Addressing Technical Challenges in Direct Lithium Extraction

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) has emerged as a revolutionary approach to lithium production, representing a significant departure from traditional extraction methods that have dominated the industry for decades. The evolution of lithium extraction technology began with conventional mining of hard rock deposits and evaporative brine processing, which have been the mainstay of lithium production since the 1950s. However, these traditional methods face substantial limitations in efficiency, environmental impact, and production capacity.

The technological trajectory of DLE has accelerated significantly in the past decade, driven by the exponential growth in demand for lithium-ion batteries in electric vehicles and energy storage systems. This surge has created an urgent need for more sustainable and efficient extraction technologies that can meet the projected demand growth of 25-30% annually through 2030.

DLE technologies encompass a diverse range of approaches including adsorption, ion exchange, solvent extraction, and membrane processes, all aimed at selectively capturing lithium ions from brine solutions. The fundamental innovation of these methods lies in their ability to extract lithium directly from brines without the need for large evaporation ponds, significantly reducing water consumption and processing time.

The primary technical objectives of DLE development focus on addressing several critical challenges. First, improving selectivity to efficiently separate lithium from other ions present in brines, particularly sodium, magnesium, and calcium. Second, enhancing recovery rates to exceed the 30-50% typical of traditional evaporation methods. Third, developing materials and processes that maintain performance over numerous extraction cycles to ensure economic viability.

Another crucial objective is reducing the environmental footprint of lithium production. Traditional evaporation pond methods consume vast quantities of water—approximately 500,000 gallons per ton of lithium—and leave behind substantial waste. DLE aims to reduce water usage by up to 90% while minimizing chemical inputs and waste generation.

The technological evolution of DLE is also shaped by geographical considerations. Unlike conventional methods that are limited to specific climatic conditions, DLE technologies can potentially unlock previously inaccessible lithium resources in regions like the Salton Sea in California, Arkansas, and various European locations, potentially reshaping the global lithium supply chain.

The ultimate goal of DLE technology development is to establish a sustainable, scalable, and economically viable alternative to conventional lithium production methods, capable of meeting the growing global demand while minimizing environmental impact and resource consumption. This represents not just an incremental improvement but a paradigm shift in how critical battery materials are sourced and processed.

The technological trajectory of DLE has accelerated significantly in the past decade, driven by the exponential growth in demand for lithium-ion batteries in electric vehicles and energy storage systems. This surge has created an urgent need for more sustainable and efficient extraction technologies that can meet the projected demand growth of 25-30% annually through 2030.

DLE technologies encompass a diverse range of approaches including adsorption, ion exchange, solvent extraction, and membrane processes, all aimed at selectively capturing lithium ions from brine solutions. The fundamental innovation of these methods lies in their ability to extract lithium directly from brines without the need for large evaporation ponds, significantly reducing water consumption and processing time.

The primary technical objectives of DLE development focus on addressing several critical challenges. First, improving selectivity to efficiently separate lithium from other ions present in brines, particularly sodium, magnesium, and calcium. Second, enhancing recovery rates to exceed the 30-50% typical of traditional evaporation methods. Third, developing materials and processes that maintain performance over numerous extraction cycles to ensure economic viability.

Another crucial objective is reducing the environmental footprint of lithium production. Traditional evaporation pond methods consume vast quantities of water—approximately 500,000 gallons per ton of lithium—and leave behind substantial waste. DLE aims to reduce water usage by up to 90% while minimizing chemical inputs and waste generation.

The technological evolution of DLE is also shaped by geographical considerations. Unlike conventional methods that are limited to specific climatic conditions, DLE technologies can potentially unlock previously inaccessible lithium resources in regions like the Salton Sea in California, Arkansas, and various European locations, potentially reshaping the global lithium supply chain.

The ultimate goal of DLE technology development is to establish a sustainable, scalable, and economically viable alternative to conventional lithium production methods, capable of meeting the growing global demand while minimizing environmental impact and resource consumption. This represents not just an incremental improvement but a paradigm shift in how critical battery materials are sourced and processed.

Lithium Market Demand Analysis

The global lithium market has experienced unprecedented growth in recent years, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Market analysis indicates that lithium demand is projected to increase by 400-500% by 2030 compared to 2021 levels, with the EV sector accounting for approximately 75% of this demand. This exponential growth trajectory presents both opportunities and challenges for lithium extraction technologies, particularly Direct Lithium Extraction (DLE) methods.

The automotive industry's transition toward electrification represents the most significant driver of lithium demand. Major automotive manufacturers have committed to ambitious EV production targets, with several planning to phase out internal combustion engine vehicles entirely within the next 10-15 years. This shift is supported by increasingly stringent emissions regulations across major markets including Europe, China, and increasingly, North America.

Beyond EVs, stationary energy storage systems are emerging as another substantial demand center for lithium-based batteries. Grid-scale storage installations grew by over 160% in 2021, with projections indicating continued robust growth as renewable energy penetration increases globally. Consumer electronics, while representing a smaller share of overall demand, continues to provide a stable baseline consumption pattern.

From a geographical perspective, China currently dominates the lithium processing industry, handling over 60% of global lithium chemical production. However, concerns about supply chain security have prompted significant investments in developing alternative processing capabilities in North America, Europe, and Australia. This regionalization trend is likely to continue, creating new market opportunities for DLE technologies that can operate effectively in diverse geographical contexts.

Price volatility has been a defining characteristic of the lithium market, with prices surging by over 400% between January 2021 and March 2022 before experiencing significant corrections. This volatility underscores the market's current imbalance between supply and demand, creating strong economic incentives for developing more efficient extraction technologies.

The sustainability profile of lithium production is becoming increasingly important to end-users and investors. Traditional extraction methods face growing scrutiny regarding water usage, land disturbance, and carbon footprint. This shift in market preferences creates a premium opportunity for DLE technologies that can demonstrate superior environmental performance while maintaining economic viability.

The automotive industry's transition toward electrification represents the most significant driver of lithium demand. Major automotive manufacturers have committed to ambitious EV production targets, with several planning to phase out internal combustion engine vehicles entirely within the next 10-15 years. This shift is supported by increasingly stringent emissions regulations across major markets including Europe, China, and increasingly, North America.

Beyond EVs, stationary energy storage systems are emerging as another substantial demand center for lithium-based batteries. Grid-scale storage installations grew by over 160% in 2021, with projections indicating continued robust growth as renewable energy penetration increases globally. Consumer electronics, while representing a smaller share of overall demand, continues to provide a stable baseline consumption pattern.

From a geographical perspective, China currently dominates the lithium processing industry, handling over 60% of global lithium chemical production. However, concerns about supply chain security have prompted significant investments in developing alternative processing capabilities in North America, Europe, and Australia. This regionalization trend is likely to continue, creating new market opportunities for DLE technologies that can operate effectively in diverse geographical contexts.

Price volatility has been a defining characteristic of the lithium market, with prices surging by over 400% between January 2021 and March 2022 before experiencing significant corrections. This volatility underscores the market's current imbalance between supply and demand, creating strong economic incentives for developing more efficient extraction technologies.

The sustainability profile of lithium production is becoming increasingly important to end-users and investors. Traditional extraction methods face growing scrutiny regarding water usage, land disturbance, and carbon footprint. This shift in market preferences creates a premium opportunity for DLE technologies that can demonstrate superior environmental performance while maintaining economic viability.

Global DLE Technology Status and Barriers

Direct Lithium Extraction (DLE) technologies have gained significant momentum globally, yet their widespread implementation faces substantial barriers. Currently, DLE adoption remains in early commercial stages, with most projects operating at pilot or demonstration scale rather than full commercial deployment. North America and South America lead in DLE research and development, while China has recently accelerated its investments in this domain to secure lithium supply chains.

The primary technical barriers hindering DLE advancement include selectivity challenges, where extraction media struggle to selectively capture lithium ions while excluding competing ions like sodium, magnesium, and calcium. This selectivity issue significantly impacts process efficiency and economics, particularly when processing brines with complex chemical compositions.

Recovery efficiency represents another major obstacle, with many current DLE technologies achieving only 30-70% lithium recovery rates, compared to the 80%+ target needed for commercial viability. This efficiency gap directly affects production costs and resource utilization effectiveness.

Durability of extraction materials poses a persistent challenge, as most sorbents and membranes experience performance degradation after multiple regeneration cycles. Field tests reveal that many materials lose 20-40% of their capacity within 100-200 cycles, necessitating frequent and costly replacements.

Water consumption remains problematic for many DLE approaches, particularly in adsorption-based systems requiring substantial freshwater for regeneration cycles. This creates a significant sustainability paradox in water-scarce regions where many lithium resources are located.

Energy requirements constitute another barrier, with most DLE processes demanding 5-15 kWh per kilogram of lithium carbonate equivalent (LCE) produced. This energy intensity affects both operational costs and environmental footprint, particularly when renewable energy sources are unavailable.

Scaling challenges persist as laboratory successes often fail to translate to field conditions. Brine chemistry variability across different deposits requires customized process adjustments, preventing standardized technology deployment across multiple sites.

Waste management represents an emerging concern, as concentrated reject streams containing various salts and potentially harmful elements require proper disposal or valorization strategies to prevent environmental contamination.

Addressing these barriers requires coordinated efforts across multiple disciplines, including materials science, chemical engineering, and process optimization. Recent technological breakthroughs in selective sorbent development and membrane technology show promise, but significant R&D investment is still needed to overcome these persistent challenges.

The primary technical barriers hindering DLE advancement include selectivity challenges, where extraction media struggle to selectively capture lithium ions while excluding competing ions like sodium, magnesium, and calcium. This selectivity issue significantly impacts process efficiency and economics, particularly when processing brines with complex chemical compositions.

Recovery efficiency represents another major obstacle, with many current DLE technologies achieving only 30-70% lithium recovery rates, compared to the 80%+ target needed for commercial viability. This efficiency gap directly affects production costs and resource utilization effectiveness.

Durability of extraction materials poses a persistent challenge, as most sorbents and membranes experience performance degradation after multiple regeneration cycles. Field tests reveal that many materials lose 20-40% of their capacity within 100-200 cycles, necessitating frequent and costly replacements.

Water consumption remains problematic for many DLE approaches, particularly in adsorption-based systems requiring substantial freshwater for regeneration cycles. This creates a significant sustainability paradox in water-scarce regions where many lithium resources are located.

Energy requirements constitute another barrier, with most DLE processes demanding 5-15 kWh per kilogram of lithium carbonate equivalent (LCE) produced. This energy intensity affects both operational costs and environmental footprint, particularly when renewable energy sources are unavailable.

Scaling challenges persist as laboratory successes often fail to translate to field conditions. Brine chemistry variability across different deposits requires customized process adjustments, preventing standardized technology deployment across multiple sites.

Waste management represents an emerging concern, as concentrated reject streams containing various salts and potentially harmful elements require proper disposal or valorization strategies to prevent environmental contamination.

Addressing these barriers requires coordinated efforts across multiple disciplines, including materials science, chemical engineering, and process optimization. Recent technological breakthroughs in selective sorbent development and membrane technology show promise, but significant R&D investment is still needed to overcome these persistent challenges.

Current DLE Technical Solutions

01 Selective ion exchange materials for lithium extraction

Direct Lithium Extraction (DLE) technologies often rely on selective ion exchange materials that can preferentially adsorb lithium ions from brine solutions. These materials include specialized sorbents, membranes, and inorganic ion exchangers designed to overcome challenges related to selectivity in the presence of competing ions like sodium, magnesium, and calcium. The development of materials with high lithium selectivity, capacity, and regeneration capabilities is crucial for efficient DLE processes.- Selective ion exchange materials for lithium extraction: Direct Lithium Extraction (DLE) technologies often rely on selective ion exchange materials that can preferentially adsorb lithium ions from brine solutions. These materials include specialized sorbents, membranes, and inorganic ion exchangers designed to overcome challenges related to lithium selectivity in the presence of competing ions like sodium, magnesium, and calcium. The development of highly selective materials with improved capacity, stability, and regeneration properties is crucial for enhancing the efficiency of DLE processes.

- Brine pre-treatment and impurity management: A significant technical challenge in DLE is the management of impurities in lithium-rich brines. Pre-treatment processes are required to remove contaminants that can interfere with lithium extraction or damage equipment. These processes may include precipitation, filtration, and chemical treatment to address issues such as scaling, fouling, and the presence of interfering ions. Effective impurity management is essential for maintaining the performance and longevity of DLE systems while ensuring the production of high-purity lithium compounds.

- Energy efficiency and process optimization: DLE technologies face challenges related to energy consumption, particularly in the regeneration of extraction media and concentration of lithium-rich solutions. Innovations focus on reducing the thermal and electrical energy requirements through process optimization, heat recovery systems, and alternative regeneration methods. Improving energy efficiency is critical for making DLE economically viable and environmentally sustainable, especially when operating in remote locations with limited infrastructure.

- Water management and environmental impact: Water usage and management represent significant challenges for DLE operations, particularly in water-scarce regions. Technologies must address water consumption, recycling, and disposal of process water containing various chemicals and concentrated salts. Minimizing the environmental footprint of DLE processes requires closed-loop water systems, efficient water recovery methods, and strategies to manage waste streams while complying with increasingly stringent environmental regulations.

- Scaling up and commercialization challenges: Transitioning DLE technologies from laboratory or pilot scale to commercial operations presents numerous technical challenges. These include maintaining extraction performance at larger scales, ensuring long-term operational stability, and adapting to variations in brine composition. The development of modular and flexible DLE systems that can be deployed in different geological settings with minimal customization is crucial for widespread adoption. Additionally, integration with downstream processing to produce battery-grade lithium compounds adds complexity to the commercialization process.

02 Brine pre-treatment and impurity management

A significant technical challenge in DLE is the pre-treatment of lithium-rich brines to remove impurities that can interfere with extraction efficiency. These impurities include suspended solids, organic compounds, and competing ions that can foul extraction media or reduce process effectiveness. Innovative filtration systems, chemical precipitation methods, and multi-stage treatment approaches are being developed to address these challenges and ensure consistent lithium recovery rates across varying brine compositions.Expand Specific Solutions03 Energy efficiency and process optimization

DLE processes face challenges related to energy consumption, particularly in the regeneration of extraction media and concentration of lithium-rich solutions. Technical innovations focus on reducing the thermal and electrical energy requirements through process optimization, heat recovery systems, and alternative regeneration methods. Advancements in process control, automation, and integration with renewable energy sources are being pursued to improve the overall energy efficiency and sustainability of DLE operations.Expand Specific Solutions04 Water management and environmental impact

Water usage and management represent critical challenges for DLE technologies, especially in water-scarce regions where many lithium resources are located. Technical solutions focus on minimizing freshwater consumption, maximizing brine reinjection rates, and developing closed-loop water systems. Innovations in water recovery, treatment of process effluents, and reduction of chemical reagent usage aim to address environmental concerns and regulatory requirements associated with DLE operations.Expand Specific Solutions05 Scaling and commercialization challenges

The transition from laboratory-scale DLE processes to commercial operations presents significant technical challenges. These include scaling up equipment design, ensuring consistent performance across varying operating conditions, and maintaining extraction efficiency over extended operational periods. Innovations in modular system design, advanced materials for equipment construction to resist corrosion, and development of robust process control systems are being pursued to overcome these challenges and enable widespread commercial adoption of DLE technologies.Expand Specific Solutions

Key Industry Players in DLE Technology

The direct lithium extraction (DLE) market is currently in an early growth phase, characterized by rapid technological innovation and increasing commercial interest. The global market size for DLE technologies is projected to expand significantly as demand for lithium continues to surge in battery applications. Technologically, the field shows varying degrees of maturity, with companies like Lilac Solutions and Sunresin New Materials leading with ion-exchange technologies, while Pure Lithium Corp and Lyten are advancing electrochemical approaches. Schlumberger has leveraged its oil industry expertise to develop DLE solutions, while academic institutions like Central South University and The University of Manchester contribute fundamental research. BYD and American Battery Technology Company are integrating DLE into broader battery material supply chains, creating a competitive landscape that spans from specialized startups to established industrial players.

Lilac Solutions, Inc.

Technical Solution: Lilac Solutions has developed an ion-exchange technology platform specifically for lithium extraction from brine resources. Their proprietary ceramic ion-exchange beads selectively absorb lithium while rejecting contaminants. The process operates as a continuous system where lithium-rich brine passes through modules containing the beads, which capture lithium ions. The beads are then washed with an acid solution to release concentrated lithium chloride that can be further processed into battery-grade lithium products. This approach enables lithium recovery rates of 80-90% compared to traditional evaporation ponds' 40-50% recovery rates. Lilac's technology can process brines in hours rather than the 18+ months required for evaporation ponds, dramatically reducing the production timeline and environmental footprint. The company has successfully demonstrated their technology at pilot scale across multiple continents and varying brine chemistries.

Strengths: High selectivity for lithium over competing ions; rapid processing time (hours vs months); significantly higher recovery rates; minimal water consumption; smaller physical footprint; adaptable to various brine chemistries. Weaknesses: Requires specialized ion-exchange materials that need periodic replacement; higher upfront capital costs compared to traditional methods; energy requirements for regeneration of ion-exchange media.

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has developed an advanced membrane-based Direct Lithium Extraction (DLE) technology that utilizes specialized nanofiltration and separation processes. Their system employs proprietary membrane technology that selectively filters lithium ions from brine solutions while rejecting unwanted elements. The process operates under continuous flow conditions, where brine passes through multiple membrane stages that progressively concentrate lithium content. Koch's approach incorporates pre-treatment systems to remove scaling compounds and contaminants before the primary lithium separation. Their technology achieves concentration factors of up to 50x from initial brine concentrations, significantly reducing subsequent processing requirements. The system is modular and scalable, allowing for deployment across various brine resources with different chemical compositions. Koch has integrated energy recovery systems that reduce overall power consumption by up to 30% compared to conventional membrane processes, addressing one of the key challenges in DLE technology.

Strengths: Highly selective membrane technology; continuous operation capability; modular design allowing for scalability; reduced energy consumption through recovery systems; minimal chemical consumption. Weaknesses: Membrane fouling can occur with certain brine compositions requiring additional pre-treatment; higher initial capital investment; specialized expertise needed for operation and maintenance; performance varies with brine chemistry.

Critical DLE Patents and Innovations

Process and product

PatentPendingUS20250161879A1

Innovation

- The process involves contacting an aqueous lithium solution with a lithium sorbent to absorb lithium, followed by separation of the loaded sorbent and depleted solution, and subsequent treatment to regenerate the sorbent. This process utilizes pH control to maintain the lithium depleted solution at a pH of about 3 to 7 and employs ultrafiltration or nanofiltration membranes for separation.

process

PatentWO2025106417A1

Innovation

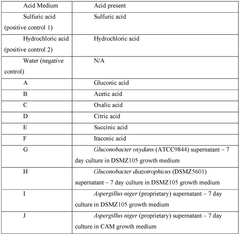

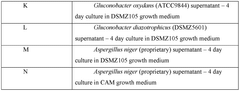

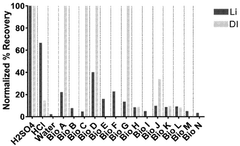

- The use of an acid medium comprising organic acids with a lowest pKa value of at least 4 or dicarboxylic acids with 3 or more carbon atoms and a lowest pKa value of at least 3.5 for desorbing lithium from adsorbents, which minimizes adsorbent damage and allows for environmentally friendly production of these acids through microorganisms.

Environmental Impact Assessment of DLE Methods

Direct Lithium Extraction (DLE) technologies, while promising for revolutionizing lithium production, carry significant environmental implications that require thorough assessment. The environmental footprint of DLE methods varies considerably depending on the specific technology employed, source material, and operational parameters.

Water usage represents one of the most critical environmental considerations for DLE operations. Unlike traditional evaporation ponds that consume massive quantities of water through evaporation, many DLE technologies advertise substantially reduced water requirements. However, field data indicates that certain DLE methods still demand significant water inputs for processing and regeneration cycles, particularly in arid regions where water resources are already stressed.

Energy consumption patterns across DLE technologies show notable variation, with implications for carbon emissions and sustainability goals. Ion-exchange and adsorption-based systems typically require less energy than membrane or solvent extraction approaches. The energy source powering DLE operations fundamentally determines their carbon footprint, with renewable-powered facilities demonstrating significantly lower lifecycle emissions compared to those dependent on fossil fuels.

Chemical usage in DLE processes presents another environmental concern requiring careful evaluation. Most DLE methods utilize acids, bases, or specialized solvents for lithium recovery and sorbent regeneration. These chemicals can pose risks if improperly managed, including potential for soil contamination, groundwater impacts, and ecosystem disruption if released into the environment. Advanced DLE systems incorporating closed-loop designs demonstrate promising reductions in chemical consumption and waste generation.

Land disturbance from DLE operations is generally less extensive than conventional mining or evaporation pond methods, representing a potential environmental advantage. The compact footprint of most DLE facilities allows for reduced habitat disruption and ecosystem impact compared to traditional extraction approaches that may require extensive land modification.

Waste management challenges persist across DLE technologies, with spent sorbents, membranes, and process residues requiring appropriate disposal or recycling pathways. The composition of these waste streams varies by technology, with some containing potentially hazardous components that necessitate specialized handling protocols to prevent environmental contamination.

Groundwater impacts remain a significant concern, particularly for DLE operations targeting subsurface brine resources. Potential risks include aquifer depletion, subsidence, and alteration of groundwater chemistry through reinjection practices. Comprehensive monitoring programs and adaptive management approaches are essential to identify and mitigate these potential impacts throughout the operational lifecycle of DLE facilities.

Water usage represents one of the most critical environmental considerations for DLE operations. Unlike traditional evaporation ponds that consume massive quantities of water through evaporation, many DLE technologies advertise substantially reduced water requirements. However, field data indicates that certain DLE methods still demand significant water inputs for processing and regeneration cycles, particularly in arid regions where water resources are already stressed.

Energy consumption patterns across DLE technologies show notable variation, with implications for carbon emissions and sustainability goals. Ion-exchange and adsorption-based systems typically require less energy than membrane or solvent extraction approaches. The energy source powering DLE operations fundamentally determines their carbon footprint, with renewable-powered facilities demonstrating significantly lower lifecycle emissions compared to those dependent on fossil fuels.

Chemical usage in DLE processes presents another environmental concern requiring careful evaluation. Most DLE methods utilize acids, bases, or specialized solvents for lithium recovery and sorbent regeneration. These chemicals can pose risks if improperly managed, including potential for soil contamination, groundwater impacts, and ecosystem disruption if released into the environment. Advanced DLE systems incorporating closed-loop designs demonstrate promising reductions in chemical consumption and waste generation.

Land disturbance from DLE operations is generally less extensive than conventional mining or evaporation pond methods, representing a potential environmental advantage. The compact footprint of most DLE facilities allows for reduced habitat disruption and ecosystem impact compared to traditional extraction approaches that may require extensive land modification.

Waste management challenges persist across DLE technologies, with spent sorbents, membranes, and process residues requiring appropriate disposal or recycling pathways. The composition of these waste streams varies by technology, with some containing potentially hazardous components that necessitate specialized handling protocols to prevent environmental contamination.

Groundwater impacts remain a significant concern, particularly for DLE operations targeting subsurface brine resources. Potential risks include aquifer depletion, subsidence, and alteration of groundwater chemistry through reinjection practices. Comprehensive monitoring programs and adaptive management approaches are essential to identify and mitigate these potential impacts throughout the operational lifecycle of DLE facilities.

Resource Efficiency and Sustainability Considerations

Direct Lithium Extraction (DLE) technologies present a paradigm shift in lithium production, offering significant improvements in resource efficiency compared to traditional evaporation ponds and hard rock mining. The environmental footprint of conventional lithium extraction methods is substantial, with evaporation ponds consuming 500,000-750,000 gallons of water per ton of lithium carbonate produced, while also occupying vast land areas and requiring 18-24 months for processing.

DLE technologies demonstrate remarkable water conservation capabilities, with advanced systems achieving up to 90% reduction in water consumption compared to evaporation methods. This efficiency is particularly critical in water-stressed regions where lithium brine resources are often located, such as the "Lithium Triangle" spanning Argentina, Bolivia, and Chile. The reduced land footprint of DLE operations—typically 90% smaller than evaporation ponds—further enhances their sustainability profile.

Energy consumption remains a significant consideration in DLE implementation. Current technologies require between 15-40 kWh per kilogram of lithium carbonate equivalent (LCE) produced, depending on the specific extraction method employed. Integration of renewable energy sources, particularly solar and geothermal, presents a promising pathway to reduce the carbon intensity of DLE operations, with pilot projects demonstrating up to 60% reduction in operational carbon emissions.

Chemical usage efficiency represents another critical sustainability dimension. Ion exchange and adsorption-based DLE methods have demonstrated up to 70% reduction in chemical reagent requirements compared to conventional processing. Recent innovations in sorbent materials have extended operational lifespans from 200-300 cycles to over 1,000 cycles before replacement is necessary, significantly reducing material consumption and waste generation.

Circular economy principles are increasingly being incorporated into DLE system designs. Brine reinjection practices maintain aquifer pressure and minimize hydrological disruption, while advanced recovery systems now achieve 85-95% recycling rates for process chemicals. Furthermore, integrated approaches that recover valuable co-products such as zinc, manganese, and potassium from brines are enhancing the overall resource efficiency of extraction operations.

Lifecycle assessment studies indicate that optimized DLE operations can reduce the overall environmental impact by 30-50% compared to conventional lithium production methods. However, these benefits are highly dependent on site-specific factors including brine chemistry, energy source availability, and water management infrastructure. The development of standardized sustainability metrics and reporting frameworks specific to DLE technologies remains an industry priority to enable meaningful comparisons and drive continuous improvement.

DLE technologies demonstrate remarkable water conservation capabilities, with advanced systems achieving up to 90% reduction in water consumption compared to evaporation methods. This efficiency is particularly critical in water-stressed regions where lithium brine resources are often located, such as the "Lithium Triangle" spanning Argentina, Bolivia, and Chile. The reduced land footprint of DLE operations—typically 90% smaller than evaporation ponds—further enhances their sustainability profile.

Energy consumption remains a significant consideration in DLE implementation. Current technologies require between 15-40 kWh per kilogram of lithium carbonate equivalent (LCE) produced, depending on the specific extraction method employed. Integration of renewable energy sources, particularly solar and geothermal, presents a promising pathway to reduce the carbon intensity of DLE operations, with pilot projects demonstrating up to 60% reduction in operational carbon emissions.

Chemical usage efficiency represents another critical sustainability dimension. Ion exchange and adsorption-based DLE methods have demonstrated up to 70% reduction in chemical reagent requirements compared to conventional processing. Recent innovations in sorbent materials have extended operational lifespans from 200-300 cycles to over 1,000 cycles before replacement is necessary, significantly reducing material consumption and waste generation.

Circular economy principles are increasingly being incorporated into DLE system designs. Brine reinjection practices maintain aquifer pressure and minimize hydrological disruption, while advanced recovery systems now achieve 85-95% recycling rates for process chemicals. Furthermore, integrated approaches that recover valuable co-products such as zinc, manganese, and potassium from brines are enhancing the overall resource efficiency of extraction operations.

Lifecycle assessment studies indicate that optimized DLE operations can reduce the overall environmental impact by 30-50% compared to conventional lithium production methods. However, these benefits are highly dependent on site-specific factors including brine chemistry, energy source availability, and water management infrastructure. The development of standardized sustainability metrics and reporting frameworks specific to DLE technologies remains an industry priority to enable meaningful comparisons and drive continuous improvement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!