Exploring the Market Landscape of Nitrogen Reduction Catalyst

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitrogen Reduction Catalyst Background and Objectives

Nitrogen reduction catalysts represent a critical frontier in sustainable chemistry, with their development tracing back to the early 20th century when the Haber-Bosch process revolutionized ammonia synthesis. This industrial breakthrough enabled large-scale nitrogen fixation, fundamentally transforming agricultural productivity and supporting global population growth. However, the conventional process operates under harsh conditions of high temperature (400-500°C) and pressure (150-300 bar), consuming approximately 1-2% of global energy production and generating significant carbon emissions.

The evolution of nitrogen reduction catalyst technology has progressed through several distinct phases. Initial iron-based catalysts have given way to more sophisticated materials including ruthenium, molybdenum, and various transition metal complexes. Recent advances in nanotechnology and computational chemistry have accelerated catalyst design, enabling more precise control over reaction mechanisms and efficiency parameters.

Current technological trajectories focus on developing ambient-condition catalysts that can operate at room temperature and atmospheric pressure, potentially revolutionizing nitrogen fixation economics and environmental impact. Electrochemical and photocatalytic nitrogen reduction represent particularly promising approaches, offering pathways to directly harness renewable electricity or solar energy for ammonia production.

The primary objective in this field is to develop catalysts capable of efficiently converting atmospheric nitrogen to ammonia under mild conditions with high selectivity, overcoming the competing hydrogen evolution reaction that plagues many systems. Specific performance targets include achieving Faradaic efficiencies exceeding 60%, ammonia production rates above 10^-9 mol cm^-2 s^-1, and catalyst stability measured in thousands of operational hours.

Secondary objectives include reducing or eliminating dependence on precious metals, enhancing scalability for industrial implementation, and developing integrated systems that can operate using intermittent renewable energy sources. The ultimate goal remains creating distributed, sustainable ammonia production systems that can operate at point-of-use, potentially transforming agricultural practices and energy storage paradigms.

Recent breakthroughs in two-dimensional materials, metal-organic frameworks, and single-atom catalysts have opened new avenues for catalyst design. These emerging platforms offer unprecedented atomic-level control over active sites, potentially addressing longstanding challenges in nitrogen activation and selectivity. Computational approaches, including machine learning and high-throughput screening, are increasingly guiding experimental efforts, accelerating discovery cycles and enabling more rational design strategies.

The nitrogen reduction catalyst landscape sits at the intersection of multiple technological trends, including renewable energy integration, decentralized chemical production, and precision agriculture, positioning it as a key enabling technology for sustainable development in the coming decades.

The evolution of nitrogen reduction catalyst technology has progressed through several distinct phases. Initial iron-based catalysts have given way to more sophisticated materials including ruthenium, molybdenum, and various transition metal complexes. Recent advances in nanotechnology and computational chemistry have accelerated catalyst design, enabling more precise control over reaction mechanisms and efficiency parameters.

Current technological trajectories focus on developing ambient-condition catalysts that can operate at room temperature and atmospheric pressure, potentially revolutionizing nitrogen fixation economics and environmental impact. Electrochemical and photocatalytic nitrogen reduction represent particularly promising approaches, offering pathways to directly harness renewable electricity or solar energy for ammonia production.

The primary objective in this field is to develop catalysts capable of efficiently converting atmospheric nitrogen to ammonia under mild conditions with high selectivity, overcoming the competing hydrogen evolution reaction that plagues many systems. Specific performance targets include achieving Faradaic efficiencies exceeding 60%, ammonia production rates above 10^-9 mol cm^-2 s^-1, and catalyst stability measured in thousands of operational hours.

Secondary objectives include reducing or eliminating dependence on precious metals, enhancing scalability for industrial implementation, and developing integrated systems that can operate using intermittent renewable energy sources. The ultimate goal remains creating distributed, sustainable ammonia production systems that can operate at point-of-use, potentially transforming agricultural practices and energy storage paradigms.

Recent breakthroughs in two-dimensional materials, metal-organic frameworks, and single-atom catalysts have opened new avenues for catalyst design. These emerging platforms offer unprecedented atomic-level control over active sites, potentially addressing longstanding challenges in nitrogen activation and selectivity. Computational approaches, including machine learning and high-throughput screening, are increasingly guiding experimental efforts, accelerating discovery cycles and enabling more rational design strategies.

The nitrogen reduction catalyst landscape sits at the intersection of multiple technological trends, including renewable energy integration, decentralized chemical production, and precision agriculture, positioning it as a key enabling technology for sustainable development in the coming decades.

Market Demand Analysis for Nitrogen Reduction Technologies

The global market for nitrogen reduction catalysts is experiencing significant growth driven by multiple factors across various industries. The demand for efficient nitrogen reduction technologies stems primarily from three key sectors: agriculture, industrial manufacturing, and environmental management. In agriculture, the need for sustainable fertilizer production represents the largest market segment, with an estimated annual growth rate of 5.7% through 2030, as conventional Haber-Bosch processes face increasing scrutiny due to their high energy consumption and carbon footprint.

Industrial applications constitute the second largest market segment, particularly in chemical manufacturing where nitrogen compounds serve as essential precursors for pharmaceuticals, polymers, and specialty chemicals. This sector's demand is projected to expand steadily as manufacturing processes increasingly prioritize energy efficiency and sustainability metrics in their production protocols.

Environmental applications represent the fastest-growing segment, with increasing regulatory pressure to reduce nitrogen oxide emissions from industrial processes and transportation. The implementation of stringent emission standards across North America, Europe, and parts of Asia has created substantial market opportunities for catalytic technologies that can effectively convert harmful nitrogen compounds into benign forms.

Geographically, the Asia-Pacific region dominates the market share, accounting for approximately 40% of global demand. This is primarily attributed to China's massive agricultural sector and industrial base, coupled with India's growing fertilizer requirements. North America and Europe follow with substantial market shares, driven by stricter environmental regulations and investment in green technologies.

Market analysis indicates a clear shift toward sustainable nitrogen reduction technologies, with particular emphasis on ambient-condition catalysts that can operate at lower temperatures and pressures than traditional methods. Venture capital investment in this sector has more than doubled in the past five years, reflecting strong confidence in the commercial potential of next-generation catalytic solutions.

Customer requirements are evolving rapidly, with end-users increasingly prioritizing catalysts that demonstrate longer operational lifespans, reduced precious metal content, and compatibility with renewable energy sources. The agricultural sector specifically seeks solutions that can be deployed at smaller scales to enable distributed fertilizer production, potentially disrupting the centralized production model that has dominated for decades.

Market barriers include high initial research and development costs, technical challenges in achieving commercially viable conversion rates, and the entrenched infrastructure supporting conventional nitrogen processing technologies. Despite these challenges, the projected market value for advanced nitrogen reduction catalysts is expected to reach significant levels by 2028, driven by the convergence of environmental imperatives, energy security concerns, and technological innovation.

Industrial applications constitute the second largest market segment, particularly in chemical manufacturing where nitrogen compounds serve as essential precursors for pharmaceuticals, polymers, and specialty chemicals. This sector's demand is projected to expand steadily as manufacturing processes increasingly prioritize energy efficiency and sustainability metrics in their production protocols.

Environmental applications represent the fastest-growing segment, with increasing regulatory pressure to reduce nitrogen oxide emissions from industrial processes and transportation. The implementation of stringent emission standards across North America, Europe, and parts of Asia has created substantial market opportunities for catalytic technologies that can effectively convert harmful nitrogen compounds into benign forms.

Geographically, the Asia-Pacific region dominates the market share, accounting for approximately 40% of global demand. This is primarily attributed to China's massive agricultural sector and industrial base, coupled with India's growing fertilizer requirements. North America and Europe follow with substantial market shares, driven by stricter environmental regulations and investment in green technologies.

Market analysis indicates a clear shift toward sustainable nitrogen reduction technologies, with particular emphasis on ambient-condition catalysts that can operate at lower temperatures and pressures than traditional methods. Venture capital investment in this sector has more than doubled in the past five years, reflecting strong confidence in the commercial potential of next-generation catalytic solutions.

Customer requirements are evolving rapidly, with end-users increasingly prioritizing catalysts that demonstrate longer operational lifespans, reduced precious metal content, and compatibility with renewable energy sources. The agricultural sector specifically seeks solutions that can be deployed at smaller scales to enable distributed fertilizer production, potentially disrupting the centralized production model that has dominated for decades.

Market barriers include high initial research and development costs, technical challenges in achieving commercially viable conversion rates, and the entrenched infrastructure supporting conventional nitrogen processing technologies. Despite these challenges, the projected market value for advanced nitrogen reduction catalysts is expected to reach significant levels by 2028, driven by the convergence of environmental imperatives, energy security concerns, and technological innovation.

Current Status and Technical Challenges in Catalyst Development

The global landscape of nitrogen reduction catalyst development presents a complex picture of significant progress alongside persistent challenges. Currently, the field is dominated by traditional Haber-Bosch catalysts based on iron and ruthenium, which remain the industrial standard despite their high energy requirements. These conventional catalysts operate under harsh conditions of 400-500°C and 150-300 bar pressure, contributing to ammonia synthesis consuming approximately 1-2% of global energy production.

Recent advances have emerged in several promising directions. Transition metal-based catalysts, particularly those incorporating molybdenum, cobalt, and nickel, have shown potential for nitrogen reduction reaction (NRR) under milder conditions. Single-atom catalysts (SACs) represent another frontier, with atomically dispersed metal sites on various supports demonstrating enhanced selectivity and activity compared to their bulk counterparts.

Electrocatalytic nitrogen reduction has gained significant research attention, with carbon-based materials, metal oxides, and metal-organic frameworks showing promising performance metrics. However, these systems still struggle with low Faradaic efficiency, typically below 15%, and ammonia yield rates that remain insufficient for commercial viability.

Geographically, research leadership is distributed across North America, Europe, and East Asia, with China producing the highest volume of publications in this field over the past five years. Industrial development remains concentrated in regions with established chemical manufacturing infrastructure, though emerging economies are increasingly investing in alternative catalyst technologies.

The primary technical challenges hindering breakthrough advancements include catalyst stability under operating conditions, with many promising materials showing significant degradation after relatively short operational periods. Selectivity remains problematic, as competing hydrogen evolution reactions often dominate in aqueous systems, reducing efficiency for nitrogen conversion.

Scale-up issues present significant barriers to commercialization. Materials that perform well in laboratory settings often fail to maintain performance at industrial scales due to mass transfer limitations, heat management challenges, and inconsistent catalyst distribution in larger reactors.

Perhaps most critically, mechanistic understanding remains incomplete. The precise pathways of nitrogen activation and reduction on various catalyst surfaces are not fully elucidated, hampering rational design approaches. Computational modeling has advanced significantly but still struggles to accurately predict catalyst performance across different operating conditions.

These challenges collectively represent the frontier of nitrogen reduction catalyst development, where fundamental research must bridge significant gaps before next-generation catalysts can meaningfully compete with established industrial processes.

Recent advances have emerged in several promising directions. Transition metal-based catalysts, particularly those incorporating molybdenum, cobalt, and nickel, have shown potential for nitrogen reduction reaction (NRR) under milder conditions. Single-atom catalysts (SACs) represent another frontier, with atomically dispersed metal sites on various supports demonstrating enhanced selectivity and activity compared to their bulk counterparts.

Electrocatalytic nitrogen reduction has gained significant research attention, with carbon-based materials, metal oxides, and metal-organic frameworks showing promising performance metrics. However, these systems still struggle with low Faradaic efficiency, typically below 15%, and ammonia yield rates that remain insufficient for commercial viability.

Geographically, research leadership is distributed across North America, Europe, and East Asia, with China producing the highest volume of publications in this field over the past five years. Industrial development remains concentrated in regions with established chemical manufacturing infrastructure, though emerging economies are increasingly investing in alternative catalyst technologies.

The primary technical challenges hindering breakthrough advancements include catalyst stability under operating conditions, with many promising materials showing significant degradation after relatively short operational periods. Selectivity remains problematic, as competing hydrogen evolution reactions often dominate in aqueous systems, reducing efficiency for nitrogen conversion.

Scale-up issues present significant barriers to commercialization. Materials that perform well in laboratory settings often fail to maintain performance at industrial scales due to mass transfer limitations, heat management challenges, and inconsistent catalyst distribution in larger reactors.

Perhaps most critically, mechanistic understanding remains incomplete. The precise pathways of nitrogen activation and reduction on various catalyst surfaces are not fully elucidated, hampering rational design approaches. Computational modeling has advanced significantly but still struggles to accurately predict catalyst performance across different operating conditions.

These challenges collectively represent the frontier of nitrogen reduction catalyst development, where fundamental research must bridge significant gaps before next-generation catalysts can meaningfully compete with established industrial processes.

Current Technical Solutions for Nitrogen Reduction

01 Metal-based catalysts for nitrogen reduction

Various metal-based catalysts have been developed for nitrogen reduction processes. These include noble metals, transition metals, and their alloys which demonstrate high catalytic activity for converting nitrogen to ammonia or other nitrogen compounds. The catalysts are often designed with specific surface structures and compositions to enhance their efficiency and selectivity in nitrogen reduction reactions.- Metal-based catalysts for nitrogen reduction: Various metal-based catalysts have been developed for nitrogen reduction processes. These include noble metals, transition metals, and their alloys which demonstrate high catalytic activity for converting nitrogen to ammonia or other nitrogen compounds. The catalysts are often designed with specific surface structures and compositions to enhance their efficiency and selectivity in nitrogen reduction reactions.

- Supported catalysts for nitrogen reduction: Nitrogen reduction catalysts can be enhanced by dispersing active components on various support materials. These supports provide increased surface area, improved stability, and better dispersion of the active catalytic sites. Common support materials include carbon-based materials, metal oxides, and zeolites. The interaction between the active catalyst and the support material plays a crucial role in determining the overall catalytic performance.

- Electrochemical nitrogen reduction catalysts: Electrochemical approaches to nitrogen reduction utilize specialized catalysts that facilitate the conversion of nitrogen to ammonia under mild conditions using electrical energy. These catalysts are designed to operate at ambient temperature and pressure, offering an energy-efficient alternative to traditional nitrogen fixation methods. The catalysts often incorporate nanostructured materials with optimized electronic properties to enhance the electron transfer process during nitrogen reduction.

- Nitrogen oxide reduction catalysts for emissions control: Specialized catalysts have been developed for reducing nitrogen oxides (NOx) in exhaust gases from combustion processes. These catalysts are crucial components in emissions control systems for vehicles, power plants, and industrial facilities. They typically operate through selective catalytic reduction (SCR) mechanisms, converting harmful nitrogen oxides into harmless nitrogen gas and water. The catalysts are designed to maintain high activity across a wide temperature range and resist poisoning from other exhaust components.

- Novel catalyst compositions and preparation methods: Innovative approaches to catalyst composition and preparation methods have led to improved nitrogen reduction performance. These include novel synthesis techniques, the incorporation of promoters and modifiers, and the development of multi-component catalyst systems. Advanced preparation methods such as controlled precipitation, sol-gel techniques, and template-assisted synthesis allow for precise control over catalyst structure and properties, resulting in enhanced activity, selectivity, and stability for nitrogen reduction reactions.

02 Supported catalysts for nitrogen reduction

Catalysts supported on various materials show enhanced performance in nitrogen reduction reactions. Support materials such as alumina, silica, carbon, and zeolites provide high surface area and stability to the active catalytic components. These supported catalysts often exhibit improved dispersion of active sites, better thermal stability, and longer operational lifetimes compared to unsupported counterparts.Expand Specific Solutions03 Electrochemical catalysts for nitrogen reduction

Electrochemical catalysts facilitate nitrogen reduction through electrical energy input. These catalysts are designed to operate at ambient conditions, offering an environmentally friendly alternative to traditional high-temperature, high-pressure processes. The electrochemical approach enables selective nitrogen reduction with potentially higher energy efficiency and can be powered by renewable electricity sources.Expand Specific Solutions04 Catalyst formulations for selective catalytic reduction (SCR) of nitrogen oxides

Specialized catalyst formulations are used in selective catalytic reduction (SCR) systems to convert nitrogen oxides (NOx) in exhaust gases to nitrogen and water. These catalysts typically contain active components such as vanadium oxide, copper, iron, or zeolites. SCR catalysts are crucial for reducing harmful emissions from power plants, industrial facilities, and vehicles, helping to meet stringent environmental regulations.Expand Specific Solutions05 Novel catalyst preparation methods for nitrogen reduction

Innovative preparation methods have been developed to enhance catalyst performance for nitrogen reduction reactions. These include sol-gel processes, impregnation techniques, precipitation methods, and advanced nanofabrication approaches. The preparation methods significantly influence catalyst properties such as particle size, dispersion, surface area, and pore structure, which in turn affect catalytic activity, selectivity, and stability in nitrogen reduction applications.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The nitrogen reduction catalyst market is currently in a growth phase, characterized by increasing demand for sustainable ammonia production technologies. The market size is expanding due to rising interest in green ammonia for fertilizers, energy storage, and transportation fuels. Technologically, the field shows varying maturity levels, with established players like Topsoe A/S and Haldor Topsoe leading commercial applications, while companies such as Siemens AG, Toshiba Corp., and Volkswagen AG are advancing innovative approaches. Academic institutions including Kyushu University and Caltech are driving fundamental research, while industrial players like Umicore SA and Mitsui Mining & Smelting focus on catalyst optimization. Korean entities (KIST, KEPCO) are emerging as significant contributors, particularly in renewable energy integration applications.

Topsoe A/S

Technical Solution: Topsoe has developed advanced nitrogen reduction catalysts based on their proprietary TITAN technology platform. Their catalysts utilize a unique iron-based formulation with specific promoters that enhance ammonia synthesis at lower pressures and temperatures compared to conventional Haber-Bosch processes. The company's catalysts feature optimized porosity and surface area characteristics, allowing for improved mass transfer and reaction kinetics. Topsoe's S-300 and S-400 series catalysts incorporate specialized stabilizers that prevent sintering during operation, extending catalyst lifetime significantly. Their technology enables ammonia production with energy consumption reduced by approximately 20-30% compared to conventional systems, with demonstrated stability over 5+ years of continuous operation in industrial settings. Recent innovations include integration with renewable hydrogen sources for green ammonia production pathways.

Strengths: Industry-leading energy efficiency with proven industrial-scale implementation; exceptional catalyst longevity; compatibility with both conventional and renewable hydrogen sources. Weaknesses: Higher initial capital investment compared to conventional catalysts; requires specific reactor design modifications for optimal performance; sensitivity to certain catalyst poisons.

Heesung Catalysts Corp.

Technical Solution: Heesung Catalysts has pioneered a novel approach to nitrogen reduction catalysis through their NRC-X platform. Their technology employs a ruthenium-based catalyst system with proprietary nano-structuring techniques that create highly active sites for N2 activation. The catalyst architecture incorporates a hierarchical pore structure that optimizes reactant diffusion while maintaining mechanical stability. Heesung's catalysts operate at significantly lower temperatures (350-400°C) than traditional iron catalysts (450-500°C), achieving comparable conversion rates. Their manufacturing process utilizes a controlled precipitation method that ensures uniform dispersion of active metals and promoters throughout the catalyst support. The company has demonstrated ammonia synthesis rates approximately 1.5-2 times higher than conventional catalysts under identical conditions, with particular effectiveness in small to medium-scale applications where energy efficiency is critical.

Strengths: Superior performance at lower operating temperatures; excellent activity maintenance over time; adaptability to variable feedstock quality. Weaknesses: Higher raw material costs due to precious metal content; more complex manufacturing process increasing production costs; limited track record in very large-scale industrial applications.

Core Patents and Technical Literature Analysis

Catalyst for reduction of nitrogen oxides

PatentInactiveUS7691769B2

Innovation

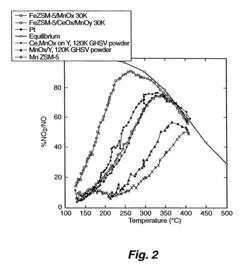

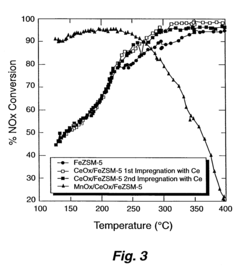

- A medium pore zeolite catalyst ion-exchanged with iron and impregnated with manganese and cerium, which acts as a hybrid catalyst for both SCR and NO oxidation, effective over a broad temperature range and high space velocities, minimizing N2O production and ammonia slip.

Catalyst comprising ferroelectric substrate for reduction of nitrogen oxides

PatentInactiveEP3292909A1

Innovation

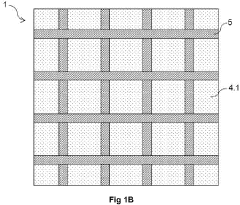

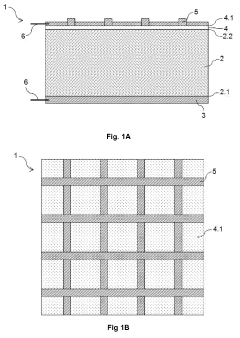

- A catalyst device comprising a ferroelectric material substrate with a conducting layer and a catalyst material layer, where the conducting material covers between 10% and 75% of the catalyst surface, allowing efficient polarization reversal and exposure to reactant molecules, facilitating the adsorption and desorption of NOx molecules at different polarization states.

Environmental Impact and Sustainability Considerations

The development and deployment of nitrogen reduction catalysts carry significant environmental implications that extend beyond their immediate technical applications. These catalysts, designed to facilitate the conversion of atmospheric nitrogen into ammonia and other nitrogen compounds, represent a critical intersection between industrial chemistry and environmental sustainability.

Nitrogen reduction catalysts offer substantial environmental benefits through their potential to revolutionize fertilizer production. The conventional Haber-Bosch process, while industrially successful, consumes approximately 1-2% of global energy production and generates considerable greenhouse gas emissions. Advanced catalysts operating at ambient conditions could dramatically reduce this carbon footprint, potentially decreasing CO2 emissions by millions of tons annually if widely implemented.

Water resource conservation represents another crucial environmental advantage. Traditional ammonia synthesis requires substantial water inputs for cooling and process operations. Newer catalyst technologies demonstrate significantly reduced water requirements, with some experimental systems showing up to 70% decreased water consumption compared to conventional methods. This aspect becomes increasingly important as water scarcity affects more regions globally.

However, environmental concerns persist regarding catalyst production and lifecycle impacts. Many high-performance catalysts incorporate rare earth elements or precious metals, raising questions about resource depletion and mining impacts. Life cycle assessments indicate that some catalysts with superior nitrogen fixation efficiency may actually present greater environmental burdens during production phases, necessitating holistic evaluation approaches.

Catalyst degradation and disposal present additional environmental challenges. Spent catalysts may contain potentially harmful compounds requiring specialized handling procedures. Research indicates approximately 20,000 tons of spent industrial catalysts enter waste streams annually worldwide, highlighting the importance of developing effective recycling protocols and designing catalysts with end-of-life considerations.

Regulatory frameworks increasingly recognize these environmental dimensions. Several jurisdictions have implemented sustainability metrics for industrial catalytic processes, with the European Union's chemical regulations specifically addressing catalyst lifecycle management. These frameworks are driving innovation toward greener catalyst designs that minimize environmental footprints while maintaining performance standards.

The sustainability profile of nitrogen reduction catalysts ultimately depends on achieving balance between performance efficiency and environmental impact. The most promising research directions focus on abundant, non-toxic materials that maintain high catalytic activity while minimizing resource-intensive production methods and maximizing recyclability potential.

Nitrogen reduction catalysts offer substantial environmental benefits through their potential to revolutionize fertilizer production. The conventional Haber-Bosch process, while industrially successful, consumes approximately 1-2% of global energy production and generates considerable greenhouse gas emissions. Advanced catalysts operating at ambient conditions could dramatically reduce this carbon footprint, potentially decreasing CO2 emissions by millions of tons annually if widely implemented.

Water resource conservation represents another crucial environmental advantage. Traditional ammonia synthesis requires substantial water inputs for cooling and process operations. Newer catalyst technologies demonstrate significantly reduced water requirements, with some experimental systems showing up to 70% decreased water consumption compared to conventional methods. This aspect becomes increasingly important as water scarcity affects more regions globally.

However, environmental concerns persist regarding catalyst production and lifecycle impacts. Many high-performance catalysts incorporate rare earth elements or precious metals, raising questions about resource depletion and mining impacts. Life cycle assessments indicate that some catalysts with superior nitrogen fixation efficiency may actually present greater environmental burdens during production phases, necessitating holistic evaluation approaches.

Catalyst degradation and disposal present additional environmental challenges. Spent catalysts may contain potentially harmful compounds requiring specialized handling procedures. Research indicates approximately 20,000 tons of spent industrial catalysts enter waste streams annually worldwide, highlighting the importance of developing effective recycling protocols and designing catalysts with end-of-life considerations.

Regulatory frameworks increasingly recognize these environmental dimensions. Several jurisdictions have implemented sustainability metrics for industrial catalytic processes, with the European Union's chemical regulations specifically addressing catalyst lifecycle management. These frameworks are driving innovation toward greener catalyst designs that minimize environmental footprints while maintaining performance standards.

The sustainability profile of nitrogen reduction catalysts ultimately depends on achieving balance between performance efficiency and environmental impact. The most promising research directions focus on abundant, non-toxic materials that maintain high catalytic activity while minimizing resource-intensive production methods and maximizing recyclability potential.

Regulatory Framework and Policy Influences

The regulatory landscape surrounding nitrogen reduction catalysts is experiencing significant evolution as governments worldwide recognize the dual importance of addressing climate change and ensuring food security. Environmental protection agencies in major economies have established increasingly stringent emissions standards for nitrogen oxides (NOx) from industrial processes and transportation, directly driving demand for more efficient catalytic technologies. The European Union's Green Deal and the United States' Clean Air Act amendments represent cornerstone policies that have accelerated research and commercialization of advanced nitrogen reduction catalysts.

Carbon pricing mechanisms and emissions trading schemes have emerged as market-based regulatory tools that indirectly benefit nitrogen reduction catalyst technologies. These frameworks create economic incentives for industries to adopt cleaner technologies, with nitrogen reduction catalysts offering a viable pathway to compliance. In agricultural applications, fertilizer management regulations in environmentally sensitive regions have stimulated interest in catalysts that can enable more efficient nitrogen fixation processes.

Research funding policies have significantly shaped the development trajectory of nitrogen reduction catalysts. Government grants specifically targeting sustainable chemistry and green catalysis have accelerated innovation in this field. Notable examples include the EU's Horizon Europe program and the U.S. Department of Energy's ARPA-E initiatives, which have allocated substantial resources to projects focused on energy-efficient nitrogen conversion technologies.

International agreements on climate change, particularly the Paris Agreement, have established frameworks that indirectly support the advancement of nitrogen reduction catalysts. As countries work toward their Nationally Determined Contributions (NDCs), technologies that reduce greenhouse gas emissions from industrial processes and agriculture have gained policy support. This has translated into tax incentives, subsidies, and preferential financing for companies developing and deploying advanced catalyst technologies.

Regulatory harmonization efforts across different jurisdictions have created more predictable market conditions for catalyst manufacturers. However, significant regional variations in regulatory approaches persist, creating complex compliance landscapes for multinational companies. Emerging economies, particularly China and India, have implemented increasingly stringent environmental regulations that are rapidly closing the gap with Western standards, expanding market opportunities for advanced nitrogen reduction catalysts in these high-growth regions.

Looking forward, policy trends indicate a continued strengthening of environmental regulations globally, with increasing focus on lifecycle assessment and circular economy principles. These developments suggest a favorable long-term regulatory environment for nitrogen reduction catalyst technologies that can demonstrate comprehensive environmental benefits beyond their immediate application.

Carbon pricing mechanisms and emissions trading schemes have emerged as market-based regulatory tools that indirectly benefit nitrogen reduction catalyst technologies. These frameworks create economic incentives for industries to adopt cleaner technologies, with nitrogen reduction catalysts offering a viable pathway to compliance. In agricultural applications, fertilizer management regulations in environmentally sensitive regions have stimulated interest in catalysts that can enable more efficient nitrogen fixation processes.

Research funding policies have significantly shaped the development trajectory of nitrogen reduction catalysts. Government grants specifically targeting sustainable chemistry and green catalysis have accelerated innovation in this field. Notable examples include the EU's Horizon Europe program and the U.S. Department of Energy's ARPA-E initiatives, which have allocated substantial resources to projects focused on energy-efficient nitrogen conversion technologies.

International agreements on climate change, particularly the Paris Agreement, have established frameworks that indirectly support the advancement of nitrogen reduction catalysts. As countries work toward their Nationally Determined Contributions (NDCs), technologies that reduce greenhouse gas emissions from industrial processes and agriculture have gained policy support. This has translated into tax incentives, subsidies, and preferential financing for companies developing and deploying advanced catalyst technologies.

Regulatory harmonization efforts across different jurisdictions have created more predictable market conditions for catalyst manufacturers. However, significant regional variations in regulatory approaches persist, creating complex compliance landscapes for multinational companies. Emerging economies, particularly China and India, have implemented increasingly stringent environmental regulations that are rapidly closing the gap with Western standards, expanding market opportunities for advanced nitrogen reduction catalysts in these high-growth regions.

Looking forward, policy trends indicate a continued strengthening of environmental regulations globally, with increasing focus on lifecycle assessment and circular economy principles. These developments suggest a favorable long-term regulatory environment for nitrogen reduction catalyst technologies that can demonstrate comprehensive environmental benefits beyond their immediate application.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!