Advanced Manufacturing Methods for Shaped UHMWPE Articles

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Manufacturing Evolution and Objectives

Ultra-high molecular weight polyethylene (UHMWPE) has undergone significant evolution in manufacturing techniques since its inception. The journey began with conventional compression molding, which, while effective, had limitations in producing complex shapes and maintaining consistent material properties. As demand for UHMWPE in various industries grew, so did the need for more advanced manufacturing methods.

The development of ram extrusion marked a significant milestone, allowing for the production of larger and more uniform UHMWPE sheets and rods. This technique improved material consistency and reduced production time compared to compression molding. However, the challenge of creating intricate shapes remained, driving further innovation in the field.

The introduction of direct compression molding (DCM) represented a leap forward in UHMWPE manufacturing. DCM enabled the production of near-net-shape components, significantly reducing material waste and post-processing requirements. This method proved particularly valuable in the medical industry for producing orthopedic implants with enhanced wear resistance and longevity.

Recent years have seen the emergence of additive manufacturing techniques for UHMWPE. 3D printing technologies, such as selective laser sintering (SLS) and fused deposition modeling (FDM), have opened new possibilities for creating complex, customized UHMWPE parts. These methods offer unprecedented design freedom and the ability to produce patient-specific medical implants.

The primary objectives driving the evolution of UHMWPE manufacturing methods include enhancing material properties, improving production efficiency, and expanding the range of achievable shapes and sizes. Researchers and manufacturers are focusing on developing techniques that can maintain or improve the exceptional wear resistance, impact strength, and chemical inertness of UHMWPE while allowing for more intricate and precise shaping.

Another key goal is to reduce production costs and material waste, making UHMWPE more accessible for a wider range of applications. This includes optimizing existing processes and exploring novel manufacturing approaches that can scale efficiently while maintaining product quality.

As the demand for UHMWPE continues to grow in sectors such as healthcare, aerospace, and industrial applications, the focus on advanced manufacturing methods intensifies. The industry aims to develop processes that can produce UHMWPE articles with tailored properties, such as gradient structures or selective reinforcement, to meet specific application requirements.

The development of ram extrusion marked a significant milestone, allowing for the production of larger and more uniform UHMWPE sheets and rods. This technique improved material consistency and reduced production time compared to compression molding. However, the challenge of creating intricate shapes remained, driving further innovation in the field.

The introduction of direct compression molding (DCM) represented a leap forward in UHMWPE manufacturing. DCM enabled the production of near-net-shape components, significantly reducing material waste and post-processing requirements. This method proved particularly valuable in the medical industry for producing orthopedic implants with enhanced wear resistance and longevity.

Recent years have seen the emergence of additive manufacturing techniques for UHMWPE. 3D printing technologies, such as selective laser sintering (SLS) and fused deposition modeling (FDM), have opened new possibilities for creating complex, customized UHMWPE parts. These methods offer unprecedented design freedom and the ability to produce patient-specific medical implants.

The primary objectives driving the evolution of UHMWPE manufacturing methods include enhancing material properties, improving production efficiency, and expanding the range of achievable shapes and sizes. Researchers and manufacturers are focusing on developing techniques that can maintain or improve the exceptional wear resistance, impact strength, and chemical inertness of UHMWPE while allowing for more intricate and precise shaping.

Another key goal is to reduce production costs and material waste, making UHMWPE more accessible for a wider range of applications. This includes optimizing existing processes and exploring novel manufacturing approaches that can scale efficiently while maintaining product quality.

As the demand for UHMWPE continues to grow in sectors such as healthcare, aerospace, and industrial applications, the focus on advanced manufacturing methods intensifies. The industry aims to develop processes that can produce UHMWPE articles with tailored properties, such as gradient structures or selective reinforcement, to meet specific application requirements.

Market Demand for Shaped UHMWPE Products

The market demand for shaped Ultra-High Molecular Weight Polyethylene (UHMWPE) products has been steadily growing across various industries due to the material's exceptional properties. UHMWPE's combination of high impact strength, low friction coefficient, and excellent wear resistance makes it an ideal choice for numerous applications, driving the increasing demand for shaped articles.

In the medical sector, shaped UHMWPE products are extensively used in orthopedic implants, particularly for joint replacements such as hip and knee prostheses. The aging global population and rising incidence of osteoarthritis have significantly boosted the demand for these implants. The market for UHMWPE-based orthopedic implants is expected to continue its upward trajectory as healthcare systems worldwide focus on improving patient outcomes and reducing revision surgeries.

The industrial sector represents another significant market for shaped UHMWPE products. In material handling and conveyor systems, UHMWPE components such as gears, sprockets, and wear strips are highly sought after due to their self-lubricating properties and resistance to abrasion. The growth in e-commerce and automation in warehouses and distribution centers has further accelerated the demand for these components, as they contribute to increased efficiency and reduced maintenance costs.

In the automotive industry, shaped UHMWPE articles are gaining traction for applications such as bearings, bushings, and seals. The material's ability to withstand harsh environments and its low weight make it an attractive option for manufacturers looking to improve fuel efficiency and reduce vehicle emissions. As the automotive sector continues to evolve with the rise of electric and autonomous vehicles, the demand for high-performance, lightweight materials like UHMWPE is expected to grow.

The marine and offshore industries have also recognized the benefits of shaped UHMWPE products. Applications include dock fenders, buoys, and underwater cable protection. The material's resistance to saltwater, UV radiation, and impact makes it ideal for these challenging environments. With the expansion of offshore wind farms and the need for reliable marine infrastructure, the demand for UHMWPE products in this sector is projected to increase.

The sports and recreation market presents another avenue for growth in shaped UHMWPE products. From ski and snowboard bases to protective gear and high-performance textiles, UHMWPE's lightweight and durable nature makes it a preferred material for manufacturers. The growing interest in outdoor activities and extreme sports is likely to drive further demand in this segment.

As industries continue to seek materials that offer superior performance, longevity, and cost-effectiveness, the market for shaped UHMWPE products is poised for sustained growth. The development of advanced manufacturing methods for these articles will be crucial in meeting the increasing demand across diverse sectors and unlocking new applications for this versatile material.

In the medical sector, shaped UHMWPE products are extensively used in orthopedic implants, particularly for joint replacements such as hip and knee prostheses. The aging global population and rising incidence of osteoarthritis have significantly boosted the demand for these implants. The market for UHMWPE-based orthopedic implants is expected to continue its upward trajectory as healthcare systems worldwide focus on improving patient outcomes and reducing revision surgeries.

The industrial sector represents another significant market for shaped UHMWPE products. In material handling and conveyor systems, UHMWPE components such as gears, sprockets, and wear strips are highly sought after due to their self-lubricating properties and resistance to abrasion. The growth in e-commerce and automation in warehouses and distribution centers has further accelerated the demand for these components, as they contribute to increased efficiency and reduced maintenance costs.

In the automotive industry, shaped UHMWPE articles are gaining traction for applications such as bearings, bushings, and seals. The material's ability to withstand harsh environments and its low weight make it an attractive option for manufacturers looking to improve fuel efficiency and reduce vehicle emissions. As the automotive sector continues to evolve with the rise of electric and autonomous vehicles, the demand for high-performance, lightweight materials like UHMWPE is expected to grow.

The marine and offshore industries have also recognized the benefits of shaped UHMWPE products. Applications include dock fenders, buoys, and underwater cable protection. The material's resistance to saltwater, UV radiation, and impact makes it ideal for these challenging environments. With the expansion of offshore wind farms and the need for reliable marine infrastructure, the demand for UHMWPE products in this sector is projected to increase.

The sports and recreation market presents another avenue for growth in shaped UHMWPE products. From ski and snowboard bases to protective gear and high-performance textiles, UHMWPE's lightweight and durable nature makes it a preferred material for manufacturers. The growing interest in outdoor activities and extreme sports is likely to drive further demand in this segment.

As industries continue to seek materials that offer superior performance, longevity, and cost-effectiveness, the market for shaped UHMWPE products is poised for sustained growth. The development of advanced manufacturing methods for these articles will be crucial in meeting the increasing demand across diverse sectors and unlocking new applications for this versatile material.

Current Challenges in UHMWPE Shaping Techniques

Despite the numerous advantages of Ultra-High Molecular Weight Polyethylene (UHMWPE), its shaping techniques present significant challenges due to its unique molecular structure and properties. One of the primary obstacles is the material's high melt viscosity, which makes conventional melt processing methods ineffective. This characteristic stems from the extremely long polymer chains and their entanglements, resulting in a material that resists flow even at elevated temperatures.

The high molecular weight of UHMWPE also contributes to its poor processability. Traditional injection molding and extrusion techniques, which are widely used for other thermoplastics, are often inadequate for UHMWPE. The material's resistance to flow can lead to incomplete mold filling, inconsistent part quality, and excessive wear on processing equipment.

Another significant challenge lies in achieving uniform consolidation during the shaping process. The high viscosity and thermal conductivity of UHMWPE can result in non-uniform heating and cooling, leading to internal stresses, voids, and potential weak points in the final product. This issue is particularly pronounced in the production of large or complex-shaped articles.

The limited solubility of UHMWPE in common solvents poses additional difficulties in processing. Unlike other polymers that can be easily dissolved and cast into various shapes, UHMWPE requires specialized techniques for solution-based processing, which can be both time-consuming and costly.

Maintaining the material's exceptional properties during shaping is another critical challenge. The high-performance characteristics of UHMWPE, such as its wear resistance and impact strength, are closely tied to its molecular structure. Conventional shaping methods may inadvertently alter this structure, potentially compromising the material's desirable properties.

Furthermore, the production of thin-walled or intricate UHMWPE components presents unique difficulties. The material's high melt strength and tendency to retain its shape make it challenging to produce fine details or thin sections without specialized techniques.

Addressing these challenges requires innovative approaches to UHMWPE processing. Advanced manufacturing methods must be developed to overcome the material's inherent resistance to flow, ensure uniform consolidation, and preserve its unique properties throughout the shaping process. These may include novel compression molding techniques, ram extrusion methods, or the development of specialized additives to enhance processability without compromising performance.

The high molecular weight of UHMWPE also contributes to its poor processability. Traditional injection molding and extrusion techniques, which are widely used for other thermoplastics, are often inadequate for UHMWPE. The material's resistance to flow can lead to incomplete mold filling, inconsistent part quality, and excessive wear on processing equipment.

Another significant challenge lies in achieving uniform consolidation during the shaping process. The high viscosity and thermal conductivity of UHMWPE can result in non-uniform heating and cooling, leading to internal stresses, voids, and potential weak points in the final product. This issue is particularly pronounced in the production of large or complex-shaped articles.

The limited solubility of UHMWPE in common solvents poses additional difficulties in processing. Unlike other polymers that can be easily dissolved and cast into various shapes, UHMWPE requires specialized techniques for solution-based processing, which can be both time-consuming and costly.

Maintaining the material's exceptional properties during shaping is another critical challenge. The high-performance characteristics of UHMWPE, such as its wear resistance and impact strength, are closely tied to its molecular structure. Conventional shaping methods may inadvertently alter this structure, potentially compromising the material's desirable properties.

Furthermore, the production of thin-walled or intricate UHMWPE components presents unique difficulties. The material's high melt strength and tendency to retain its shape make it challenging to produce fine details or thin sections without specialized techniques.

Addressing these challenges requires innovative approaches to UHMWPE processing. Advanced manufacturing methods must be developed to overcome the material's inherent resistance to flow, ensure uniform consolidation, and preserve its unique properties throughout the shaping process. These may include novel compression molding techniques, ram extrusion methods, or the development of specialized additives to enhance processability without compromising performance.

State-of-the-Art UHMWPE Shaping Methods

01 Processing methods for UHMWPE shapes

Various processing methods are employed to create UHMWPE shapes, including compression molding, ram extrusion, and gel spinning. These techniques allow for the production of different forms such as sheets, rods, and fibers, each with specific properties suited for various applications.- Processing methods for UHMWPE shapes: Various processing methods are employed to create UHMWPE shapes, including compression molding, ram extrusion, and gel spinning. These techniques allow for the production of different forms such as sheets, rods, and fibers, each with specific properties suited for various applications.

- UHMWPE composites and blends: UHMWPE is often combined with other materials to create composites or blends with enhanced properties. These can include reinforcing fibers, nanoparticles, or other polymers to improve strength, wear resistance, or other specific characteristics for specialized applications.

- Surface modification of UHMWPE shapes: Surface treatments and modifications are applied to UHMWPE shapes to enhance their properties. These can include crosslinking, plasma treatment, or chemical grafting to improve wear resistance, biocompatibility, or adhesion to other materials.

- UHMWPE in medical applications: UHMWPE shapes are widely used in medical applications, particularly for orthopedic implants. Specific processing and treatment methods are employed to enhance biocompatibility, reduce wear, and improve longevity of medical devices made from UHMWPE.

- UHMWPE fiber and film production: Specialized techniques are used to produce UHMWPE fibers and films with high strength and unique properties. These include gel spinning for fibers and biaxial stretching for films, resulting in materials suitable for applications in ballistics, ropes, and high-performance textiles.

02 UHMWPE composites and blends

UHMWPE is often combined with other materials to create composites or blends with enhanced properties. These can include reinforcing fibers, nanoparticles, or other polymers to improve strength, wear resistance, or other specific characteristics for specialized applications.Expand Specific Solutions03 Surface modification of UHMWPE shapes

Surface treatments and modifications are applied to UHMWPE shapes to enhance their performance in specific applications. These can include plasma treatment, chemical grafting, or coating processes to improve properties such as adhesion, wear resistance, or biocompatibility.Expand Specific Solutions04 UHMWPE shape applications

UHMWPE shapes find applications in various industries due to their unique properties. These include use in medical implants, industrial machinery components, protective gear, and high-performance textiles. The specific shape and processing method are tailored to the intended application.Expand Specific Solutions05 Characterization and testing of UHMWPE shapes

Various methods are used to characterize and test UHMWPE shapes to ensure quality and performance. These include mechanical testing, thermal analysis, and microscopy techniques to evaluate properties such as tensile strength, impact resistance, and crystallinity.Expand Specific Solutions

Key Players in Advanced UHMWPE Manufacturing

The advanced manufacturing methods for shaped UHMWPE articles market is in a growth phase, driven by increasing demand in orthopedic implants and industrial applications. The market size is expanding, with a projected CAGR of 9.5% from 2021 to 2028. Technologically, the field is advancing rapidly, with companies like Howmedica Osteonics Corp. and DSM IP Assets BV leading innovations in processing techniques. Academic institutions such as Beijing University of Chemical Technology and Maastricht University are contributing to research and development. The competitive landscape is diverse, including established medical device manufacturers, chemical companies, and emerging specialized firms, indicating a maturing but still evolving market with significant potential for further technological advancements and market expansion.

Howmedica Osteonics Corp.

Technical Solution: Howmedica Osteonics Corp. has developed advanced manufacturing methods for shaped UHMWPE articles, particularly focusing on orthopedic implants. Their approach involves a multi-step process including compression molding, ram extrusion, and machining to create highly wear-resistant UHMWPE components[1]. The company has implemented crosslinking techniques using gamma or electron beam radiation to enhance the material's mechanical properties[2]. They have also developed a proprietary antioxidant-doped UHMWPE, which combines the wear resistance of crosslinked UHMWPE with improved oxidation resistance[3]. This method allows for the creation of complex shapes while maintaining the material's superior wear characteristics and longevity in joint replacement applications.

Strengths: Expertise in orthopedic applications, proprietary antioxidant technology, and established manufacturing processes. Weaknesses: Potentially limited to medical applications, high production costs for specialized components.

SABIC Global Technologies BV

Technical Solution: SABIC has pioneered advanced manufacturing methods for shaped UHMWPE articles using their UHMWPE resins. Their process involves a combination of compression molding and ram extrusion techniques, allowing for the production of large, complex shapes with consistent material properties[4]. SABIC has developed a unique thermal treatment process that enhances the crystallinity of UHMWPE, resulting in improved mechanical properties and wear resistance[5]. They have also implemented a novel cooling method during the manufacturing process, which helps to minimize internal stresses and enhance the overall performance of the shaped articles[6]. Additionally, SABIC has explored the use of nanocomposites to further improve the properties of UHMWPE, particularly for high-performance applications in industries such as aerospace and defense.

Strengths: Diverse industry applications, advanced thermal treatment processes, and expertise in large-scale production. Weaknesses: May face challenges in highly specialized medical applications compared to dedicated medical device manufacturers.

Breakthrough Patents in UHMWPE Forming

Process for manufacturing a shaped part of ultra high molecular weight polyethylene

PatentInactiveUS7799258B2

Innovation

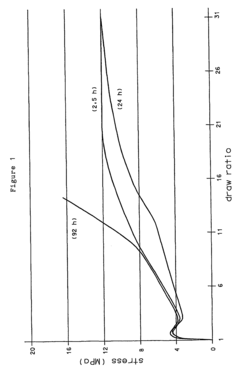

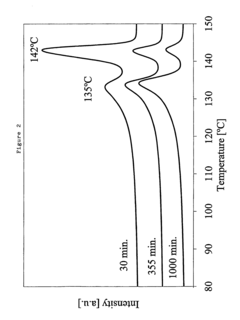

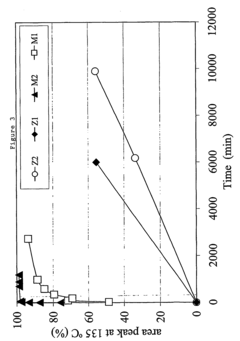

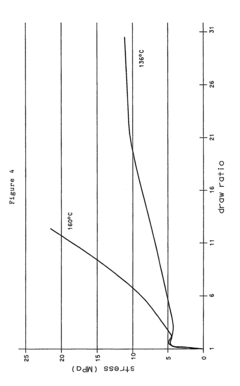

- Annealing UHMW-PE at 130-136°C for at least 1 hour, followed by processing into a shaped part above 142°C and cooling below 135°C, reduces entanglement density, allowing for good drawability below the melting point and minimizing residual solvent content.

Shaped part of an ultra high molecular weight polyethylene

PatentInactiveUS20100087929A1

Innovation

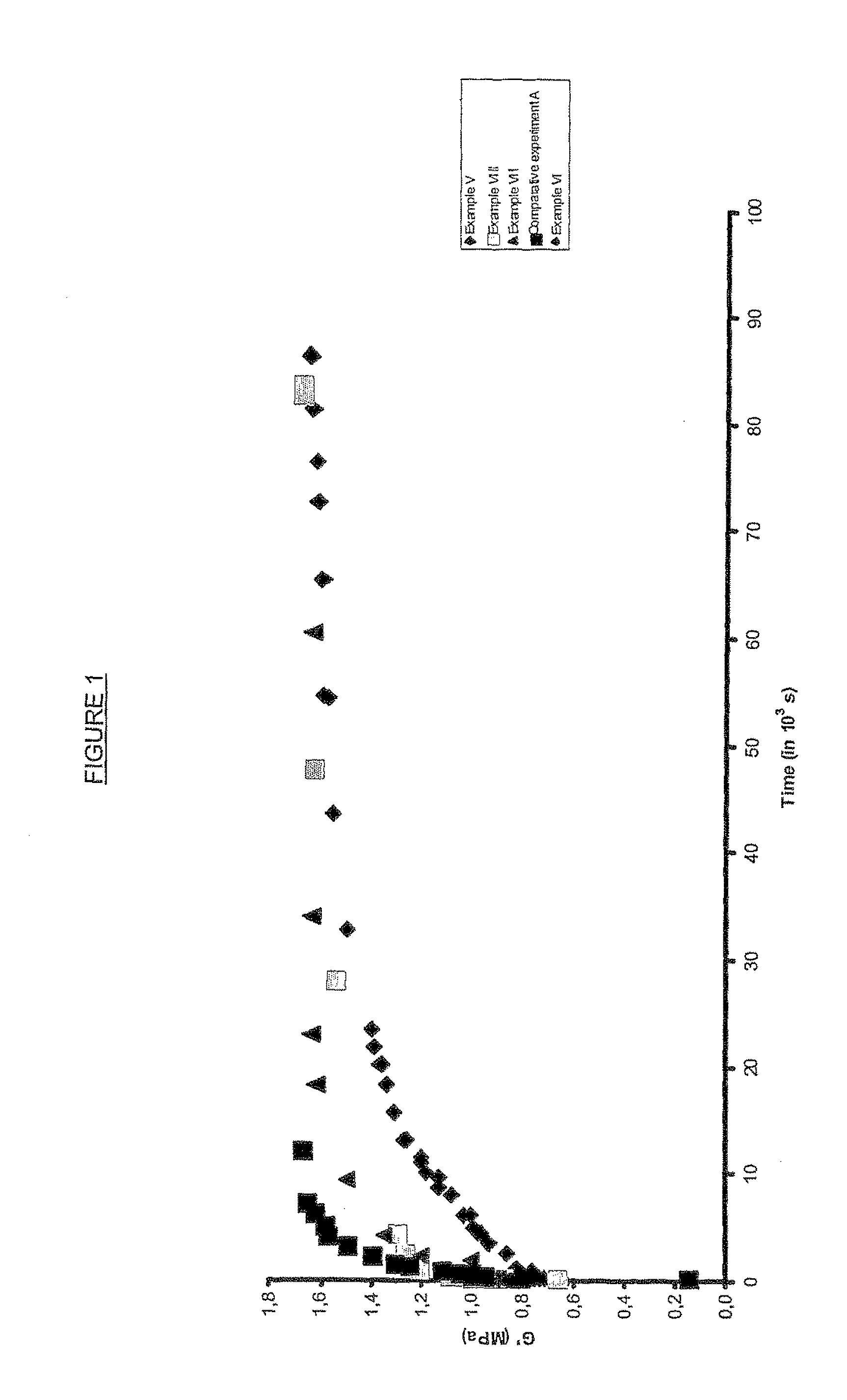

- A process involving UHMWPE with a weight average molecular weight of at least 1*10^6 g/mol, where the storage plateau modulus (G*) is kept at most 1.5 MPa during shaping, and then raised to a final value, allowing for processing as a partly entangled melt, without the need for additional annealing, by controlling heating rates and polymerization conditions.

Material Properties and Performance Metrics

Ultra-high molecular weight polyethylene (UHMWPE) is a high-performance thermoplastic polymer known for its exceptional mechanical properties and wear resistance. The material properties and performance metrics of UHMWPE are crucial factors in determining its suitability for various advanced manufacturing applications, particularly in the production of shaped articles.

UHMWPE exhibits a unique combination of properties that make it ideal for demanding applications. Its high molecular weight, typically ranging from 3.5 to 7.5 million g/mol, contributes to its outstanding wear resistance, impact strength, and chemical inertness. The material's low coefficient of friction, high abrasion resistance, and self-lubricating properties make it particularly suitable for applications involving moving parts and high-wear environments.

One of the key performance metrics for UHMWPE is its tensile strength, which can range from 20 to 40 MPa, depending on the specific grade and processing conditions. This strength, combined with its excellent elongation at break (typically 350-525%), provides UHMWPE with superior toughness and impact resistance. The material's ability to absorb energy and resist crack propagation makes it an excellent choice for applications requiring high durability and longevity.

The thermal properties of UHMWPE are also noteworthy. With a melting point of approximately 130-135°C and a glass transition temperature below -100°C, UHMWPE maintains its mechanical properties over a wide temperature range. This characteristic is particularly valuable in applications exposed to extreme temperature variations or cryogenic environments.

UHMWPE's chemical resistance is another critical performance metric. The material exhibits excellent resistance to most chemicals, including acids, bases, and organic solvents. This property, combined with its low moisture absorption (less than 0.01%), makes UHMWPE suitable for use in corrosive environments and applications requiring high purity.

In terms of electrical properties, UHMWPE is an excellent electrical insulator with a dielectric strength of about 45-50 kV/mm. This property, along with its low dielectric constant and dissipation factor, makes it suitable for various electrical and electronic applications.

The biocompatibility of UHMWPE is a crucial performance metric for medical applications. The material's inertness, low wear particle generation, and resistance to degradation in the human body have made it a preferred choice for orthopedic implants, particularly in joint replacement surgeries.

When considering advanced manufacturing methods for shaped UHMWPE articles, it is essential to account for the material's high melt viscosity and its tendency to retain its shape after processing. These characteristics can present challenges in traditional manufacturing processes but also open up opportunities for innovative shaping techniques that can leverage the material's unique properties to create complex geometries and tailored performance characteristics.

UHMWPE exhibits a unique combination of properties that make it ideal for demanding applications. Its high molecular weight, typically ranging from 3.5 to 7.5 million g/mol, contributes to its outstanding wear resistance, impact strength, and chemical inertness. The material's low coefficient of friction, high abrasion resistance, and self-lubricating properties make it particularly suitable for applications involving moving parts and high-wear environments.

One of the key performance metrics for UHMWPE is its tensile strength, which can range from 20 to 40 MPa, depending on the specific grade and processing conditions. This strength, combined with its excellent elongation at break (typically 350-525%), provides UHMWPE with superior toughness and impact resistance. The material's ability to absorb energy and resist crack propagation makes it an excellent choice for applications requiring high durability and longevity.

The thermal properties of UHMWPE are also noteworthy. With a melting point of approximately 130-135°C and a glass transition temperature below -100°C, UHMWPE maintains its mechanical properties over a wide temperature range. This characteristic is particularly valuable in applications exposed to extreme temperature variations or cryogenic environments.

UHMWPE's chemical resistance is another critical performance metric. The material exhibits excellent resistance to most chemicals, including acids, bases, and organic solvents. This property, combined with its low moisture absorption (less than 0.01%), makes UHMWPE suitable for use in corrosive environments and applications requiring high purity.

In terms of electrical properties, UHMWPE is an excellent electrical insulator with a dielectric strength of about 45-50 kV/mm. This property, along with its low dielectric constant and dissipation factor, makes it suitable for various electrical and electronic applications.

The biocompatibility of UHMWPE is a crucial performance metric for medical applications. The material's inertness, low wear particle generation, and resistance to degradation in the human body have made it a preferred choice for orthopedic implants, particularly in joint replacement surgeries.

When considering advanced manufacturing methods for shaped UHMWPE articles, it is essential to account for the material's high melt viscosity and its tendency to retain its shape after processing. These characteristics can present challenges in traditional manufacturing processes but also open up opportunities for innovative shaping techniques that can leverage the material's unique properties to create complex geometries and tailored performance characteristics.

Sustainability in UHMWPE Manufacturing

Sustainability in UHMWPE manufacturing has become increasingly important as industries strive to reduce their environmental impact while maintaining product quality and performance. The production of Ultra-High Molecular Weight Polyethylene (UHMWPE) articles traditionally involves energy-intensive processes and the use of non-renewable resources. However, recent advancements in manufacturing methods have opened up new possibilities for more sustainable practices.

One key area of focus is the reduction of energy consumption during the manufacturing process. Advanced manufacturing techniques, such as compression molding and ram extrusion, have been optimized to improve energy efficiency. These methods allow for better control of temperature and pressure, resulting in reduced energy requirements without compromising the material's properties. Additionally, the implementation of heat recovery systems and more efficient heating elements has further decreased the overall energy footprint of UHMWPE production.

Material waste reduction is another crucial aspect of sustainable UHMWPE manufacturing. Innovative approaches, such as near-net-shape molding and precision machining, have significantly minimized material waste during the production of shaped UHMWPE articles. These techniques enable manufacturers to create complex geometries with minimal excess material, reducing the need for post-processing and decreasing overall material consumption.

The use of recycled UHMWPE in manufacturing processes has gained traction as a sustainable practice. Advanced sorting and purification technologies have made it possible to incorporate a higher percentage of recycled content into new UHMWPE products without sacrificing performance. This circular approach not only reduces the demand for virgin materials but also helps address the issue of plastic waste in the environment.

Water conservation has also become a priority in sustainable UHMWPE manufacturing. Closed-loop cooling systems and advanced filtration technologies have been implemented to minimize water consumption and reduce wastewater discharge. These systems allow for the recirculation and reuse of process water, significantly reducing the overall water footprint of UHMWPE production facilities.

The development of bio-based alternatives to traditional UHMWPE is an emerging area of research in sustainable manufacturing. Scientists are exploring the use of renewable resources, such as plant-based polymers, to create materials with similar properties to UHMWPE. While these alternatives are still in the early stages of development, they show promise for reducing the reliance on fossil fuel-derived raw materials in the future.

As the demand for sustainable manufacturing practices continues to grow, the UHMWPE industry is actively investing in research and development to further improve the environmental performance of its production processes. This ongoing commitment to sustainability is driving innovation in advanced manufacturing methods, material science, and process optimization, paving the way for a more environmentally friendly future in UHMWPE production.

One key area of focus is the reduction of energy consumption during the manufacturing process. Advanced manufacturing techniques, such as compression molding and ram extrusion, have been optimized to improve energy efficiency. These methods allow for better control of temperature and pressure, resulting in reduced energy requirements without compromising the material's properties. Additionally, the implementation of heat recovery systems and more efficient heating elements has further decreased the overall energy footprint of UHMWPE production.

Material waste reduction is another crucial aspect of sustainable UHMWPE manufacturing. Innovative approaches, such as near-net-shape molding and precision machining, have significantly minimized material waste during the production of shaped UHMWPE articles. These techniques enable manufacturers to create complex geometries with minimal excess material, reducing the need for post-processing and decreasing overall material consumption.

The use of recycled UHMWPE in manufacturing processes has gained traction as a sustainable practice. Advanced sorting and purification technologies have made it possible to incorporate a higher percentage of recycled content into new UHMWPE products without sacrificing performance. This circular approach not only reduces the demand for virgin materials but also helps address the issue of plastic waste in the environment.

Water conservation has also become a priority in sustainable UHMWPE manufacturing. Closed-loop cooling systems and advanced filtration technologies have been implemented to minimize water consumption and reduce wastewater discharge. These systems allow for the recirculation and reuse of process water, significantly reducing the overall water footprint of UHMWPE production facilities.

The development of bio-based alternatives to traditional UHMWPE is an emerging area of research in sustainable manufacturing. Scientists are exploring the use of renewable resources, such as plant-based polymers, to create materials with similar properties to UHMWPE. While these alternatives are still in the early stages of development, they show promise for reducing the reliance on fossil fuel-derived raw materials in the future.

As the demand for sustainable manufacturing practices continues to grow, the UHMWPE industry is actively investing in research and development to further improve the environmental performance of its production processes. This ongoing commitment to sustainability is driving innovation in advanced manufacturing methods, material science, and process optimization, paving the way for a more environmentally friendly future in UHMWPE production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!