Advanced FTIR Methods for Optimizing Polymer Composites

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FTIR Technology Evolution and Research Objectives

Fourier Transform Infrared Spectroscopy (FTIR) has evolved significantly since its inception in the mid-20th century, transforming from a basic analytical technique to a sophisticated tool for material characterization. The early development of FTIR technology in the 1950s and 1960s marked a significant advancement over dispersive infrared spectroscopy, offering improved signal-to-noise ratios and faster data acquisition. By the 1980s, FTIR had become a standard analytical method in polymer science, enabling researchers to identify chemical compositions and structural characteristics of various materials.

The evolution of FTIR technology accelerated in the 1990s with the integration of computerized systems and advanced data processing algorithms, which enhanced spectral resolution and analytical capabilities. The introduction of attenuated total reflectance (ATR) accessories in the early 2000s revolutionized sample preparation requirements, eliminating the need for complex preparation procedures and enabling direct analysis of solid and liquid samples. This development significantly expanded the application scope of FTIR in polymer composite research.

Recent technological advancements have further refined FTIR capabilities, including the development of micro-FTIR systems capable of analyzing microscopic samples and mapping chemical distributions across composite surfaces. Time-resolved FTIR techniques now allow for real-time monitoring of polymerization reactions and curing processes, providing invaluable insights into reaction kinetics and mechanisms. Additionally, the integration of FTIR with other analytical techniques, such as thermogravimetric analysis (TGA-FTIR) and gas chromatography (GC-FTIR), has created powerful hybrid systems for comprehensive material characterization.

The current research landscape focuses on leveraging advanced FTIR methodologies to optimize polymer composite properties for specific applications. Key objectives include developing more sensitive detection methods for identifying trace components and impurities that may affect composite performance, establishing standardized protocols for quantitative analysis of composite materials, and creating predictive models that correlate spectral data with mechanical and thermal properties of composites.

Looking forward, the field aims to advance FTIR techniques for in-situ monitoring of composite manufacturing processes, enabling real-time quality control and process optimization. There is also significant interest in developing portable FTIR systems for field applications and on-site quality assessment. The ultimate goal is to establish FTIR as not merely an analytical tool but as an integral component of intelligent manufacturing systems for polymer composites, capable of providing feedback for automated process adjustments and quality assurance.

These research objectives align with broader industry trends toward digitalization and smart manufacturing, positioning advanced FTIR methods as a critical enabling technology for the next generation of high-performance polymer composites with tailored properties and enhanced reliability.

The evolution of FTIR technology accelerated in the 1990s with the integration of computerized systems and advanced data processing algorithms, which enhanced spectral resolution and analytical capabilities. The introduction of attenuated total reflectance (ATR) accessories in the early 2000s revolutionized sample preparation requirements, eliminating the need for complex preparation procedures and enabling direct analysis of solid and liquid samples. This development significantly expanded the application scope of FTIR in polymer composite research.

Recent technological advancements have further refined FTIR capabilities, including the development of micro-FTIR systems capable of analyzing microscopic samples and mapping chemical distributions across composite surfaces. Time-resolved FTIR techniques now allow for real-time monitoring of polymerization reactions and curing processes, providing invaluable insights into reaction kinetics and mechanisms. Additionally, the integration of FTIR with other analytical techniques, such as thermogravimetric analysis (TGA-FTIR) and gas chromatography (GC-FTIR), has created powerful hybrid systems for comprehensive material characterization.

The current research landscape focuses on leveraging advanced FTIR methodologies to optimize polymer composite properties for specific applications. Key objectives include developing more sensitive detection methods for identifying trace components and impurities that may affect composite performance, establishing standardized protocols for quantitative analysis of composite materials, and creating predictive models that correlate spectral data with mechanical and thermal properties of composites.

Looking forward, the field aims to advance FTIR techniques for in-situ monitoring of composite manufacturing processes, enabling real-time quality control and process optimization. There is also significant interest in developing portable FTIR systems for field applications and on-site quality assessment. The ultimate goal is to establish FTIR as not merely an analytical tool but as an integral component of intelligent manufacturing systems for polymer composites, capable of providing feedback for automated process adjustments and quality assurance.

These research objectives align with broader industry trends toward digitalization and smart manufacturing, positioning advanced FTIR methods as a critical enabling technology for the next generation of high-performance polymer composites with tailored properties and enhanced reliability.

Market Analysis for FTIR in Polymer Composite Industry

The global market for FTIR technology in polymer composite analysis has experienced significant growth over the past decade, driven by increasing demand for high-performance materials across multiple industries. The current market size for FTIR instrumentation and services specifically targeting polymer composite applications is estimated at $1.2 billion, with a compound annual growth rate of 6.8% projected through 2028.

Automotive and aerospace sectors represent the largest market segments, collectively accounting for approximately 45% of FTIR applications in polymer composite analysis. These industries require precise material characterization to ensure structural integrity and performance under extreme conditions. The healthcare and electronics sectors follow closely, with growing adoption rates as polymer composites increasingly replace traditional materials in medical devices and electronic components.

Regionally, North America dominates the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region demonstrates the fastest growth trajectory, particularly in China and India, where rapid industrialization and increasing R&D investments are driving demand for advanced analytical technologies.

The market landscape reveals distinct customer segments with varying needs. Large manufacturing enterprises typically invest in comprehensive FTIR systems with advanced capabilities, while smaller organizations often utilize contract testing services or invest in more affordable, specialized instruments. Academic and research institutions constitute another significant market segment, focusing on cutting-edge applications and method development.

Key market drivers include increasingly stringent quality control requirements, growing complexity of polymer composite formulations, and the push toward sustainable materials. The trend toward miniaturization and automation in FTIR instrumentation is creating new market opportunities, particularly for in-line process monitoring applications that enable real-time quality control during manufacturing.

Market challenges include high initial investment costs for advanced FTIR systems, technical expertise requirements for data interpretation, and competition from alternative analytical techniques such as Raman spectroscopy and thermal analysis methods. However, the superior molecular-level insights provided by FTIR continue to secure its position as an essential analytical tool for polymer composite development and optimization.

The service segment of the market, including contract testing, method development, and consulting, is growing at a faster rate than hardware sales, indicating a shift toward knowledge-based offerings rather than purely instrumental solutions.

Automotive and aerospace sectors represent the largest market segments, collectively accounting for approximately 45% of FTIR applications in polymer composite analysis. These industries require precise material characterization to ensure structural integrity and performance under extreme conditions. The healthcare and electronics sectors follow closely, with growing adoption rates as polymer composites increasingly replace traditional materials in medical devices and electronic components.

Regionally, North America dominates the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region demonstrates the fastest growth trajectory, particularly in China and India, where rapid industrialization and increasing R&D investments are driving demand for advanced analytical technologies.

The market landscape reveals distinct customer segments with varying needs. Large manufacturing enterprises typically invest in comprehensive FTIR systems with advanced capabilities, while smaller organizations often utilize contract testing services or invest in more affordable, specialized instruments. Academic and research institutions constitute another significant market segment, focusing on cutting-edge applications and method development.

Key market drivers include increasingly stringent quality control requirements, growing complexity of polymer composite formulations, and the push toward sustainable materials. The trend toward miniaturization and automation in FTIR instrumentation is creating new market opportunities, particularly for in-line process monitoring applications that enable real-time quality control during manufacturing.

Market challenges include high initial investment costs for advanced FTIR systems, technical expertise requirements for data interpretation, and competition from alternative analytical techniques such as Raman spectroscopy and thermal analysis methods. However, the superior molecular-level insights provided by FTIR continue to secure its position as an essential analytical tool for polymer composite development and optimization.

The service segment of the market, including contract testing, method development, and consulting, is growing at a faster rate than hardware sales, indicating a shift toward knowledge-based offerings rather than purely instrumental solutions.

Current FTIR Limitations in Polymer Analysis

Despite its widespread use in polymer analysis, Fourier Transform Infrared Spectroscopy (FTIR) faces several significant limitations when applied to complex polymer composite systems. Traditional FTIR techniques often struggle with spatial resolution constraints, typically limited to 10-20 micrometers, which proves inadequate for analyzing nanoscale dispersion of fillers or interfacial regions in advanced composites. This resolution barrier prevents researchers from fully understanding critical polymer-filler interactions that determine composite performance.

Sample preparation represents another major challenge, as conventional transmission FTIR requires thin, uniform samples that are difficult to achieve with heterogeneous composites. Attenuated Total Reflection (ATR) techniques partially address this issue but remain limited to surface analysis, failing to capture the internal structure and composition gradients that are often crucial in composite materials.

Quantitative analysis presents persistent difficulties, particularly when dealing with overlapping spectral bands common in multi-component systems. Current algorithms for spectral deconvolution often produce ambiguous results when applied to complex polymer blends or composites with varying degrees of crystallinity and multiple additives. This ambiguity significantly hampers accurate determination of component ratios and chemical interactions.

Time-resolved measurements represent another limitation area, as standard FTIR instruments typically require several minutes for a complete scan, making them unsuitable for monitoring rapid curing processes, polymerization reactions, or degradation phenomena in real-time. This temporal constraint restricts understanding of kinetic processes critical to composite optimization.

Environmental sensitivity further complicates analysis, as moisture absorption from ambient air can interfere with spectral interpretation, particularly for hygroscopic polymers. Current environmental control systems for FTIR are often inadequate for maintaining consistent measurement conditions over extended periods.

Data interpretation challenges persist due to the complex nature of polymer composite spectra. Current spectral libraries and reference databases are predominantly focused on pure polymers rather than composite systems, creating significant gaps in automated identification capabilities. Machine learning approaches show promise but remain in early development stages for composite analysis applications.

Finally, in-situ and non-destructive testing capabilities are severely limited with conventional FTIR setups, preventing real-time monitoring during processing or in service conditions. This gap significantly hinders the development of process-structure-property relationships necessary for optimizing composite manufacturing and performance prediction.

Sample preparation represents another major challenge, as conventional transmission FTIR requires thin, uniform samples that are difficult to achieve with heterogeneous composites. Attenuated Total Reflection (ATR) techniques partially address this issue but remain limited to surface analysis, failing to capture the internal structure and composition gradients that are often crucial in composite materials.

Quantitative analysis presents persistent difficulties, particularly when dealing with overlapping spectral bands common in multi-component systems. Current algorithms for spectral deconvolution often produce ambiguous results when applied to complex polymer blends or composites with varying degrees of crystallinity and multiple additives. This ambiguity significantly hampers accurate determination of component ratios and chemical interactions.

Time-resolved measurements represent another limitation area, as standard FTIR instruments typically require several minutes for a complete scan, making them unsuitable for monitoring rapid curing processes, polymerization reactions, or degradation phenomena in real-time. This temporal constraint restricts understanding of kinetic processes critical to composite optimization.

Environmental sensitivity further complicates analysis, as moisture absorption from ambient air can interfere with spectral interpretation, particularly for hygroscopic polymers. Current environmental control systems for FTIR are often inadequate for maintaining consistent measurement conditions over extended periods.

Data interpretation challenges persist due to the complex nature of polymer composite spectra. Current spectral libraries and reference databases are predominantly focused on pure polymers rather than composite systems, creating significant gaps in automated identification capabilities. Machine learning approaches show promise but remain in early development stages for composite analysis applications.

Finally, in-situ and non-destructive testing capabilities are severely limited with conventional FTIR setups, preventing real-time monitoring during processing or in service conditions. This gap significantly hinders the development of process-structure-property relationships necessary for optimizing composite manufacturing and performance prediction.

Contemporary FTIR Methods for Polymer Characterization

01 Sample preparation techniques for FTIR analysis

Various sample preparation methods can be optimized for FTIR analysis to improve spectral quality and reproducibility. These techniques include proper grinding, mixing with KBr for pellet formation, thin film preparation, and specialized holders for different sample types. Optimization of sample thickness, homogeneity, and positioning can significantly enhance the quality of FTIR spectra and analytical results.- Sample preparation techniques for FTIR analysis: Various sample preparation methods can be optimized for FTIR analysis to improve spectral quality and reproducibility. These techniques include proper grinding, mixing with KBr for pellet formation, thin film preparation, and specialized holders for different sample types. Optimization of sample thickness, homogeneity, and surface characteristics significantly impacts the quality of FTIR spectra and subsequent data interpretation.

- Advanced FTIR instrumentation and hardware optimization: Optimization of FTIR hardware components such as detectors, beam splitters, and optical configurations can enhance sensitivity and resolution. This includes improvements in interferometer design, detector cooling systems, and beam path optimization to reduce noise and increase signal-to-noise ratio. Advanced instrumentation developments focus on miniaturization, automation, and integration with other analytical techniques for comprehensive material characterization.

- Data processing and spectral analysis algorithms: Computational methods for processing FTIR spectral data can be optimized to extract maximum information from measurements. These include baseline correction algorithms, spectral deconvolution techniques, multivariate analysis, and machine learning approaches for pattern recognition. Advanced software solutions enable automated peak identification, quantitative analysis, and handling of complex spectral matrices from heterogeneous samples.

- Real-time monitoring and in-situ FTIR applications: Optimization of FTIR methods for real-time process monitoring and in-situ measurements allows for dynamic analysis of chemical reactions and material transformations. This includes specialized sampling interfaces, flow cells, and reaction chambers integrated with FTIR systems. Techniques for rapid scanning, time-resolved spectroscopy, and data handling enable continuous monitoring of industrial processes and research applications.

- Calibration and validation protocols for FTIR methods: Standardized protocols for calibration and validation of FTIR methods ensure accuracy, precision, and reproducibility across different instruments and laboratories. This includes development of reference materials, internal standards, and quality control procedures. Optimization of calibration models, validation parameters, and statistical evaluation methods enhances the reliability of quantitative and qualitative FTIR analyses in research, industrial, and regulatory applications.

02 Advanced FTIR instrumentation and hardware optimization

Optimization of FTIR hardware components such as detectors, beam splitters, and optical configurations can significantly improve analytical performance. This includes adjustments to resolution settings, scan speed, aperture size, and signal-to-noise ratio. Modern FTIR systems incorporate automated calibration routines, self-diagnostic features, and modular components that can be optimized for specific applications.Expand Specific Solutions03 Data processing algorithms for FTIR spectral analysis

Advanced computational methods can be applied to optimize FTIR data processing, including baseline correction, smoothing algorithms, deconvolution techniques, and multivariate analysis. Machine learning approaches can enhance spectral interpretation and pattern recognition. Optimization of these algorithms improves the accuracy of quantitative and qualitative analysis while reducing interference from environmental factors and instrumental variations.Expand Specific Solutions04 Real-time monitoring and in-situ FTIR optimization

Methods for optimizing real-time and in-situ FTIR analysis in industrial processes and reaction monitoring. This includes specialized sampling interfaces, flow cells, and probe designs that allow for continuous measurement under varying conditions. Optimization techniques focus on minimizing sampling delays, ensuring representative sampling, and maintaining optical path stability under challenging environmental conditions.Expand Specific Solutions05 Calibration and validation protocols for FTIR methods

Systematic approaches to optimize calibration and validation procedures for FTIR methods, ensuring accuracy and reliability across different applications. This includes selection of appropriate reference standards, development of robust calibration models, and statistical methods to evaluate method performance. Optimization strategies address matrix effects, interference compensation, and transfer of calibration between instruments.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Advanced FTIR Methods for Polymer Composites market is currently in a growth phase, with increasing adoption across aerospace, automotive, and materials science sectors. The global market size is estimated at $2.5-3 billion, expanding at 7-9% CAGR as industries seek enhanced material characterization capabilities. Technologically, the field is moderately mature but rapidly evolving, with key players driving innovation at different maturity levels. DuPont de Nemours and SABIC Global Technologies lead with comprehensive commercial solutions, while academic institutions like Swiss Federal Institute of Technology and Sichuan University contribute cutting-edge research. W.L. Gore & Associates and Stratasys focus on specialized applications, while Boeing and NASA leverage these technologies for high-performance composite development, creating a competitive landscape balanced between established corporations and research institutions.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced FTIR methodologies specifically tailored for polymer composite optimization, employing both transmission and attenuated total reflection (ATR) techniques. Their approach integrates multivariate analysis with FTIR spectroscopy to characterize polymer blends and interfaces at molecular levels. DuPont's proprietary time-resolved FTIR spectroscopy allows real-time monitoring of curing processes and cross-linking reactions in composite manufacturing, enabling precise control over material properties. The company has pioneered the use of 2D correlation FTIR spectroscopy to analyze complex polymer interactions and phase separations in multi-component systems. Their methodology includes specialized sample preparation techniques that preserve the structural integrity of interfaces between polymer matrices and reinforcement materials, allowing for more accurate spectral analysis of these critical regions.

Strengths: Exceptional expertise in correlating FTIR data with mechanical properties, allowing for predictive modeling of composite performance. Their integrated approach combines multiple analytical techniques with FTIR for comprehensive characterization. Weaknesses: Their methods often require specialized equipment not widely available in standard laboratories, and the complexity of their analytical approaches necessitates significant expertise for proper implementation and interpretation.

SABIC Global Technologies BV

Technical Solution: SABIC has developed a comprehensive FTIR-based methodology for polymer composite optimization that focuses on interfacial analysis and degradation monitoring. Their approach utilizes micro-FTIR imaging combined with chemometric analysis to map chemical distributions across composite interfaces with spatial resolution down to 10 μm. SABIC's technique incorporates temperature-controlled FTIR cells that enable in-situ monitoring of thermal stability and degradation pathways in polymer composites under various environmental conditions. The company has pioneered the use of FTIR photoacoustic spectroscopy for non-destructive depth profiling of multilayer composite structures, allowing analysis of subsurface chemical compositions without sample preparation. Their methodology also includes specialized algorithms for spectral deconvolution that can identify and quantify overlapping absorption bands from multiple polymer components, enabling precise determination of blend compositions and detection of trace contaminants that might affect performance.

Strengths: Superior capability in analyzing complex multi-component systems and detecting subtle chemical changes at interfaces that affect mechanical properties. Their methods provide exceptional depth profiling capabilities without destructive sample preparation. Weaknesses: The sophisticated equipment and expertise required for implementation limits accessibility, and the approach may be overly complex for routine quality control applications in manufacturing environments.

Key Patents and Breakthroughs in FTIR Spectroscopy

FTIR data quality optimization

PatentWO2021207542A1

Innovation

- A method involving surface treatment such as abrasion to create varying particle sizes on the composite surface, combined with FTIR spectrometry techniques like diffuse reflection, attenuated total reflectance, and external reflection, to optimize data quality by enhancing infrared light absorption and reflection, and using calibration models to determine material type and resin-hardener mixture ratios.

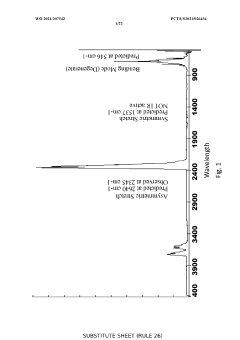

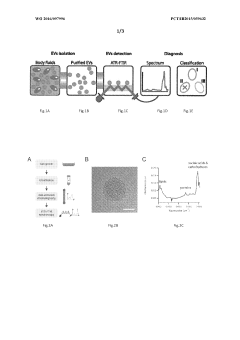

Use of fourier transform infrared spectroscopy analysis of extracellular vesicles isolated from body fluids for diagnosing, prognosing and monitoring pathophysiological states and method therfor

PatentWO2016097996A1

Innovation

- The use of Fourier Transform Infrared Spectroscopy (FTIR) to analyze extracellular vesicles (EVs) isolated from body fluids, combined with multivariate analysis, provides a non-invasive and label-free method for classifying EVs based on their molecular composition, enabling early diagnosis, prognosis, and monitoring of cancer and other proliferative diseases.

Standardization and Quality Control Protocols

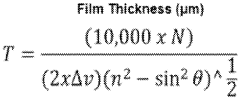

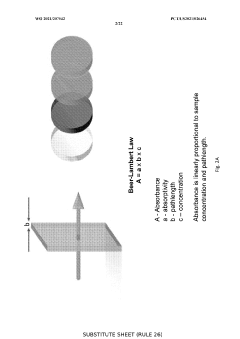

The standardization of FTIR methodologies for polymer composite analysis represents a critical foundation for ensuring reproducible and reliable results across different laboratories and research environments. Current industry practices have established several key protocols that address sample preparation, instrument calibration, and data interpretation. These protocols typically include specific guidelines for sample thickness control (generally between 0.5-2.0 mm), surface preparation requirements, and environmental condition specifications during measurement (temperature 23±2°C, relative humidity 50±5%).

Quality control in FTIR analysis of polymer composites necessitates regular verification using certified reference materials (CRMs) that match the composition of the materials being analyzed. The American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) have developed comprehensive standards such as ASTM E1252 and ISO 10326 specifically for FTIR analysis of polymers. These standards define acceptable ranges for spectral resolution (typically 4 cm⁻¹ for routine analysis), signal-to-noise ratios (minimum 1000:1 for quantitative work), and baseline stability parameters.

Advanced FTIR methods require more stringent quality control measures, particularly when used for optimization of polymer composites. Statistical process control (SPC) charts are increasingly being implemented to monitor instrument performance over time, with control limits typically set at ±3σ from established baseline measurements. Multivariate statistical approaches, including Principal Component Analysis (PCA) and Partial Least Squares (PLS), have become essential tools for validating spectral data quality and identifying outliers that may indicate measurement errors or sample inconsistencies.

Inter-laboratory comparison studies have revealed that standardization challenges persist, with variation coefficients ranging from 5-15% for identical samples analyzed across different facilities. To address this issue, several international initiatives are underway to develop more robust standardization frameworks. The Polymer Composite FTIR Consortium (PCFC) has recently proposed a unified protocol that incorporates machine learning algorithms for automated quality assessment of spectral data, with preliminary results showing a reduction in inter-laboratory variation to below 3%.

Documentation requirements constitute another critical aspect of standardization, with current best practices mandating detailed records of instrument parameters, sample preparation methods, environmental conditions, and data processing techniques. Digital laboratory information management systems (LIMS) are increasingly being integrated with FTIR instrumentation to ensure automatic capture of these parameters and maintain an unbroken chain of data integrity from sample preparation through final analysis and reporting.

Quality control in FTIR analysis of polymer composites necessitates regular verification using certified reference materials (CRMs) that match the composition of the materials being analyzed. The American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) have developed comprehensive standards such as ASTM E1252 and ISO 10326 specifically for FTIR analysis of polymers. These standards define acceptable ranges for spectral resolution (typically 4 cm⁻¹ for routine analysis), signal-to-noise ratios (minimum 1000:1 for quantitative work), and baseline stability parameters.

Advanced FTIR methods require more stringent quality control measures, particularly when used for optimization of polymer composites. Statistical process control (SPC) charts are increasingly being implemented to monitor instrument performance over time, with control limits typically set at ±3σ from established baseline measurements. Multivariate statistical approaches, including Principal Component Analysis (PCA) and Partial Least Squares (PLS), have become essential tools for validating spectral data quality and identifying outliers that may indicate measurement errors or sample inconsistencies.

Inter-laboratory comparison studies have revealed that standardization challenges persist, with variation coefficients ranging from 5-15% for identical samples analyzed across different facilities. To address this issue, several international initiatives are underway to develop more robust standardization frameworks. The Polymer Composite FTIR Consortium (PCFC) has recently proposed a unified protocol that incorporates machine learning algorithms for automated quality assessment of spectral data, with preliminary results showing a reduction in inter-laboratory variation to below 3%.

Documentation requirements constitute another critical aspect of standardization, with current best practices mandating detailed records of instrument parameters, sample preparation methods, environmental conditions, and data processing techniques. Digital laboratory information management systems (LIMS) are increasingly being integrated with FTIR instrumentation to ensure automatic capture of these parameters and maintain an unbroken chain of data integrity from sample preparation through final analysis and reporting.

Environmental Impact of Polymer Composite Manufacturing

The manufacturing of polymer composites presents significant environmental challenges that must be addressed as the industry continues to expand. Traditional polymer composite production processes are energy-intensive, with substantial carbon footprints stemming from raw material extraction, processing, and curing operations. The use of petroleum-based polymers further contributes to resource depletion and greenhouse gas emissions, creating a pressing need for more sustainable alternatives.

Advanced FTIR (Fourier Transform Infrared) spectroscopy methods offer promising capabilities for monitoring and optimizing these environmental impacts. By providing real-time molecular-level analysis during manufacturing, FTIR enables precise control of curing processes, potentially reducing energy consumption by 15-30% compared to conventional time-based curing schedules. This optimization directly translates to lower carbon emissions and resource utilization.

Volatile organic compound (VOC) emissions represent another critical environmental concern in composite manufacturing. FTIR techniques can accurately detect and quantify these emissions during processing, allowing manufacturers to implement targeted mitigation strategies. Recent studies demonstrate that FTIR-guided process modifications can reduce harmful VOC emissions by up to 40% without compromising material performance.

Waste generation during composite manufacturing contributes significantly to environmental degradation. Advanced FTIR methods support waste reduction through improved quality control, detecting defects earlier in the production process before additional resources are invested. This capability has been shown to decrease scrap rates by 20-25% in industrial applications, substantially reducing the environmental burden of waste disposal.

The recyclability and end-of-life management of polymer composites present ongoing challenges. FTIR spectroscopy aids in developing more recyclable composites by characterizing the molecular structure of novel biodegradable polymers and bio-based composites. These techniques help researchers understand degradation mechanisms and optimize material formulations for improved environmental compatibility.

Water consumption and contamination also represent significant environmental concerns in composite manufacturing. FTIR analysis can monitor water quality throughout the production process, identifying potential contaminants and enabling more efficient water management systems. This application is particularly valuable in closed-loop manufacturing systems where water recycling is implemented to reduce overall consumption.

As regulatory frameworks increasingly emphasize environmental performance, FTIR methods provide valuable tools for compliance verification and environmental impact assessment. The ability to precisely characterize emissions and material compositions supports manufacturers in meeting stringent environmental standards while maintaining competitive production capabilities.

Advanced FTIR (Fourier Transform Infrared) spectroscopy methods offer promising capabilities for monitoring and optimizing these environmental impacts. By providing real-time molecular-level analysis during manufacturing, FTIR enables precise control of curing processes, potentially reducing energy consumption by 15-30% compared to conventional time-based curing schedules. This optimization directly translates to lower carbon emissions and resource utilization.

Volatile organic compound (VOC) emissions represent another critical environmental concern in composite manufacturing. FTIR techniques can accurately detect and quantify these emissions during processing, allowing manufacturers to implement targeted mitigation strategies. Recent studies demonstrate that FTIR-guided process modifications can reduce harmful VOC emissions by up to 40% without compromising material performance.

Waste generation during composite manufacturing contributes significantly to environmental degradation. Advanced FTIR methods support waste reduction through improved quality control, detecting defects earlier in the production process before additional resources are invested. This capability has been shown to decrease scrap rates by 20-25% in industrial applications, substantially reducing the environmental burden of waste disposal.

The recyclability and end-of-life management of polymer composites present ongoing challenges. FTIR spectroscopy aids in developing more recyclable composites by characterizing the molecular structure of novel biodegradable polymers and bio-based composites. These techniques help researchers understand degradation mechanisms and optimize material formulations for improved environmental compatibility.

Water consumption and contamination also represent significant environmental concerns in composite manufacturing. FTIR analysis can monitor water quality throughout the production process, identifying potential contaminants and enabling more efficient water management systems. This application is particularly valuable in closed-loop manufacturing systems where water recycling is implemented to reduce overall consumption.

As regulatory frameworks increasingly emphasize environmental performance, FTIR methods provide valuable tools for compliance verification and environmental impact assessment. The ability to precisely characterize emissions and material compositions supports manufacturers in meeting stringent environmental standards while maintaining competitive production capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!