Analysis of Biomass-Derived Solvents in Industrial Processes

OCT 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biomass Solvent Evolution and Research Objectives

Biomass-derived solvents have emerged as a promising alternative to conventional petroleum-based solvents, driven by increasing environmental concerns and the push towards sustainable industrial practices. The evolution of these solvents can be traced back to the early 20th century, but significant research momentum has only built up in the past two decades. Initially, simple alcohols like bioethanol dominated the biomass solvent landscape, but recent advancements have expanded the portfolio to include more complex molecules such as esters, ethers, and terpenes derived from various biomass feedstocks.

The technological trajectory has been shaped by breakthroughs in biomass conversion processes, including fermentation, catalytic conversion, and thermochemical treatments. These developments have enabled more efficient extraction of solvents from agricultural residues, forestry waste, and dedicated energy crops. Particularly noteworthy is the shift from first-generation biomass sources (food crops) to second-generation (non-food crops and waste) and third-generation (algae) feedstocks, addressing earlier concerns about competition with food production.

Current research trends indicate a growing interest in developing solvent systems with tailored properties for specific industrial applications. This includes solvents with enhanced selectivity, reduced toxicity, improved biodegradability, and optimized physical properties such as boiling point, viscosity, and polarity. The concept of "designer solvents" has gained traction, where molecular structures are engineered to achieve desired functionality while maintaining sustainability credentials.

The primary objective of biomass solvent research is to develop economically viable alternatives that can directly substitute petroleum-based solvents without requiring significant modifications to existing industrial processes. This includes addressing challenges related to production scale-up, purification techniques, and consistent quality control. Additionally, there is a focus on reducing the energy intensity of biomass solvent production to ensure a genuinely positive environmental impact across the entire lifecycle.

Another critical research goal is to establish comprehensive sustainability metrics for biomass-derived solvents, encompassing carbon footprint, water usage, land use impacts, and biodegradability. This holistic approach aims to prevent unintended consequences and ensure that biomass solvents deliver genuine environmental benefits compared to conventional alternatives. The development of standardized assessment methodologies is essential for enabling fair comparisons between different solvent options.

Looking forward, the field is moving toward integrated biorefinery concepts, where solvent production is incorporated into broader biomass valorization strategies. This approach maximizes resource efficiency by utilizing all components of the biomass feedstock, creating multiple value streams that improve overall economic viability. The ultimate technological goal is to establish closed-loop systems where solvents can be efficiently recovered and reused, minimizing waste and environmental impact throughout the industrial process lifecycle.

The technological trajectory has been shaped by breakthroughs in biomass conversion processes, including fermentation, catalytic conversion, and thermochemical treatments. These developments have enabled more efficient extraction of solvents from agricultural residues, forestry waste, and dedicated energy crops. Particularly noteworthy is the shift from first-generation biomass sources (food crops) to second-generation (non-food crops and waste) and third-generation (algae) feedstocks, addressing earlier concerns about competition with food production.

Current research trends indicate a growing interest in developing solvent systems with tailored properties for specific industrial applications. This includes solvents with enhanced selectivity, reduced toxicity, improved biodegradability, and optimized physical properties such as boiling point, viscosity, and polarity. The concept of "designer solvents" has gained traction, where molecular structures are engineered to achieve desired functionality while maintaining sustainability credentials.

The primary objective of biomass solvent research is to develop economically viable alternatives that can directly substitute petroleum-based solvents without requiring significant modifications to existing industrial processes. This includes addressing challenges related to production scale-up, purification techniques, and consistent quality control. Additionally, there is a focus on reducing the energy intensity of biomass solvent production to ensure a genuinely positive environmental impact across the entire lifecycle.

Another critical research goal is to establish comprehensive sustainability metrics for biomass-derived solvents, encompassing carbon footprint, water usage, land use impacts, and biodegradability. This holistic approach aims to prevent unintended consequences and ensure that biomass solvents deliver genuine environmental benefits compared to conventional alternatives. The development of standardized assessment methodologies is essential for enabling fair comparisons between different solvent options.

Looking forward, the field is moving toward integrated biorefinery concepts, where solvent production is incorporated into broader biomass valorization strategies. This approach maximizes resource efficiency by utilizing all components of the biomass feedstock, creating multiple value streams that improve overall economic viability. The ultimate technological goal is to establish closed-loop systems where solvents can be efficiently recovered and reused, minimizing waste and environmental impact throughout the industrial process lifecycle.

Market Analysis for Bio-based Industrial Solvents

The global market for bio-based industrial solvents has experienced significant growth in recent years, driven by increasing environmental concerns and regulatory pressures to reduce dependence on petroleum-derived chemicals. As of 2023, the market size for bio-based solvents reached approximately $9.3 billion, with a compound annual growth rate (CAGR) of 7.8% projected through 2030, outpacing the conventional solvent market's growth rate of 3.2%.

Key market drivers include stringent environmental regulations, particularly in Europe and North America, where policies like the European Green Deal and the U.S. Renewable Chemicals and Clean Manufacturing Act have created favorable conditions for bio-based alternatives. Consumer demand for sustainable products has also pushed manufacturers to adopt greener production processes, creating a pull effect in the market.

The industrial applications segment dominates the bio-based solvents market, accounting for approximately 62% of total consumption. Within this segment, paints and coatings represent the largest application area (28%), followed by pharmaceuticals (21%), adhesives (17%), and cleaning products (14%). The remaining 20% is distributed across various other industrial applications including printing inks, agrochemicals, and personal care products.

Regionally, Europe leads the market with a 38% share, followed by North America (29%), Asia-Pacific (24%), and the rest of the world (9%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 9.3% annually through 2030, primarily driven by rapid industrialization in China and India, coupled with increasing environmental awareness and regulatory developments.

From a competitive landscape perspective, the market features both established chemical companies diversifying into bio-based offerings and specialized bio-solvent producers. Major players include Cargill, Archer Daniels Midland, BASF, Corbion, and GF Biochemicals, collectively holding approximately 45% market share. The remaining market is fragmented among numerous smaller specialized producers and regional players.

Price sensitivity remains a significant market challenge, with bio-based solvents typically commanding a 15-30% premium over conventional alternatives. However, this price gap has been narrowing due to economies of scale, technological improvements, and increasing costs of petroleum-based products due to carbon pricing mechanisms in various regions.

Customer adoption patterns indicate that industries with direct consumer visibility or strict regulatory requirements, such as food packaging and pharmaceutical manufacturing, show higher willingness to transition to bio-based solvents despite price premiums. Industrial sectors with tighter margins and less consumer visibility demonstrate slower adoption rates, primarily driven by regulatory compliance rather than voluntary sustainability initiatives.

Key market drivers include stringent environmental regulations, particularly in Europe and North America, where policies like the European Green Deal and the U.S. Renewable Chemicals and Clean Manufacturing Act have created favorable conditions for bio-based alternatives. Consumer demand for sustainable products has also pushed manufacturers to adopt greener production processes, creating a pull effect in the market.

The industrial applications segment dominates the bio-based solvents market, accounting for approximately 62% of total consumption. Within this segment, paints and coatings represent the largest application area (28%), followed by pharmaceuticals (21%), adhesives (17%), and cleaning products (14%). The remaining 20% is distributed across various other industrial applications including printing inks, agrochemicals, and personal care products.

Regionally, Europe leads the market with a 38% share, followed by North America (29%), Asia-Pacific (24%), and the rest of the world (9%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 9.3% annually through 2030, primarily driven by rapid industrialization in China and India, coupled with increasing environmental awareness and regulatory developments.

From a competitive landscape perspective, the market features both established chemical companies diversifying into bio-based offerings and specialized bio-solvent producers. Major players include Cargill, Archer Daniels Midland, BASF, Corbion, and GF Biochemicals, collectively holding approximately 45% market share. The remaining market is fragmented among numerous smaller specialized producers and regional players.

Price sensitivity remains a significant market challenge, with bio-based solvents typically commanding a 15-30% premium over conventional alternatives. However, this price gap has been narrowing due to economies of scale, technological improvements, and increasing costs of petroleum-based products due to carbon pricing mechanisms in various regions.

Customer adoption patterns indicate that industries with direct consumer visibility or strict regulatory requirements, such as food packaging and pharmaceutical manufacturing, show higher willingness to transition to bio-based solvents despite price premiums. Industrial sectors with tighter margins and less consumer visibility demonstrate slower adoption rates, primarily driven by regulatory compliance rather than voluntary sustainability initiatives.

Current Status and Technical Barriers in Biomass Solvent Development

The global landscape of biomass-derived solvents has witnessed significant advancements in recent years, with research institutions and industrial players across North America, Europe, and Asia making substantial contributions. Currently, several biomass-derived solvents have reached commercial production scales, including ethanol, ethyl lactate, 2-methyltetrahydrofuran, and gamma-valerolactone. These solvents demonstrate promising performance characteristics comparable to their petroleum-based counterparts in various industrial applications.

Despite these achievements, the widespread adoption of biomass-derived solvents faces several critical technical barriers. The primary challenge remains the economic viability of production processes, with most bio-based solvents still costing 1.5-3 times more than conventional alternatives. This cost differential stems from complex extraction and purification processes required to achieve industrial-grade purity standards.

Feedstock variability presents another significant obstacle. Biomass sources exhibit seasonal and geographical variations in composition, making it difficult to establish consistent production protocols. This inconsistency affects product quality and process reliability, creating hesitation among potential industrial adopters who require standardized inputs for their manufacturing processes.

Scalability issues further complicate the transition from laboratory success to industrial implementation. Many promising biomass solvent technologies demonstrate excellent performance in controlled laboratory environments but encounter significant challenges during scale-up. Reactor design, heat transfer limitations, and catalyst deactivation under industrial conditions remain persistent problems that require innovative engineering solutions.

Energy intensity of production processes represents another major barrier. Current conversion technologies for biomass-derived solvents often require substantial energy inputs for pretreatment, reaction conditions, and separation processes. This high energy demand can undermine the environmental benefits these solvents aim to provide, creating a sustainability paradox that must be resolved through process optimization.

Catalyst performance and longevity constitute critical technical challenges. Many biomass conversion processes rely on specialized catalysts that suffer from rapid deactivation due to impurities in biomass feedstocks. Developing robust, regenerable catalysts capable of maintaining activity under industrial conditions remains an active area of research with significant technical hurdles.

Separation and purification technologies present additional barriers, particularly for complex biomass-derived mixtures. Conventional distillation approaches often prove energy-intensive and inefficient for bio-based systems with similar boiling points or tendency to form azeotropes. Advanced separation technologies such as membrane processes and molecular distillation show promise but require further development for industrial implementation.

Despite these achievements, the widespread adoption of biomass-derived solvents faces several critical technical barriers. The primary challenge remains the economic viability of production processes, with most bio-based solvents still costing 1.5-3 times more than conventional alternatives. This cost differential stems from complex extraction and purification processes required to achieve industrial-grade purity standards.

Feedstock variability presents another significant obstacle. Biomass sources exhibit seasonal and geographical variations in composition, making it difficult to establish consistent production protocols. This inconsistency affects product quality and process reliability, creating hesitation among potential industrial adopters who require standardized inputs for their manufacturing processes.

Scalability issues further complicate the transition from laboratory success to industrial implementation. Many promising biomass solvent technologies demonstrate excellent performance in controlled laboratory environments but encounter significant challenges during scale-up. Reactor design, heat transfer limitations, and catalyst deactivation under industrial conditions remain persistent problems that require innovative engineering solutions.

Energy intensity of production processes represents another major barrier. Current conversion technologies for biomass-derived solvents often require substantial energy inputs for pretreatment, reaction conditions, and separation processes. This high energy demand can undermine the environmental benefits these solvents aim to provide, creating a sustainability paradox that must be resolved through process optimization.

Catalyst performance and longevity constitute critical technical challenges. Many biomass conversion processes rely on specialized catalysts that suffer from rapid deactivation due to impurities in biomass feedstocks. Developing robust, regenerable catalysts capable of maintaining activity under industrial conditions remains an active area of research with significant technical hurdles.

Separation and purification technologies present additional barriers, particularly for complex biomass-derived mixtures. Conventional distillation approaches often prove energy-intensive and inefficient for bio-based systems with similar boiling points or tendency to form azeotropes. Advanced separation technologies such as membrane processes and molecular distillation show promise but require further development for industrial implementation.

Mainstream Biomass Solvent Production Technologies

01 Production of biomass-derived solvents from lignocellulosic materials

Lignocellulosic biomass can be processed to produce renewable solvents through various conversion methods. These processes typically involve the breakdown of cellulose, hemicellulose, and lignin components through hydrolysis, fermentation, or thermochemical treatments. The resulting solvents offer environmentally friendly alternatives to petroleum-based products while utilizing abundant and sustainable feedstocks. These methods can produce various green solvents including esters, alcohols, and other oxygenated compounds with applications across multiple industries.- Production of bio-based solvents from lignocellulosic biomass: Lignocellulosic biomass can be processed to produce environmentally friendly solvents through various conversion methods. These processes typically involve the breakdown of cellulose, hemicellulose, and lignin components to create sustainable solvent alternatives. The resulting bio-based solvents offer reduced environmental impact compared to petroleum-derived counterparts while maintaining similar performance characteristics for industrial applications.

- Fermentation processes for biomass-derived solvent production: Microbial fermentation represents a key pathway for converting biomass into valuable solvents. These bioprocesses utilize specialized microorganisms to transform biomass sugars into solvents such as ethanol, butanol, and acetone. Advanced fermentation techniques have been developed to improve yields, reduce inhibitory effects, and enhance the economic viability of biomass-derived solvent production through biological conversion routes.

- Chemical catalytic conversion of biomass to solvents: Chemical catalytic processes enable the transformation of biomass feedstocks into high-value solvents through controlled reactions. These methods typically employ heterogeneous catalysts to facilitate selective conversion of biomass components under specific temperature and pressure conditions. Catalytic approaches offer advantages in terms of reaction selectivity, process efficiency, and the ability to produce solvents with tailored properties for specific applications.

- Applications of biomass-derived solvents in industrial processes: Biomass-derived solvents find diverse applications across multiple industries as sustainable alternatives to conventional petroleum-based solvents. These bio-based alternatives are increasingly utilized in adhesives, coatings, cleaning products, pharmaceutical processing, and other industrial applications. Their adoption is driven by environmental regulations, corporate sustainability goals, and consumer demand for greener products, while offering comparable performance to traditional solvents.

- Novel biomass-derived solvent formulations and blends: Innovative formulations and blends of biomass-derived solvents have been developed to enhance performance characteristics for specific applications. These formulations often combine multiple bio-based components to achieve synergistic effects, improved functionality, and expanded application potential. Research in this area focuses on optimizing solvent properties such as solvency power, volatility, stability, and environmental profile to meet the requirements of various industrial processes.

02 Bio-based solvent formulations for industrial applications

Biomass-derived solvents can be formulated into specialized products for various industrial applications including cleaning, degreasing, coating, and extraction processes. These formulations often combine multiple bio-based components to achieve desired properties such as volatility, solvency power, and environmental profile. The formulations can be tailored to specific applications by adjusting the ratios of different biomass-derived components, potentially incorporating additives to enhance performance. These green solvent systems offer reduced toxicity and environmental impact compared to conventional petroleum-based alternatives.Expand Specific Solutions03 Conversion of biomass to furan-based solvents

Furan-based compounds derived from biomass represent an important class of renewable solvents. These include furfural, 5-hydroxymethylfurfural (HMF), and their derivatives, which can be produced from the dehydration of sugars present in biomass. The production processes typically involve catalytic conversion of carbohydrates under specific temperature and pressure conditions. These furan-based solvents offer unique properties including high solvency power and biodegradability, making them suitable replacements for traditional petroleum-derived solvents in various applications.Expand Specific Solutions04 Extraction and purification methods for biomass-derived solvents

Various extraction and purification techniques are employed to obtain high-quality biomass-derived solvents. These methods include distillation, membrane separation, chromatography, and liquid-liquid extraction. The purification processes are crucial for removing impurities that could affect solvent performance or stability. Advanced separation technologies can be used to isolate specific compounds from complex biomass-derived mixtures, allowing for the production of solvents with tailored properties for specific applications. These methods help improve yield and quality while reducing energy consumption in the production process.Expand Specific Solutions05 Glycerol-based solvents from biomass processing

Glycerol, a byproduct of biodiesel production from biomass, can be converted into valuable solvents through various chemical transformations. These include etherification, esterification, and other modifications to produce glycerol derivatives with enhanced solvent properties. The resulting glycerol-based solvents offer advantages such as low volatility, biodegradability, and low toxicity. These renewable solvents can replace traditional petroleum-based products in applications ranging from cleaning agents to reaction media for chemical synthesis, providing environmentally friendly alternatives derived from biomass resources.Expand Specific Solutions

Leading Companies and Research Institutions in Bio-Solvent Industry

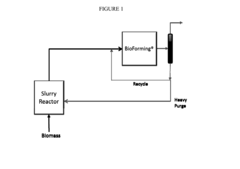

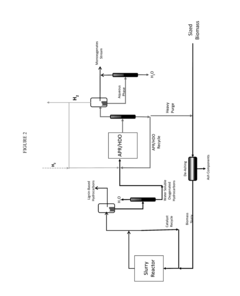

The biomass-derived solvents market is in a growth phase, with increasing industrial adoption driven by sustainability demands and regulatory pressures. The market is projected to expand significantly as industries seek greener alternatives to petroleum-based solvents. Technologically, the field shows varying maturity levels across applications. Leading players include Genomatica, which has commercialized bio-based processes for chemicals like butanediol and butylene glycol, and Virent with its BioForming platform technology. Established corporations like Procter & Gamble and Clariant are investing in this space, while research institutions such as EPFL and University of California contribute significant innovations. Companies like Furanix Technologies and Xyleco are developing specialized technologies to convert biomass into valuable industrial solvents, indicating a competitive landscape with both specialized startups and diversified chemical companies.

Furanix Technologies BV

Technical Solution: Furanix Technologies has developed an innovative platform for converting biomass-derived carbohydrates into 5-hydroxymethylfurfural (HMF) and its derivatives, particularly focusing on 2,5-furandicarboxylic acid (FDCA). Their patented technology utilizes specialized catalysts and reaction conditions to efficiently convert fructose and glucose into HMF in biphasic solvent systems. The process employs environmentally friendly solvents like methyl isobutyl ketone (MIBK) and water, with carefully controlled reaction parameters to maximize yields and minimize byproduct formation. Their continuous flow reactor design allows for industrial-scale production with reduced energy consumption compared to batch processes. Furanix has also developed purification techniques that achieve high-purity FDCA suitable for polyester production, particularly polyethylene furanoate (PEF), a sustainable alternative to petroleum-based PET.

Strengths: Highly selective conversion of carbohydrates to furan derivatives with minimal byproducts; scalable continuous process design; reduced environmental impact compared to petroleum-based alternatives. Weaknesses: Process still requires optimization for lignocellulosic feedstocks; energy requirements for solvent recovery and purification steps remain significant; economic viability depends on fluctuating biomass feedstock prices.

Virent, Inc.

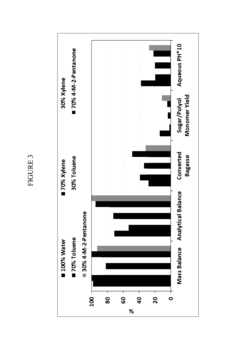

Technical Solution: Virent has pioneered the BioForming® process, a comprehensive technology platform for converting plant-based sugars into a spectrum of hydrocarbon molecules identical to those produced from petroleum. Their approach centers on aqueous phase reforming (APR) using proprietary catalysts that enable the conversion of biomass-derived oxygenates in water-based solutions. The process begins with the dissolution of biomass-derived sugars in water, followed by catalytic reactions that reduce oxygen content while preserving carbon chains. A key innovation is their solvent system that combines water with specific organic co-solvents to enhance reaction efficiency and product separation. The technology produces drop-in biofuels and biochemicals without the oxygen content typical of traditional biofuels, resulting in products with higher energy density and complete compatibility with existing infrastructure. Virent's process can utilize various biomass feedstocks including corn starch, sugarcane, and cellulosic materials.

Strengths: Production of true "drop-in" hydrocarbons chemically identical to petroleum-derived counterparts; flexible feedstock capabilities; integration potential with existing petroleum infrastructure; products with superior properties to traditional biofuels. Weaknesses: Complex multi-stage process requiring precise control; catalyst cost and longevity challenges; water management and purification requirements add operational complexity.

Key Patents and Scientific Breakthroughs in Biomass Solvent Research

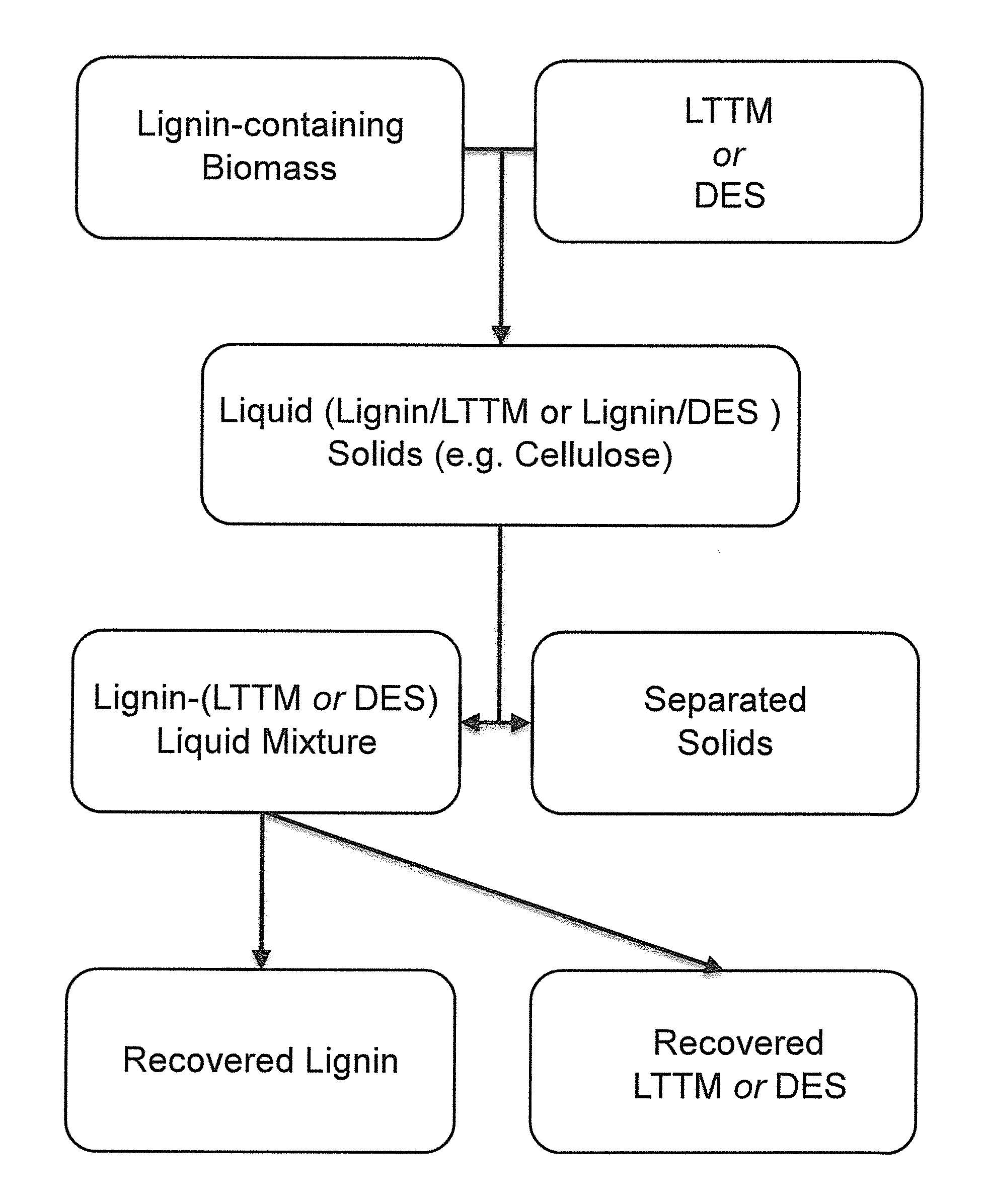

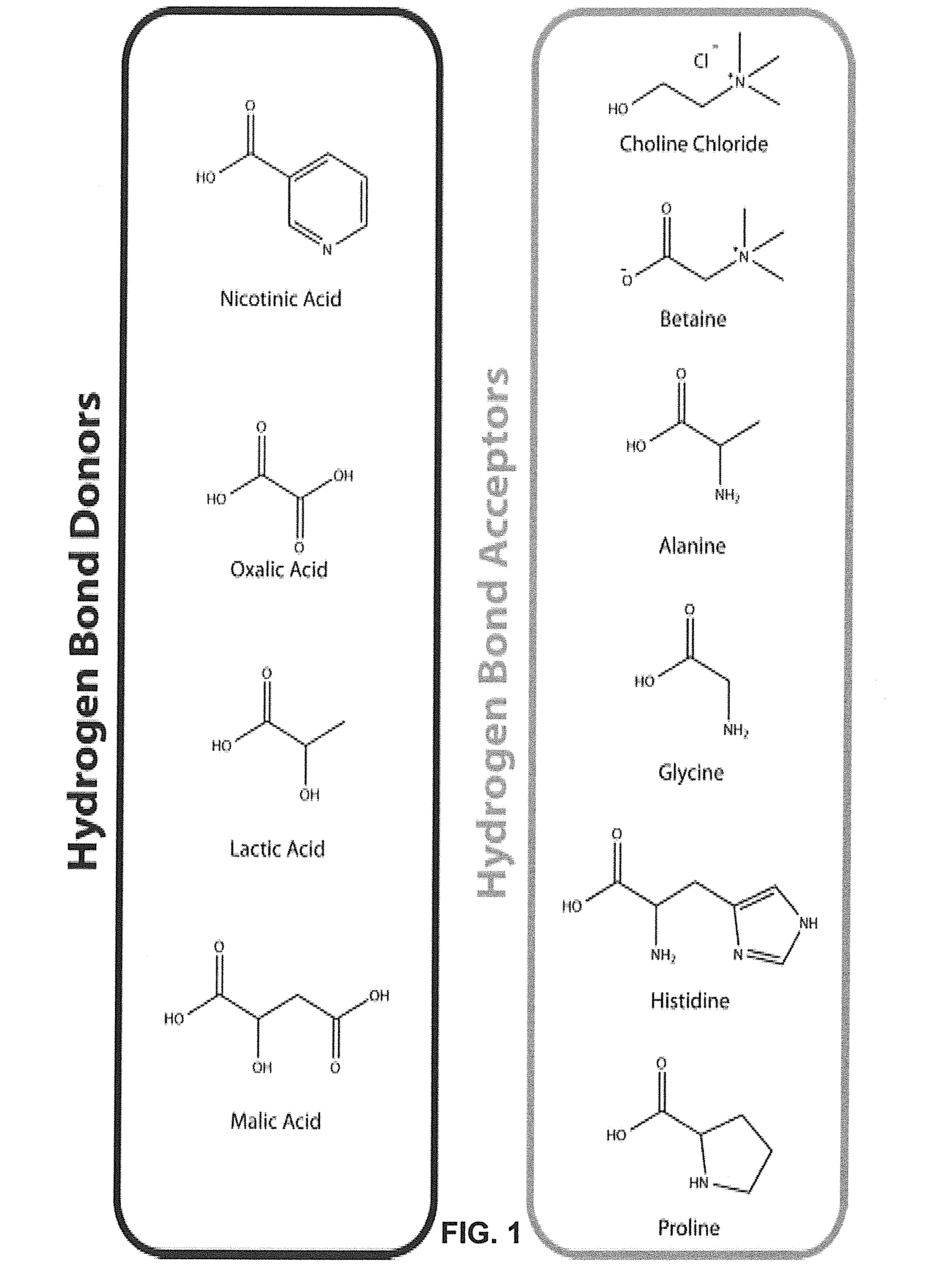

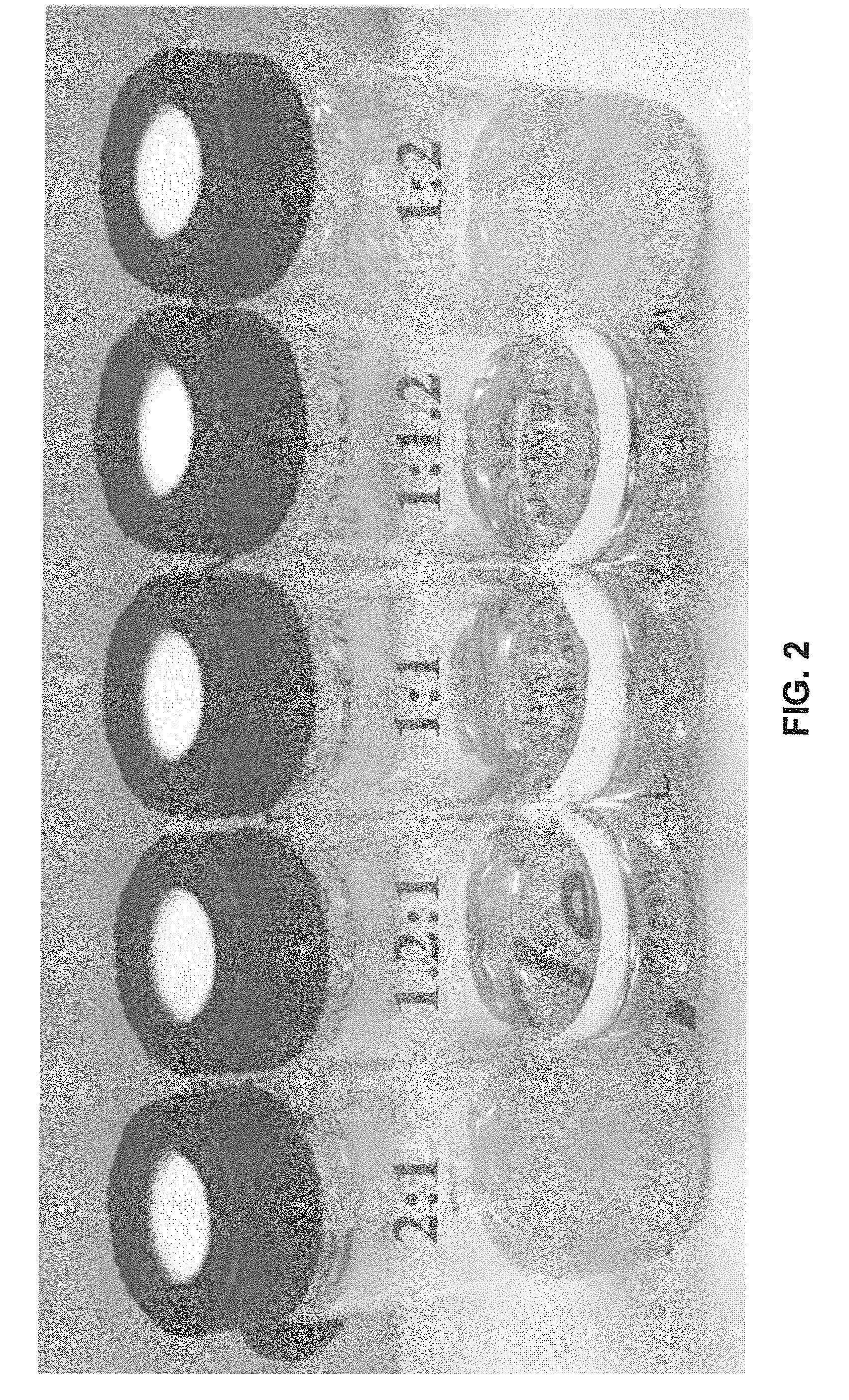

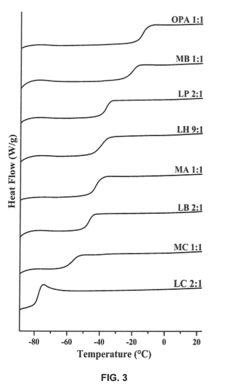

Pretreatment of Lignocellulosic Biomass and Recovery of Substituents using Natural Deep Eutectic Solvents/Compound Mixtures with Low Transition Temperatures

PatentInactiveUS20150094459A1

Innovation

- Development of low transition temperature mixtures (LTTMs) composed of renewable components, which selectively dissolve lignin from lignin-containing biomass at mild conditions, allowing for energy-efficient separation of lignin from cellulose without degradation, and enable recovery of high-quality lignin and cellulose.

Solvolysis of biomass using solvent from a bioreforming process

PatentActiveUS20170058370A1

Innovation

- A method involving catalytically reacting water and a water-soluble oxygenated hydrocarbon with hydrogen in the presence of a deoxygenation catalyst to produce a biomass processing solvent, which is then used to deconstruct biomass at specific temperatures and pressures to produce a biomass hydrolysate containing soluble derivatives and carbohydrates.

Environmental Impact Assessment of Bio-based Solvents

The environmental impact assessment of bio-based solvents reveals significant advantages over conventional petroleum-derived alternatives. Life cycle analyses consistently demonstrate that biomass-derived solvents generally produce lower greenhouse gas emissions, with reductions ranging from 30-80% depending on feedstock source and production methods. This substantial carbon footprint reduction stems primarily from the renewable nature of biomass feedstocks, which capture carbon during growth phases, creating a more balanced carbon cycle compared to fossil-based alternatives.

Water consumption patterns vary considerably among different bio-based solvent production pathways. While some biomass feedstocks require intensive irrigation during cultivation, potentially increasing water footprint, advanced production technologies have demonstrated up to 40% reduction in process water requirements compared to conventional solvent manufacturing. Particularly promising are processes utilizing agricultural waste streams and forestry residues, which minimize additional land and water resource demands.

Biodegradability represents another critical environmental advantage of bio-based solvents. Studies indicate that many biomass-derived solvents degrade 3-5 times faster in natural environments than their petroleum counterparts, significantly reducing persistence in ecosystems following accidental release or disposal. This characteristic substantially mitigates potential aquatic toxicity concerns, with ecotoxicological assessments showing reduced impact on aquatic organisms for most bio-based alternatives.

Land use considerations present complex tradeoffs that require careful assessment. First-generation bio-based solvents derived from food crops raise concerns about competition with food production and potential indirect land use changes. However, second and third-generation approaches utilizing lignocellulosic biomass, agricultural residues, and dedicated energy crops grown on marginal lands offer pathways to minimize these impacts while maintaining environmental benefits.

Energy efficiency metrics across production lifecycles indicate that many bio-based solvent manufacturing processes consume 15-25% less total energy than conventional routes. This advantage is further amplified when renewable energy sources are integrated into production facilities. Several commercial-scale operations have successfully implemented biomass-powered cogeneration systems, creating partially self-sustaining production ecosystems that further enhance environmental performance.

Waste generation profiles show mixed results, with some bio-based processes generating higher volumes of biological waste streams but significantly lower quantities of hazardous chemical waste requiring specialized disposal. Advanced biorefinery concepts implementing circular economy principles have demonstrated potential to valorize these biological side streams into additional value-added products, potentially transforming waste challenges into economic opportunities while further improving overall environmental performance.

Water consumption patterns vary considerably among different bio-based solvent production pathways. While some biomass feedstocks require intensive irrigation during cultivation, potentially increasing water footprint, advanced production technologies have demonstrated up to 40% reduction in process water requirements compared to conventional solvent manufacturing. Particularly promising are processes utilizing agricultural waste streams and forestry residues, which minimize additional land and water resource demands.

Biodegradability represents another critical environmental advantage of bio-based solvents. Studies indicate that many biomass-derived solvents degrade 3-5 times faster in natural environments than their petroleum counterparts, significantly reducing persistence in ecosystems following accidental release or disposal. This characteristic substantially mitigates potential aquatic toxicity concerns, with ecotoxicological assessments showing reduced impact on aquatic organisms for most bio-based alternatives.

Land use considerations present complex tradeoffs that require careful assessment. First-generation bio-based solvents derived from food crops raise concerns about competition with food production and potential indirect land use changes. However, second and third-generation approaches utilizing lignocellulosic biomass, agricultural residues, and dedicated energy crops grown on marginal lands offer pathways to minimize these impacts while maintaining environmental benefits.

Energy efficiency metrics across production lifecycles indicate that many bio-based solvent manufacturing processes consume 15-25% less total energy than conventional routes. This advantage is further amplified when renewable energy sources are integrated into production facilities. Several commercial-scale operations have successfully implemented biomass-powered cogeneration systems, creating partially self-sustaining production ecosystems that further enhance environmental performance.

Waste generation profiles show mixed results, with some bio-based processes generating higher volumes of biological waste streams but significantly lower quantities of hazardous chemical waste requiring specialized disposal. Advanced biorefinery concepts implementing circular economy principles have demonstrated potential to valorize these biological side streams into additional value-added products, potentially transforming waste challenges into economic opportunities while further improving overall environmental performance.

Regulatory Framework and Green Chemistry Standards

The regulatory landscape governing biomass-derived solvents is increasingly complex and dynamic, reflecting growing global emphasis on sustainable industrial practices. At the international level, frameworks such as the United Nations Framework Convention on Climate Change (UNFCCC) and the Paris Agreement establish overarching commitments to reduce greenhouse gas emissions, indirectly promoting the adoption of bio-based alternatives to petrochemical solvents. These agreements create market incentives through carbon pricing mechanisms that favor renewable feedstocks.

In the European Union, the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation provides comprehensive oversight of chemical substances, including solvents. Biomass-derived solvents benefit from REACH's tiered approach, which often grants preferential treatment to substances of natural origin. The EU's Renewable Energy Directive (RED II) further supports bio-based solvents by establishing sustainability criteria and certification schemes that validate their environmental credentials.

The United States regulatory framework operates primarily through the Toxic Substances Control Act (TSCA), administered by the Environmental Protection Agency. Recent amendments to TSCA have strengthened provisions for evaluating new chemicals, with expedited review processes available for substances deemed environmentally preferable. The USDA's BioPreferred program provides certification and federal procurement preferences for bio-based products, including industrial solvents.

Green Chemistry Standards have emerged as critical benchmarks for evaluating biomass-derived solvents. The 12 Principles of Green Chemistry, developed by Anastas and Warner, serve as foundational guidelines emphasizing waste prevention, atom economy, and safer solvent design. Industry-specific standards such as ASTM D6866 provide methods for determining the biobased content of solvents through radiocarbon analysis, enabling verification of renewable content claims.

Third-party certification systems have gained prominence in validating environmental claims. Programs like Cradle to Cradle Certified™ and the Environmental Working Group's verification process assess multiple sustainability attributes of biomass-derived solvents, including toxicity profiles, biodegradability, and lifecycle impacts. These certifications provide market differentiation and consumer confidence in an increasingly eco-conscious marketplace.

Emerging regulatory trends indicate a shift toward lifecycle-based approaches that consider environmental impacts across the entire value chain of biomass-derived solvents. This holistic perspective encompasses feedstock sustainability, processing efficiency, use-phase performance, and end-of-life management. As regulatory frameworks continue to evolve, they increasingly incorporate circular economy principles that favor renewable, biodegradable solvents capable of being reintegrated into biological or technical cycles.

In the European Union, the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation provides comprehensive oversight of chemical substances, including solvents. Biomass-derived solvents benefit from REACH's tiered approach, which often grants preferential treatment to substances of natural origin. The EU's Renewable Energy Directive (RED II) further supports bio-based solvents by establishing sustainability criteria and certification schemes that validate their environmental credentials.

The United States regulatory framework operates primarily through the Toxic Substances Control Act (TSCA), administered by the Environmental Protection Agency. Recent amendments to TSCA have strengthened provisions for evaluating new chemicals, with expedited review processes available for substances deemed environmentally preferable. The USDA's BioPreferred program provides certification and federal procurement preferences for bio-based products, including industrial solvents.

Green Chemistry Standards have emerged as critical benchmarks for evaluating biomass-derived solvents. The 12 Principles of Green Chemistry, developed by Anastas and Warner, serve as foundational guidelines emphasizing waste prevention, atom economy, and safer solvent design. Industry-specific standards such as ASTM D6866 provide methods for determining the biobased content of solvents through radiocarbon analysis, enabling verification of renewable content claims.

Third-party certification systems have gained prominence in validating environmental claims. Programs like Cradle to Cradle Certified™ and the Environmental Working Group's verification process assess multiple sustainability attributes of biomass-derived solvents, including toxicity profiles, biodegradability, and lifecycle impacts. These certifications provide market differentiation and consumer confidence in an increasingly eco-conscious marketplace.

Emerging regulatory trends indicate a shift toward lifecycle-based approaches that consider environmental impacts across the entire value chain of biomass-derived solvents. This holistic perspective encompasses feedstock sustainability, processing efficiency, use-phase performance, and end-of-life management. As regulatory frameworks continue to evolve, they increasingly incorporate circular economy principles that favor renewable, biodegradable solvents capable of being reintegrated into biological or technical cycles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!