Biomass-Derived Solvents and Their Effect on Catalytic Conversions

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biomass Solvents Background and Research Objectives

Biomass-derived solvents have emerged as a promising alternative to conventional petroleum-based solvents, representing a significant shift towards sustainable chemistry practices. The evolution of these bio-solvents can be traced back to early 21st century research initiatives focused on developing renewable alternatives to toxic industrial solvents. Over the past two decades, the field has witnessed remarkable growth, transitioning from conceptual research to commercial applications across various industries.

The technological trajectory of biomass-derived solvents has been characterized by continuous innovation in extraction methods, purification techniques, and molecular modification approaches. Initial developments centered on simple alcohols and esters derived from plant oils, while recent advancements have expanded to include more complex structures with tailored properties for specific applications. This progression reflects the industry's growing sophistication in biomass conversion technologies.

Current research trends indicate a convergence of green chemistry principles with industrial practicality, focusing on solvents that not only offer environmental benefits but also enhance process efficiency. Particularly noteworthy is the emerging understanding of how these bio-solvents interact with catalytic systems, potentially offering performance advantages beyond mere environmental compliance.

The primary technical objectives of this research are multifaceted. First, we aim to comprehensively characterize the physicochemical properties of leading biomass-derived solvents, with particular emphasis on polarity, hydrogen-bonding capacity, and thermal stability. Second, we seek to elucidate the fundamental mechanisms by which these solvents influence catalytic reactions, including effects on reaction kinetics, selectivity, and catalyst stability.

Additionally, this investigation will explore the structure-function relationships that determine solvent performance in catalytic systems, with the goal of establishing predictive models for rational solvent design. The research will also address practical considerations such as scalability, economic viability, and integration with existing industrial processes.

Beyond technical parameters, this research aims to quantify the environmental impact of biomass-derived solvents through comprehensive life cycle assessments, comparing their overall sustainability profiles with conventional alternatives. This holistic approach will provide valuable insights for industries seeking to reduce their environmental footprint while maintaining or improving process performance.

The ultimate goal is to develop a decision framework that guides the selection and implementation of biomass-derived solvents for specific catalytic applications, thereby accelerating their adoption across the chemical manufacturing sector and contributing to the broader transition toward sustainable industrial practices.

The technological trajectory of biomass-derived solvents has been characterized by continuous innovation in extraction methods, purification techniques, and molecular modification approaches. Initial developments centered on simple alcohols and esters derived from plant oils, while recent advancements have expanded to include more complex structures with tailored properties for specific applications. This progression reflects the industry's growing sophistication in biomass conversion technologies.

Current research trends indicate a convergence of green chemistry principles with industrial practicality, focusing on solvents that not only offer environmental benefits but also enhance process efficiency. Particularly noteworthy is the emerging understanding of how these bio-solvents interact with catalytic systems, potentially offering performance advantages beyond mere environmental compliance.

The primary technical objectives of this research are multifaceted. First, we aim to comprehensively characterize the physicochemical properties of leading biomass-derived solvents, with particular emphasis on polarity, hydrogen-bonding capacity, and thermal stability. Second, we seek to elucidate the fundamental mechanisms by which these solvents influence catalytic reactions, including effects on reaction kinetics, selectivity, and catalyst stability.

Additionally, this investigation will explore the structure-function relationships that determine solvent performance in catalytic systems, with the goal of establishing predictive models for rational solvent design. The research will also address practical considerations such as scalability, economic viability, and integration with existing industrial processes.

Beyond technical parameters, this research aims to quantify the environmental impact of biomass-derived solvents through comprehensive life cycle assessments, comparing their overall sustainability profiles with conventional alternatives. This holistic approach will provide valuable insights for industries seeking to reduce their environmental footprint while maintaining or improving process performance.

The ultimate goal is to develop a decision framework that guides the selection and implementation of biomass-derived solvents for specific catalytic applications, thereby accelerating their adoption across the chemical manufacturing sector and contributing to the broader transition toward sustainable industrial practices.

Market Analysis for Sustainable Catalytic Processes

The global market for sustainable catalytic processes is experiencing significant growth, driven by increasing environmental regulations, corporate sustainability commitments, and consumer demand for eco-friendly products. The market size for green chemistry, which encompasses sustainable catalytic processes, was valued at approximately $67 billion in 2020 and is projected to reach $135 billion by 2027, growing at a CAGR of 10.5% during the forecast period.

Biomass-derived solvents represent a rapidly expanding segment within this market, with an estimated value of $8 billion in 2021. These bio-based solvents are increasingly replacing conventional petroleum-based solvents in various industrial applications, particularly in catalytic conversion processes. The market penetration of biomass-derived solvents in catalytic applications is currently around 15% but is expected to reach 30% by 2030.

Key market drivers include stringent environmental regulations limiting the use of toxic solvents, particularly in Europe and North America. The European Union's REACH regulation and similar frameworks worldwide are accelerating the transition toward greener solvent alternatives. Additionally, major chemical companies are setting ambitious sustainability targets, with many pledging to increase their bio-based raw material usage to 25-50% by 2030.

The pharmaceutical industry represents the largest end-user segment for sustainable catalytic processes utilizing biomass-derived solvents, accounting for approximately 35% of the market share. This is followed by fine chemicals (25%), agrochemicals (20%), and food processing (15%). The remaining 5% is distributed across various other industries.

Regional analysis reveals that Europe leads the market with a 40% share, followed by North America (30%), Asia-Pacific (20%), and the rest of the world (10%). However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, primarily due to rapid industrialization in China and India coupled with increasing environmental awareness.

From a competitive landscape perspective, the market is moderately fragmented with several key players. Major chemical companies like BASF, Solvay, and DuPont have established dedicated divisions for sustainable chemistry solutions. Meanwhile, specialized companies focusing exclusively on bio-based solvents and catalytic processes, such as GFBiochemicals and Circa Group, are gaining significant market traction through technological innovation.

Customer willingness to pay premiums for sustainable alternatives varies significantly across industries. While pharmaceutical and food industries demonstrate readiness to pay 15-20% premiums for green alternatives, price sensitivity remains higher in bulk chemical applications, where premium tolerance rarely exceeds 5-10%.

Biomass-derived solvents represent a rapidly expanding segment within this market, with an estimated value of $8 billion in 2021. These bio-based solvents are increasingly replacing conventional petroleum-based solvents in various industrial applications, particularly in catalytic conversion processes. The market penetration of biomass-derived solvents in catalytic applications is currently around 15% but is expected to reach 30% by 2030.

Key market drivers include stringent environmental regulations limiting the use of toxic solvents, particularly in Europe and North America. The European Union's REACH regulation and similar frameworks worldwide are accelerating the transition toward greener solvent alternatives. Additionally, major chemical companies are setting ambitious sustainability targets, with many pledging to increase their bio-based raw material usage to 25-50% by 2030.

The pharmaceutical industry represents the largest end-user segment for sustainable catalytic processes utilizing biomass-derived solvents, accounting for approximately 35% of the market share. This is followed by fine chemicals (25%), agrochemicals (20%), and food processing (15%). The remaining 5% is distributed across various other industries.

Regional analysis reveals that Europe leads the market with a 40% share, followed by North America (30%), Asia-Pacific (20%), and the rest of the world (10%). However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, primarily due to rapid industrialization in China and India coupled with increasing environmental awareness.

From a competitive landscape perspective, the market is moderately fragmented with several key players. Major chemical companies like BASF, Solvay, and DuPont have established dedicated divisions for sustainable chemistry solutions. Meanwhile, specialized companies focusing exclusively on bio-based solvents and catalytic processes, such as GFBiochemicals and Circa Group, are gaining significant market traction through technological innovation.

Customer willingness to pay premiums for sustainable alternatives varies significantly across industries. While pharmaceutical and food industries demonstrate readiness to pay 15-20% premiums for green alternatives, price sensitivity remains higher in bulk chemical applications, where premium tolerance rarely exceeds 5-10%.

Current Challenges in Biomass-Derived Solvent Technology

Despite significant advancements in biomass-derived solvent technology, several critical challenges continue to impede widespread industrial adoption and optimal catalytic performance. Solvent purity remains a primary concern, as biomass-derived solvents often contain trace impurities that can poison catalysts or interfere with reaction mechanisms. These impurities, including sulfur compounds, nitrogen-containing molecules, and residual water, can significantly reduce catalyst lifetime and selectivity in conversion processes.

Thermal and chemical stability presents another substantial challenge. Many biomass-derived solvents exhibit limited stability under the harsh conditions required for catalytic conversions, particularly at elevated temperatures or in strongly acidic/basic environments. This instability can lead to solvent degradation, formation of unwanted byproducts, and reduced efficiency of catalytic systems.

Scalability and production costs continue to hinder commercial viability. Current production methods for many biomass-derived solvents remain economically unfavorable compared to petroleum-based alternatives. The complex and energy-intensive processes required for extraction, purification, and modification of these solvents contribute to higher production costs, making market penetration difficult despite environmental benefits.

Standardization issues further complicate industrial implementation. Unlike petroleum-derived solvents with well-established specifications, biomass-derived solvents often exhibit batch-to-batch variability depending on feedstock source, growing conditions, and processing methods. This inconsistency creates challenges for process design and quality control in catalytic applications.

Solvent recovery and recycling efficiency represents a significant technical hurdle. Many catalytic processes require solvent separation and recovery steps that are more complex with biomass-derived solvents due to their higher boiling points, tendency to form azeotropes, or susceptibility to degradation during recovery operations.

Compatibility with existing infrastructure poses practical limitations. Industrial facilities designed for conventional solvents may require substantial modifications to accommodate the different physical and chemical properties of biomass-derived alternatives, including changes to materials of construction, sealing systems, and process control parameters.

Performance gaps compared to conventional solvents remain problematic in certain applications. Some biomass-derived solvents exhibit lower solvation power for specific substrates, different mass transfer properties, or unfavorable interaction with catalyst supports, resulting in reduced reaction rates or selectivity in catalytic conversions.

Thermal and chemical stability presents another substantial challenge. Many biomass-derived solvents exhibit limited stability under the harsh conditions required for catalytic conversions, particularly at elevated temperatures or in strongly acidic/basic environments. This instability can lead to solvent degradation, formation of unwanted byproducts, and reduced efficiency of catalytic systems.

Scalability and production costs continue to hinder commercial viability. Current production methods for many biomass-derived solvents remain economically unfavorable compared to petroleum-based alternatives. The complex and energy-intensive processes required for extraction, purification, and modification of these solvents contribute to higher production costs, making market penetration difficult despite environmental benefits.

Standardization issues further complicate industrial implementation. Unlike petroleum-derived solvents with well-established specifications, biomass-derived solvents often exhibit batch-to-batch variability depending on feedstock source, growing conditions, and processing methods. This inconsistency creates challenges for process design and quality control in catalytic applications.

Solvent recovery and recycling efficiency represents a significant technical hurdle. Many catalytic processes require solvent separation and recovery steps that are more complex with biomass-derived solvents due to their higher boiling points, tendency to form azeotropes, or susceptibility to degradation during recovery operations.

Compatibility with existing infrastructure poses practical limitations. Industrial facilities designed for conventional solvents may require substantial modifications to accommodate the different physical and chemical properties of biomass-derived alternatives, including changes to materials of construction, sealing systems, and process control parameters.

Performance gaps compared to conventional solvents remain problematic in certain applications. Some biomass-derived solvents exhibit lower solvation power for specific substrates, different mass transfer properties, or unfavorable interaction with catalyst supports, resulting in reduced reaction rates or selectivity in catalytic conversions.

Existing Biomass Solvent Applications in Catalysis

01 Catalytic conversion of biomass to renewable solvents

Various catalytic processes can be employed to convert biomass feedstocks into renewable solvents. These processes typically involve the transformation of cellulose, hemicellulose, and lignin components into valuable solvent products. Catalysts such as metal oxides, supported metals, and acid catalysts facilitate these conversions under specific reaction conditions. The resulting bio-based solvents can serve as sustainable alternatives to petroleum-derived solvents in various industrial applications.- Catalytic conversion of biomass to renewable solvents: Various catalytic processes can be employed to convert biomass feedstocks into renewable solvents. These processes typically involve the transformation of cellulose, hemicellulose, and lignin components into valuable solvent products. Catalysts such as metal oxides, supported metals, and acid catalysts facilitate these conversions under specific reaction conditions, enabling the production of bio-based solvents with properties comparable to petroleum-derived alternatives.

- Production of furan-based solvents from biomass: Furan-based compounds, particularly furfural and 5-hydroxymethylfurfural (HMF), can be produced from biomass through catalytic dehydration of sugars. These furan derivatives serve as platform chemicals for the synthesis of various solvents. The process typically involves acid-catalyzed dehydration of pentoses and hexoses derived from lignocellulosic biomass, followed by further catalytic transformations to produce solvents with specific properties suitable for industrial applications.

- Conversion of glycerol to solvent applications: Glycerol, a byproduct of biodiesel production, can be catalytically converted into various solvents. These transformations include dehydration to produce acrolein, hydrogenolysis to yield propanediols, and esterification to form glycerol esters. The catalytic processes typically employ acid catalysts, metal catalysts, or bifunctional catalytic systems under specific reaction conditions to selectively convert glycerol into solvents with applications in pharmaceuticals, cosmetics, and other industries.

- Catalytic upgrading of bio-oils to solvent products: Bio-oils derived from biomass pyrolysis or liquefaction can be catalytically upgraded to produce high-quality solvents. These upgrading processes typically involve hydrodeoxygenation, hydrogenation, and fractionation steps to reduce oxygen content and improve stability. Various catalysts, including supported noble metals, transition metal sulfides, and zeolites, are employed to selectively convert the complex mixture of oxygenated compounds in bio-oils into more uniform and stable solvent products.

- Green solvent systems from biomass carbohydrates: Carbohydrates from biomass can be transformed into green solvent systems through various catalytic pathways. These include the production of ethyl lactate from lactic acid, gamma-valerolactone from levulinic acid, and dialkyl carbonates from CO2 and alcohols. The processes typically employ heterogeneous catalysts under mild conditions to achieve high selectivity and yield. These bio-derived solvents offer environmentally friendly alternatives to conventional petroleum-based solvents with comparable or superior performance in various applications.

02 Production of furan-based solvents from biomass

Furan-based compounds, particularly furfural and 5-hydroxymethylfurfural (HMF), can be produced from biomass through catalytic dehydration of sugars. These furan derivatives serve as platform chemicals for the production of various solvents. The process typically involves acid-catalyzed dehydration of pentoses and hexoses derived from lignocellulosic biomass. The resulting furan-based solvents offer favorable properties such as low toxicity and biodegradability, making them suitable replacements for conventional organic solvents.Expand Specific Solutions03 Conversion of glycerol to solvent applications

Glycerol, a byproduct of biodiesel production, can be catalytically converted into various solvents and solvent precursors. Processes include dehydration to produce acrolein, hydrogenolysis to yield propanediols, and esterification to form glycerol esters. These transformations typically employ heterogeneous catalysts under varying reaction conditions. The resulting glycerol-derived solvents offer advantages such as biodegradability, low volatility, and reduced toxicity compared to conventional petroleum-based alternatives.Expand Specific Solutions04 Catalytic upgrading of bio-oils to solvent products

Bio-oils obtained from biomass pyrolysis can be catalytically upgraded to produce high-quality solvents. The upgrading processes typically involve hydrodeoxygenation, hydrocracking, and reforming reactions to remove oxygen and improve stability. Various catalysts, including supported noble metals and transition metal sulfides, are employed in these transformations. The upgraded bio-oil fractions can serve as renewable solvents with properties comparable to those of conventional petroleum-derived solvents.Expand Specific Solutions05 Biomass-derived alcohols and esters as green solvents

Alcohols and esters derived from biomass represent an important class of bio-based solvents. These compounds can be produced through various catalytic routes, including fermentation followed by catalytic upgrading, direct catalytic conversion of sugars, and transesterification of plant oils. The resulting alcohols (such as ethanol, butanol) and esters (such as lactate esters, acetates) offer favorable solvent properties while providing environmental benefits compared to conventional solvents. Their production often employs biocatalysts or heterogeneous catalysts under mild conditions.Expand Specific Solutions

Leading Organizations in Biomass Solvent Research

The biomass-derived solvents market is in a growth phase, driven by increasing demand for sustainable alternatives to petroleum-based chemicals. The global market is projected to expand significantly as industries seek greener solvent options for catalytic conversions. Technologically, the field shows varying maturity levels across applications. Leading players include Shell and its subsidiary Virent, who have established strong positions through strategic collaborations in bio-based solvent development. Research institutions like RTI International and Wisconsin Alumni Research Foundation provide critical innovation support. Companies such as Archer-Daniels-Midland and Phillips 66 are leveraging their petrochemical expertise to transition into bio-based alternatives, while academic institutions in China and the US are advancing fundamental research to improve catalytic efficiency and selectivity with these novel solvents.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed advanced catalytic conversion processes utilizing biomass-derived solvents, particularly focusing on lignocellulosic biomass conversion. Their technology employs bio-derived solvents like gamma-valerolactone (GVL) and 2-methyltetrahydrofuran (2-MTHF) in catalytic systems to enhance the efficiency of biomass conversion to fuels and chemicals. Shell's approach involves a two-stage process: first using biomass-derived solvents for fractionation of lignocellulosic materials, followed by catalytic upgrading of the resulting fractions. Their research demonstrates that these bio-solvents can significantly improve catalyst performance by enhancing mass transfer, reducing catalyst deactivation, and enabling milder reaction conditions compared to conventional petroleum-derived solvents[1]. Shell has particularly focused on developing solvent systems that facilitate the dissolution of lignin components, allowing for more efficient conversion to aromatic compounds and other value-added chemicals[3].

Strengths: Shell's technology leverages their extensive refining expertise and global infrastructure, allowing for potential large-scale implementation. Their bio-solvent systems demonstrate improved catalyst longevity and selectivity toward desired products. Weaknesses: The processes may still require significant energy inputs and face challenges in solvent recovery and recycling, potentially impacting economic viability at commercial scale.

Virent, Inc.

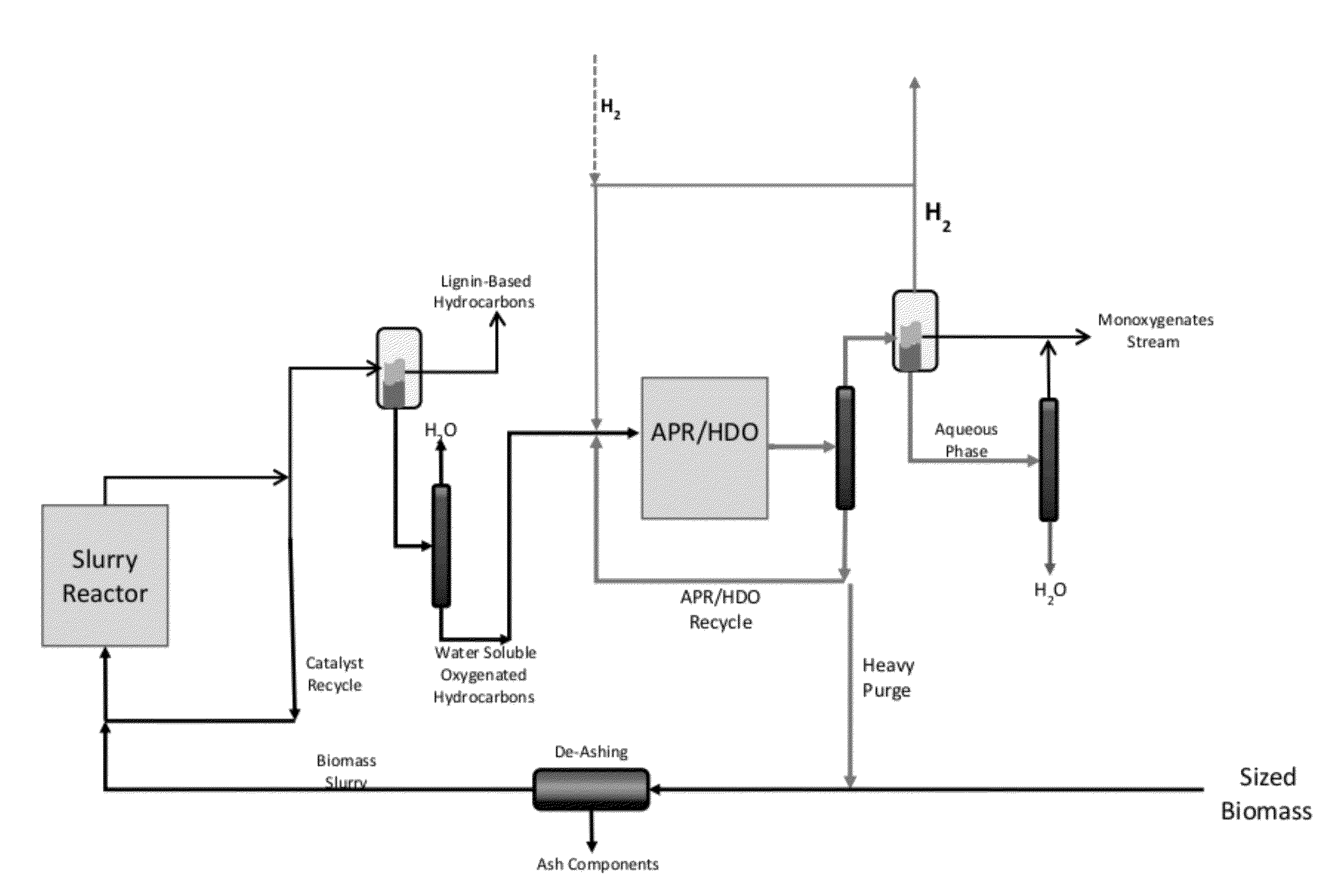

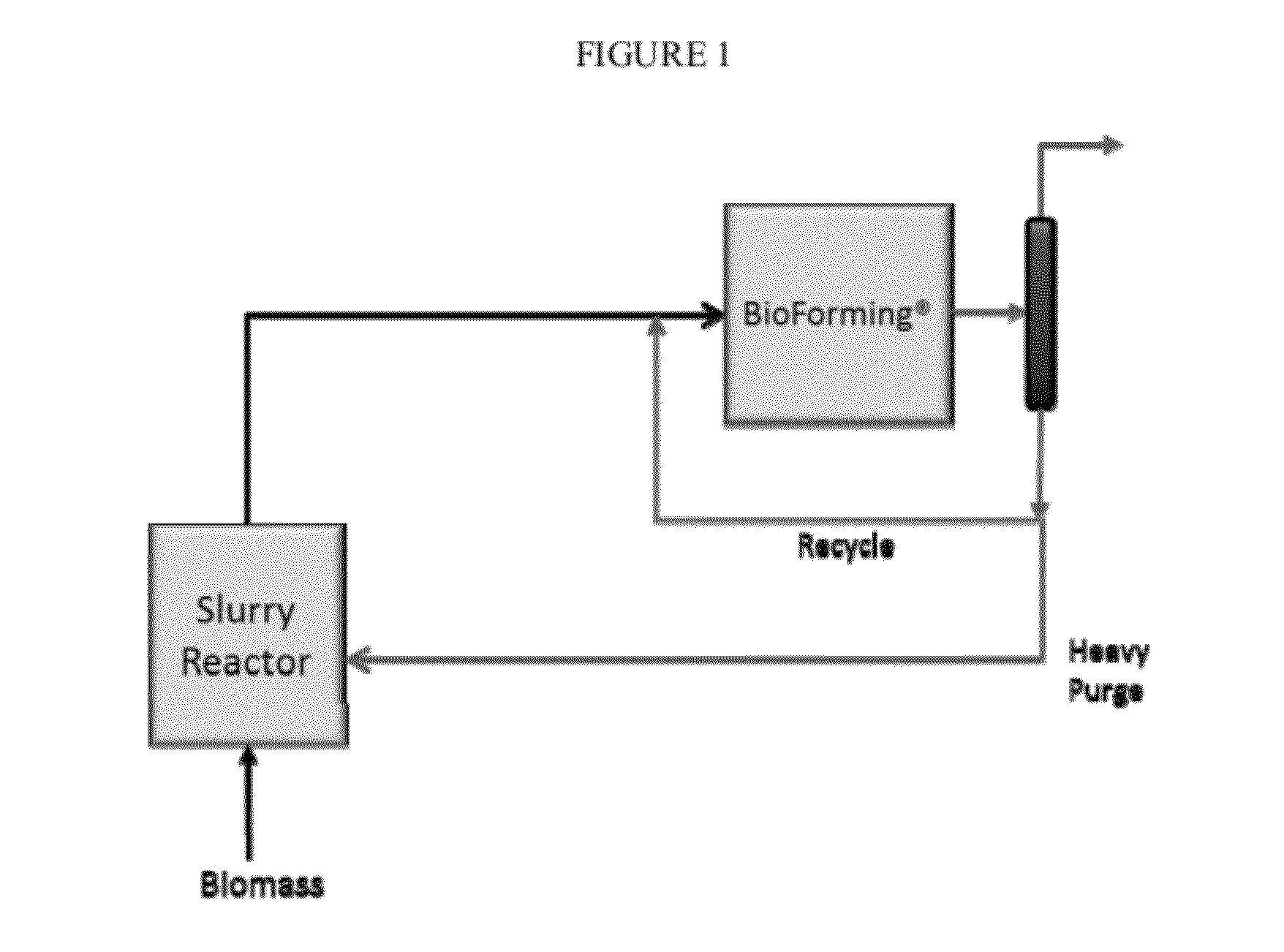

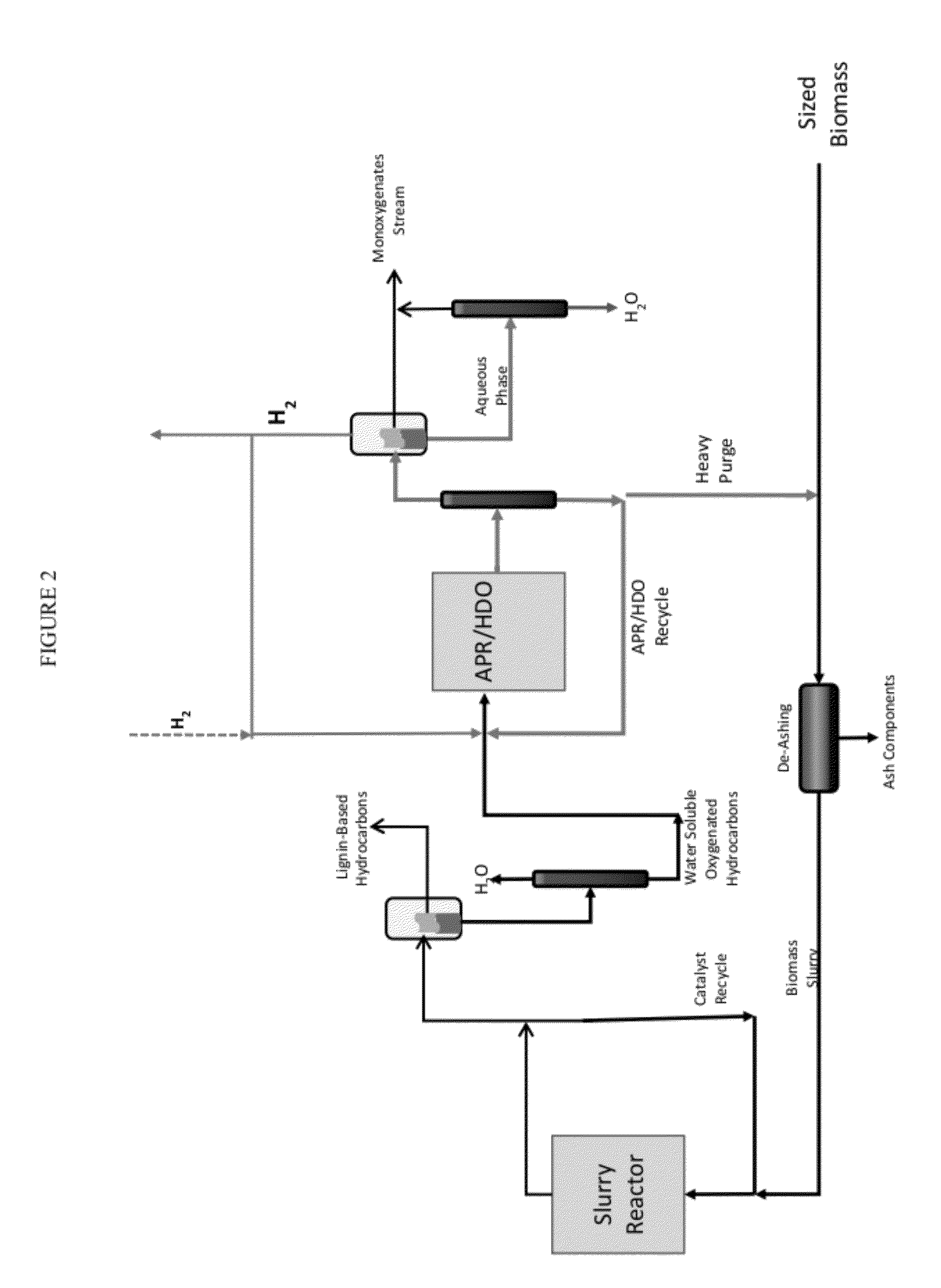

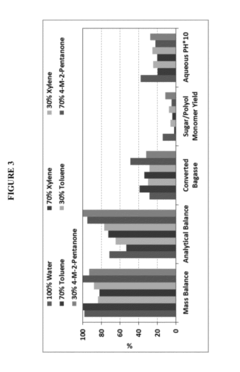

Technical Solution: Virent has pioneered the BioForming® process, a catalytic technology that utilizes biomass-derived oxygenated compounds in aqueous phase reforming (APR) reactions. Their approach employs specific biomass-derived solvents as both reactants and reaction media for catalytic conversions. The technology converts plant sugars into a range of hydrocarbon products through a series of catalytic steps where the solvent environment plays a crucial role in reaction selectivity and efficiency. Virent's catalytic systems operate in bio-derived solvent environments that enhance the stability of their proprietary catalysts while facilitating the conversion of biomass-derived feedstocks to drop-in fuels and chemicals[2]. Their research has demonstrated that carefully selected biomass-derived solvents can significantly improve catalyst performance by preventing coking and other deactivation mechanisms. The company has developed specific solvent formulations that optimize the solubility of both reactants and products, enhancing mass transfer to catalyst active sites and improving overall conversion rates[4]. Virent's technology has shown particular success with catalytic conversions of C5 and C6 sugars in bio-derived solvent systems.

Strengths: Virent's technology produces true "drop-in" hydrocarbon fuels and chemicals that are fully compatible with existing infrastructure. Their catalytic systems show high selectivity toward desired products with minimal byproduct formation. Weaknesses: The process requires relatively pure sugar streams as input, potentially necessitating costly pretreatment steps for lignocellulosic feedstocks. The catalysts used may contain precious metals, raising concerns about cost and sustainability.

Key Mechanisms of Solvent-Catalyst Interactions

Method to convert monosaccharides to 5-(hydroxymethyl) furfural (HMF) using biomass-derived solvents

PatentWO2014058859A3

Innovation

- Using biomass-derived lactones (beta-, gamma-, and/or delta-) as co-solvents in the conversion of monosaccharides to HMF, providing a more sustainable approach compared to traditional petroleum-based solvents.

- Employing biomass-derived THF and MTHF as co-solvents in a monophasic or biphasic reaction system for HMF production, creating a more integrated biorefinery approach.

- Combining acid catalysis with dehydration catalysis in biomass-derived solvent systems for effective conversion of C5 and C6 sugars to HMF.

Solvolysis of biomass using solvent from a bioreforming process

PatentActiveUS20120167875A1

Innovation

- A method involving the catalytic reaction of water and a water-soluble oxygenated hydrocarbon with hydrogen in the presence of a deoxygenation catalyst to produce a biomass processing solvent, which is then used to deconstruct biomass into a hydrolysate containing soluble derivatives and carbohydrates, facilitating further processing in bioreforming.

Environmental Impact Assessment of Bio-Solvents

The environmental impact assessment of bio-solvents derived from biomass reveals significant advantages over conventional petroleum-based solvents. These bio-solvents, including ethanol, glycerol, and γ-valerolactone, demonstrate lower carbon footprints throughout their lifecycle. Life Cycle Assessment (LCA) studies indicate that biomass-derived solvents can reduce greenhouse gas emissions by 50-80% compared to their petrochemical counterparts, primarily due to carbon sequestration during biomass growth.

Water consumption patterns vary significantly among different bio-solvents. While some require substantial irrigation during feedstock cultivation, others derived from agricultural waste streams or forestry residues demonstrate more favorable water usage profiles. The water footprint of bio-solvents must be evaluated regionally, considering local water availability and stress factors in production areas.

Biodegradability represents another critical environmental advantage of bio-solvents. Most biomass-derived solvents demonstrate enhanced biodegradation rates in natural environments compared to petroleum-based alternatives. For instance, ethyl lactate typically degrades 80-95% within 28 days under standard testing conditions, whereas many conventional solvents persist significantly longer in ecosystems.

Land use implications remain a complex consideration in bio-solvent production. First-generation bio-solvents derived from food crops raise concerns about competition with food production and potential indirect land use changes. However, second and third-generation approaches utilizing lignocellulosic biomass, agricultural residues, and waste streams substantially mitigate these concerns while maintaining environmental benefits.

Toxicity profiles of bio-solvents generally demonstrate reduced environmental and human health hazards. Many biomass-derived solvents exhibit lower aquatic toxicity, reduced bioaccumulation potential, and decreased persistence in environmental systems. This translates to reduced ecological risk in case of accidental releases or disposal scenarios.

The catalytic conversion processes employed in bio-solvent production present their own environmental considerations. While some conversion pathways require significant energy inputs or generate waste streams, technological innovations are continuously improving process efficiency. Advanced catalytic systems enable lower temperature conversions, reduced reaction times, and improved selectivity, collectively enhancing the environmental performance of production processes.

Regulatory frameworks increasingly recognize the environmental advantages of bio-solvents, with policies in various regions incentivizing their adoption through green chemistry initiatives, reduced volatile organic compound (VOC) allowances, and sustainability certification programs. These policy instruments further accelerate the transition toward more environmentally benign solvent systems in industrial applications.

Water consumption patterns vary significantly among different bio-solvents. While some require substantial irrigation during feedstock cultivation, others derived from agricultural waste streams or forestry residues demonstrate more favorable water usage profiles. The water footprint of bio-solvents must be evaluated regionally, considering local water availability and stress factors in production areas.

Biodegradability represents another critical environmental advantage of bio-solvents. Most biomass-derived solvents demonstrate enhanced biodegradation rates in natural environments compared to petroleum-based alternatives. For instance, ethyl lactate typically degrades 80-95% within 28 days under standard testing conditions, whereas many conventional solvents persist significantly longer in ecosystems.

Land use implications remain a complex consideration in bio-solvent production. First-generation bio-solvents derived from food crops raise concerns about competition with food production and potential indirect land use changes. However, second and third-generation approaches utilizing lignocellulosic biomass, agricultural residues, and waste streams substantially mitigate these concerns while maintaining environmental benefits.

Toxicity profiles of bio-solvents generally demonstrate reduced environmental and human health hazards. Many biomass-derived solvents exhibit lower aquatic toxicity, reduced bioaccumulation potential, and decreased persistence in environmental systems. This translates to reduced ecological risk in case of accidental releases or disposal scenarios.

The catalytic conversion processes employed in bio-solvent production present their own environmental considerations. While some conversion pathways require significant energy inputs or generate waste streams, technological innovations are continuously improving process efficiency. Advanced catalytic systems enable lower temperature conversions, reduced reaction times, and improved selectivity, collectively enhancing the environmental performance of production processes.

Regulatory frameworks increasingly recognize the environmental advantages of bio-solvents, with policies in various regions incentivizing their adoption through green chemistry initiatives, reduced volatile organic compound (VOC) allowances, and sustainability certification programs. These policy instruments further accelerate the transition toward more environmentally benign solvent systems in industrial applications.

Scalability and Industrial Implementation Strategies

The scalability of biomass-derived solvents from laboratory to industrial scale represents a critical challenge in their widespread adoption. Current production methods often involve complex extraction processes, purification steps, and yield optimization that work efficiently at small scales but face significant hurdles during scale-up. The economic viability of large-scale production remains a key concern, with cost factors including feedstock availability, processing energy requirements, and purification expenses often determining commercial feasibility.

Industrial implementation requires strategic approaches to overcome these challenges. Integration with existing biorefinery infrastructure presents a promising pathway, allowing biomass-derived solvents to be produced as co-products within established facilities. This approach leverages existing supply chains and processing capabilities while distributing overhead costs across multiple product streams. Several pioneering companies have successfully implemented this strategy, achieving production capacities of 10,000-50,000 tons annually for solvents like 2-methyltetrahydrofuran and γ-valerolactone.

Process intensification techniques offer additional avenues for improving scalability. Continuous flow processing, for instance, has demonstrated significant advantages over batch production, including better heat transfer, improved reaction control, and reduced solvent requirements. Recent pilot studies have shown that continuous processing can increase throughput by 30-40% while reducing energy consumption by up to 25% compared to conventional batch methods for certain biomass-derived solvents.

Catalyst recycling and recovery systems represent another crucial aspect of industrial implementation. The development of heterogeneous catalysts with enhanced stability and magnetic separation capabilities has enabled more efficient catalyst recovery processes, with some systems achieving recovery rates exceeding 95% over multiple cycles. These advances significantly reduce operational costs and environmental impact, making large-scale production more economically viable.

Standardization of quality metrics and performance parameters remains essential for market acceptance. Industry consortia have begun establishing specifications for biomass-derived solvents, focusing on purity levels, moisture content, and performance consistency. These standards facilitate integration into existing industrial processes and provide confidence to potential industrial users considering transitions from petroleum-based solvents.

Regulatory frameworks and sustainability certification systems are evolving to accommodate these novel solvents. Life cycle assessment methodologies specifically adapted for bio-based chemicals help quantify environmental benefits and identify optimization opportunities. Several biomass-derived solvents have already received favorable sustainability certifications, creating market advantages through green premium pricing and regulatory compliance benefits.

Industrial implementation requires strategic approaches to overcome these challenges. Integration with existing biorefinery infrastructure presents a promising pathway, allowing biomass-derived solvents to be produced as co-products within established facilities. This approach leverages existing supply chains and processing capabilities while distributing overhead costs across multiple product streams. Several pioneering companies have successfully implemented this strategy, achieving production capacities of 10,000-50,000 tons annually for solvents like 2-methyltetrahydrofuran and γ-valerolactone.

Process intensification techniques offer additional avenues for improving scalability. Continuous flow processing, for instance, has demonstrated significant advantages over batch production, including better heat transfer, improved reaction control, and reduced solvent requirements. Recent pilot studies have shown that continuous processing can increase throughput by 30-40% while reducing energy consumption by up to 25% compared to conventional batch methods for certain biomass-derived solvents.

Catalyst recycling and recovery systems represent another crucial aspect of industrial implementation. The development of heterogeneous catalysts with enhanced stability and magnetic separation capabilities has enabled more efficient catalyst recovery processes, with some systems achieving recovery rates exceeding 95% over multiple cycles. These advances significantly reduce operational costs and environmental impact, making large-scale production more economically viable.

Standardization of quality metrics and performance parameters remains essential for market acceptance. Industry consortia have begun establishing specifications for biomass-derived solvents, focusing on purity levels, moisture content, and performance consistency. These standards facilitate integration into existing industrial processes and provide confidence to potential industrial users considering transitions from petroleum-based solvents.

Regulatory frameworks and sustainability certification systems are evolving to accommodate these novel solvents. Life cycle assessment methodologies specifically adapted for bio-based chemicals help quantify environmental benefits and identify optimization opportunities. Several biomass-derived solvents have already received favorable sustainability certifications, creating market advantages through green premium pricing and regulatory compliance benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!