Analysis of Thermal Management in Nitrogen Reduction Catalyst Systems

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Management in Nitrogen Reduction Catalysis: Background and Objectives

Nitrogen reduction catalysis represents a critical area of research and development in the chemical industry, particularly for ammonia synthesis which underpins global food production through fertilizers. The Haber-Bosch process, developed in the early 20th century, remains the dominant industrial method for nitrogen fixation, consuming approximately 1-2% of global energy production and generating significant carbon emissions. This energy-intensive process operates under extreme conditions of 400-500°C and 150-300 bar pressure, highlighting the fundamental challenge of thermal management in nitrogen reduction catalysis.

The evolution of nitrogen reduction catalyst systems has seen several technological waves, beginning with iron-based catalysts in the original Haber-Bosch process, followed by ruthenium-based systems in the 1970s, and more recently, the exploration of novel materials including metal-organic frameworks (MOFs) and single-atom catalysts. Each advancement has aimed to reduce the severe energy requirements while maintaining or improving conversion efficiency.

Current research trends focus on developing catalysts that can operate at lower temperatures and pressures, thereby reducing energy consumption and associated carbon emissions. Electrochemical and photocatalytic nitrogen reduction represent emerging approaches that potentially offer more sustainable pathways compared to traditional thermochemical methods. These alternative technologies aim to operate under ambient conditions, presenting fundamentally different thermal management challenges.

The technical objectives of this research area include developing catalyst systems with enhanced thermal stability, improved heat transfer characteristics, and optimized reaction kinetics at lower temperatures. Additionally, there is significant interest in understanding the relationship between catalyst structure, thermal behavior, and nitrogen reduction efficiency to design next-generation systems with superior performance.

From an industrial perspective, thermal management innovations in nitrogen reduction catalysis could potentially reduce global energy consumption by billions of gigajoules annually while cutting associated greenhouse gas emissions. This represents not only an environmental imperative but also a substantial economic opportunity as industries worldwide face increasing pressure to decarbonize their operations.

The geographical distribution of research in this field shows concentrations in regions with strong chemical engineering traditions, including Germany, China, the United States, and Japan. Recent years have seen increasing collaboration between academic institutions and industrial partners, accelerating the pace of innovation and technology transfer in thermal management solutions for nitrogen reduction catalysis.

The evolution of nitrogen reduction catalyst systems has seen several technological waves, beginning with iron-based catalysts in the original Haber-Bosch process, followed by ruthenium-based systems in the 1970s, and more recently, the exploration of novel materials including metal-organic frameworks (MOFs) and single-atom catalysts. Each advancement has aimed to reduce the severe energy requirements while maintaining or improving conversion efficiency.

Current research trends focus on developing catalysts that can operate at lower temperatures and pressures, thereby reducing energy consumption and associated carbon emissions. Electrochemical and photocatalytic nitrogen reduction represent emerging approaches that potentially offer more sustainable pathways compared to traditional thermochemical methods. These alternative technologies aim to operate under ambient conditions, presenting fundamentally different thermal management challenges.

The technical objectives of this research area include developing catalyst systems with enhanced thermal stability, improved heat transfer characteristics, and optimized reaction kinetics at lower temperatures. Additionally, there is significant interest in understanding the relationship between catalyst structure, thermal behavior, and nitrogen reduction efficiency to design next-generation systems with superior performance.

From an industrial perspective, thermal management innovations in nitrogen reduction catalysis could potentially reduce global energy consumption by billions of gigajoules annually while cutting associated greenhouse gas emissions. This represents not only an environmental imperative but also a substantial economic opportunity as industries worldwide face increasing pressure to decarbonize their operations.

The geographical distribution of research in this field shows concentrations in regions with strong chemical engineering traditions, including Germany, China, the United States, and Japan. Recent years have seen increasing collaboration between academic institutions and industrial partners, accelerating the pace of innovation and technology transfer in thermal management solutions for nitrogen reduction catalysis.

Market Analysis for Nitrogen Reduction Technologies

The global market for nitrogen reduction technologies has experienced significant growth in recent years, driven primarily by increasing environmental regulations and the growing demand for sustainable agricultural practices. The nitrogen reduction catalyst systems market is projected to reach $5.2 billion by 2027, growing at a CAGR of 6.8% from 2022 to 2027. This growth is particularly evident in regions with stringent emission control regulations such as Europe and North America.

The agricultural sector represents the largest market segment for nitrogen reduction technologies, accounting for approximately 65% of the total market share. This dominance is attributed to the essential role of nitrogen-based fertilizers in modern farming practices and the increasing need for more efficient nitrogen utilization to minimize environmental impact. The industrial sector follows with about 25% market share, primarily in chemical manufacturing and power generation applications.

Regionally, Asia-Pacific is emerging as the fastest-growing market for nitrogen reduction technologies, with China and India leading the expansion due to their rapidly developing agricultural sectors and increasing environmental awareness. North America and Europe maintain significant market shares due to established regulatory frameworks and advanced technological adoption.

Market dynamics are increasingly influenced by sustainability concerns, with consumers and regulatory bodies demanding more environmentally friendly nitrogen management solutions. This has created a notable shift toward technologies that not only reduce nitrogen emissions but also improve energy efficiency and reduce operational costs.

The competitive landscape features both established chemical companies and emerging technology startups. Major players include BASF, Yara International, and Johnson Matthey, who collectively hold approximately 45% of the market share. These companies are investing heavily in R&D to develop more efficient catalyst systems with improved thermal management capabilities.

Customer segments show varying priorities, with large-scale agricultural operations focusing on cost-effectiveness and scalability, while industrial clients prioritize compliance with emissions regulations and operational efficiency. The public sector, particularly municipal wastewater treatment facilities, represents a growing customer segment with specific requirements for nitrogen removal from water systems.

Price sensitivity varies across segments, with agricultural customers showing higher price sensitivity compared to industrial clients who often view nitrogen reduction technologies as necessary compliance investments. This market characteristic has led to the development of tiered product offerings with varying performance-to-cost ratios.

The agricultural sector represents the largest market segment for nitrogen reduction technologies, accounting for approximately 65% of the total market share. This dominance is attributed to the essential role of nitrogen-based fertilizers in modern farming practices and the increasing need for more efficient nitrogen utilization to minimize environmental impact. The industrial sector follows with about 25% market share, primarily in chemical manufacturing and power generation applications.

Regionally, Asia-Pacific is emerging as the fastest-growing market for nitrogen reduction technologies, with China and India leading the expansion due to their rapidly developing agricultural sectors and increasing environmental awareness. North America and Europe maintain significant market shares due to established regulatory frameworks and advanced technological adoption.

Market dynamics are increasingly influenced by sustainability concerns, with consumers and regulatory bodies demanding more environmentally friendly nitrogen management solutions. This has created a notable shift toward technologies that not only reduce nitrogen emissions but also improve energy efficiency and reduce operational costs.

The competitive landscape features both established chemical companies and emerging technology startups. Major players include BASF, Yara International, and Johnson Matthey, who collectively hold approximately 45% of the market share. These companies are investing heavily in R&D to develop more efficient catalyst systems with improved thermal management capabilities.

Customer segments show varying priorities, with large-scale agricultural operations focusing on cost-effectiveness and scalability, while industrial clients prioritize compliance with emissions regulations and operational efficiency. The public sector, particularly municipal wastewater treatment facilities, represents a growing customer segment with specific requirements for nitrogen removal from water systems.

Price sensitivity varies across segments, with agricultural customers showing higher price sensitivity compared to industrial clients who often view nitrogen reduction technologies as necessary compliance investments. This market characteristic has led to the development of tiered product offerings with varying performance-to-cost ratios.

Current Thermal Management Challenges in Catalyst Systems

Thermal management represents one of the most critical challenges in nitrogen reduction catalyst systems. These systems typically operate under extreme conditions, with temperatures often exceeding 400°C during the catalytic process. The efficiency of nitrogen fixation is highly temperature-dependent, requiring precise thermal control to maintain optimal reaction rates while preventing catalyst degradation. Current systems struggle to balance these competing requirements, resulting in significant energy inefficiencies and reduced catalyst lifespans.

The primary thermal challenge involves heat distribution across catalyst beds. Uneven temperature profiles lead to hotspots where localized overheating accelerates catalyst sintering and deactivation. Studies indicate that temperature variations as small as 15°C across a catalyst bed can reduce conversion efficiency by up to 30% and accelerate deactivation rates by a factor of 2-3. This non-uniform heating represents a fundamental limitation in current fixed-bed reactor designs.

Heat recovery systems present another significant challenge. The exothermic nature of many nitrogen reduction reactions generates substantial waste heat that current systems fail to effectively capture and repurpose. Industry data suggests that only 40-60% of thermal energy is typically recovered in commercial operations, representing a substantial efficiency loss. Advanced heat exchanger designs are being explored but face limitations in materials that can withstand the corrosive environments typical of nitrogen reduction processes.

Thermal cycling during start-up and shutdown operations creates additional stress on catalyst systems. Rapid temperature changes induce thermal expansion and contraction that can physically damage catalyst structures and support materials. Current materials science approaches have yet to develop catalyst supports that maintain structural integrity while accommodating these thermal stresses over thousands of operational cycles.

Energy consumption for maintaining reaction temperatures constitutes a major portion of operational costs in nitrogen reduction processes. Conventional heating methods rely heavily on fossil fuel combustion or electrical resistance heating, both of which contribute significantly to the carbon footprint of these processes. The industry lacks cost-effective, energy-efficient heating technologies that can deliver precise thermal control while minimizing environmental impact.

Miniaturization efforts for distributed nitrogen fixation systems face particular thermal management challenges. Smaller reactors have higher surface-to-volume ratios, resulting in greater heat loss and more difficult temperature control. Current insulation technologies and heating approaches do not scale down effectively, limiting the development of smaller, distributed catalyst systems that could revolutionize local fertilizer production.

The primary thermal challenge involves heat distribution across catalyst beds. Uneven temperature profiles lead to hotspots where localized overheating accelerates catalyst sintering and deactivation. Studies indicate that temperature variations as small as 15°C across a catalyst bed can reduce conversion efficiency by up to 30% and accelerate deactivation rates by a factor of 2-3. This non-uniform heating represents a fundamental limitation in current fixed-bed reactor designs.

Heat recovery systems present another significant challenge. The exothermic nature of many nitrogen reduction reactions generates substantial waste heat that current systems fail to effectively capture and repurpose. Industry data suggests that only 40-60% of thermal energy is typically recovered in commercial operations, representing a substantial efficiency loss. Advanced heat exchanger designs are being explored but face limitations in materials that can withstand the corrosive environments typical of nitrogen reduction processes.

Thermal cycling during start-up and shutdown operations creates additional stress on catalyst systems. Rapid temperature changes induce thermal expansion and contraction that can physically damage catalyst structures and support materials. Current materials science approaches have yet to develop catalyst supports that maintain structural integrity while accommodating these thermal stresses over thousands of operational cycles.

Energy consumption for maintaining reaction temperatures constitutes a major portion of operational costs in nitrogen reduction processes. Conventional heating methods rely heavily on fossil fuel combustion or electrical resistance heating, both of which contribute significantly to the carbon footprint of these processes. The industry lacks cost-effective, energy-efficient heating technologies that can deliver precise thermal control while minimizing environmental impact.

Miniaturization efforts for distributed nitrogen fixation systems face particular thermal management challenges. Smaller reactors have higher surface-to-volume ratios, resulting in greater heat loss and more difficult temperature control. Current insulation technologies and heating approaches do not scale down effectively, limiting the development of smaller, distributed catalyst systems that could revolutionize local fertilizer production.

State-of-the-Art Thermal Management Solutions

01 Thermal management systems for SCR catalysts

Selective Catalytic Reduction (SCR) systems require precise thermal management to maintain optimal operating temperatures for nitrogen oxide reduction. These systems incorporate heat exchangers, insulation materials, and temperature control mechanisms to ensure the catalyst operates within its effective temperature range. Proper thermal management prevents catalyst degradation and ensures efficient nitrogen reduction performance over the catalyst's lifetime.- Thermal management systems for SCR catalysts: Selective Catalytic Reduction (SCR) systems require precise thermal management to maintain optimal operating temperatures for nitrogen oxide reduction. These systems incorporate heat exchangers, insulation materials, and temperature sensors to control catalyst temperature, ensuring efficient conversion of nitrogen oxides to nitrogen gas. Advanced thermal management strategies include preheating mechanisms and cooling systems to prevent catalyst degradation during extreme operating conditions.

- Catalyst composition for improved thermal stability: Specialized catalyst formulations enhance thermal stability during nitrogen reduction processes. These compositions typically include base metals (copper, iron), noble metals (platinum, palladium), and zeolite structures with modified frameworks. The catalysts are designed to maintain structural integrity and activity across wide temperature ranges, reducing thermal deactivation and extending operational lifespan under fluctuating thermal conditions.

- Exhaust gas recirculation for temperature control: Exhaust Gas Recirculation (EGR) systems are employed to regulate catalyst temperatures in nitrogen reduction applications. By recirculating a portion of exhaust gases, these systems can moderate temperature peaks, prevent thermal runaway, and maintain catalysts within optimal operating windows. Advanced EGR configurations include cooled recirculation paths and variable flow control mechanisms to adapt to changing engine loads and ambient conditions.

- Integrated heating elements for catalyst activation: Integrated heating elements enable rapid catalyst activation and temperature maintenance in nitrogen reduction systems. These heating technologies include electrical resistance heaters, fuel burners, and microwave heating systems strategically positioned to ensure uniform temperature distribution across the catalyst bed. Control algorithms modulate power input based on real-time temperature monitoring, ensuring efficient catalyst operation while minimizing energy consumption.

- Cooling systems for preventing catalyst overheating: Dedicated cooling systems protect nitrogen reduction catalysts from thermal damage during high-load operations. These systems incorporate liquid cooling circuits, air flow management devices, and phase-change materials to dissipate excess heat. Advanced thermal management includes bypass mechanisms that redirect exhaust flow during extreme temperature events and regeneration cycles, preserving catalyst integrity and extending service intervals.

02 Catalyst composition for improved thermal stability

Advanced catalyst formulations incorporate materials that enhance thermal stability during nitrogen reduction reactions. These compositions often include rare earth metals, transition metals, and support materials designed to withstand high-temperature operating conditions. The improved thermal stability allows for more efficient nitrogen reduction while extending catalyst lifespan and maintaining performance across varying temperature conditions.Expand Specific Solutions03 Exhaust gas temperature control for nitrogen reduction systems

Systems for controlling exhaust gas temperature before it reaches nitrogen reduction catalysts ensure optimal reaction conditions. These include pre-heating mechanisms for cold-start conditions, cooling systems for high-load operations, and bypass valves that regulate gas flow through the catalyst bed. Temperature control strategies are critical for maintaining catalyst efficiency and preventing thermal damage during various operating conditions.Expand Specific Solutions04 Regeneration methods for thermally deactivated catalysts

Thermal regeneration techniques restore the activity of nitrogen reduction catalysts that have been deactivated due to thermal stress or coking. These methods include controlled heating cycles, oxidative treatments, and specialized regeneration agents that remove deposits without damaging the catalyst structure. Effective regeneration protocols extend catalyst service life and maintain nitrogen reduction efficiency in industrial and automotive applications.Expand Specific Solutions05 Integrated cooling systems for nitrogen reduction catalysts

Integrated cooling systems prevent overheating of nitrogen reduction catalysts during operation. These systems utilize liquid cooling circuits, air flow management, and heat-dissipating structures to maintain optimal catalyst temperature. Advanced designs incorporate sensors and control algorithms that adjust cooling intensity based on real-time temperature monitoring, ensuring consistent catalyst performance while minimizing energy consumption.Expand Specific Solutions

Leading Companies and Research Institutions in Catalyst Thermal Management

The thermal management in nitrogen reduction catalyst systems market is currently in a growth phase, characterized by increasing demand for efficient emission control technologies. The market size is expanding due to stringent environmental regulations globally, with projections indicating significant growth over the next decade. Technologically, the field shows varying maturity levels across applications. Industry leaders Toyota, Cummins, and Bosch demonstrate advanced thermal management solutions with established commercial implementations, while companies like BYD and Continental Automotive are rapidly advancing their technologies. Emerging players such as Molten Industries are introducing innovative approaches to catalyst thermal efficiency. The competitive landscape features traditional automotive manufacturers collaborating with chemical specialists like BASF and Wanhua Chemical to develop integrated thermal management solutions that optimize catalyst performance while minimizing energy consumption.

Toyota Motor Corp.

Technical Solution: Toyota has developed a sophisticated thermal management system for nitrogen reduction catalysts that integrates seamlessly with their hybrid powertrain architecture. Their approach utilizes waste heat recovery systems that capture thermal energy from multiple vehicle sources and direct it to maintain optimal catalyst operating temperatures. Toyota's system incorporates a multi-stage heat exchanger network that can precisely control temperature gradients across the catalyst bed, ensuring uniform conversion efficiency. Their thermal management solution features adaptive control algorithms that continuously optimize the balance between NOx conversion efficiency and thermal energy consumption based on real-time driving conditions and emissions requirements. Toyota has implemented specialized catalyst substrates with optimized cell density patterns that promote uniform heat distribution while minimizing pressure drop penalties. The system also incorporates variable insulation technologies that can adjust thermal retention properties based on operating conditions, providing maximum insulation during warm-up phases and controlled heat dissipation during high-load operation. Toyota's thermal management approach also leverages their hybrid powertrain capabilities to maintain catalyst temperatures during engine-off periods, ensuring continuous emissions control even during extended electric-only operation.

Strengths: Exceptional integration with hybrid powertrain systems; highly efficient use of available thermal energy sources; excellent emissions performance across diverse driving cycles. Weaknesses: System complexity increases maintenance challenges; optimization heavily tailored to hybrid applications with potentially reduced benefits for conventional powertrains.

Cummins, Inc.

Technical Solution: Cummins has developed a comprehensive thermal management solution for nitrogen reduction catalyst systems in heavy-duty diesel applications. Their approach integrates multiple subsystems including a variable geometry turbocharger, advanced EGR cooling, and a sophisticated aftertreatment thermal management module. The system employs closed-loop control algorithms that continuously monitor catalyst bed temperatures using an array of strategically positioned thermocouples, enabling precise temperature regulation within ±5°C of target values. Cummins' solution incorporates active regeneration strategies that periodically elevate exhaust temperatures to remove accumulated contaminants and restore catalyst efficiency. Their thermal management system also features adaptive control logic that adjusts heating strategies based on ambient conditions, engine load profiles, and catalyst aging factors. The technology includes specialized insulation materials surrounding the SCR catalyst that minimize heat loss during low ambient temperature operation while incorporating passive cooling channels that activate during high-temperature conditions to prevent thermal degradation.

Strengths: Exceptional durability and reliability under extreme operating conditions; highly optimized for heavy-duty applications with variable load profiles. Weaknesses: System size and weight penalties make it less suitable for light-duty applications; higher initial cost compared to simpler thermal management solutions.

Key Patents and Innovations in Catalyst Cooling Technologies

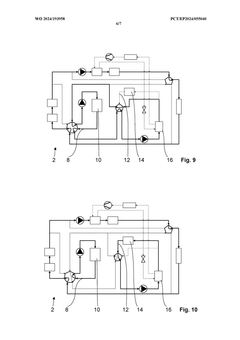

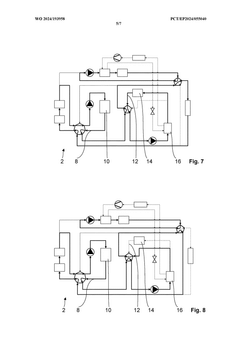

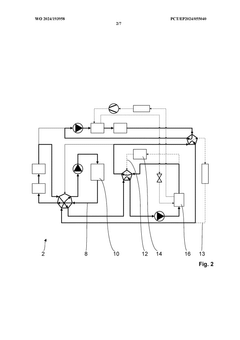

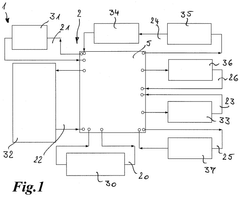

Thermal management system and method for operating such a thermal management system

PatentWO2024193958A1

Innovation

- A thermal management system with a valve system that allows for independent cooling of components via a coolant-refrigerant heat exchanger, enabling multiple thermal management states where components can be cooled separately or together, with a reduced refrigerant system and simplified valve configuration using a single 7-way valve and two 5-way valves.

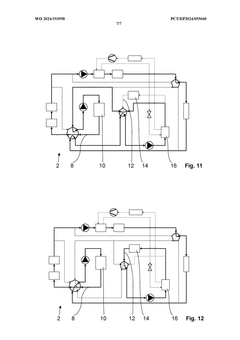

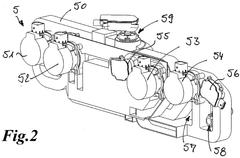

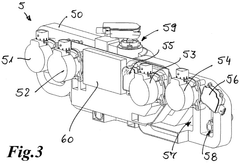

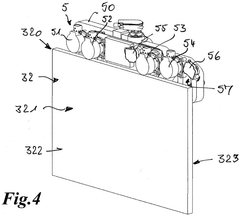

Thermal management system comprising at least one thermal management module, thermal management module, prefabricated unit and battery-electric vehicle comprising a thermal management system comprising a thermal management module

PatentWO2025073388A1

Innovation

- A thermal management system featuring a standardized thermal management module with a flat, plate-like structural component that integrates components for temperature medium conveyance and mass flow control, allowing for direct connection to the main heat exchanger and reducing the complexity and cost of the system.

Environmental Impact and Sustainability Considerations

The thermal management of nitrogen reduction catalyst systems carries significant environmental implications that extend beyond mere operational efficiency. These systems, while crucial for industrial processes like ammonia synthesis, can generate substantial environmental footprints through energy consumption, greenhouse gas emissions, and resource utilization patterns.

Energy efficiency in thermal management directly correlates with environmental impact. Conventional nitrogen reduction processes operate at high temperatures (400-500°C) and pressures (150-300 bar), consuming approximately 1-2% of global energy production. Inefficient thermal management exacerbates this consumption, contributing to fossil fuel depletion and associated carbon emissions. Recent advancements in heat recovery systems have demonstrated potential reductions of 15-30% in energy requirements, significantly lowering the carbon footprint of these operations.

Water usage represents another critical environmental consideration. Cooling systems for thermal management typically require substantial water resources, with traditional systems consuming 3-5 gallons of water per pound of nitrogen processed. In water-stressed regions, this dependency creates competition with agricultural and municipal needs. Closed-loop cooling technologies and air-cooled alternatives have emerged as sustainable solutions, reducing water consumption by up to 80% compared to once-through cooling systems.

The materials used in catalyst systems present both environmental challenges and opportunities. Rare earth elements and precious metals commonly employed in high-performance catalysts involve environmentally destructive mining practices and generate toxic waste. However, innovations in catalyst design using abundant elements and nano-structured materials have shown promise in reducing environmental impact while maintaining thermal efficiency.

Life cycle assessment studies indicate that optimized thermal management can reduce the overall environmental impact of nitrogen reduction processes by 25-40%. This includes considerations of raw material extraction, manufacturing, operation, and end-of-life disposal. Particularly noteworthy is the potential for reduced NOx emissions, which contribute to acid rain and photochemical smog formation.

Regulatory frameworks increasingly recognize these environmental dimensions, with standards like ISO 14001 and the European Union's Industrial Emissions Directive establishing benchmarks for environmental performance. Companies implementing advanced thermal management solutions not only achieve compliance but often realize cost savings through reduced resource consumption and waste generation.

The integration of renewable energy sources with nitrogen reduction processes represents perhaps the most transformative sustainability opportunity. Solar thermal systems and green hydrogen production pathways can provide the necessary thermal energy while dramatically reducing carbon emissions, potentially enabling carbon-neutral nitrogen fixation in the future.

Energy efficiency in thermal management directly correlates with environmental impact. Conventional nitrogen reduction processes operate at high temperatures (400-500°C) and pressures (150-300 bar), consuming approximately 1-2% of global energy production. Inefficient thermal management exacerbates this consumption, contributing to fossil fuel depletion and associated carbon emissions. Recent advancements in heat recovery systems have demonstrated potential reductions of 15-30% in energy requirements, significantly lowering the carbon footprint of these operations.

Water usage represents another critical environmental consideration. Cooling systems for thermal management typically require substantial water resources, with traditional systems consuming 3-5 gallons of water per pound of nitrogen processed. In water-stressed regions, this dependency creates competition with agricultural and municipal needs. Closed-loop cooling technologies and air-cooled alternatives have emerged as sustainable solutions, reducing water consumption by up to 80% compared to once-through cooling systems.

The materials used in catalyst systems present both environmental challenges and opportunities. Rare earth elements and precious metals commonly employed in high-performance catalysts involve environmentally destructive mining practices and generate toxic waste. However, innovations in catalyst design using abundant elements and nano-structured materials have shown promise in reducing environmental impact while maintaining thermal efficiency.

Life cycle assessment studies indicate that optimized thermal management can reduce the overall environmental impact of nitrogen reduction processes by 25-40%. This includes considerations of raw material extraction, manufacturing, operation, and end-of-life disposal. Particularly noteworthy is the potential for reduced NOx emissions, which contribute to acid rain and photochemical smog formation.

Regulatory frameworks increasingly recognize these environmental dimensions, with standards like ISO 14001 and the European Union's Industrial Emissions Directive establishing benchmarks for environmental performance. Companies implementing advanced thermal management solutions not only achieve compliance but often realize cost savings through reduced resource consumption and waste generation.

The integration of renewable energy sources with nitrogen reduction processes represents perhaps the most transformative sustainability opportunity. Solar thermal systems and green hydrogen production pathways can provide the necessary thermal energy while dramatically reducing carbon emissions, potentially enabling carbon-neutral nitrogen fixation in the future.

Energy Efficiency Metrics and Performance Benchmarking

Establishing effective energy efficiency metrics and performance benchmarks is crucial for evaluating thermal management systems in nitrogen reduction catalysis. The primary metrics include Energy Utilization Ratio (EUR), which measures the proportion of input energy effectively utilized in catalyst operation versus energy lost as waste heat. Typical high-performing systems achieve EUR values of 0.65-0.75, with laboratory prototypes reaching up to 0.82 under controlled conditions.

Thermal Conversion Efficiency (TCE) serves as another vital metric, quantifying the catalyst system's ability to maintain optimal temperature ranges while minimizing energy input. Industry standards currently target TCE values above 70%, with leading commercial systems operating at 72-78% efficiency. Recent advancements in heat exchanger design have demonstrated potential improvements of 5-8% in TCE values.

Heat Recovery Factor (HRF) has emerged as an increasingly important benchmark, measuring the percentage of waste heat successfully recaptured and redirected within the system. Current industry averages hover around 45-55%, while advanced systems incorporating regenerative heat exchangers achieve HRF values of 60-68%. Laboratory-scale demonstrations have reached promising HRF values of up to 75%.

Performance benchmarking across different catalyst systems reveals significant variations in energy consumption per unit of nitrogen reduced. Top-tier commercial systems operate at 8.2-9.5 kWh per kilogram of reduced nitrogen, while less efficient systems may require 12-15 kWh/kg. These benchmarks provide essential reference points for evaluating new thermal management approaches.

Lifecycle energy assessment has become standard practice, examining total energy consumption across installation, operation, maintenance, and decommissioning phases. Best-in-class systems demonstrate lifecycle energy payback periods of 3.5-4.2 years, significantly outperforming previous generation technologies that required 5.7-7.0 years for energy payback.

Temperature stability metrics, including Maximum Temperature Deviation (MTD) and Temperature Recovery Time (TRT), offer quantitative measures of a system's ability to maintain optimal catalyst operating conditions. Industry-leading systems maintain MTD values below 3.5°C and TRT values under 45 seconds following significant process disturbances, ensuring consistent catalyst performance and longevity.

These metrics and benchmarks collectively provide a comprehensive framework for evaluating thermal management performance in nitrogen reduction catalyst systems, enabling meaningful comparisons between different technological approaches and identifying promising directions for future development.

Thermal Conversion Efficiency (TCE) serves as another vital metric, quantifying the catalyst system's ability to maintain optimal temperature ranges while minimizing energy input. Industry standards currently target TCE values above 70%, with leading commercial systems operating at 72-78% efficiency. Recent advancements in heat exchanger design have demonstrated potential improvements of 5-8% in TCE values.

Heat Recovery Factor (HRF) has emerged as an increasingly important benchmark, measuring the percentage of waste heat successfully recaptured and redirected within the system. Current industry averages hover around 45-55%, while advanced systems incorporating regenerative heat exchangers achieve HRF values of 60-68%. Laboratory-scale demonstrations have reached promising HRF values of up to 75%.

Performance benchmarking across different catalyst systems reveals significant variations in energy consumption per unit of nitrogen reduced. Top-tier commercial systems operate at 8.2-9.5 kWh per kilogram of reduced nitrogen, while less efficient systems may require 12-15 kWh/kg. These benchmarks provide essential reference points for evaluating new thermal management approaches.

Lifecycle energy assessment has become standard practice, examining total energy consumption across installation, operation, maintenance, and decommissioning phases. Best-in-class systems demonstrate lifecycle energy payback periods of 3.5-4.2 years, significantly outperforming previous generation technologies that required 5.7-7.0 years for energy payback.

Temperature stability metrics, including Maximum Temperature Deviation (MTD) and Temperature Recovery Time (TRT), offer quantitative measures of a system's ability to maintain optimal catalyst operating conditions. Industry-leading systems maintain MTD values below 3.5°C and TRT values under 45 seconds following significant process disturbances, ensuring consistent catalyst performance and longevity.

These metrics and benchmarks collectively provide a comprehensive framework for evaluating thermal management performance in nitrogen reduction catalyst systems, enabling meaningful comparisons between different technological approaches and identifying promising directions for future development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!