The Role of Biomass-Derived Solvents in Sustainable Catalysis

OCT 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biomass Solvents Evolution and Research Objectives

The evolution of biomass-derived solvents represents a significant paradigm shift in the field of sustainable chemistry. Historically, petroleum-based solvents have dominated industrial processes, accounting for approximately 80-90% of all solvents used in chemical manufacturing. However, growing environmental concerns, stricter regulations, and the finite nature of fossil resources have driven research toward renewable alternatives since the early 2000s.

Biomass-derived solvents emerged as promising candidates due to their renewable nature, biodegradability, and potential for reduced toxicity. The development trajectory began with first-generation bio-solvents like ethanol and glycerol, which were directly extracted from food crops. This raised sustainability concerns regarding land use and food security, prompting a shift toward second-generation solvents derived from lignocellulosic biomass, agricultural residues, and non-food crops.

The technical evolution accelerated significantly between 2010-2020, with breakthroughs in conversion technologies enabling the production of diverse solvent platforms including 2-methyltetrahydrofuran (2-MeTHF), γ-valerolactone (GVL), and cyrene. These solvents demonstrated comparable or superior performance to traditional options in various catalytic applications while offering improved environmental profiles.

Recent advancements have focused on developing integrated biorefinery concepts where biomass-derived solvents are produced as part of larger value chains, maximizing resource efficiency. The concept of "solvent design" has gained prominence, with researchers tailoring solvent properties for specific catalytic reactions rather than adapting processes to available solvents.

The primary research objectives in this field now center on addressing several key challenges. First, developing more efficient and economical conversion pathways to reduce production costs, which remain higher than petroleum-based alternatives. Second, expanding the range of biomass feedstocks to include waste streams and marine biomass, reducing dependence on terrestrial resources.

Third, enhancing fundamental understanding of how biomass-derived solvents interact with catalysts at the molecular level, as their unique functional groups and polarity profiles often create unexpected effects on reaction mechanisms and selectivity. Fourth, establishing standardized methodologies for comprehensive life cycle assessments to accurately quantify environmental benefits.

Finally, research aims to bridge the gap between laboratory demonstrations and industrial implementation through process intensification, catalyst stability studies in bio-derived media, and development of continuous flow technologies compatible with these sustainable solvents. The ultimate goal is to establish biomass-derived solvents as mainstream options in industrial catalysis, contributing significantly to circular economy principles and reduced environmental footprint of chemical manufacturing.

Biomass-derived solvents emerged as promising candidates due to their renewable nature, biodegradability, and potential for reduced toxicity. The development trajectory began with first-generation bio-solvents like ethanol and glycerol, which were directly extracted from food crops. This raised sustainability concerns regarding land use and food security, prompting a shift toward second-generation solvents derived from lignocellulosic biomass, agricultural residues, and non-food crops.

The technical evolution accelerated significantly between 2010-2020, with breakthroughs in conversion technologies enabling the production of diverse solvent platforms including 2-methyltetrahydrofuran (2-MeTHF), γ-valerolactone (GVL), and cyrene. These solvents demonstrated comparable or superior performance to traditional options in various catalytic applications while offering improved environmental profiles.

Recent advancements have focused on developing integrated biorefinery concepts where biomass-derived solvents are produced as part of larger value chains, maximizing resource efficiency. The concept of "solvent design" has gained prominence, with researchers tailoring solvent properties for specific catalytic reactions rather than adapting processes to available solvents.

The primary research objectives in this field now center on addressing several key challenges. First, developing more efficient and economical conversion pathways to reduce production costs, which remain higher than petroleum-based alternatives. Second, expanding the range of biomass feedstocks to include waste streams and marine biomass, reducing dependence on terrestrial resources.

Third, enhancing fundamental understanding of how biomass-derived solvents interact with catalysts at the molecular level, as their unique functional groups and polarity profiles often create unexpected effects on reaction mechanisms and selectivity. Fourth, establishing standardized methodologies for comprehensive life cycle assessments to accurately quantify environmental benefits.

Finally, research aims to bridge the gap between laboratory demonstrations and industrial implementation through process intensification, catalyst stability studies in bio-derived media, and development of continuous flow technologies compatible with these sustainable solvents. The ultimate goal is to establish biomass-derived solvents as mainstream options in industrial catalysis, contributing significantly to circular economy principles and reduced environmental footprint of chemical manufacturing.

Market Analysis for Green Catalysis Solutions

The global market for green catalysis solutions is experiencing robust growth, driven by increasing environmental regulations and corporate sustainability commitments. Current market valuations indicate the sustainable catalysis sector reached approximately 5.7 billion USD in 2022, with projections suggesting a compound annual growth rate of 6.8% through 2030. Biomass-derived solvents represent a rapidly expanding segment within this market, currently valued at around 1.2 billion USD and expected to double within the next five years.

Key market drivers include stringent environmental regulations in Europe and North America, with the European Green Deal and the US Inflation Reduction Act providing significant financial incentives for green chemistry adoption. Additionally, consumer demand for sustainably produced products has created market pull across industries including pharmaceuticals, fine chemicals, and consumer goods manufacturing.

Regional analysis reveals Europe leading the green catalysis market with approximately 38% market share, followed by North America (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth rate at 8.3% annually, primarily driven by China's aggressive environmental policies and industrial transformation initiatives.

Industry segmentation shows pharmaceutical manufacturing as the largest end-user of biomass-derived solvents in catalytic processes (31% market share), followed by specialty chemicals (26%), and agrochemicals (18%). This distribution reflects the high-value applications where sustainable processes command premium pricing despite potentially higher production costs.

Market challenges include price competition with conventional petroleum-derived solvents, which typically maintain a 15-30% cost advantage depending on petroleum market fluctuations. Supply chain reliability represents another significant barrier, as biomass feedstock availability can be subject to seasonal variations and agricultural market dynamics.

Customer demand analysis indicates growing willingness to pay premium prices for sustainably produced chemicals, particularly in consumer-facing industries. Corporate sustainability targets among Fortune 500 companies increasingly include specific commitments to green chemistry adoption, creating stable demand forecasts for the next decade.

Emerging market opportunities exist in developing economies where environmental regulations are tightening, particularly in India, Brazil, and Southeast Asian nations. These regions represent potential high-growth markets as their chemical manufacturing sectors expand while simultaneously adopting more sustainable practices.

Return on investment analyses suggest that despite higher initial capital expenditures for green catalysis implementation, payback periods are decreasing, currently averaging 3-5 years compared to 7-9 years a decade ago. This improvement is attributed to technological advancements, economies of scale, and increasing regulatory costs associated with conventional processes.

Key market drivers include stringent environmental regulations in Europe and North America, with the European Green Deal and the US Inflation Reduction Act providing significant financial incentives for green chemistry adoption. Additionally, consumer demand for sustainably produced products has created market pull across industries including pharmaceuticals, fine chemicals, and consumer goods manufacturing.

Regional analysis reveals Europe leading the green catalysis market with approximately 38% market share, followed by North America (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth rate at 8.3% annually, primarily driven by China's aggressive environmental policies and industrial transformation initiatives.

Industry segmentation shows pharmaceutical manufacturing as the largest end-user of biomass-derived solvents in catalytic processes (31% market share), followed by specialty chemicals (26%), and agrochemicals (18%). This distribution reflects the high-value applications where sustainable processes command premium pricing despite potentially higher production costs.

Market challenges include price competition with conventional petroleum-derived solvents, which typically maintain a 15-30% cost advantage depending on petroleum market fluctuations. Supply chain reliability represents another significant barrier, as biomass feedstock availability can be subject to seasonal variations and agricultural market dynamics.

Customer demand analysis indicates growing willingness to pay premium prices for sustainably produced chemicals, particularly in consumer-facing industries. Corporate sustainability targets among Fortune 500 companies increasingly include specific commitments to green chemistry adoption, creating stable demand forecasts for the next decade.

Emerging market opportunities exist in developing economies where environmental regulations are tightening, particularly in India, Brazil, and Southeast Asian nations. These regions represent potential high-growth markets as their chemical manufacturing sectors expand while simultaneously adopting more sustainable practices.

Return on investment analyses suggest that despite higher initial capital expenditures for green catalysis implementation, payback periods are decreasing, currently averaging 3-5 years compared to 7-9 years a decade ago. This improvement is attributed to technological advancements, economies of scale, and increasing regulatory costs associated with conventional processes.

Current Status and Barriers in Biomass-Derived Solvent Technology

Biomass-derived solvents have gained significant attention in sustainable catalysis as environmentally friendly alternatives to conventional petroleum-based solvents. Currently, several biomass-derived solvents have been successfully commercialized, including ethanol, glycerol, 2-methyltetrahydrofuran (2-MeTHF), γ-valerolactone (GVL), and cyrene. These solvents are primarily produced from lignocellulosic biomass, agricultural residues, and food waste through various conversion processes such as fermentation, hydrogenation, and catalytic transformations.

The global market for green solvents, including biomass-derived options, was valued at approximately $4.3 billion in 2021 and is projected to reach $6.8 billion by 2028, with a compound annual growth rate of 6.7%. This growth is driven by increasing environmental regulations, consumer demand for sustainable products, and corporate sustainability initiatives across various industries.

Despite promising developments, several technical challenges impede the widespread adoption of biomass-derived solvents in catalytic applications. The inconsistent quality and variable composition of biomass feedstocks result in batch-to-batch variations in solvent properties, affecting catalytic performance reproducibility. Additionally, the purification processes required to achieve high-purity solvents often involve energy-intensive distillation steps, potentially offsetting their environmental benefits.

Scalability remains a significant barrier, as many biomass-derived solvents are produced at laboratory or pilot scales, with limited industrial-scale production facilities. This results in higher production costs compared to conventional petroleum-based solvents, making economic viability challenging without policy support or premium pricing for green products.

From a catalytic performance perspective, biomass-derived solvents often exhibit different solvation properties compared to traditional solvents, necessitating the redesign of catalytic systems. The presence of impurities or functional groups in these solvents can interfere with catalytic active sites, leading to catalyst deactivation or unwanted side reactions.

Geographically, research and development in biomass-derived solvents for catalysis is concentrated in North America, Western Europe, and East Asia, particularly in countries with strong biorefinery infrastructure. The United States, Germany, China, and Japan lead in patent filings and research publications in this field, with emerging contributions from Brazil and India leveraging their abundant biomass resources.

Regulatory frameworks also present challenges, as many biomass-derived solvents lack comprehensive toxicological and environmental impact assessments required for industrial applications. The absence of standardized testing protocols and certification systems for bio-based solvents creates uncertainty for potential adopters in catalysis applications.

The global market for green solvents, including biomass-derived options, was valued at approximately $4.3 billion in 2021 and is projected to reach $6.8 billion by 2028, with a compound annual growth rate of 6.7%. This growth is driven by increasing environmental regulations, consumer demand for sustainable products, and corporate sustainability initiatives across various industries.

Despite promising developments, several technical challenges impede the widespread adoption of biomass-derived solvents in catalytic applications. The inconsistent quality and variable composition of biomass feedstocks result in batch-to-batch variations in solvent properties, affecting catalytic performance reproducibility. Additionally, the purification processes required to achieve high-purity solvents often involve energy-intensive distillation steps, potentially offsetting their environmental benefits.

Scalability remains a significant barrier, as many biomass-derived solvents are produced at laboratory or pilot scales, with limited industrial-scale production facilities. This results in higher production costs compared to conventional petroleum-based solvents, making economic viability challenging without policy support or premium pricing for green products.

From a catalytic performance perspective, biomass-derived solvents often exhibit different solvation properties compared to traditional solvents, necessitating the redesign of catalytic systems. The presence of impurities or functional groups in these solvents can interfere with catalytic active sites, leading to catalyst deactivation or unwanted side reactions.

Geographically, research and development in biomass-derived solvents for catalysis is concentrated in North America, Western Europe, and East Asia, particularly in countries with strong biorefinery infrastructure. The United States, Germany, China, and Japan lead in patent filings and research publications in this field, with emerging contributions from Brazil and India leveraging their abundant biomass resources.

Regulatory frameworks also present challenges, as many biomass-derived solvents lack comprehensive toxicological and environmental impact assessments required for industrial applications. The absence of standardized testing protocols and certification systems for bio-based solvents creates uncertainty for potential adopters in catalysis applications.

Contemporary Approaches to Biomass-Derived Solvent Implementation

01 Production of biomass-derived solvents from lignocellulosic materials

Lignocellulosic materials such as agricultural residues, forestry waste, and dedicated energy crops can be processed to produce various green solvents. These processes typically involve pretreatment, hydrolysis, and fermentation steps to convert cellulose and hemicellulose into solvent precursors. The resulting bio-based solvents offer environmentally friendly alternatives to petroleum-derived solvents with comparable performance characteristics while reducing carbon footprint.- Production of bio-based solvents from lignocellulosic biomass: Lignocellulosic biomass can be converted into various bio-based solvents through processes such as hydrolysis, fermentation, and chemical conversion. These processes break down cellulose, hemicellulose, and lignin components to produce renewable solvents that can replace petroleum-derived alternatives. The resulting bio-solvents typically have lower toxicity and environmental impact while maintaining similar performance characteristics to conventional solvents.

- Enzymatic and microbial conversion methods for biomass-derived solvents: Enzymatic and microbial conversion technologies enable the transformation of biomass into solvents through biological pathways. These methods utilize specialized enzymes or microorganisms to break down complex biomass structures and convert them into useful solvent compounds. The processes typically operate under mild conditions, reducing energy requirements and environmental impact compared to chemical conversion methods, while producing solvents with high purity and specificity.

- Green solvent applications in pulp and paper processing: Biomass-derived solvents offer sustainable alternatives for pulp and paper processing applications. These bio-based solvents can effectively dissolve lignin and separate cellulose fibers while reducing the environmental impact associated with traditional chemical pulping processes. The use of these solvents enables more efficient delignification, reduces chemical consumption, and minimizes harmful emissions while maintaining or improving the quality of the final paper products.

- Biomass-derived solvents for polymer processing and composites: Bio-based solvents derived from renewable biomass sources can be effectively used in polymer processing and composite manufacturing. These solvents provide environmentally friendly alternatives for dissolving polymers, facilitating composite formation, and enabling various polymer modification processes. They offer advantages such as reduced toxicity, lower VOC emissions, and improved biodegradability while maintaining the necessary solvent properties for effective polymer processing and composite manufacturing.

- Biomass-derived solvents for extraction and separation processes: Bio-based solvents can be utilized in various extraction and separation processes as greener alternatives to petroleum-derived solvents. These renewable solvents demonstrate effective performance in extracting valuable compounds from natural materials, separating mixtures, and purifying products across pharmaceutical, food, and chemical industries. Their advantages include reduced environmental impact, lower toxicity, and potential for improved selectivity in certain extraction applications while meeting sustainability goals.

02 Bio-based ester solvents from renewable resources

Ester-based solvents can be synthesized from biomass-derived alcohols and organic acids. These bio-esters serve as effective replacements for traditional petroleum-based solvents in applications such as coatings, adhesives, cleaning products, and pharmaceutical processing. The production methods typically involve esterification reactions using catalysts under controlled conditions, resulting in solvents with low toxicity, biodegradability, and reduced environmental impact.Expand Specific Solutions03 Furan-based solvents from biomass carbohydrates

Furan derivatives such as 2-methyltetrahydrofuran, tetrahydrofurfuryl alcohol, and furfural can be produced from biomass carbohydrates through catalytic conversion processes. These furan-based solvents offer excellent solubilizing properties for various applications including extraction processes, polymer production, and as reaction media. Their production involves the dehydration of pentoses and hexoses derived from biomass, followed by selective hydrogenation or oxidation steps to yield the desired solvent compounds.Expand Specific Solutions04 Glycerol-derived solvents from biodiesel production

Glycerol, a byproduct of biodiesel production, can be converted into various solvent compounds through chemical modifications. These include glycerol ethers, glycerol carbonates, and glycerol acetals, which serve as green alternatives to conventional solvents. The conversion processes typically involve etherification, carbonation, or acetalization reactions using catalysts. These glycerol-derived solvents offer advantages such as low volatility, biodegradability, and reduced toxicity for applications in cleaning products, coatings, and pharmaceutical formulations.Expand Specific Solutions05 Applications of biomass-derived solvents in industrial processes

Biomass-derived solvents find applications across various industrial sectors as replacements for conventional petroleum-based solvents. These applications include use in pulp and paper processing, textile manufacturing, pharmaceutical production, and as extraction media for natural products. The bio-based solvents offer advantages such as reduced environmental impact, improved worker safety, and compliance with stricter environmental regulations. Their implementation often requires process optimization to accommodate differences in solvent properties while maintaining or enhancing process efficiency.Expand Specific Solutions

Leading Organizations in Biomass Solvent Research

The biomass-derived solvents market in sustainable catalysis is in a growth phase, with increasing market size driven by environmental regulations and sustainability initiatives. The technology is advancing from early commercial to mature stages, with varying degrees of implementation across sectors. Key players represent diverse segments: academic institutions (Wisconsin Alumni Research Foundation, Zhejiang University, King Abdullah University) focus on fundamental research; energy corporations (Shell Oil, SCG Chemicals) invest in commercial applications; specialized companies (Virent, Renmatix, Intramicron) develop proprietary technologies; and established industrial players (Archer-Daniels-Midland, Seiko Epson) integrate these solutions into existing processes. This competitive landscape reflects a technology transitioning from research to commercial implementation, with collaborations between academia and industry accelerating development.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell Internationale Research has developed advanced catalytic systems for biomass conversion utilizing bio-derived solvents like gamma-valerolactone (GVL) and 2-methyltetrahydrofuran (2-MeTHF). Their technology focuses on the catalytic upgrading of lignocellulosic biomass through a cascade process that integrates solvent effects with selective catalysis. The company has pioneered biphasic catalytic systems where biomass-derived solvents serve dual roles as reaction media and co-catalysts, enhancing selectivity and yield in biomass valorization reactions. Shell's approach includes the development of specialized metal-organic frameworks (MOFs) and zeolite catalysts that function optimally in these green solvent environments. Their research has demonstrated significant improvements in catalyst stability and product selectivity when using biomass-derived solvents compared to conventional organic solvents. The technology enables the production of platform chemicals and fuels from renewable resources with reduced environmental impact and improved process economics[5][7].

Strengths: Extensive catalyst development expertise, integration capabilities with existing petroleum refining infrastructure, and global scale for technology deployment. Weaknesses: Higher costs compared to conventional petroleum processes, challenges in catalyst longevity when exposed to biomass impurities, and dependence on consistent biomass feedstock quality.

Virent, Inc.

Technical Solution: Virent has developed a proprietary BioForming® platform technology that converts plant-based sugars into a range of hydrocarbon products identical to those made from petroleum. Their catalytic biorefinery approach uses biomass-derived solvents in conjunction with heterogeneous catalysts to produce drop-in renewable fuels and chemicals. The process employs aqueous phase reforming (APR) technology that utilizes water as a reaction medium combined with proprietary catalysts to convert plant sugars into a mixture of oxygenated hydrocarbons. These intermediate compounds are then processed using conventional catalytic chemistry to create gasoline, diesel, jet fuel, and chemicals for plastics and fibers. Virent's technology stands out for its ability to work with a variety of feedstocks including conventional sugars, cellulosic biomass, and glycerol, making it highly adaptable to different biomass sources[1][3].

Strengths: Versatility in feedstock utilization, production of true "drop-in" fuels chemically identical to petroleum-derived counterparts, and integration potential with existing petroleum infrastructure. Weaknesses: Energy-intensive process steps, potential catalyst deactivation issues in biomass-derived media, and competition from other renewable fuel technologies with lower capital requirements.

Key Innovations in Sustainable Catalysis Mechanisms

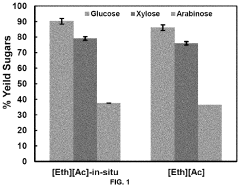

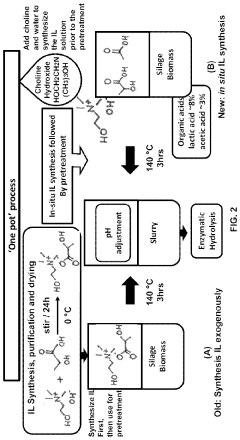

Use of in-situ ionic liquid (IL) and deep eutectic solvent (DES) synthesis using chemically synthesized or biomass-derived ions in the pretreatment of biomass

PatentActiveUS20210363696A1

Innovation

- The method involves synthesizing ionic liquids and deep eutectic solvents in-situ during biomass pretreatment by adding their individual components directly to the pretreatment vessel with the biomass, utilizing endogenous organic acids present in the biomass to form the solvents, thereby eliminating the need for pre-synthesis and reducing costs.

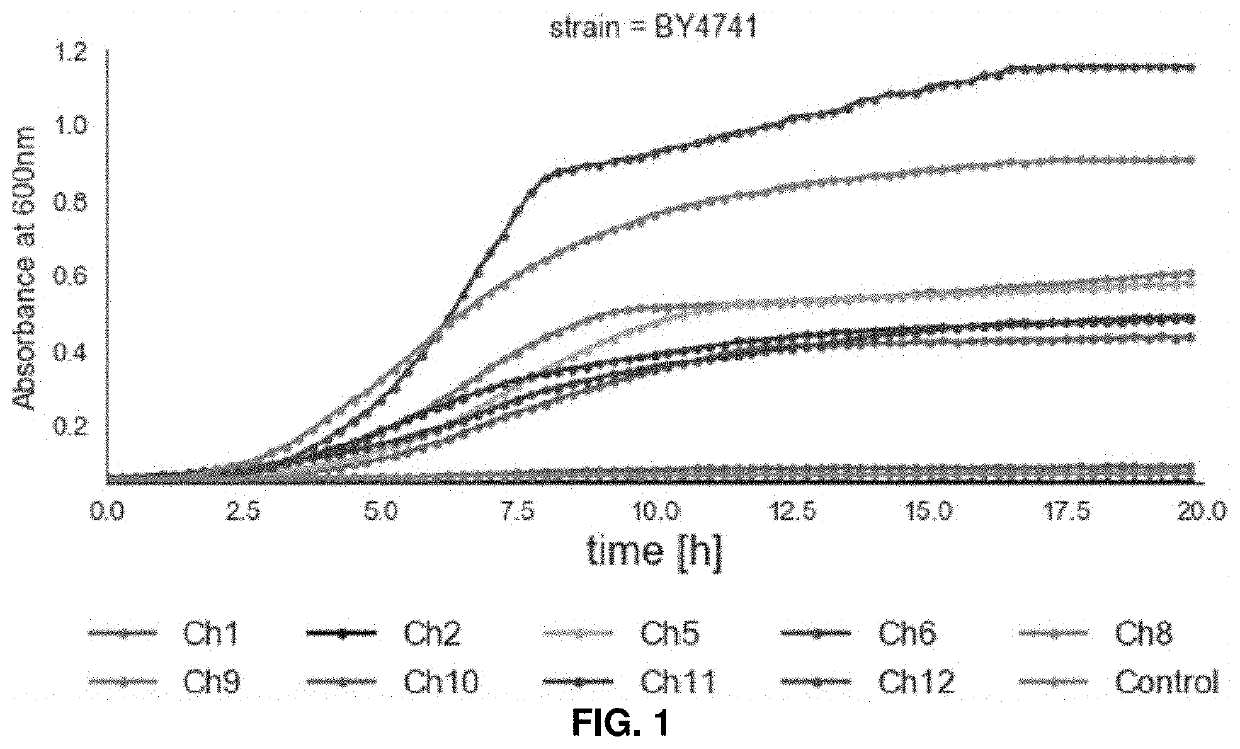

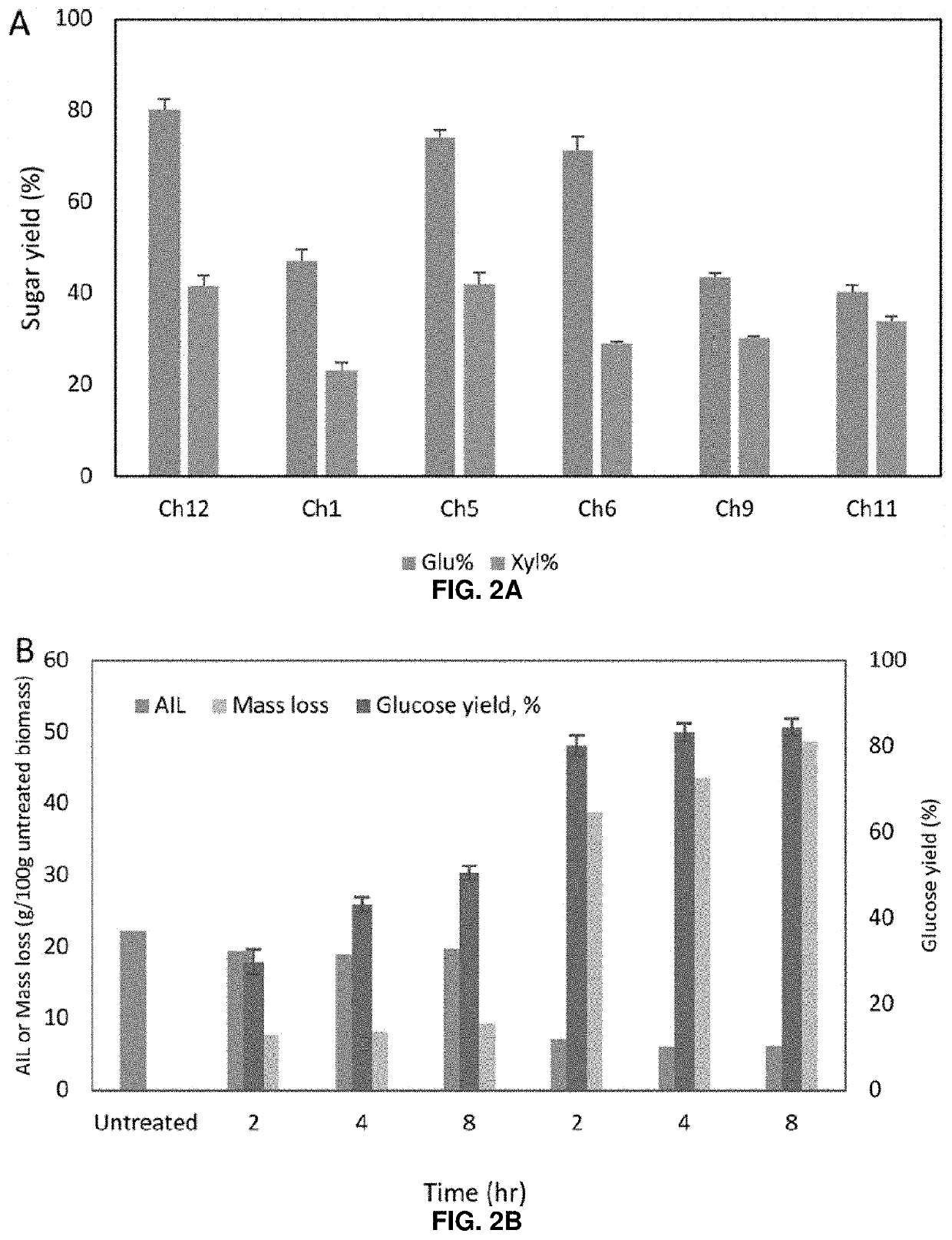

Use of renewable deep eutectic solvents in a one-pot process for a biomass

PatentInactiveUS20200216863A1

Innovation

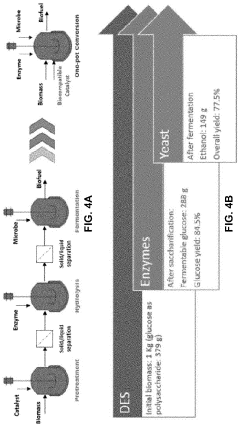

- The use of biocompatible deep eutectic solvents (DESs), specifically choline chloride and glycerol mixtures, for a one-pot biomass pretreatment, saccharification, and fermentation process that eliminates the need for pH adjustments, water dilution, and solid-liquid separations, allowing for continuous operation and compatibility with enzymes and microbes.

Life Cycle Assessment of Biomass-Derived Catalytic Systems

Life Cycle Assessment (LCA) of biomass-derived catalytic systems provides critical insights into the environmental sustainability of these emerging technologies. When evaluating biomass-derived solvents in catalytic processes, a comprehensive LCA must consider all stages from raw material extraction through production, use, and end-of-life disposal.

The assessment begins with the biomass feedstock production phase, where agricultural practices significantly impact the overall environmental footprint. Studies indicate that biomass-derived solvents from agricultural residues generally demonstrate lower environmental impacts compared to those requiring dedicated crop cultivation. For instance, lignocellulosic biomass-derived solvents show 30-45% reduced greenhouse gas emissions compared to conventional petroleum-based alternatives.

Processing and conversion stages represent energy-intensive phases in the life cycle. Current data suggests that solvent production from biomass requires 15-25% less fossil energy input than conventional solvent synthesis pathways. However, the purification processes often demand significant energy, potentially offsetting some environmental benefits if not optimized properly.

During the catalytic application phase, biomass-derived solvents demonstrate notable advantages. Their lower toxicity profiles reduce workplace hazards and environmental risks associated with accidental releases. Additionally, their biodegradability characteristics result in reduced persistence in environmental compartments, with degradation rates typically 3-5 times faster than petroleum-derived counterparts.

End-of-life considerations reveal further sustainability benefits. Many biomass-derived solvents can be recovered and reused through distillation processes with recovery rates exceeding 85%, significantly extending their functional lifetime. When ultimately disposed of, their biodegradable nature minimizes long-term environmental accumulation concerns.

Comparative LCAs between conventional and biomass-derived catalytic systems demonstrate that the latter can reduce global warming potential by 40-60% when optimally implemented. However, these benefits may be accompanied by trade-offs in other impact categories such as land use and eutrophication potential, particularly when dedicated crops serve as feedstock sources.

Sensitivity analyses within these LCAs highlight the importance of regional factors, including electricity grid composition, transportation distances, and agricultural practices. For instance, biomass-derived catalytic systems powered by renewable energy demonstrate up to 75% lower environmental impacts compared to those relying on fossil fuel-based energy sources.

Future LCA research should focus on addressing data gaps regarding emerging biomass conversion technologies and developing standardized methodologies specifically tailored to these complex biological systems. This will enable more accurate comparisons and support evidence-based decision-making in sustainable catalysis development.

The assessment begins with the biomass feedstock production phase, where agricultural practices significantly impact the overall environmental footprint. Studies indicate that biomass-derived solvents from agricultural residues generally demonstrate lower environmental impacts compared to those requiring dedicated crop cultivation. For instance, lignocellulosic biomass-derived solvents show 30-45% reduced greenhouse gas emissions compared to conventional petroleum-based alternatives.

Processing and conversion stages represent energy-intensive phases in the life cycle. Current data suggests that solvent production from biomass requires 15-25% less fossil energy input than conventional solvent synthesis pathways. However, the purification processes often demand significant energy, potentially offsetting some environmental benefits if not optimized properly.

During the catalytic application phase, biomass-derived solvents demonstrate notable advantages. Their lower toxicity profiles reduce workplace hazards and environmental risks associated with accidental releases. Additionally, their biodegradability characteristics result in reduced persistence in environmental compartments, with degradation rates typically 3-5 times faster than petroleum-derived counterparts.

End-of-life considerations reveal further sustainability benefits. Many biomass-derived solvents can be recovered and reused through distillation processes with recovery rates exceeding 85%, significantly extending their functional lifetime. When ultimately disposed of, their biodegradable nature minimizes long-term environmental accumulation concerns.

Comparative LCAs between conventional and biomass-derived catalytic systems demonstrate that the latter can reduce global warming potential by 40-60% when optimally implemented. However, these benefits may be accompanied by trade-offs in other impact categories such as land use and eutrophication potential, particularly when dedicated crops serve as feedstock sources.

Sensitivity analyses within these LCAs highlight the importance of regional factors, including electricity grid composition, transportation distances, and agricultural practices. For instance, biomass-derived catalytic systems powered by renewable energy demonstrate up to 75% lower environmental impacts compared to those relying on fossil fuel-based energy sources.

Future LCA research should focus on addressing data gaps regarding emerging biomass conversion technologies and developing standardized methodologies specifically tailored to these complex biological systems. This will enable more accurate comparisons and support evidence-based decision-making in sustainable catalysis development.

Circular Economy Integration Strategies

Integrating biomass-derived solvents into circular economy frameworks represents a critical advancement in sustainable catalysis. These solvents, derived from renewable resources, can be designed to function within closed-loop systems where materials are continuously reused and recycled, minimizing waste and environmental impact. The implementation of such circular strategies requires systematic approaches at multiple levels of the value chain.

At the industrial level, companies can adopt biomass-derived solvents as direct replacements for conventional petroleum-based solvents in catalytic processes. This substitution creates opportunities for establishing take-back programs where spent solvents are collected, purified, and reintroduced into production cycles. Several chemical manufacturers have already demonstrated successful solvent recovery systems that maintain over 90% efficiency across multiple use cycles.

Policy frameworks play an essential role in facilitating this transition. Extended Producer Responsibility (EPR) schemes can incentivize manufacturers to design catalytic processes with biomass-derived solvents that are inherently recyclable. Tax incentives for companies implementing closed-loop solvent systems have shown promising results in European markets, with measurable reductions in virgin material consumption.

From a technical perspective, designing biomass-derived solvents with regeneration capabilities is paramount. Recent advances in bio-based solvent chemistry have yielded products that can be efficiently separated from reaction mixtures and regenerated through simple physical processes like distillation or more advanced techniques such as membrane separation. These innovations significantly reduce the energy requirements traditionally associated with solvent recovery.

Supply chain integration represents another crucial dimension of circular economy implementation. Establishing partnerships between biomass producers, solvent manufacturers, and end-users creates resilient networks that can optimize resource utilization. Agricultural waste streams can be directed toward solvent production, creating additional value from materials previously considered waste.

Life cycle assessment (LCA) methodologies must be applied to evaluate the true circularity of biomass-derived solvent systems. Recent studies indicate that properly designed bio-based solvent cycles can achieve carbon footprint reductions of 60-85% compared to linear models using conventional solvents, particularly when renewable energy sources power the regeneration processes.

Digital technologies and tracking systems further enhance circular economy integration by providing real-time monitoring of solvent quality throughout multiple use cycles. Blockchain-based traceability solutions have emerged as valuable tools for verifying the sustainable sourcing and processing of biomass feedstocks used in solvent production, thereby strengthening the integrity of circular claims.

At the industrial level, companies can adopt biomass-derived solvents as direct replacements for conventional petroleum-based solvents in catalytic processes. This substitution creates opportunities for establishing take-back programs where spent solvents are collected, purified, and reintroduced into production cycles. Several chemical manufacturers have already demonstrated successful solvent recovery systems that maintain over 90% efficiency across multiple use cycles.

Policy frameworks play an essential role in facilitating this transition. Extended Producer Responsibility (EPR) schemes can incentivize manufacturers to design catalytic processes with biomass-derived solvents that are inherently recyclable. Tax incentives for companies implementing closed-loop solvent systems have shown promising results in European markets, with measurable reductions in virgin material consumption.

From a technical perspective, designing biomass-derived solvents with regeneration capabilities is paramount. Recent advances in bio-based solvent chemistry have yielded products that can be efficiently separated from reaction mixtures and regenerated through simple physical processes like distillation or more advanced techniques such as membrane separation. These innovations significantly reduce the energy requirements traditionally associated with solvent recovery.

Supply chain integration represents another crucial dimension of circular economy implementation. Establishing partnerships between biomass producers, solvent manufacturers, and end-users creates resilient networks that can optimize resource utilization. Agricultural waste streams can be directed toward solvent production, creating additional value from materials previously considered waste.

Life cycle assessment (LCA) methodologies must be applied to evaluate the true circularity of biomass-derived solvent systems. Recent studies indicate that properly designed bio-based solvent cycles can achieve carbon footprint reductions of 60-85% compared to linear models using conventional solvents, particularly when renewable energy sources power the regeneration processes.

Digital technologies and tracking systems further enhance circular economy integration by providing real-time monitoring of solvent quality throughout multiple use cycles. Blockchain-based traceability solutions have emerged as valuable tools for verifying the sustainable sourcing and processing of biomass feedstocks used in solvent production, thereby strengthening the integrity of circular claims.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!