptional energy efficiency with documented power savings of 15-30% compared to conventional systems; comprehensive chemical management capabilities; robust performance with highly variable feed water quality. Weaknesses: Higher implementation complexity in retrofitting existing plants; requires specialized technical support; significant initial investment compared to basic filtration systems.

Critical Technologies for Stable Ultrafiltration Output

Automated low volume crossflow filtration

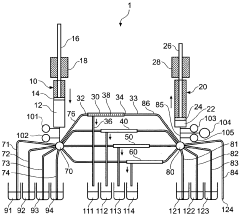

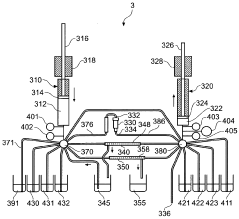

PatentWO2007110203A1

Innovation

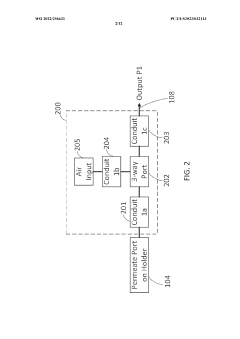

- An automated crossflow filtration method and system that uses a dual-pump system with moveable walls and flow-directing valves to control membrane flux and pressure, allowing for precise separation of components in 50 ml or less of a solution, with the option to reuse membranes and implement computer-controlled processes.

Particle filtration

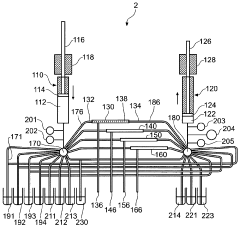

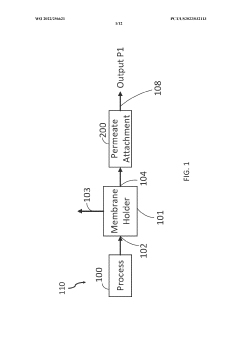

PatentWO2022256621A1

Innovation

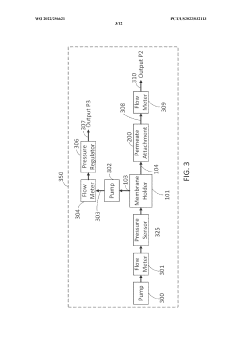

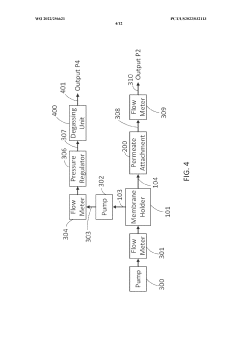

- A modified UF/DF/TFF filtration system with a membrane holder, permeate attachment, flow meters, pressure sensors, and pulsating flow control to manage pressure and flow rates, reducing membrane fouling and enabling continuous operation with controlled concentration and cleaning capabilities.

Regulatory Standards for Ultrafiltration Applications

Regulatory standards for ultrafiltration applications have evolved significantly over the past decades, reflecting the growing importance of this technology across various industries. The primary regulatory bodies governing ultrafiltration processes include the FDA in the United States, the European Medicines Agency (EMA) in Europe, and similar authorities in other regions. These organizations have established comprehensive frameworks that address both the equipment specifications and process parameters essential for consistent ultrafiltration output.

In the pharmaceutical and bioprocessing sectors, regulations such as FDA's 21 CFR Part 210/211 and EMA's GMP guidelines mandate strict validation protocols for ultrafiltration systems. These regulations emphasize the need for robust process control strategies to ensure reproducible performance. Key requirements include the implementation of continuous monitoring systems, validation of cleaning procedures, and establishment of acceptable operating ranges for critical parameters such as transmembrane pressure (TMP), cross-flow velocity, and temperature.

For water treatment applications, the EPA in the United States and the Drinking Water Directive in Europe have established specific standards for ultrafiltration membrane performance. These standards typically specify minimum log reduction values (LRV) for various contaminants, including bacteria, viruses, and particulates. Additionally, they mandate regular integrity testing of membrane systems to verify continued compliance with removal efficiency requirements.

The food and beverage industry faces regulations from bodies such as the FDA and EFSA, which focus on material compatibility and prevention of product contamination. These standards require that ultrafiltration membranes and associated equipment be constructed from food-grade materials and that process controls be implemented to prevent microbial growth and cross-contamination between production batches.

ISO standards, particularly ISO 9001 and industry-specific derivatives, provide frameworks for quality management systems that support consistent ultrafiltration performance. These standards emphasize the importance of documented procedures, regular calibration of monitoring instruments, and systematic approaches to process validation and verification.

Recent regulatory trends have moved toward risk-based approaches, requiring manufacturers to implement Quality by Design (QbD) principles in ultrafiltration processes. This approach necessitates thorough understanding of process parameters and their impact on filtration performance, enabling the establishment of a design space within which consistent output can be maintained despite minor variations in operating conditions.

Compliance with these regulatory standards requires comprehensive documentation systems, including batch records, equipment logs, and validation reports. Many regulations now also mandate electronic data integrity measures to ensure that process control data remains accurate, complete, and attributable throughout the product lifecycle.

In the pharmaceutical and bioprocessing sectors, regulations such as FDA's 21 CFR Part 210/211 and EMA's GMP guidelines mandate strict validation protocols for ultrafiltration systems. These regulations emphasize the need for robust process control strategies to ensure reproducible performance. Key requirements include the implementation of continuous monitoring systems, validation of cleaning procedures, and establishment of acceptable operating ranges for critical parameters such as transmembrane pressure (TMP), cross-flow velocity, and temperature.

For water treatment applications, the EPA in the United States and the Drinking Water Directive in Europe have established specific standards for ultrafiltration membrane performance. These standards typically specify minimum log reduction values (LRV) for various contaminants, including bacteria, viruses, and particulates. Additionally, they mandate regular integrity testing of membrane systems to verify continued compliance with removal efficiency requirements.

The food and beverage industry faces regulations from bodies such as the FDA and EFSA, which focus on material compatibility and prevention of product contamination. These standards require that ultrafiltration membranes and associated equipment be constructed from food-grade materials and that process controls be implemented to prevent microbial growth and cross-contamination between production batches.

ISO standards, particularly ISO 9001 and industry-specific derivatives, provide frameworks for quality management systems that support consistent ultrafiltration performance. These standards emphasize the importance of documented procedures, regular calibration of monitoring instruments, and systematic approaches to process validation and verification.

Recent regulatory trends have moved toward risk-based approaches, requiring manufacturers to implement Quality by Design (QbD) principles in ultrafiltration processes. This approach necessitates thorough understanding of process parameters and their impact on filtration performance, enabling the establishment of a design space within which consistent output can be maintained despite minor variations in operating conditions.

Compliance with these regulatory standards requires comprehensive documentation systems, including batch records, equipment logs, and validation reports. Many regulations now also mandate electronic data integrity measures to ensure that process control data remains accurate, complete, and attributable throughout the product lifecycle.

Environmental Impact and Sustainability Considerations

Ultrafiltration processes, while effective for separation and purification, carry significant environmental implications that must be addressed through sustainable process control strategies. The energy consumption associated with ultrafiltration operations represents a major environmental concern, particularly in maintaining consistent output. Traditional systems often require continuous high-pressure pumping, resulting in substantial electricity usage and corresponding carbon emissions. Process control innovations that optimize pressure cycles and implement energy recovery devices can reduce energy requirements by 30-45%, significantly decreasing the carbon footprint of ultrafiltration operations.

Water usage efficiency presents another critical environmental dimension. Conventional ultrafiltration systems typically require substantial volumes of water for membrane cleaning and maintenance procedures, which can account for up to 25% of total operational water consumption. Advanced process control algorithms that optimize cleaning cycles based on real-time membrane performance data rather than fixed schedules can reduce this water consumption by 15-20%, contributing to water conservation efforts particularly in water-stressed regions.

Chemical usage in ultrafiltration processes also poses environmental challenges. Cleaning agents, anti-fouling compounds, and pH adjusters can contribute to wastewater contamination if not properly managed. Intelligent process control systems that precisely dose chemicals based on actual membrane condition rather than standardized protocols can reduce chemical consumption by up to 35% while maintaining consistent output quality. This reduction directly translates to decreased chemical waste discharge and associated environmental impacts.

Membrane lifespan optimization through effective process control represents a significant sustainability opportunity. Premature membrane replacement due to inconsistent operation conditions generates substantial waste and embodied energy losses. Adaptive control systems that maintain optimal operating parameters can extend membrane life by 40-60%, reducing material consumption and waste generation. Some facilities implementing advanced process control have reported doubling their membrane replacement intervals while maintaining consistent ultrafiltration output.

The circular economy potential of ultrafiltration processes is increasingly recognized as an environmental benefit. Process control systems that enable the recovery and reuse of concentrate streams can transform what was previously considered waste into valuable resources. In food processing applications, for example, protein concentrates recovered through controlled ultrafiltration can be repurposed as nutritional supplements, creating economic value while reducing waste discharge by up to 70%.

Water usage efficiency presents another critical environmental dimension. Conventional ultrafiltration systems typically require substantial volumes of water for membrane cleaning and maintenance procedures, which can account for up to 25% of total operational water consumption. Advanced process control algorithms that optimize cleaning cycles based on real-time membrane performance data rather than fixed schedules can reduce this water consumption by 15-20%, contributing to water conservation efforts particularly in water-stressed regions.

Chemical usage in ultrafiltration processes also poses environmental challenges. Cleaning agents, anti-fouling compounds, and pH adjusters can contribute to wastewater contamination if not properly managed. Intelligent process control systems that precisely dose chemicals based on actual membrane condition rather than standardized protocols can reduce chemical consumption by up to 35% while maintaining consistent output quality. This reduction directly translates to decreased chemical waste discharge and associated environmental impacts.

Membrane lifespan optimization through effective process control represents a significant sustainability opportunity. Premature membrane replacement due to inconsistent operation conditions generates substantial waste and embodied energy losses. Adaptive control systems that maintain optimal operating parameters can extend membrane life by 40-60%, reducing material consumption and waste generation. Some facilities implementing advanced process control have reported doubling their membrane replacement intervals while maintaining consistent ultrafiltration output.

The circular economy potential of ultrafiltration processes is increasingly recognized as an environmental benefit. Process control systems that enable the recovery and reuse of concentrate streams can transform what was previously considered waste into valuable resources. In food processing applications, for example, protein concentrates recovered through controlled ultrafiltration can be repurposed as nutritional supplements, creating economic value while reducing waste discharge by up to 70%.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!