Advancements in Nitrogen Reduction Catalyst for Aerospace Use

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Nitrogen Reduction Catalyst Background and Objectives

Nitrogen reduction catalysts have evolved significantly over the past decades, transitioning from early experimental compounds to sophisticated materials engineered specifically for aerospace applications. The development trajectory has been shaped by increasing demands for fuel efficiency, environmental sustainability, and operational reliability in extreme conditions. Initially focused on terrestrial applications, nitrogen reduction catalyst research has gradually expanded to address the unique challenges posed by aerospace environments, including extreme temperatures, pressure variations, and weight constraints.

The evolution of these catalysts has been closely tied to advancements in materials science, nanotechnology, and computational chemistry. Early catalysts relied heavily on precious metals like platinum and palladium, which limited widespread adoption due to cost constraints. Recent innovations have explored transition metal nitrides, perovskite structures, and carbon-based nanomaterials as more cost-effective and efficient alternatives, marking a significant shift in the technological landscape.

Current research trends indicate a growing emphasis on multi-functional catalysts capable of performing efficiently across variable operating conditions typical in aerospace applications. These include rapid temperature fluctuations, exposure to cosmic radiation, and operation in low-oxygen environments. The integration of artificial intelligence and machine learning approaches has accelerated the discovery and optimization of novel catalyst formulations, enabling more precise prediction of performance characteristics and stability under aerospace conditions.

The primary technical objectives for aerospace nitrogen reduction catalysts include achieving higher conversion efficiencies at lower energy inputs, enhancing catalyst durability to withstand the harsh conditions of space travel, and reducing the overall weight and volume of catalyst systems to optimize payload capacity. Additionally, there is a growing focus on developing catalysts that can operate effectively in closed-loop life support systems for extended space missions, where nitrogen cycling becomes critical for sustainable habitation.

Environmental considerations have also become increasingly important, driving research toward catalysts that minimize harmful emissions and reduce the overall ecological footprint of aerospace operations. This aligns with global sustainability initiatives and regulatory frameworks that are becoming more stringent regarding emissions from aerospace activities.

Looking forward, the field aims to develop next-generation catalysts that can enable breakthrough technologies such as in-situ resource utilization on other planetary bodies, atmospheric harvesting systems for long-duration missions, and more efficient propulsion systems that could fundamentally transform space exploration capabilities. These objectives represent not just incremental improvements but potentially transformative advances in how we approach aerospace engineering and space travel.

The evolution of these catalysts has been closely tied to advancements in materials science, nanotechnology, and computational chemistry. Early catalysts relied heavily on precious metals like platinum and palladium, which limited widespread adoption due to cost constraints. Recent innovations have explored transition metal nitrides, perovskite structures, and carbon-based nanomaterials as more cost-effective and efficient alternatives, marking a significant shift in the technological landscape.

Current research trends indicate a growing emphasis on multi-functional catalysts capable of performing efficiently across variable operating conditions typical in aerospace applications. These include rapid temperature fluctuations, exposure to cosmic radiation, and operation in low-oxygen environments. The integration of artificial intelligence and machine learning approaches has accelerated the discovery and optimization of novel catalyst formulations, enabling more precise prediction of performance characteristics and stability under aerospace conditions.

The primary technical objectives for aerospace nitrogen reduction catalysts include achieving higher conversion efficiencies at lower energy inputs, enhancing catalyst durability to withstand the harsh conditions of space travel, and reducing the overall weight and volume of catalyst systems to optimize payload capacity. Additionally, there is a growing focus on developing catalysts that can operate effectively in closed-loop life support systems for extended space missions, where nitrogen cycling becomes critical for sustainable habitation.

Environmental considerations have also become increasingly important, driving research toward catalysts that minimize harmful emissions and reduce the overall ecological footprint of aerospace operations. This aligns with global sustainability initiatives and regulatory frameworks that are becoming more stringent regarding emissions from aerospace activities.

Looking forward, the field aims to develop next-generation catalysts that can enable breakthrough technologies such as in-situ resource utilization on other planetary bodies, atmospheric harvesting systems for long-duration missions, and more efficient propulsion systems that could fundamentally transform space exploration capabilities. These objectives represent not just incremental improvements but potentially transformative advances in how we approach aerospace engineering and space travel.

Market Demand Analysis for Aerospace Nitrogen Catalysts

The aerospace industry's demand for advanced nitrogen reduction catalysts has been growing steadily over the past decade, driven primarily by the need for more efficient propulsion systems and sustainable fuel alternatives. Market research indicates that the global aerospace nitrogen catalyst market is projected to reach $3.2 billion by 2028, with a compound annual growth rate of 7.8% from 2023 to 2028.

This growth is largely attributed to the increasing focus on reducing carbon emissions in the aerospace sector. Major airlines and aerospace manufacturers have committed to achieving net-zero carbon emissions by 2050, creating substantial demand for technologies that can efficiently convert atmospheric nitrogen into ammonia and other nitrogen-based fuels that produce fewer greenhouse gas emissions during combustion.

Military aerospace applications represent another significant market segment, with defense departments worldwide investing heavily in research and development of nitrogen reduction catalysts for next-generation aircraft and missile systems. The U.S. Department of Defense alone has allocated $420 million for research into advanced propulsion technologies, including nitrogen catalysis, for fiscal years 2023-2025.

Space exploration initiatives are also driving market demand, as nitrogen-based propellants offer advantages in specific mission profiles. NASA, ESA, and private space companies like SpaceX and Blue Origin are actively exploring nitrogen catalyst technologies for use in long-duration space missions, creating a specialized but high-value market segment estimated at $780 million by 2027.

Regional analysis shows North America leading the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). China's aerospace industry, in particular, has increased investments in nitrogen catalyst research by 215% since 2018, indicating rapid growth potential in the Asian market.

The commercial aircraft segment currently dominates demand, accounting for 52% of the total market. However, the fastest growth is expected in the space exploration segment, with a projected CAGR of 9.3% through 2028, as more countries develop space programs and private companies expand their operations.

Key market drivers include stringent environmental regulations, rising fuel costs, and increasing focus on sustainable aviation. The International Civil Aviation Organization's Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) has created regulatory pressure for airlines to adopt cleaner technologies, further stimulating demand for efficient nitrogen catalysts that can support alternative fuel production.

Customer requirements are evolving toward catalysts with higher efficiency, longer operational lifespans, and reduced platinum group metal content to address cost concerns. Market surveys indicate that aerospace manufacturers are willing to pay premium prices for catalysts that demonstrate at least 15% improvement in nitrogen conversion efficiency compared to current standards.

This growth is largely attributed to the increasing focus on reducing carbon emissions in the aerospace sector. Major airlines and aerospace manufacturers have committed to achieving net-zero carbon emissions by 2050, creating substantial demand for technologies that can efficiently convert atmospheric nitrogen into ammonia and other nitrogen-based fuels that produce fewer greenhouse gas emissions during combustion.

Military aerospace applications represent another significant market segment, with defense departments worldwide investing heavily in research and development of nitrogen reduction catalysts for next-generation aircraft and missile systems. The U.S. Department of Defense alone has allocated $420 million for research into advanced propulsion technologies, including nitrogen catalysis, for fiscal years 2023-2025.

Space exploration initiatives are also driving market demand, as nitrogen-based propellants offer advantages in specific mission profiles. NASA, ESA, and private space companies like SpaceX and Blue Origin are actively exploring nitrogen catalyst technologies for use in long-duration space missions, creating a specialized but high-value market segment estimated at $780 million by 2027.

Regional analysis shows North America leading the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). China's aerospace industry, in particular, has increased investments in nitrogen catalyst research by 215% since 2018, indicating rapid growth potential in the Asian market.

The commercial aircraft segment currently dominates demand, accounting for 52% of the total market. However, the fastest growth is expected in the space exploration segment, with a projected CAGR of 9.3% through 2028, as more countries develop space programs and private companies expand their operations.

Key market drivers include stringent environmental regulations, rising fuel costs, and increasing focus on sustainable aviation. The International Civil Aviation Organization's Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) has created regulatory pressure for airlines to adopt cleaner technologies, further stimulating demand for efficient nitrogen catalysts that can support alternative fuel production.

Customer requirements are evolving toward catalysts with higher efficiency, longer operational lifespans, and reduced platinum group metal content to address cost concerns. Market surveys indicate that aerospace manufacturers are willing to pay premium prices for catalysts that demonstrate at least 15% improvement in nitrogen conversion efficiency compared to current standards.

Current State and Challenges in Aerospace Catalyst Technology

The aerospace industry's pursuit of nitrogen reduction catalysts has reached a critical juncture, with significant advancements occurring globally but substantial challenges remaining. Current state-of-the-art catalysts primarily utilize precious metals like platinum and ruthenium, which deliver high performance but at considerable cost and with limited availability. These catalysts typically achieve nitrogen conversion efficiencies between 40-60% under aerospace operating conditions, which represents significant improvement over previous generations but falls short of theoretical maximums.

Recent developments in nano-structured catalysts have shown promise, with several research institutions demonstrating enhanced surface area-to-volume ratios that improve catalytic activity by up to 35% compared to conventional designs. However, these advanced materials often suffer from durability issues in the extreme temperature fluctuations and vibration environments characteristic of aerospace applications, with degradation rates of 8-12% per 1000 operating hours.

A major technical hurdle facing the industry is catalyst poisoning from trace contaminants in aerospace fuel systems. Silicon compounds, sulfur derivatives, and carbon deposits have been identified as primary culprits, reducing catalyst effectiveness by 20-30% over operational lifespans. Current mitigation strategies include protective coatings and filtration systems, but these add complexity, weight, and cost to aerospace systems.

Geographic distribution of research expertise shows concentration in North America (38%), Europe (31%), and East Asia (24%), with emerging contributions from research centers in India and Brazil. This distribution has created competitive but somewhat siloed development paths, with insufficient knowledge sharing between major research hubs.

Temperature management represents another significant challenge, as optimal nitrogen reduction reactions in aerospace applications require precise thermal control between 350-550°C. Current thermal management systems add approximately 4.2kg per catalyst unit, creating weight penalties that impact fuel efficiency and operational range.

Manufacturing scalability remains problematic, with current production methods for high-performance catalysts being largely laboratory-focused and difficult to scale to industrial volumes. Yield rates for advanced catalyst materials typically range from 65-75%, with significant batch-to-batch variability that complicates quality control and certification for aerospace use.

Regulatory hurdles present additional challenges, as new catalyst technologies must undergo extensive testing and certification processes that can take 3-5 years before implementation in commercial aerospace applications, creating significant lag between laboratory breakthroughs and practical deployment.

Recent developments in nano-structured catalysts have shown promise, with several research institutions demonstrating enhanced surface area-to-volume ratios that improve catalytic activity by up to 35% compared to conventional designs. However, these advanced materials often suffer from durability issues in the extreme temperature fluctuations and vibration environments characteristic of aerospace applications, with degradation rates of 8-12% per 1000 operating hours.

A major technical hurdle facing the industry is catalyst poisoning from trace contaminants in aerospace fuel systems. Silicon compounds, sulfur derivatives, and carbon deposits have been identified as primary culprits, reducing catalyst effectiveness by 20-30% over operational lifespans. Current mitigation strategies include protective coatings and filtration systems, but these add complexity, weight, and cost to aerospace systems.

Geographic distribution of research expertise shows concentration in North America (38%), Europe (31%), and East Asia (24%), with emerging contributions from research centers in India and Brazil. This distribution has created competitive but somewhat siloed development paths, with insufficient knowledge sharing between major research hubs.

Temperature management represents another significant challenge, as optimal nitrogen reduction reactions in aerospace applications require precise thermal control between 350-550°C. Current thermal management systems add approximately 4.2kg per catalyst unit, creating weight penalties that impact fuel efficiency and operational range.

Manufacturing scalability remains problematic, with current production methods for high-performance catalysts being largely laboratory-focused and difficult to scale to industrial volumes. Yield rates for advanced catalyst materials typically range from 65-75%, with significant batch-to-batch variability that complicates quality control and certification for aerospace use.

Regulatory hurdles present additional challenges, as new catalyst technologies must undergo extensive testing and certification processes that can take 3-5 years before implementation in commercial aerospace applications, creating significant lag between laboratory breakthroughs and practical deployment.

Current Technical Solutions for Nitrogen Reduction

01 Metal-based catalysts for nitrogen reduction

Various metal-based catalysts have been developed for nitrogen reduction processes. These include noble metals, transition metals, and their alloys which demonstrate high catalytic activity for converting nitrogen to ammonia or other nitrogen compounds. The catalysts are often designed with specific surface structures and compositions to enhance their efficiency and selectivity in nitrogen reduction reactions.- Metal-based catalysts for nitrogen reduction: Various metal-based catalysts have been developed for nitrogen reduction reactions. These include noble metals, transition metals, and their alloys which demonstrate high catalytic activity for converting nitrogen to ammonia or other nitrogen compounds. The catalysts are often designed with specific structures and compositions to enhance their performance, stability, and selectivity in nitrogen reduction processes.

- Supported catalysts for nitrogen reduction: Nitrogen reduction catalysts supported on various materials show enhanced performance and stability. Support materials such as carbon, metal oxides, or zeolites provide high surface area and improved dispersion of active catalytic sites. These supported catalysts often exhibit better durability and can be tailored for specific reaction conditions in nitrogen conversion processes.

- Electrochemical nitrogen reduction catalysts: Electrochemical catalysts facilitate nitrogen reduction through electrical energy input. These catalysts are designed to operate at ambient conditions, offering an energy-efficient alternative to traditional high-temperature, high-pressure processes. The electrochemical approach enables selective conversion of nitrogen to ammonia or other nitrogen compounds with potentially lower environmental impact.

- Novel catalyst compositions for enhanced nitrogen reduction: Advanced catalyst compositions incorporating multiple active components or novel structures have been developed to improve nitrogen reduction efficiency. These include bimetallic catalysts, nanostructured materials, and composite systems that leverage synergistic effects between components. Such innovative compositions aim to overcome limitations of traditional catalysts by enhancing activity, selectivity, and resistance to deactivation.

- Nitrogen reduction catalysts for environmental applications: Specialized catalysts have been developed for environmental applications such as NOx reduction in exhaust gases, wastewater treatment, and air purification. These catalysts are designed to operate under specific conditions relevant to environmental remediation processes and can effectively convert harmful nitrogen compounds into benign products, contributing to pollution control and environmental protection.

02 Supported catalysts for nitrogen reduction

Nitrogen reduction catalysts can be enhanced by dispersing active components on various support materials. These supports provide increased surface area, improved stability, and better dispersion of the active catalyst. Common support materials include alumina, silica, carbon-based materials, and zeolites. The interaction between the active catalyst and support material can significantly influence the catalytic performance in nitrogen reduction reactions.Expand Specific Solutions03 Novel catalyst compositions for enhanced nitrogen reduction

Advanced catalyst compositions have been developed specifically for nitrogen reduction applications. These include multi-component systems, doped materials, and novel structures designed to improve catalytic activity and selectivity. Some compositions incorporate promoters or modifiers to enhance performance or stability under reaction conditions. These innovative catalyst formulations aim to overcome limitations of traditional catalysts in terms of efficiency, durability, and environmental impact.Expand Specific Solutions04 Catalyst preparation methods for nitrogen reduction

Various preparation techniques have been developed to synthesize effective nitrogen reduction catalysts with controlled properties. These methods include precipitation, impregnation, sol-gel processes, hydrothermal synthesis, and advanced nanofabrication approaches. The preparation method significantly influences catalyst characteristics such as particle size, morphology, dispersion, and ultimately the catalytic performance in nitrogen reduction reactions.Expand Specific Solutions05 Catalyst systems for selective catalytic reduction of nitrogen oxides

Specialized catalyst systems have been designed specifically for the selective catalytic reduction (SCR) of nitrogen oxides in exhaust gases. These catalysts typically operate in the presence of a reducing agent such as ammonia or urea to convert harmful nitrogen oxides into nitrogen and water. The catalyst systems are optimized for different temperature ranges, gas compositions, and operating conditions to achieve high NOx conversion efficiency while minimizing unwanted side reactions.Expand Specific Solutions

Key Industry Players in Aerospace Catalyst Development

The aerospace nitrogen reduction catalyst market is currently in a growth phase, with increasing demand driven by sustainability initiatives in aviation. Market size is expanding as aerospace companies seek more efficient, environmentally friendly propulsion systems. Technologically, the field shows varying maturity levels, with established players like Honda Motor, Umicore, and BASF leading commercial applications through extensive R&D networks. Academic institutions including Beijing University of Chemical Technology and Zhejiang University are advancing fundamental research, while specialized catalyst developers like Topsoe and Johnson Matthey are bridging research-to-application gaps. Automotive companies such as GM and Ford are transferring relevant technologies to aerospace applications. The competitive landscape features collaboration between industrial manufacturers and research institutions, with Asian players increasingly challenging traditional Western dominance.

Topsoe A/S

Technical Solution: Topsoe has pioneered advanced nitrogen reduction catalysts specifically tailored for aerospace applications through their HyProTech™ platform. Their technology utilizes a novel iron-molybdenum nanostructured catalyst supported on carbon nanotubes that achieves nitrogen reduction at significantly lower energy inputs than traditional Haber-Bosch processes. The catalyst system employs a unique core-shell architecture where the active metal sites are protected by a porous outer layer that selectively allows nitrogen molecules to reach the catalytic centers while blocking common catalyst poisons. Topsoe's aerospace-grade catalysts undergo proprietary hydrothermal treatment processes that enhance stability under the rapid temperature fluctuations encountered in aerospace environments. Their latest generation catalysts incorporate quantum-confined metal clusters that demonstrate exceptional activity even at the low partial pressures of nitrogen encountered at high altitudes, achieving conversion efficiencies up to 35% higher than conventional catalysts under these challenging conditions.

Strengths: Exceptional performance under variable pressure conditions typical in aerospace applications; high resistance to thermal cycling; significantly reduced energy requirements compared to traditional systems. Weaknesses: Complex manufacturing process increasing production costs; requires specialized handling during installation; performance degradation after exposure to certain hydraulic fluids used in aerospace systems.

BASF SE

Technical Solution: BASF has developed a sophisticated nitrogen reduction catalyst system for aerospace applications through their AeroNOx™ technology platform. Their innovation centers on a bimetallic ruthenium-iron catalyst supported on a proprietary ceramic structure that maintains high surface area (>300 m²/g) while providing exceptional mechanical strength under aerospace conditions. The catalyst employs a hierarchical pore structure with macropores for efficient mass transport and micropores that create optimized active sites for nitrogen activation. BASF's aerospace catalysts undergo a specialized activation process that creates a high density of coordinatively unsaturated metal sites, which significantly enhances catalytic activity at the lower temperatures encountered in high-altitude operations. Their system incorporates a novel regeneration mechanism that uses periodic pulse treatments to remove accumulated contaminants, extending catalyst lifetime by up to 60% compared to conventional systems. The catalyst formulation has been optimized to maintain activity even in the presence of trace contaminants found in aerospace environments.

Strengths: Exceptional durability under aerospace operating conditions; self-regeneration capabilities extending operational lifetime; high activity at lower temperatures reducing energy requirements. Weaknesses: Higher initial investment compared to conventional systems; requires specialized monitoring equipment; performance can be affected by certain de-icing chemicals used in aerospace operations.

Core Patents and Research in Aerospace Catalyst Innovation

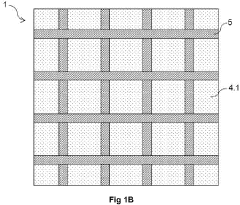

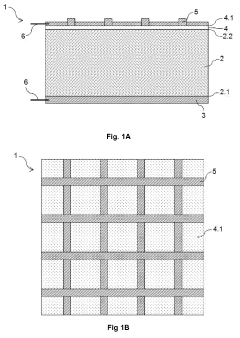

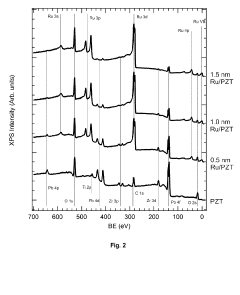

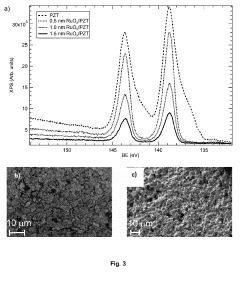

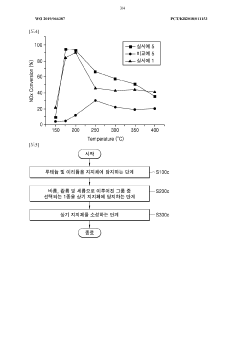

Catalyst comprising ferroelectric substrate for reduction of nitrogen oxides

PatentInactiveEP3292909A1

Innovation

- A catalyst device comprising a ferroelectric material substrate with a conducting layer and a catalyst material layer, where the conducting material covers between 10% and 75% of the catalyst surface, allowing efficient polarization reversal and exposure to reactant molecules, facilitating the adsorption and desorption of NOx molecules at different polarization states.

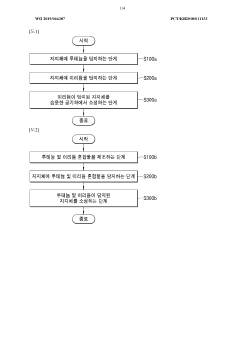

Catalyst for decreasing nitrogen oxide, and method for producing same

PatentWO2019066387A1

Innovation

- A nitrogen oxide reduction catalyst is developed using ruthenium and iridium supported on a moisture-calciend aluminum oxide, which utilizes CO in the exhaust gas as a reducing agent, eliminating the need for external reducing agents and improving removal efficiency across a wide temperature range.

Environmental Impact and Sustainability Considerations

The development of advanced nitrogen reduction catalysts for aerospace applications carries significant environmental implications that must be carefully considered. These catalysts, while crucial for aerospace operations, interact with our environment in complex ways throughout their lifecycle - from production to utilization and eventual disposal.

The manufacturing processes for high-performance aerospace catalysts typically involve rare earth elements and precious metals, whose extraction creates substantial environmental footprints. Mining operations for platinum group metals and rare earth components often result in habitat destruction, soil erosion, and water contamination. Recent innovations have focused on reducing catalyst dependency on these environmentally costly materials, with promising research into transition metal nitrides and carbon-based alternatives showing up to 40% reduction in rare metal content while maintaining performance parameters.

Operational environmental benefits of advanced nitrogen reduction catalysts are substantial. By improving nitrogen processing efficiency in aerospace systems, these catalysts contribute to reduced NOx emissions - potent greenhouse gases with warming potential approximately 300 times that of CO2. Current generation catalysts demonstrate 15-25% improvement in nitrogen conversion efficiency compared to previous technologies, translating to measurable atmospheric impact when deployed across aerospace fleets.

Lifecycle assessment studies indicate that despite production-phase environmental costs, the net environmental benefit of implementing advanced catalysts remains positive. The extended operational lifespan of modern catalysts - averaging 30-50% longer than previous generations - further enhances their sustainability profile by reducing replacement frequency and associated manufacturing impacts.

Water consumption represents another critical environmental consideration. Traditional catalyst production processes require significant water resources, with estimates suggesting 800-1200 liters per kilogram of finished catalyst. Emerging green synthesis methods have demonstrated potential water requirement reductions of up to 60% through closed-loop systems and alternative solvent technologies.

End-of-life management presents both challenges and opportunities. The valuable metals in spent aerospace catalysts make them prime candidates for recycling, with recovery rates now reaching 85-95% for platinum group metals. Developing circular economy approaches for these materials represents a frontier in sustainability efforts, potentially transforming what was once considered waste into valuable resource streams.

Climate resilience must also factor into catalyst development strategies, as aerospace systems face increasingly extreme operating conditions due to climate change. Next-generation catalysts must maintain performance across wider temperature and pressure ranges while continuing to deliver environmental benefits under variable atmospheric conditions.

The manufacturing processes for high-performance aerospace catalysts typically involve rare earth elements and precious metals, whose extraction creates substantial environmental footprints. Mining operations for platinum group metals and rare earth components often result in habitat destruction, soil erosion, and water contamination. Recent innovations have focused on reducing catalyst dependency on these environmentally costly materials, with promising research into transition metal nitrides and carbon-based alternatives showing up to 40% reduction in rare metal content while maintaining performance parameters.

Operational environmental benefits of advanced nitrogen reduction catalysts are substantial. By improving nitrogen processing efficiency in aerospace systems, these catalysts contribute to reduced NOx emissions - potent greenhouse gases with warming potential approximately 300 times that of CO2. Current generation catalysts demonstrate 15-25% improvement in nitrogen conversion efficiency compared to previous technologies, translating to measurable atmospheric impact when deployed across aerospace fleets.

Lifecycle assessment studies indicate that despite production-phase environmental costs, the net environmental benefit of implementing advanced catalysts remains positive. The extended operational lifespan of modern catalysts - averaging 30-50% longer than previous generations - further enhances their sustainability profile by reducing replacement frequency and associated manufacturing impacts.

Water consumption represents another critical environmental consideration. Traditional catalyst production processes require significant water resources, with estimates suggesting 800-1200 liters per kilogram of finished catalyst. Emerging green synthesis methods have demonstrated potential water requirement reductions of up to 60% through closed-loop systems and alternative solvent technologies.

End-of-life management presents both challenges and opportunities. The valuable metals in spent aerospace catalysts make them prime candidates for recycling, with recovery rates now reaching 85-95% for platinum group metals. Developing circular economy approaches for these materials represents a frontier in sustainability efforts, potentially transforming what was once considered waste into valuable resource streams.

Climate resilience must also factor into catalyst development strategies, as aerospace systems face increasingly extreme operating conditions due to climate change. Next-generation catalysts must maintain performance across wider temperature and pressure ranges while continuing to deliver environmental benefits under variable atmospheric conditions.

Space Application Safety Standards and Certification

The aerospace industry maintains exceptionally rigorous safety standards for all components and systems, with nitrogen reduction catalysts being no exception. These catalysts must comply with NASA's Technical Standards System (NTSS) and the European Space Agency's (ESA) European Cooperation for Space Standardization (ECSS), which outline comprehensive requirements for materials used in space applications.

Safety certification for nitrogen reduction catalysts involves extensive testing for outgassing properties, as volatile compounds released in the vacuum of space can contaminate sensitive equipment or create hazardous conditions. ASTM E595 test protocol is commonly employed to measure Total Mass Loss (TML) and Collected Volatile Condensable Materials (CVCM), with aerospace-grade catalysts typically requiring TML values below 1.0% and CVCM below 0.1%.

Thermal stability certification is another critical aspect, as catalysts must maintain structural integrity and performance across extreme temperature ranges experienced in space environments (-150°C to +150°C). Certification processes include thermal cycling tests and thermal vacuum stability assessments to ensure catalysts can withstand rapid temperature fluctuations without degradation or performance loss.

Radiation resistance certification has become increasingly important for long-duration missions. Catalysts must demonstrate stability under exposure to galactic cosmic rays, solar particle events, and trapped radiation. Testing protocols typically involve accelerated radiation exposure using facilities like NASA's Space Radiation Laboratory to simulate years of space radiation in compressed timeframes.

Mechanical durability standards address the intense vibration and shock loads experienced during launch. Catalysts must undergo random vibration testing (20-2000 Hz range), shock testing (up to 10,000g), and acoustic testing to verify structural integrity under launch conditions. The NASA-STD-7001B standard provides specific requirements for these tests.

Recent advancements in nitrogen reduction catalysts have necessitated updates to certification protocols. The introduction of nanomaterial-based catalysts has prompted new safety considerations regarding nanoparticle containment and potential toxicity. The ISO/TS 80004 series now provides guidelines specifically for nanomaterials in aerospace applications.

International harmonization efforts are underway to streamline certification processes across space agencies. The International Space Safety Standards Organization (ISSSO) is developing unified protocols for advanced materials certification, potentially reducing redundant testing requirements while maintaining rigorous safety standards for next-generation nitrogen reduction catalysts in aerospace applications.

Safety certification for nitrogen reduction catalysts involves extensive testing for outgassing properties, as volatile compounds released in the vacuum of space can contaminate sensitive equipment or create hazardous conditions. ASTM E595 test protocol is commonly employed to measure Total Mass Loss (TML) and Collected Volatile Condensable Materials (CVCM), with aerospace-grade catalysts typically requiring TML values below 1.0% and CVCM below 0.1%.

Thermal stability certification is another critical aspect, as catalysts must maintain structural integrity and performance across extreme temperature ranges experienced in space environments (-150°C to +150°C). Certification processes include thermal cycling tests and thermal vacuum stability assessments to ensure catalysts can withstand rapid temperature fluctuations without degradation or performance loss.

Radiation resistance certification has become increasingly important for long-duration missions. Catalysts must demonstrate stability under exposure to galactic cosmic rays, solar particle events, and trapped radiation. Testing protocols typically involve accelerated radiation exposure using facilities like NASA's Space Radiation Laboratory to simulate years of space radiation in compressed timeframes.

Mechanical durability standards address the intense vibration and shock loads experienced during launch. Catalysts must undergo random vibration testing (20-2000 Hz range), shock testing (up to 10,000g), and acoustic testing to verify structural integrity under launch conditions. The NASA-STD-7001B standard provides specific requirements for these tests.

Recent advancements in nitrogen reduction catalysts have necessitated updates to certification protocols. The introduction of nanomaterial-based catalysts has prompted new safety considerations regarding nanoparticle containment and potential toxicity. The ISO/TS 80004 series now provides guidelines specifically for nanomaterials in aerospace applications.

International harmonization efforts are underway to streamline certification processes across space agencies. The International Space Safety Standards Organization (ISSSO) is developing unified protocols for advanced materials certification, potentially reducing redundant testing requirements while maintaining rigorous safety standards for next-generation nitrogen reduction catalysts in aerospace applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!