How Do Biomass-Derived Solvents Enhance Drug Manufacturing Processes

OCT 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biomass-Derived Solvents in Pharmaceutical Manufacturing: Background and Objectives

The pharmaceutical industry has witnessed a significant shift towards sustainable manufacturing practices over the past decade. Biomass-derived solvents have emerged as promising alternatives to conventional petroleum-based solvents, offering enhanced performance while reducing environmental impact. These bio-solvents, obtained from renewable resources such as agricultural waste, forestry residues, and dedicated energy crops, represent a crucial advancement in green chemistry principles applied to pharmaceutical manufacturing.

Historically, pharmaceutical production has heavily relied on petroleum-derived solvents like acetone, toluene, and various chlorinated compounds. These traditional solvents, while effective, present substantial environmental concerns including toxicity, persistence in ecosystems, and contribution to greenhouse gas emissions. The evolution of biomass-derived alternatives began in earnest during the early 2000s, gaining momentum as sustainability became a strategic priority across industries.

The technical evolution of biomass-derived solvents has progressed through several distinct phases. Initial developments focused on simple alcohols and esters derived from plant oils and sugars. This was followed by more sophisticated processing techniques yielding complex solvent systems with tailored properties. Recent innovations have introduced advanced bio-solvents with performance characteristics that match or exceed their petroleum-based counterparts.

Current market trends indicate accelerating adoption of these sustainable alternatives, driven by stringent regulatory frameworks, corporate sustainability commitments, and consumer demand for environmentally responsible products. The European Medicines Agency and the U.S. Food and Drug Administration have both issued guidance encouraging pharmaceutical manufacturers to implement greener solvent alternatives where feasible, further catalyzing industry transition.

The primary technical objectives in this field include developing biomass-derived solvents with enhanced selectivity for pharmaceutical compounds, improved reaction efficiency, reduced energy requirements, and compatibility with existing manufacturing infrastructure. Additionally, researchers aim to establish scalable, economically viable production pathways that minimize land use competition with food crops.

Looking forward, the biomass-derived solvent landscape is expected to continue its rapid evolution, with particular emphasis on circular economy principles. This includes developing integrated biorefinery concepts where pharmaceutical manufacturing waste becomes feedstock for solvent production, creating closed-loop systems. The convergence of biotechnology, green chemistry, and pharmaceutical engineering promises to deliver increasingly sophisticated bio-solvent solutions tailored specifically for drug manufacturing applications.

Historically, pharmaceutical production has heavily relied on petroleum-derived solvents like acetone, toluene, and various chlorinated compounds. These traditional solvents, while effective, present substantial environmental concerns including toxicity, persistence in ecosystems, and contribution to greenhouse gas emissions. The evolution of biomass-derived alternatives began in earnest during the early 2000s, gaining momentum as sustainability became a strategic priority across industries.

The technical evolution of biomass-derived solvents has progressed through several distinct phases. Initial developments focused on simple alcohols and esters derived from plant oils and sugars. This was followed by more sophisticated processing techniques yielding complex solvent systems with tailored properties. Recent innovations have introduced advanced bio-solvents with performance characteristics that match or exceed their petroleum-based counterparts.

Current market trends indicate accelerating adoption of these sustainable alternatives, driven by stringent regulatory frameworks, corporate sustainability commitments, and consumer demand for environmentally responsible products. The European Medicines Agency and the U.S. Food and Drug Administration have both issued guidance encouraging pharmaceutical manufacturers to implement greener solvent alternatives where feasible, further catalyzing industry transition.

The primary technical objectives in this field include developing biomass-derived solvents with enhanced selectivity for pharmaceutical compounds, improved reaction efficiency, reduced energy requirements, and compatibility with existing manufacturing infrastructure. Additionally, researchers aim to establish scalable, economically viable production pathways that minimize land use competition with food crops.

Looking forward, the biomass-derived solvent landscape is expected to continue its rapid evolution, with particular emphasis on circular economy principles. This includes developing integrated biorefinery concepts where pharmaceutical manufacturing waste becomes feedstock for solvent production, creating closed-loop systems. The convergence of biotechnology, green chemistry, and pharmaceutical engineering promises to deliver increasingly sophisticated bio-solvent solutions tailored specifically for drug manufacturing applications.

Market Analysis of Green Solvents in Pharmaceutical Industry

The global market for green solvents in the pharmaceutical industry has experienced significant growth in recent years, driven primarily by increasing environmental regulations and sustainability initiatives. As of 2023, the green pharmaceutical solvents market is valued at approximately $1.8 billion, with projections indicating a compound annual growth rate of 6.7% through 2030, potentially reaching $2.9 billion by the end of the decade.

Biomass-derived solvents represent the fastest-growing segment within this market, currently accounting for about 23% of all green solvents used in pharmaceutical manufacturing. This growth is attributed to their renewable nature, biodegradability, and increasingly competitive cost structures compared to traditional petroleum-based alternatives.

Regional analysis reveals that Europe leads the market adoption of green solvents in pharmaceutical production, holding roughly 38% of the global market share. This dominance stems from stringent EU regulations on volatile organic compounds (VOCs) and strong governmental support for sustainable chemistry initiatives. North America follows with approximately 32% market share, while the Asia-Pacific region, particularly China and India, demonstrates the highest growth rate at 8.9% annually.

The pharmaceutical industry's demand for green solvents is segmented by application areas, with reaction media representing the largest segment (41%), followed by separation processes (27%), crystallization (18%), and formulation (14%). Biomass-derived solvents have shown particular promise in reaction media and crystallization applications, where their unique properties often enhance drug purity profiles and yield rates.

Key market drivers include tightening environmental regulations worldwide, pharmaceutical companies' sustainability commitments, and increasing consumer demand for environmentally responsible medications. The FDA and EMA have both issued guidance documents encouraging the adoption of green chemistry principles in pharmaceutical manufacturing, creating regulatory tailwinds for the sector.

Challenges limiting faster market penetration include higher initial costs for some bio-based solvents, technical limitations in certain applications requiring specific solvent properties, and the pharmaceutical industry's inherently conservative approach to manufacturing changes due to regulatory validation requirements.

Market forecasts suggest that bio-derived esters, alcohols, and terpenes will see the strongest growth among biomass-derived solvents, with projected market expansion rates of 9.2%, 8.7%, and 7.9% respectively. These categories demonstrate particularly favorable performance characteristics in pharmaceutical applications while offering compelling environmental benefits.

Biomass-derived solvents represent the fastest-growing segment within this market, currently accounting for about 23% of all green solvents used in pharmaceutical manufacturing. This growth is attributed to their renewable nature, biodegradability, and increasingly competitive cost structures compared to traditional petroleum-based alternatives.

Regional analysis reveals that Europe leads the market adoption of green solvents in pharmaceutical production, holding roughly 38% of the global market share. This dominance stems from stringent EU regulations on volatile organic compounds (VOCs) and strong governmental support for sustainable chemistry initiatives. North America follows with approximately 32% market share, while the Asia-Pacific region, particularly China and India, demonstrates the highest growth rate at 8.9% annually.

The pharmaceutical industry's demand for green solvents is segmented by application areas, with reaction media representing the largest segment (41%), followed by separation processes (27%), crystallization (18%), and formulation (14%). Biomass-derived solvents have shown particular promise in reaction media and crystallization applications, where their unique properties often enhance drug purity profiles and yield rates.

Key market drivers include tightening environmental regulations worldwide, pharmaceutical companies' sustainability commitments, and increasing consumer demand for environmentally responsible medications. The FDA and EMA have both issued guidance documents encouraging the adoption of green chemistry principles in pharmaceutical manufacturing, creating regulatory tailwinds for the sector.

Challenges limiting faster market penetration include higher initial costs for some bio-based solvents, technical limitations in certain applications requiring specific solvent properties, and the pharmaceutical industry's inherently conservative approach to manufacturing changes due to regulatory validation requirements.

Market forecasts suggest that bio-derived esters, alcohols, and terpenes will see the strongest growth among biomass-derived solvents, with projected market expansion rates of 9.2%, 8.7%, and 7.9% respectively. These categories demonstrate particularly favorable performance characteristics in pharmaceutical applications while offering compelling environmental benefits.

Current Status and Technical Barriers in Biomass-Derived Solvent Development

The global landscape of biomass-derived solvents has witnessed significant advancement in recent years, with research institutions and companies across North America, Europe, and Asia making substantial contributions. Currently, several bio-based solvents have successfully transitioned from laboratory research to commercial applications in pharmaceutical manufacturing, including ethyl lactate, 2-methyltetrahydrofuran (2-MeTHF), and cyrene. These solvents have demonstrated promising capabilities in enhancing drug solubility, improving reaction efficiency, and reducing environmental impact compared to traditional petroleum-based solvents.

Despite these advancements, the widespread adoption of biomass-derived solvents in pharmaceutical manufacturing faces several critical technical barriers. One major challenge is the inconsistent quality and purity of these solvents due to variations in biomass feedstock composition. The heterogeneous nature of biomass sources results in fluctuating solvent properties, which can adversely affect drug synthesis reproducibility and final product quality—a critical concern in pharmaceutical manufacturing where stringent quality standards must be maintained.

Another significant technical hurdle is the scalability of production processes. While many bio-solvents show excellent performance in laboratory settings, scaling up their production to industrial levels often encounters efficiency losses and increased production costs. The complex purification steps required to achieve pharmaceutical-grade purity standards further exacerbate this challenge, making some bio-solvents economically unviable compared to their conventional counterparts.

Stability issues also present substantial barriers to implementation. Some biomass-derived solvents exhibit limited shelf-life or degradation under certain processing conditions commonly used in pharmaceutical manufacturing. This instability can lead to the formation of unwanted by-products during drug synthesis, potentially compromising product safety and efficacy.

The geographic distribution of biomass-derived solvent development shows interesting patterns. European countries, particularly Germany and France, lead in research and development of lignocellulosic-based solvents, while the United States focuses more on corn and soybean-derived alternatives. Asian countries, notably China and India, are rapidly expanding their research capabilities in this field, with particular emphasis on agricultural waste valorization for solvent production.

Regulatory hurdles constitute another significant barrier. The pharmaceutical industry operates under strict regulatory frameworks, and the introduction of new solvents requires extensive toxicological studies and validation processes. Many promising biomass-derived solvents lack comprehensive safety data packages, slowing their regulatory approval and subsequent industry adoption.

Technical compatibility with existing pharmaceutical manufacturing equipment and processes remains a challenge. Some bio-solvents exhibit different physical properties (viscosity, boiling point, polarity) compared to conventional solvents, necessitating modifications to established manufacturing protocols and equipment—a costly and time-consuming process for pharmaceutical companies.

Despite these advancements, the widespread adoption of biomass-derived solvents in pharmaceutical manufacturing faces several critical technical barriers. One major challenge is the inconsistent quality and purity of these solvents due to variations in biomass feedstock composition. The heterogeneous nature of biomass sources results in fluctuating solvent properties, which can adversely affect drug synthesis reproducibility and final product quality—a critical concern in pharmaceutical manufacturing where stringent quality standards must be maintained.

Another significant technical hurdle is the scalability of production processes. While many bio-solvents show excellent performance in laboratory settings, scaling up their production to industrial levels often encounters efficiency losses and increased production costs. The complex purification steps required to achieve pharmaceutical-grade purity standards further exacerbate this challenge, making some bio-solvents economically unviable compared to their conventional counterparts.

Stability issues also present substantial barriers to implementation. Some biomass-derived solvents exhibit limited shelf-life or degradation under certain processing conditions commonly used in pharmaceutical manufacturing. This instability can lead to the formation of unwanted by-products during drug synthesis, potentially compromising product safety and efficacy.

The geographic distribution of biomass-derived solvent development shows interesting patterns. European countries, particularly Germany and France, lead in research and development of lignocellulosic-based solvents, while the United States focuses more on corn and soybean-derived alternatives. Asian countries, notably China and India, are rapidly expanding their research capabilities in this field, with particular emphasis on agricultural waste valorization for solvent production.

Regulatory hurdles constitute another significant barrier. The pharmaceutical industry operates under strict regulatory frameworks, and the introduction of new solvents requires extensive toxicological studies and validation processes. Many promising biomass-derived solvents lack comprehensive safety data packages, slowing their regulatory approval and subsequent industry adoption.

Technical compatibility with existing pharmaceutical manufacturing equipment and processes remains a challenge. Some bio-solvents exhibit different physical properties (viscosity, boiling point, polarity) compared to conventional solvents, necessitating modifications to established manufacturing protocols and equipment—a costly and time-consuming process for pharmaceutical companies.

Existing Applications of Biomass-Derived Solvents in Drug Synthesis

01 Production of biomass-derived solvents from lignocellulosic materials

Lignocellulosic materials can be processed to produce various biomass-derived solvents through methods such as hydrolysis, fermentation, and chemical conversion. These processes typically involve breaking down cellulose and hemicellulose components into sugars, which are then further converted into solvents like ethanol, butanol, and acetone. The enhancement of these processes often involves optimizing reaction conditions, using specialized catalysts, and developing more efficient separation techniques to improve yield and purity.- Production of biomass-derived solvents from lignocellulosic materials: Methods for producing biomass-derived solvents from lignocellulosic materials involve processes such as hydrolysis, fermentation, and chemical conversion. These techniques transform plant-based biomass into renewable solvents that can replace petroleum-based alternatives. The processes typically include pretreatment of the biomass, enzymatic or acid hydrolysis to break down cellulose and hemicellulose into sugars, and subsequent conversion to solvents through biological or chemical pathways.

- Enhancement of biomass-derived solvent properties through chemical modification: Chemical modification techniques can enhance the properties of biomass-derived solvents to improve their performance for specific applications. These modifications may include esterification, etherification, or other chemical reactions that alter the molecular structure of the solvent. Such modifications can improve properties like solvency power, volatility, stability, and compatibility with various substrates, making the bio-based solvents more competitive with conventional petroleum-derived alternatives.

- Formulation of biomass-derived solvent blends for enhanced performance: Blending different biomass-derived solvents or combining them with other components can create formulations with enhanced performance characteristics. These blends can be tailored for specific applications by optimizing properties such as solvency power, evaporation rate, surface tension, and environmental impact. The synergistic effects between different bio-based solvents in these blends often result in superior performance compared to single-component systems.

- Process optimization for biomass-derived solvent production: Optimization of production processes for biomass-derived solvents focuses on improving efficiency, yield, and quality while reducing costs. This includes developing novel catalysts, optimizing reaction conditions, implementing continuous processing methods, and integrating biorefinery concepts. Advanced separation and purification techniques are also employed to obtain high-purity solvents suitable for industrial applications. These optimizations help make bio-based solvents more economically competitive with conventional alternatives.

- Applications of enhanced biomass-derived solvents in various industries: Enhanced biomass-derived solvents find applications across multiple industries including coatings, adhesives, cleaning products, pharmaceuticals, and agricultural formulations. These renewable solvents can replace conventional petroleum-based solvents in many applications, offering advantages such as reduced toxicity, lower environmental impact, and improved sustainability profiles. The performance enhancements achieved through various modification techniques enable these bio-based alternatives to meet or exceed the performance requirements of traditional solvents in specific applications.

02 Green solvent formulations with enhanced properties

Biomass-derived solvents can be formulated with additives or through specific processing methods to enhance their properties such as solvency power, stability, and environmental compatibility. These enhanced formulations may include combinations of different bio-based solvents, addition of stabilizers, or modification of molecular structures to improve performance characteristics. Such formulations aim to match or exceed the performance of conventional petroleum-based solvents while maintaining their renewable and environmentally friendly nature.Expand Specific Solutions03 Application-specific biomass solvent enhancements

Biomass-derived solvents can be specifically enhanced for particular applications such as cleaning products, coatings, adhesives, or extraction processes. These enhancements may involve adjusting solvent parameters like polarity, volatility, or viscosity to optimize performance in the target application. The modifications can include blending multiple bio-solvents, incorporating co-solvents, or adding functional additives to achieve the desired application-specific properties.Expand Specific Solutions04 Enzymatic and microbial processes for biomass solvent production

Enhanced enzymatic and microbial processes can be employed to convert biomass into solvents with improved efficiency and selectivity. These biological approaches utilize specialized enzymes or engineered microorganisms to break down complex biomass components and convert them into valuable solvents. Process enhancements may include enzyme immobilization techniques, continuous fermentation systems, or genetic modification of microorganisms to increase yields and production rates of target solvents.Expand Specific Solutions05 Catalytic upgrading of biomass-derived solvents

Catalytic processes can be used to upgrade and enhance the properties of biomass-derived solvents. These processes may involve hydrogenation, dehydration, esterification, or other chemical transformations that modify the molecular structure of bio-based solvents to improve their performance characteristics. Advanced catalysts, including heterogeneous, homogeneous, and biocatalysts, play a crucial role in these upgrading processes by enabling more selective and efficient transformations under milder conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Green Solvent Technology

Biomass-derived solvents in drug manufacturing are gaining momentum in an emerging market characterized by rapid growth and increasing adoption. The industry is transitioning from early-stage development to commercial implementation, with market size projected to expand significantly due to pharmaceutical sustainability initiatives. Technologically, the field shows varying maturity levels across players. Companies like BASF Corp. and DSM IP Assets BV demonstrate advanced capabilities in commercial applications, while academic institutions such as Dartmouth College and Sun Yat-Sen University contribute fundamental research. Specialized firms like Furanix Technologies and SweetWater Energy focus on innovative extraction processes, while pharmaceutical manufacturers including CJ CheilJedang and KPC Pharmaceuticals are integrating these green solvents into production workflows, driving industry-wide adoption through collaborative development efforts.

Furanix Technologies BV

Technical Solution: Furanix Technologies has developed a groundbreaking platform focused on furan-based chemistry for pharmaceutical applications. Their flagship technology converts biomass-derived carbohydrates into 5-hydroxymethylfurfural (HMF) and further into 2,5-furandicarboxylic acid (FDCA) and methyltetrahydrofuran (MTHF) solvents. The process utilizes a unique catalytic dehydration system that operates in a biphasic reactor, allowing for continuous extraction of furan compounds and high conversion efficiency exceeding 85%. Their biomass-derived MTHF solvent has demonstrated exceptional performance in pharmaceutical applications, particularly in chiral separations and asymmetric synthesis, where it has shown to improve enantiomeric excess by up to 15% compared to traditional solvents. Furanix's technology produces solvents with water content below 50 ppm, meeting stringent pharmaceutical purity requirements. In drug crystallization processes, their bio-based solvents have demonstrated improved polymorphic control, leading to more consistent API crystal morphology and enhanced bioavailability. Implementation in pharmaceutical processes has shown reduced solvent consumption by approximately 30-40% while maintaining or improving product quality.

Strengths: Specialized expertise in furan chemistry provides unique solvents with properties particularly suited for challenging pharmaceutical processes like chiral separations. Their catalytic technology allows for efficient conversion of various biomass sources, including agricultural waste streams. Weaknesses: Limited production scale compared to major chemical manufacturers may affect ability to supply large pharmaceutical operations, and the specialized nature of their solvents may require process modifications for implementation in existing pharmaceutical manufacturing lines.

DSM IP Assets BV

Technical Solution: DSM has developed an innovative platform called "Bio-based Performance Materials" that includes specialized biomass-derived solvents for pharmaceutical manufacturing. Their technology converts agricultural residues and non-food biomass into high-performance solvents through a proprietary enzymatic hydrolysis process followed by catalytic conversion. DSM's bio-based solvents, including bio-derived methyl ethyl ketone (MEK) and dimethyl isosorbide (DMI), have been engineered specifically for pharmaceutical applications. Their DMI solvent has demonstrated exceptional capabilities in enhancing drug solubility, with studies showing up to 3-5 times improvement in dissolution rates for poorly water-soluble APIs. The company's integrated biorefinery approach ensures complete utilization of biomass components, with cellulose fractions converted to solvents and remaining lignin used for energy recovery. DSM's life cycle analyses indicate their biomass-derived solvents reduce greenhouse gas emissions by approximately 70-85% compared to petroleum-based alternatives while maintaining pharmaceutical quality standards. Their solvents have been successfully implemented in continuous manufacturing processes, reducing solvent consumption by up to 50%.

Strengths: DSM's extensive experience in biotechnology and enzymatic processes enables production of highly pure biomass-derived solvents suitable for GMP pharmaceutical manufacturing. Their established position in the pharmaceutical value chain facilitates adoption of these green solvents by drug manufacturers. Weaknesses: The enzymatic processes require precise control conditions and may have higher production costs than conventional solvent manufacturing, potentially limiting widespread adoption for lower-value pharmaceutical applications.

Key Innovations in Biomass-Derived Solvent Chemistry and Engineering

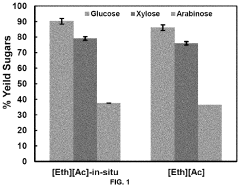

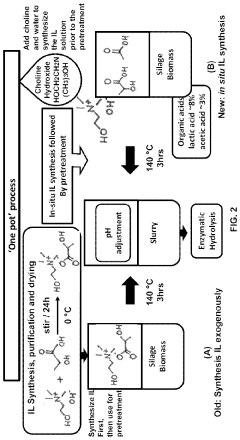

Use of in-situ ionic liquid (IL) and deep eutectic solvent (DES) synthesis using chemically synthesized or biomass-derived ions in the pretreatment of biomass

PatentActiveUS20210363696A1

Innovation

- The method involves synthesizing ionic liquids and deep eutectic solvents in-situ during biomass pretreatment by adding their individual components directly to the pretreatment vessel with the biomass, utilizing endogenous organic acids present in the biomass to form the solvents, thereby eliminating the need for pre-synthesis and reducing costs.

Use of renewable deep eutectic solvents in a one-pot process for a biomass

PatentInactiveUS20200216863A1

Innovation

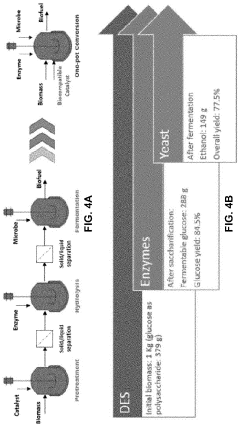

- The use of biocompatible deep eutectic solvents (DESs), specifically choline chloride and glycerol mixtures, for a one-pot biomass pretreatment, saccharification, and fermentation process that eliminates the need for pH adjustments, water dilution, and solid-liquid separations, allowing for continuous operation and compatibility with enzymes and microbes.

Environmental Impact Assessment and Life Cycle Analysis

The environmental impact of biomass-derived solvents in pharmaceutical manufacturing represents a critical dimension of sustainability assessment. Compared to conventional petroleum-based solvents, biomass-derived alternatives typically demonstrate significantly reduced carbon footprints, with studies indicating potential reductions of 50-90% in greenhouse gas emissions depending on the specific solvent and production pathway. This advantage stems primarily from the renewable nature of biomass feedstocks, which capture carbon during growth and create a more balanced carbon cycle.

Life cycle analyses (LCA) of biomass-derived solvents reveal multifaceted environmental benefits beyond carbon metrics. Water consumption patterns differ markedly from conventional solvents, with some bio-solvents requiring less process water during manufacturing, though agricultural water requirements must be factored into comprehensive assessments. Toxicity profiles generally favor biomass-derived options, with reduced aquatic toxicity and lower volatile organic compound (VOC) emissions, contributing to improved air quality around manufacturing facilities.

Land use considerations present complex trade-offs in environmental assessment frameworks. While biomass cultivation requires agricultural land, potentially competing with food production, second-generation biomass-derived solvents utilizing agricultural waste streams, forestry residues, or non-food crops grown on marginal lands can substantially mitigate these concerns. The pharmaceutical industry's transition toward these more sustainable feedstock sources represents an evolving best practice.

Energy efficiency metrics across the full production lifecycle reveal that some biomass-derived solvents require less energy-intensive purification processes compared to their petroleum counterparts. However, certain bio-based production pathways may involve energy-intensive conversion steps that partially offset carbon benefits. Technological innovations in enzymatic and catalytic processes are progressively addressing these efficiency gaps, improving overall environmental performance.

Waste management implications of biomass-derived solvents in pharmaceutical manufacturing merit particular attention. These solvents typically demonstrate enhanced biodegradability, reducing environmental persistence when released as waste. Additionally, many biomass-derived solvents exhibit superior recyclability profiles, enabling more efficient solvent recovery systems that minimize waste generation. This characteristic aligns with pharmaceutical industry sustainability initiatives targeting zero-waste manufacturing operations.

Regulatory frameworks increasingly recognize these environmental advantages, with the European Medicines Agency and FDA both developing green chemistry guidelines that favor biomass-derived solvents with demonstrated environmental benefits. Pharmaceutical companies implementing these solvents can potentially benefit from regulatory incentives while simultaneously addressing corporate sustainability commitments and responding to growing market demand for environmentally responsible manufacturing practices.

Life cycle analyses (LCA) of biomass-derived solvents reveal multifaceted environmental benefits beyond carbon metrics. Water consumption patterns differ markedly from conventional solvents, with some bio-solvents requiring less process water during manufacturing, though agricultural water requirements must be factored into comprehensive assessments. Toxicity profiles generally favor biomass-derived options, with reduced aquatic toxicity and lower volatile organic compound (VOC) emissions, contributing to improved air quality around manufacturing facilities.

Land use considerations present complex trade-offs in environmental assessment frameworks. While biomass cultivation requires agricultural land, potentially competing with food production, second-generation biomass-derived solvents utilizing agricultural waste streams, forestry residues, or non-food crops grown on marginal lands can substantially mitigate these concerns. The pharmaceutical industry's transition toward these more sustainable feedstock sources represents an evolving best practice.

Energy efficiency metrics across the full production lifecycle reveal that some biomass-derived solvents require less energy-intensive purification processes compared to their petroleum counterparts. However, certain bio-based production pathways may involve energy-intensive conversion steps that partially offset carbon benefits. Technological innovations in enzymatic and catalytic processes are progressively addressing these efficiency gaps, improving overall environmental performance.

Waste management implications of biomass-derived solvents in pharmaceutical manufacturing merit particular attention. These solvents typically demonstrate enhanced biodegradability, reducing environmental persistence when released as waste. Additionally, many biomass-derived solvents exhibit superior recyclability profiles, enabling more efficient solvent recovery systems that minimize waste generation. This characteristic aligns with pharmaceutical industry sustainability initiatives targeting zero-waste manufacturing operations.

Regulatory frameworks increasingly recognize these environmental advantages, with the European Medicines Agency and FDA both developing green chemistry guidelines that favor biomass-derived solvents with demonstrated environmental benefits. Pharmaceutical companies implementing these solvents can potentially benefit from regulatory incentives while simultaneously addressing corporate sustainability commitments and responding to growing market demand for environmentally responsible manufacturing practices.

Regulatory Compliance and Safety Considerations for Novel Solvents

The integration of biomass-derived solvents into pharmaceutical manufacturing processes necessitates careful navigation of complex regulatory frameworks. The FDA, EMA, and ICH have established stringent guidelines for solvent use in drug production, categorizing solvents into different classes based on toxicity profiles. Class 1 solvents, known for high toxicity, are generally prohibited, while Class 2 and 3 solvents face usage limitations or are considered less harmful, respectively.

Biomass-derived solvents present unique regulatory challenges due to their novel nature. Manufacturers must provide comprehensive safety data, including toxicological profiles, impurity assessments, and residual solvent limits. The ICH Q3C guideline specifically addresses residual solvent thresholds in pharmaceutical products, requiring manufacturers to demonstrate that their biomass-derived alternatives meet these established safety parameters.

Environmental regulations also significantly impact the adoption of these green solvents. The EPA in the United States and the REACH regulation in Europe impose requirements regarding chemical registration, environmental impact assessment, and waste management. While biomass-derived solvents often offer improved environmental profiles, manufacturers must still document their ecological footprint through life cycle assessments and biodegradability studies.

Worker safety considerations represent another critical regulatory dimension. OSHA standards mandate proper handling protocols, exposure limits, and safety training for all solvents used in manufacturing environments. Biomass-derived alternatives frequently offer reduced flammability and volatility compared to petroleum-based counterparts, potentially simplifying compliance with these occupational safety requirements.

The pharmaceutical industry's transition to biomass-derived solvents is further complicated by validation requirements. Any change in manufacturing solvents necessitates extensive process validation to ensure consistent drug quality and stability. Regulatory bodies require evidence that the new solvent does not adversely affect critical quality attributes of the final pharmaceutical product.

International harmonization efforts are gradually addressing regulatory barriers to green solvent adoption. The ICH, FDA, and EMA have shown increasing receptiveness to environmentally sustainable alternatives, provided they meet safety and efficacy standards. Several regulatory frameworks now incorporate sustainability considerations, creating pathways for expedited review of manufacturing processes utilizing green chemistry principles.

Manufacturers implementing biomass-derived solvents must develop comprehensive regulatory strategies that address these multifaceted compliance requirements. This includes generating appropriate toxicological data, conducting thorough environmental impact assessments, establishing worker safety protocols, and validating manufacturing processes. Success in navigating this complex regulatory landscape ultimately determines the commercial viability of these sustainable alternatives in pharmaceutical manufacturing.

Biomass-derived solvents present unique regulatory challenges due to their novel nature. Manufacturers must provide comprehensive safety data, including toxicological profiles, impurity assessments, and residual solvent limits. The ICH Q3C guideline specifically addresses residual solvent thresholds in pharmaceutical products, requiring manufacturers to demonstrate that their biomass-derived alternatives meet these established safety parameters.

Environmental regulations also significantly impact the adoption of these green solvents. The EPA in the United States and the REACH regulation in Europe impose requirements regarding chemical registration, environmental impact assessment, and waste management. While biomass-derived solvents often offer improved environmental profiles, manufacturers must still document their ecological footprint through life cycle assessments and biodegradability studies.

Worker safety considerations represent another critical regulatory dimension. OSHA standards mandate proper handling protocols, exposure limits, and safety training for all solvents used in manufacturing environments. Biomass-derived alternatives frequently offer reduced flammability and volatility compared to petroleum-based counterparts, potentially simplifying compliance with these occupational safety requirements.

The pharmaceutical industry's transition to biomass-derived solvents is further complicated by validation requirements. Any change in manufacturing solvents necessitates extensive process validation to ensure consistent drug quality and stability. Regulatory bodies require evidence that the new solvent does not adversely affect critical quality attributes of the final pharmaceutical product.

International harmonization efforts are gradually addressing regulatory barriers to green solvent adoption. The ICH, FDA, and EMA have shown increasing receptiveness to environmentally sustainable alternatives, provided they meet safety and efficacy standards. Several regulatory frameworks now incorporate sustainability considerations, creating pathways for expedited review of manufacturing processes utilizing green chemistry principles.

Manufacturers implementing biomass-derived solvents must develop comprehensive regulatory strategies that address these multifaceted compliance requirements. This includes generating appropriate toxicological data, conducting thorough environmental impact assessments, establishing worker safety protocols, and validating manufacturing processes. Success in navigating this complex regulatory landscape ultimately determines the commercial viability of these sustainable alternatives in pharmaceutical manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!